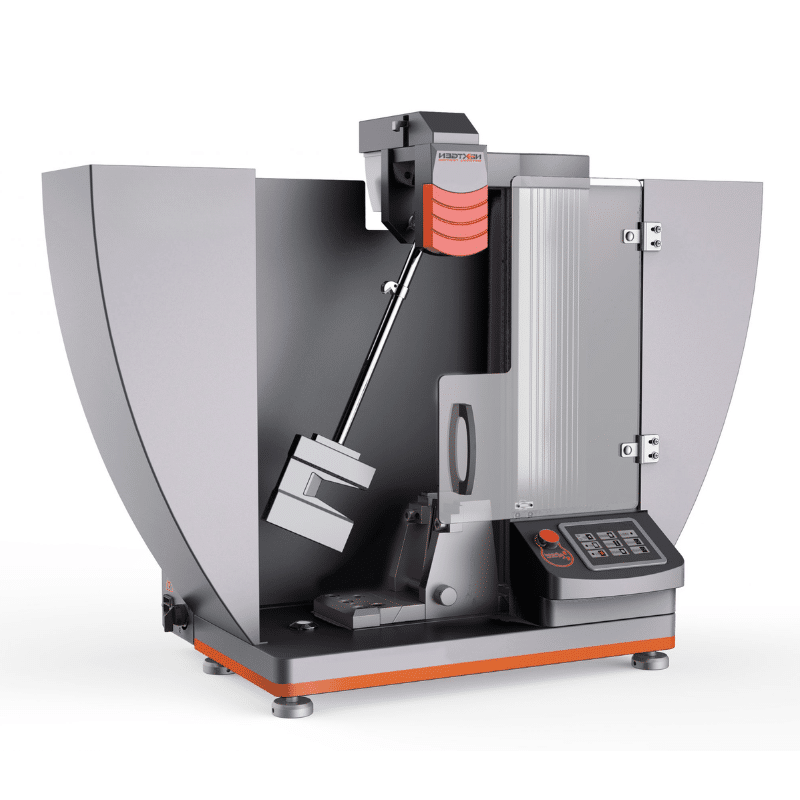

Impact Testing Machine

Home » Test Machines » Impact Testing Machine

The Impact Testing Machine is the highly essential tool to check the qualities of a material with hardness and resistance to a sudden force. These also include machines for the charpy impact test, which are mostly called charpy test machines, such that the test results can be relied upon. In China, if ever you want to know about any good manufacturer, this machine would have been sufficient in verifying some of the precision and quality-related claims.

Get Information on Spaghetti Production Line Manufacturers

Find Your Impact Testing Machine

The ability to resist a sudden load is endowed upon a material by describing such its constitution and behavior. Such a test gives valuable information on the toughness and strength of materials to ensure their reliability in real conditions. In essence, one of the main advantages of impact testing is its capacity to pinpoint weakness areas in materials, thus leading to the manufacture of safer and more durable products. Using state-of-the-art impact testing machines has allowed industries to assess how materials perform under dynamic conditions, greatly improving quality control and risk reduction. Choosing the right testing machine is fundamental to obtaining precise and repeatable testing results.

- Reduces manual effort during operation.

- Semi-automatic pendulum release mechanism.

- High-precision measurement capabilities.

- Offers detailed, real-time test data.

- Enhances efficiency with automated data analysis.

- Highly accurate and reliable performance.

- Suitable for extreme low-temperature environments.

- Prevents material deformation during testing.

- Compact design, space-saving solution.

- Enhances overall testing accuracy and reliability.

- Provides versatility for various testing scenarios.

- Durable design ensures long-term usage.

- Delivers precise and repeatable testing results.

- Improves efficiency in conducting impact analysis.

- Cost-effective for high-performance testing needs.

- Measures material resilience with high precision.

- Suitable for a wide range of materials.

- Adjustable testing parameters for customization.

Impact Testing Machine Specification

| Specification | Semi-automatic Impact Testing Machine | Computerized Impact Testing Machine | Low Temperature Impact Testing Machine |

|---|---|---|---|

| Control Type | Semi-automatic | Computerized | Computerized |

| Display | Analog | Digital | Digital |

| Maximum Impact Energy | 300 Joules | 500 Joules | 300 Joules |

| Temperature Range | Not Applicable | Not Applicable | -196°C to Room Temperature |

| Test Accuracy | ±0.5% | ±0.2% | ±0.2% |

| Software Integration | Not Available | Available | Available |

| Specimen Size | Standard | Standard | Standard |

| Application | Material Toughness Testing | Material Toughness Testing | Material Toughness at Low Temperatures |

| Additional Features | Manual Reset | Automatic Reset | Integrated Cooling System |

| Specification | Other Equipment for Impact Testing | Impact Test Equipment | Impact Strength Testing Machine |

|---|---|---|---|

| Purpose | General impact testing of materials | Testing toughness of materials under impact | Determining impact strength of materials |

| Material Capability | Various materials | Metals, polymers, and composites | Metals and composite materials |

| Load Range | Up to 300J | 150J – 450J | 200J – 500J |

| Accuracy | ±1.5% | ±1% | ±0.5% |

| Operation Type | Manual | Semi-automatic | Fully automatic |

| Display Type | Analog or digital | Digital | Advanced digital interface |

| Applicable Standards | ASTM, ISO | ISO 148-1, EN 10045 | ASTM E23, ISO 179 |

| Energy Measurement Range | Basic | Medium | High precision |

| Testing Speed | Variable | Fixed or variable | Highly controlled |

| Installation Requirement | Bench-mounted | Floor-standing | Floor-standing |

Application of Impact Testing Machine

Strength Evaluation

Material Selection

Quality Control

Failure Analysis

Research and Development

Frequently Asked Questions

The standard for impact testing varies depending on the region and application, but commonly used standards include ASTM E23 and ISO 148. These standards provide guidelines on how to conduct impact tests, including specimen preparation, equipment specifications, and testing procedures.

The principle of impact testing is to determine the ability of a material to absorb energy and resist impact under rapid loading conditions. This is achieved by striking a notched specimen with a pendulum or hammer and measuring the energy absorbed during fracture. The results provide insight into the material’s toughness and ductility.

There are primarily two main types of impact tests—Charpy and Izod tests. The key difference between them lies in the positioning of the specimen and the notch during testing. Additionally, other variations of impact testing may include drop weight tests and dynamic fracture toughness tests.

An impact testing machine is specialized equipment designed to evaluate the impact strength of materials. It typically consists of a pendulum or a hammer, a supporting frame, and a sample holder. The machine measures the amount of energy absorbed by the material during fracture, providing valuable data about its mechanical properties.

Impact testing has several advantages, including determining a material’s toughness and resilience, assessing its ability to withstand sudden forces, and providing critical data for safety and reliability in engineering designs. It also helps identify brittle materials that may fail under service conditions.

To conduct impact testing, a notched specimen is prepared and positioned in the impact testing machine according to the test standard being followed. The pendulum or hammer is released to strike the specimen, and the absorbed energy is recorded. Proper calibration of the machine and adherence to the standard procedures are essential to ensure accurate results.