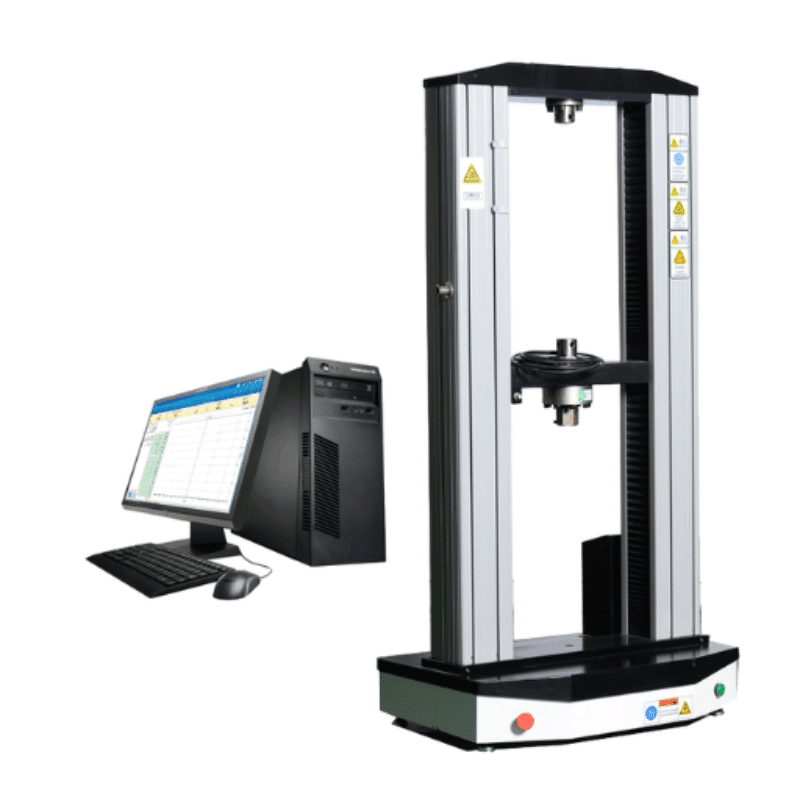

Material Testing Machine

Home » Test Machines » Material Testing Machine

The use of material testing machines is a requirment for quality control and fue efficient operation of various industries. These technologically advanced material testing instruments are created for the purpose of assessing specific qualities such as the ability to withstand pressure, the level of elasticity, or reactivity and other similar traits. For whichever material, be it metal, plastics or a composite, the material test machine is there to assure any user the effectiveness of the material for intended purposes.

Get Information on Spaghetti Production Line Manufacturers

Find Your Material Testing Machine

To obtain the best material test machine you need, there are considerations in the various types of designs. It is essential to have in mind the type that you will want, which makes it easier for you to decide on what material testing system – machines and devices – you will look at. Some of these systems take the structural shape of Tables, The reaching functionality of each of these testing systems is different and some include a variety of machines such as the universal testing machines(hardness testers), impact testing machines and tension testing devices among others. A good material testing machine that will help achieve precision, robustness and efficiency in doing materials analysis is achievable if one first knows what type of tests they want to do before listing down the types of material testing characters or procedures they need.

- Ensures durability under various stress conditions.

- Provides precise measurement of strength and quality.

- Enhances product reliability and safety standards.

- Verifies composite material’s structural integrity.

- Tests tensile and flexural strength parameters.

- Capable of adaptive environmental simulations.

- Sensitive deformation measurement sensors installed.

- Multi-functionality for diverse foam materials.

- Energy absorption testing functionality included.

- Ensures product durability and safety standards.

- Improves quality control in household items.

- Reduces product failure rates significantly.

- Accurately measures composite strength and performance.

- Enhances material reliability and market pertinence.

- High precision load sensors included.

- Determines adhesive and tensile properties reliably.

- Determines adhesive and tensile properties reliably. Measures peel and stretch strength precisely.

- Compatible with various film tape types.

Material Testing Machine Technical Parameters

| Specification | Glass and Tile Testing Machine | Wood Plastic Testing Machine | Foam Sponge Testing Machine |

|---|---|---|---|

| Testing Capability | Measures hardness, strength, and durability of glass and tiles | Assesses tensile, compressive, and flexural properties of wood plastic | Evaluates compression resilience and softness of foam and sponge |

| Max Load Capacity | 1000 kg | 500 kg | 200 kg |

| Accuracy Level | ± 0.5% | ± 1% | ± 1% |

| Operating Temperature | 10°C - 35°C | 10°C - 40°C | 5°C - 40°C |

| Power Supply | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz |

| Testing Speed Range | 0.1 - 500 mm/min | 0.1 - 300 mm/min | 0.1 - 100 mm/min |

| Machine Dimensions (mm) | 1200 x 800 x 1600 | 1000 x 700 x 1500 | 800 x 600 x 1300 |

| Weight | 250 kg | 200 kg | 150 kg |

| Specification | Daily Necessities Testing Machine | Composite Material Testing Machine | Film Tape Testing Machine |

|---|---|---|---|

| Application | Testing durability and strength of daily use items | Analyzing the properties of composite materials | Assessing tensile strength and adhesion properties of film tapes |

| Max Load Capacity | 10 kN | 50 kN | 5 kN |

| Testing Methods | Tensile, Compression, and Flexural | Tensile, Compression, and Shearing | Tensile and Peel Tests |

| Accuracy | ±0.5% | ±0.3% | ±0.2% |

| Display Type | Digital Display | Touch Screen Interface | Digital Display |

| Suitable Industries | Consumer Goods Manufacturing | Aerospace, Automotive, and Construction | Packaging and Electronics |

| Dimensions | 1200 x 800 x 1600 mm | 1500 x 1000 x 2000 mm | 1000 x 700 x 1400 mm |

| Weight | 180 kg | 400 kg | 150 kg |

Application of Material Testing Machine

Strength Testing

Flexibility Testing

Hardness Testing

Elasticity Testing

Fracture Analysis

Frequently Asked Questions

A material testing machine is a device used to evaluate the mechanical properties of various materials, such as metals, plastics, and composites. It performs tests like tensile, compression, bending, and hardness to measure strength, durability, and other critical characteristics.

The purpose of materials testing is to ensure that the materials used in manufacturing meet specific standards and performance requirements. It helps assess a material’s suitability for a particular application, ensuring safety, reliability, and quality in the final product.

The principle of material testing involves applying controlled forces to a material sample and measuring its response, such as deformation, failure, or resistance. These responses help determine the material’s mechanical properties, such as tensile strength, elasticity, ductility, and toughness.

Material testing provides valuable insights into the performance and limitations of materials, enabling informed decision-making for design, production, and quality assurance. It minimizes the risk of structural failures, ensures compliance with industry standards, and optimizes material selection for specific applications.

Materials need to be tested to confirm they meet the required specifications for safety, strength, and performance. Testing ensures that materials can withstand the stresses and conditions they will face during use, preventing product failures and maintaining the integrity of engineering and manufacturing processes.

A material testing machine is used to analyze and evaluate the mechanical properties of materials under various loads and conditions. It provides data for research and development, quality control, and product certification, helping manufacturers create reliable and high-quality products.