Trusted Pharmaceutical Equipment for High-Quality Manufacturing

Home » Pharmaceutical Equipment

Pharmaceutical equipment is essential for ensuring efficiency and precision in production. From reliable machinery to industry-compliant systems, these solutions optimize manufacturing processes and enhance output quality. The right equipment helps streamline operations and improve overall performance.

Get Information on Pharmaceutical Equipment Manufacturers

Find Your Pharmaceutical Equipment

Pharmaceutical equipment encompasses various machines tailored to different stages of the manufacturing process. Each machine is crucial for ensuring precision, efficiency, and compliance with industry standards, from tablet presses and capsule fillers to liquid filling systems and packaging equipment. Choosing the right equipment optimizes production while maintaining high quality and safety.

Pharmaceutical Equipment Options for Every Need

A capsule filling machine efficiently fills capsules with powders, granules, or liquids, ensuring precise dosage and consistency with every cycle.

Tablet press machines compress powders into tablets, balancing speed with accuracy, and handling complex formulations without compromising quality.

Pharmacy isolators create a sterile barrier for sensitive pharmaceutical processes, protecting both products and operators from contamination.

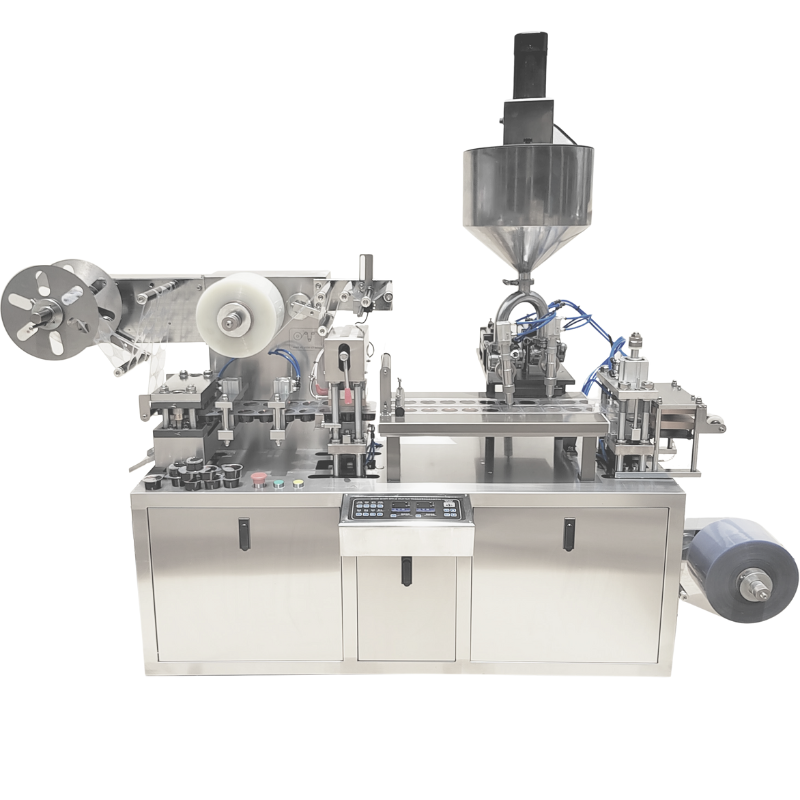

Automating the final packaging stage, these machines efficiently seal, box, and label pharmaceutical products, enhancing productivity and accuracy.

Tablet coating machines apply a protective layer to tablets, improving their appearance, taste, and stability while ensuring uniformity in every batch.

This tester measures the durability of tablets, simulating handling and transport to ensure they remain intact throughout their lifecycle.

Pharmaceutical filling machines accurately dispense liquids, powders, and solids into containers, ensuring consistent dosages and meeting safety and quality standards.

Pharmaceutical mixers blend powders and ingredients evenly, creating uniform formulations for tablets, capsules, and liquids with high consistency.

Granulator machines convert powders into uniform granules, improving flow properties and consistency, essential for efficient tablet and capsule manufacturing.

Lyophilizers preserve sensitive pharmaceutical products by removing moisture under controlled freezing and vacuum conditions, maintaining long-term stability and potency.

Capsule polishing machines remove surface dust and polish capsules, enhancing their appearance and ensuring smooth, uniform surfaces for better presentation and quality.

Tablet dedusters remove excess powder from tablets after compression, ensuring clean, smooth surfaces for better packaging and presentation while maintaining product quality.

Tablet hardness testers measure the strength of tablets, ensuring they can withstand handling and transport without breaking, critical for quality control in pharmaceutical production.

Powder grinder machines finely grind raw materials into uniform powders, ensuring consistency and precision for pharmaceutical formulations and other applications.

Fluid bed dryers use heated air to dry powders and granules efficiently, providing consistent results and maintaining product quality for pharmaceutical production.