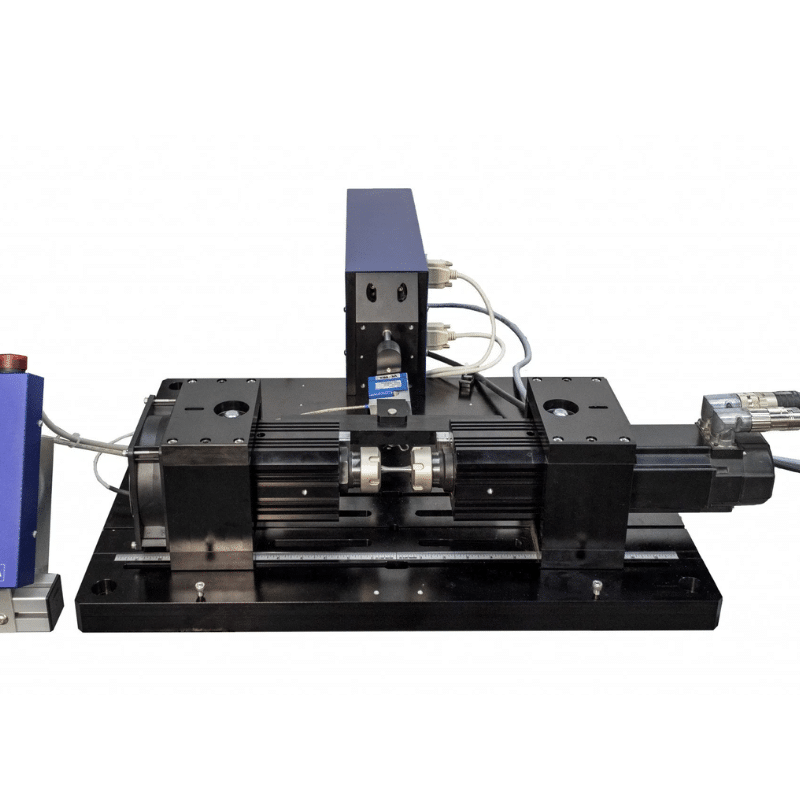

Bending Testing Machine

Home » Test Machines » Bending Testing Machine

The Bending Testing Machine or Tool is one of the most important equipment used for testing strength and flexibility in materials under different conditions of stress. Meaning one of the best bending testing machines in the market, it is designed with great precision by leading bending testing machine manufacturers. A trusted Manufacturer from China promises quality and reliability.

Get Information on Spaghetti Production Line Manufacturers

Find Your Bending Testing Machine

In the study of material properties, the bending test machine holds an eternal place in its importance regarding accurate observations on durability and flexibility. The machine casts the mechanical strength of different materials in given conditions, hence called universal because it holds extreme importance in industrial sectors such as construction, manufacturing, and aerospace. When it comes to repeated stress evaluation, the bending fatigue testing machine proves to be invaluable, as it subjects materials to cyclic loads to assess their resistance to fatigue and destruction. All these instruments stand as quality keepers; by making sure of quality and durability, they assist engineers and researchers in developing safer and more reliable products applicable in many areas.

- High accuracy in deformation analysis.

- Measures bending under controlled loads.

- Compact design for lab convenience.

- Advantages: Reliable results for repeated stress cycles.

- Precision motorized bending system.

- Accurate repeated load execution.

- Efficient fatigue testing for materials.

- Continuous rotational stress application.

- Sturdy construction for heavy-duty use.

Bending Testing Machine Technical Parameters

| Specification | Bending Moment Testing Machine | Wire Repeated Bending Testing Machine | Rotating Bending Testing Machine |

|---|---|---|---|

| Purpose | Measures bending moments on materials and structures | Tests wire durability under repeated bending | Tests endurance under rotating bending loads |

| Maximum Load Capacity | 500 kN | 50 N | 1000 N |

| Test Speed | Variable (0.1 - 10 RPM) | 60 cycles/min | Variable (up to 5,000 RPM) |

| Material Compatibility | Metals, Polymers, Composites | Wires and Thin Filaments | Metals, Alloys |

| Display Type | Digital with Graphical Output | Digital Counter | Digital with Load and Speed Display |

| Power Supply | 220V, 50/60 Hz | 110V/220V, 50 Hz | 220V, 50/60 Hz |

| Test Standard Compliance | ASTM E290, ISO 7438 | IEC 60811-3 | ISO 1143 |

Application of Bending Testing Machine

Material Testing

Quality Control

Product Development

Research and Development

Construction Industry

Frequently Asked Questions

A bending machine works by applying a precise amount of force to a material, typically a metal or composite, to deform it into a desired shape or angle without causing fractures. This is achieved using a combination of clamps, rollers, and a controlled hydraulic or mechanical system to ensure accuracy and consistency in the bending process.

To perform a bending test, a sample material is placed on supports within the bending testing machine. A load is then applied at the center (three-point or four-point bending method) until the material bends or fractures. This test helps evaluate the material’s flexibility, strength, and elasticity under applied stress.

Bending tests are typically performed using a universal testing machine (UTM) equipped with fixtures or bending attachments. Specially designed bending testing machines can also be used for specific materials or tests requiring higher precision.

A bend test works by subjecting a material to a force that creates a bend, allowing engineers or researchers to assess its ductility and resistance to cracking. The test measures the material’s ability to withstand deformation without failing and is often used to evaluate weld quality or metal toughness.

A bending machine is designed to modify the shape of materials such as metal sheets, tubes, or bars by applying controlled force. It is widely used in manufacturing, construction, and engineering to produce components for various applications, ensuring precise angles and curves.

The standard for bend testing depends on the material and industry requirements. Common international standards include ASTM E290 for metallic materials and ISO 7438. These outline the test methods, equipment specifications, and procedures to ensure accurate and consistent results.