Advanced Laser Marking Machines from China Leading Manufacturer

Home » Laser Marking Machine

Achieve exceptional marking accuracy with laser marking machines designed for high-speed and high-quality engraving on various materials. Engineered for durability and efficiency, these systems support applications in manufacturing, electronics, automotive, and more. Explore reliable China laser marking machine manufacturers to find the perfect solution tailored to your needs. Contact us today for more details on available laser marking machine price and models.

Get Information on Laser Marker Manufacturers

Find Best Laser Marking Machine for You

Selecting the right laser machine for marking depends on factors such as material type, marking depth, and production speed. Power levels, beam quality, and software compatibility all impact performance, making it essential to choose a system that aligns with your business needs. Whether you need a cheap laser marking machine for basic applications or an industrial laser marking machine for high-volume production, understanding key specifications ensures optimal results.

Laser Marking Machine for Sale

Engineered for speed and precision, fiber laser technology etches crisp, permanent markings on metals, plastics, and industrial components.

Ideal for delicate materials, UV laser mark creates ultra-fine, high-contrast marks on glass, ceramics, and sensitive electronic components.

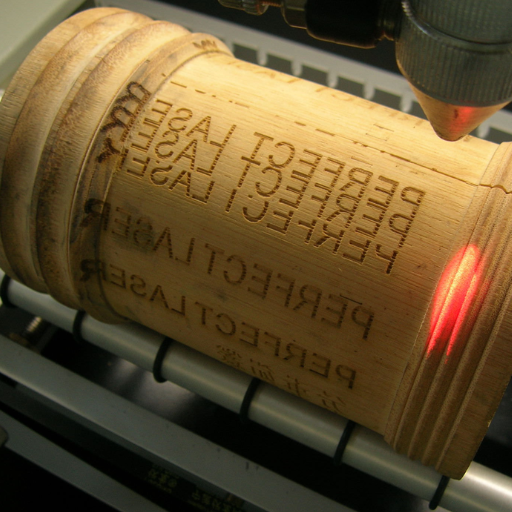

Optimized for organic materials, CO2 lasers engrave wood, leather, glass, and acrylic with smooth precision, making them ideal for custom branding.

A compact, portable solution that brings laser mark flexibility to large, immovable objects—perfect for fieldwork and industrial tagging.

Designed for depth and complexity, 3D laser mark adjusts dynamically to curved, uneven, and textured surfaces with unparalleled accuracy.

Offering adjustable pulse durations, MOPA lasers achieve vibrant color marking on stainless steel while excelling in deep engraving on various metals.

Built for durability, metal marking lasers engrave serial numbers, barcodes, and logos with clarity that withstands harsh industrial environments.

Perfect for artistic engraving and branding, wood laser mark burns clean, detailed patterns into hardwoods, MDF, and natural grain surfaces.

Benefits of Laser Marker

- High Precision: Laser marking ensures extremely fine detail and accuracy, making it ideal for intricate designs, serial numbers, logos, and barcodes.

- Permanent Marking: Unlike traditional marking methods, laser marks are permanent and won’t fade or wear off over time, even in harsh environments.

- Speed and Efficiency: Laser marker can operate at high speeds, allowing for faster production times and greater output in less time.

- No Consumables: Since lasers don’t require inks, paints, or other consumables, operating costs are significantly reduced.

- Versatile: Laser marking is compatible with a wide range of materials, including metals, plastics, wood, leather, and glass, allowing for diverse applications across industries.

- Minimal Surface Contact: The non-contact nature of laser marking reduces the risk of material damage, maintaining the integrity of the item being marked.

- Environmentally Friendly: Without the need for chemicals or materials that can pollute, laser marking is a cleaner and greener solution.

Which Materials Can You Laser Engrave?

| Material | Fiber Laser Machine | UV Laser Machine | CO2 Laser Machine |

|---|---|---|---|

| Metals | ✔️ | ❌ | ❌ |

| Plastics | ✔️ | ✔️ | ❌ |

| Glass | ❌ | ✔️ | ✔️ |

| Wood | ❌ | ❌ | ✔️ |

| Leather | ❌ | ❌ | ✔️ |

| Ceramics | ✔️ | ✔️ | ❌ |

| Rubber | ✔️ | ✔️ | ✔️ |

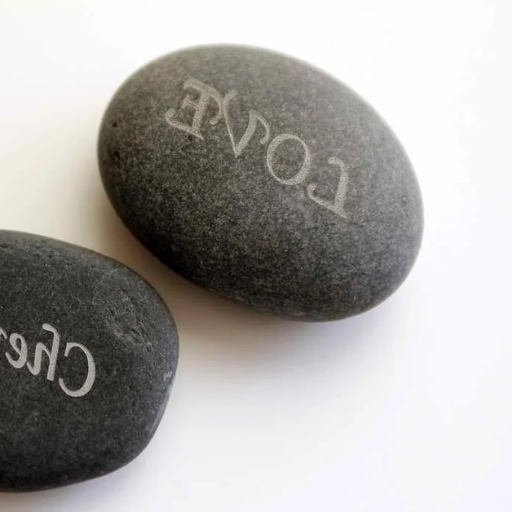

| Stone | ❌ | ✔️ | ✔️ |

| Textiles | ❌ | ✔️ | ✔️ |

| Acrylic | ✔️ | ✔️ | ✔️ |

Materials Examples for Laser Marking Engraving Machine

Laser Marker Related Articles

Related Topics About Laser Marker

Frequently Asked Questions

What materials can be processed with this technology?

These machines are capable of marking metals, plastics, ceramics, glass, leather, and more. The type of system used determines the best material compatibility.

How does this process differ from engraving?

Marking alters the surface color or texture without removing material, while engraving physically etches into the surface, creating a deeper mark.

What industries benefit the most from this technology?

Industries such as aerospace, medical devices, automotive, and electronics use it for serial numbers, branding, and traceability markings.

Is this method safe for delicate materials?

Yes, certain models, such as UV-based systems, are designed for minimal heat impact, making them ideal for delicate surfaces like glass or plastics.

How do I choose the right model for my application?

Factors like material type, marking depth, production speed, and required durability should be considered when selecting a system. A trusted laser marking machine supplier can help determine the best fit.

What maintenance is required?

Regular cleaning of optics, checking cooling systems, and updating software ensure long-term performance with minimal downtime.

Can this technology be integrated into automated production lines?

Yes, many models are designed for seamless integration into industrial automation, improving efficiency and consistency in mass production.

Where can I find a reliable provider?

Working with a trusted laser marking machine dealer ensures access to high-quality equipment, professional support, and tailored solutions for different marking applications. Contact us today for more information and to find the best solution for your needs.