Laser Marking Machine For Metal

Home » Laser Marking Machine » Laser Marking Machine For Metal

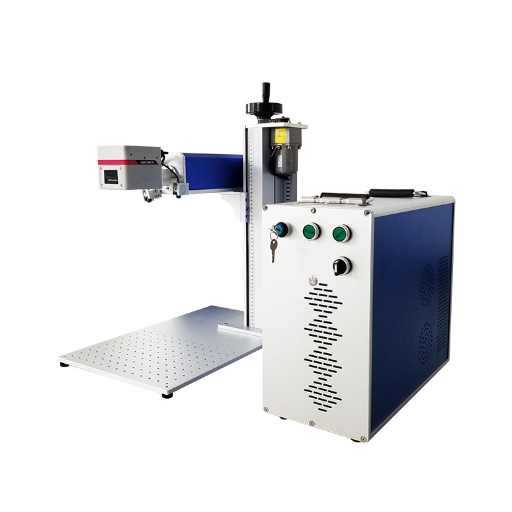

The Laser Marking Machine for Metal is a high-precision tool designed to create permanent markings on various metal surfaces. It uses advanced laser technology to etch, engrave, or mark metals like steel, aluminum, and brass with excellent durability and clarity. As a leading manufacturer and distributor in China, we are committed to providing high-quality machines and exceptional customer service; find the perfect machine for your business and learn how our solutions can help optimize your production process.

Get Information on Fiber Laser Engraving Machine Manufacturers

Find Your Stainless Steel Laser Marking Machine

When selecting the right laser marking machine for metal, consider factors such as material compatibility, precision, and production volume. Our stainless steel laser marking machines are designed to provide high-quality, durable markings on a variety of metals, including steel, aluminum, and brass. Whether you need laser metal marking, color laser marking on metal, or laser engraving on metal, we offer a range of machines to meet your specific requirements.

- High-precision metal marking

- Compact and cost-effective

- Ideal for small-scale production

- Fast engraving speed

- Suitable for medium-sized production

- High-quality marks on stainless steel

- Powerful and efficient

- Ideal for thick metal materials

- Deep engraving and high contrast marks

- Lightweight and easy to move

- Flexible for on-site marking

- High precision for small and intricate designs

- Excellent for non-ferrous metals

- Long lifespan and minimal maintenance

- High-speed marking with fine detail

- Heavy-duty for large-scale production

- Handles high-volume manufacturing

- Advanced software for precision control

Laser Marker Machine For Metal Technical Parameters

| Product Type | Power | Laser Type | Marking Speed | Engraving Depth | Applications |

|---|---|---|---|---|---|

| 30W Laser Marker Machine for Metal | 30W | Fiber Laser | 7000mm/s | Shallow engraving | Small metal parts, logo marking |

| 50W Laser Marking Machines for Metal | 50W | Fiber Laser | 10000mm/s | Medium depth | Stainless steel, jewelry, automotive components |

| 100W Laser Marker Machine for Metal | 100W | Fiber Laser | 12000mm/s | Deep engraving | Heavy-duty engraving on metals, industrial parts |

| Portable Laser Marking Machines for Metal | 20-30W | Fiber Laser | 3000mm/s | Shallow engraving | Portable marking for small items and repairs |

| Fiber Laser Marker Machine for Metal | 20-100W | Fiber Laser | 8000mm/s | Medium to deep | Engraving on metals like steel, brass, and aluminum |

| Industrial Laser Marking Machines for Metal | 150W | Fiber Laser | 15000mm/s | Deep engraving | Large scale industrial marking, heavy-duty usage |

Metal Laser Marking Machine Components

Fiber Laser Source

The fiber laser source is the core component of a Laser Marking Machine for Metal, providing the energy required for high-precision engraving and marking on various metals like steel, aluminum, and titanium.

Galvo Scanner

The Galvo scanner is an essential component in Laser Marking Machines for Metal, and it is responsible for directing the laser beam across the marking surface with high precision.

Laser Marking Head

The laser marking head is part of the Laser Marking Machine for Metal that houses the laser focusing lens and directs the focused laser beam onto the workpiece.

CNC Controller

The CNC controller is the brain behind the Laser Marking Machine for Metal.

Worktable/Workbed

The worktable or workbed is the platform on which the metal parts are placed for engraving. It provides stability and support during the marking process and is often adjustable to accommodate different sizes of workpieces.

Protective Housing

The protective housing shields the machine's internal components, such as the laser source and electronics, from dust, debris, and external contaminants.

Frequently Asked Questions

Laser marking machines are versatile and can be used to mark a wide range of metals, including stainless steel, aluminum, brass, copper, titanium, and carbon steel. They are commonly used in industries like aerospace, automotive, and electronics.

The machine uses a high-powered laser beam that is directed onto the metal surface. The beam’s heat causes the metal to either melt or oxidize, creating a permanent mark or engraving. The machine’s software allows you to control the speed, depth, and intensity of the laser.

Laser engraving involves creating deeper and more pronounced marks or designs on the metal, while laser marking typically refers to changing the surface properties of the metal without significant depth. Marking is often used for text or serial numbers, while engraving is used for logos or intricate designs.

Yes, Laser Marking Machines for Metal are well-suited for large-scale industrial applications, including mass production of parts and components. Their high-speed operation, low maintenance, and precision make them ideal for manufacturing environments.

Yes, you can mark a wide variety of designs, including logos, text, serial numbers, barcodes, QR codes, and graphics. The laser marking software allows for precise control, enabling you to engrave complex and intricate designs on metals.

Maintenance for Laser Marking Machines is generally low. Regular tasks include cleaning the lens, checking the cooling system, and ensuring the machine is calibrated correctly. It’s also essential to perform software updates when necessary and inspect the laser source for any issues.