Test Fixtures

Home » Test Machines » Test Fixtures

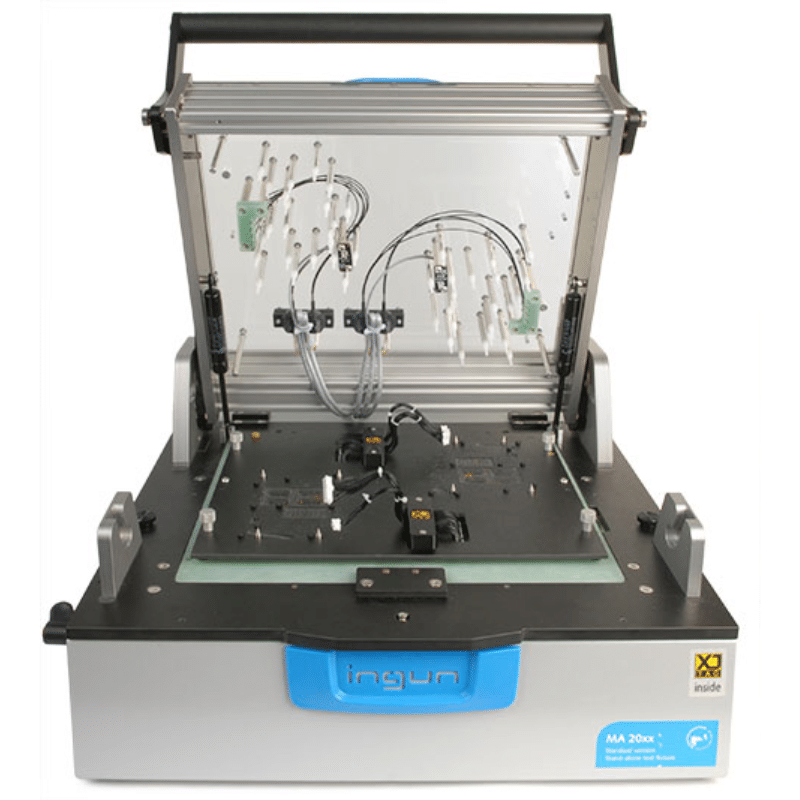

With their crucial significance, test fixtures assure the accuracy and reliability of testing processes across various industries. They are specially designed tools that hold components or systems in place while being tested. Trusted test fixture manufacturers provide innovative solutions to support a smooth workflow, keeping consistency and quality intact in the companies’ testing routines.

Get Information on Spaghetti Production Line Manufacturers

Find Your Test Fixtures

Test fixtures are important for achieving testing accuracy and reliability in the industry. By simplifying design, engineers and manufacturers are able to create systems suited for specific testing needs, thus improving efficiency and accuracy. However, knowing what kind of results you are looking for from your project really dictates whether you want standard test solutions or fully custom-built test fixtures. Test fixtures are usually custom-made to work with complicated issues and offer sturdy and repeatable testing surroundings. An excellent test fixture design takes your product testing to the next level in terms of quality and performance at every stage.

- Ensure accurate performance testing of components.

- Improve testing speed and reliability.

- Customizable for different testing needs.

- Test circuit integrity and electronic functionality effectively.

- Precise voltage and current testing capabilities.

- Modular designs for enhanced flexibility.

- Simulate real-world impact scenarios for durability testing.

- Increase accuracy of material strength assessments.

- Robust construction for high-impact testing needs.

- Durable and long-lasting for repeated testing applications.

- Designed to handle high mechanical stress effectively.

- Suitable for various industries and testing environments.

- Cost-effective for general testing needs.

- Standardized tooling for interchangeability.

- Versatile compatibility with multiple devices.

- Specifically tailored for material tensile strength testing.

- Accurate and repeatable results for tear resistance analysis.

- Compact design integrating seamlessly into testing setups.

- Precise grip alignment for accurate tension testing.

- Durable construction for heavy-duty applications.

- Adjustable clamps for versatile sample sizes.

- High-sensitivity design for puncture resistance evaluation.

- Interchangeable needle sizes for flexibility in testing parameters.

- Compact and robust structure for lab environments.

- Specialized grips to handle geotextile materials securely.

- Prevents material slippage for reliable test results.

- Corrosion-resistant components for outdoor specimen analysis.

Test Fixtures Technical Parameters

| Specification | Functional Test Fixtures | Electronic Test Fixtures | Impact Test Fixtures |

|---|---|---|---|

| Purpose | Verifies product functionality | Tests electronic components and circuits | Assesses durability under physical stress |

| Key Components | Sensors, actuators, and controllers | PCB testing units, connectors, probes | Shock absorbers, strain gauges |

| Application | Software and hardware validation | Circuit board manufacturing | Automotive, aerospace, and industrial sectors |

| Operating Conditions | Controlled environments | Laboratory or production settings | Simulated real-world impact scenarios |

| Advantages | Highly customizable and accurate results | Efficient for mass production testing | Ensures product safety and reliability |

| Specification | Mechanical Test Fixtures | Standard Test Fixtures | Tear Test Fixtures |

|---|---|---|---|

| Purpose | For testing mechanical components under specific conditions. | Designed for general testing applications across industries. | Specifically used to measure tearing strength of materials. |

| Material | Typically made of durable metals like steel or aluminum. | Made from a variety of materials, depending on the application. | Often constructed with precision alloys for accurate readings. |

| Applications | Commonly used in automotive, aerospace, and manufacturing testing. | Suitable for a wide range of standard testing needs. | Ideal for textiles, plastics, and paper materials. |

| Customization Options | Highly customizable to meet specific mechanical testing requirements. | Limited customization, primarily standardized. | Can be tailored for specific tear strength testing scenarios. |

| Durability | Built for heavy-duty use and repeated testing cycles. | Moderately durable, varies by test purpose. | Durable for high-stress material testing. |

| Specification | Tensile Test Fixture | Puncture Test Fixture | Geotextile Test Fixtures |

|---|---|---|---|

| Purpose | Used to measure the tensile strength of materials by applying axial force. | Designed to evaluate the puncture resistance of materials. | Tests the strength, durability, and permeability of geotextile fabric. |

| Material Compatibility | Metals, plastics, textiles, and composites. | Films, sheets, membranes, and fabrics. | Geotextile fabrics and construction materials. |

| Load Capacity | Up to 50 kN (varies by model). | Up to 20 kN (varies by model). | Varies based on geotextile properties. |

| Adjustable Features | Gripping system for various sample sizes. | Customized fixture inserts for specific materials. | Configurable grips and clamps to accommodate different tests. |

| Common Standards | ASTM D638, ISO 527. | ASTM D4833. | ASTM D4595, ISO 10319. |

| Typical Applications | Quality control, material certification, and R&D. | Packaging materials, industrial films, and protective materials testing. | Testing in civil engineering and environmental projects. |

Application of Test Fixtures

Validation

Isolation

Reusability

Error Detection

Efficiency

Frequently Asked Questions

A test fixture is a setup or device that replicates specific conditions required to test a product, material, or system. It ensures controlled and repeatable testing by providing support, alignment, or environment simulation so that accurate results can be achieved. Test fixtures are commonly used in quality assurance to validate performance, functionality, or durability.

To use a test fixture, first ensure it is properly calibrated and configured to match the specifications of your test requirements. Secure the test subject within the fixture, ensuring correct alignment and stability. Follow the testing protocol or procedure that defines conditions such as load, temperature, or pressure, and observe or record the results. Regular maintenance and calibration of the test fixture are crucial for consistent performance.

There are several types of test fixtures based on their purpose and design, including mechanical fixtures, electrical test fixtures, hydraulic or pneumatic fixtures, and environmental test fixtures. Mechanical fixtures stabilize components for physical stress tests, while electrical fixtures are used for testing circuits or electronic systems. Hydraulic and pneumatic fixtures simulate fluid dynamics, and environmental fixtures recreate specific environmental conditions like temperature, humidity, or vibration.

Several factors influence the performance and effectiveness of test fixtures, including material quality, precision in design, calibration, environmental conditions, and compatibility with the item being tested. Any deviation in these factors can result in inaccurate or unreliable test results.

A wide variety of tests can be conducted with test fixtures, such as stress tests, load-bearing tests, circuit functionality tests, environmental simulation tests, vibration tests, and fatigue tests. The type of test depends on the product or system being evaluated and the specific conditions or behaviors being examined.

Test fixtures are widely used across industries including manufacturing, electronics, automotive, aerospace, medical devices, and consumer goods. They play a key role in product development, quality control, and certification by ensuring products meet required standards and specifications.