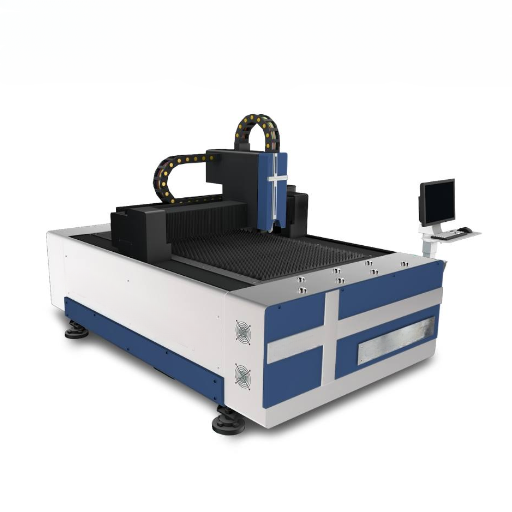

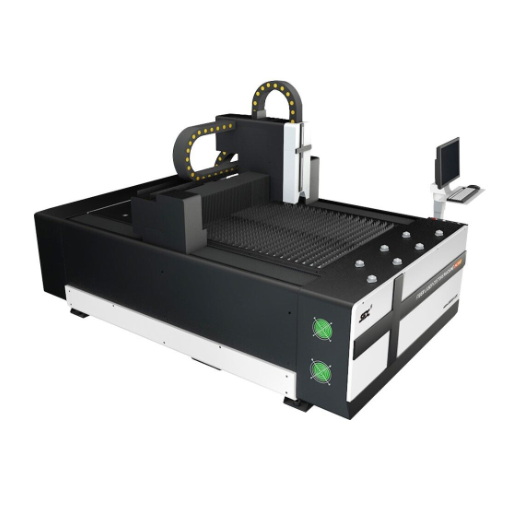

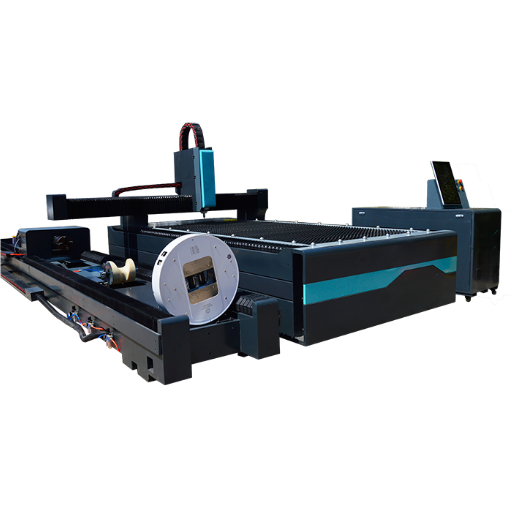

Fiber Laser Cutting Machine

Home » Laser Cutting Machine » Fiber Laser Cutting Machine

Our Fiber Laser Cutting Machines offer cutting-edge technology for precise and efficient metal cutting. With high power and speed, these machines are designed to meet the diverse needs of industries such as automotive, aerospace, and manufacturing. Whether you need to cut stainless steel, carbon steel, aluminum, or other metals, we provide a variety of models to suit your production requirements. As a leading China manufacturer and distributor, our enterprise offers customizable solutions tailored to your needs.

Get Information on Fiber Laser Engraving Machine Manufacturers

Find Your Fiber Optic Laser Cutting Machine

When selecting a fiber laser cutter machine, factors like cutting speed, precision, material compatibility, and power requirements must be considered. We offer a variety of models, including desktop fiber laser cutters for small businesses and CNC fiber laser cutters for large-scale industrial applications.

- High-speed metal cutting

- Ideal for thin sheet metal

- Cost-effective for small to medium production

- Excellent for cutting stainless steel

- Enhanced cutting precision

- Suitable for both thin and medium thickness materials

- Increased power for thicker materials

- Efficient for high-volume production

- Advanced fiber laser technology for superior performance

- Capable of cutting large metal sheets

- High cutting speed and accuracy

- Perfect for automotive and heavy-duty applications

- Great for cutting thick plates

- Ideal for high-speed, heavy-duty cutting tasks

- Superior cutting quality with minimal material distortion

- High-power for industrial-grade applications

- Cuts through thick stainless steel and carbon steel

- large-scale production and high-efficiency cutting

Fiber Laser Cutter Machine Technical Parameters

| Product Type | Laser Power | Cutting Thickness (Stainless Steel) | Cutting Speed | Application |

|---|---|---|---|---|

| 500W Fiber Laser Cutter Machine | 500W | Up to 6mm | 15-25 m/min | Thin metal cutting (mild steel, aluminum) |

| 1000W Fiber Laser Cutting Machines | 1kW | Up to 8mm | 12-20 m/min | Small to medium thickness materials |

| 2000W Fiber Laser Cutter Machine | 2kW | Up to 12mm | 10-18 m/min | Stainless steel, carbon steel |

| 3000W Fiber Laser Cutting Machines | 3kW | Up to 16mm | 8-15 m/min | High-speed cutting for medium to thick sheets |

| 4000W Fiber Laser Cutter Machine | 4kW | Up to 20mm | 6-12 m/min | Heavy-duty, thick sheet cutting |

| 6000W Fiber Laser Cutting Machines | 6kW | Up to 25mm | 5-10 m/min | Industrial-grade cutting for thick plates |

Fiber Laser Cutting Machine Components

Fiber Laser Source

The fiber laser source is the core component of a fiber laser cutter machine. It provides the focused laser beam that cuts through metal.

CNC Control System

The CNC control system manages the overall operation of the fiber laser cutting machine. This system controls the movement of the cutting head, the laser power, and the cutting speed.

Laser Cutting Head

The laser cutting head is a crucial component in fiber laser cutting, as it houses the lens that focuses the laser beam onto the material’s surface.

Beam Delivery System

The beam delivery system in a fiber laser cutting machine ensures that the laser source's laser beam is accurately directed to the cutting head.

Assist Gas System

The assist gas system plays a significant role in cutting by providing the necessary gas (such as nitrogen, oxygen, or air) to blow away molten material during cutting.

Cutting Bed

The worktable or cutting bed supports the cut material and is equipped with mesh grids or perforated surfaces to hold the workpiece in place securely.

Frequently Asked Questions

Fiber laser cutting machines are ideal for cutting metals like stainless steel, aluminum, carbon steel, brass, and copper. They can also cut non-metals like plastics, wood, and acrylic, depending on the laser source and settings.

Fiber laser cutting machines use a solid-state fiber-optic laser, which is more energy-efficient and provides better beam quality than the gas-based CO2 laser cutting machines. Fiber lasers also cut metals more effectively, particularly thin metals, and have lower operating costs and longer lifespans.

A fiber laser cutting machine works by focusing a high-powered laser beam on the material. The laser heats the material to its melting point, and an assist gas (such as oxygen or nitrogen) blows the molten metal away, resulting in a clean and precise cut. The CNC control system moves the cutting head along the predefined paths based on the design.

Maintenance for a fiber laser cutting machine typically involves regular cleaning of the lens and nozzles, ensuring proper alignment of the cutting head, and checking the cooling system to prevent overheating. The fiber laser source requires little maintenance, but the assist gas system should be checked regularly. Routine inspections and servicing by qualified technicians are also recommended.

Yes, fiber laser cutting machines can cut non-metal materials like wood, acrylic, plastic, and rubber with the appropriate settings. However, for cutting non-metals, CO2 lasers might be more efficient in certain cases, especially when cutting thicker plastics. Fiber lasers are still effective for cutting thin non-metal sheets.

The maximum cutting thickness depends on the machine’s laser power and the type of material. For example, a 1000W fiber laser cutter can typically cut up to 12mm stainless steel and 8mm carbon steel, while higher-powered systems (such as 3000W or 4000W) can cut thicker materials. Always check the specifications of the specific machine you’re using.