Professional Laser Cutting Machines Offered by Chinese Manufacturers

Home » Laser Cutting Machine

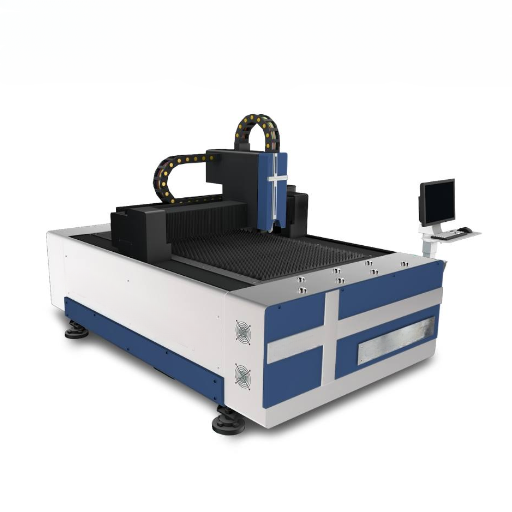

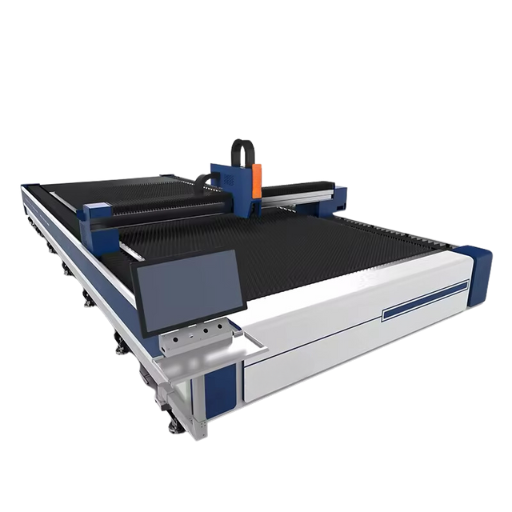

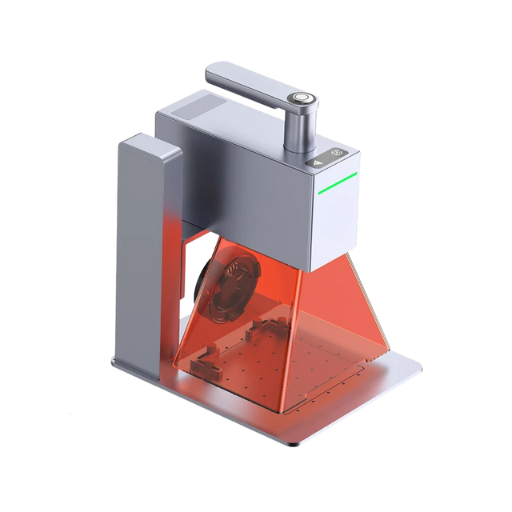

Precision and versatility define modern laser cutting machines, built for industries demanding accuracy and speed. Whether shaping metal components, crafting intricate acrylic designs, or engraving fine details, these systems handle diverse materials with ease. From industrial laser cutting machines for large-scale production to table top laser cutting machines for compact workspaces, advanced technology ensures smooth, clean cuts. Contact us today to get the latest information on laser cutting machine price, models, and manufacturer details.

Get Information on Laser Cutting Machine Manufacturer

Find the Best Laser Cutting Machine for You

When selecting a laser cutting machine, factors like material compatibility, cutting speed, and power output should be carefully evaluated. The right system depends on your production scale, whether for industrial fabrication or precision engraving. A laser cutting and engraving machine with advanced controls ensures efficiency, while considerations like cutting bed size and maintenance requirements impact long-term performance. For expert guidance and supplier details, contact us today.

Laser Cutting Machine for Sale

Engineered for speed and precision, this system slices through metals with ease, delivering clean, burr-free edges for industrial applications.

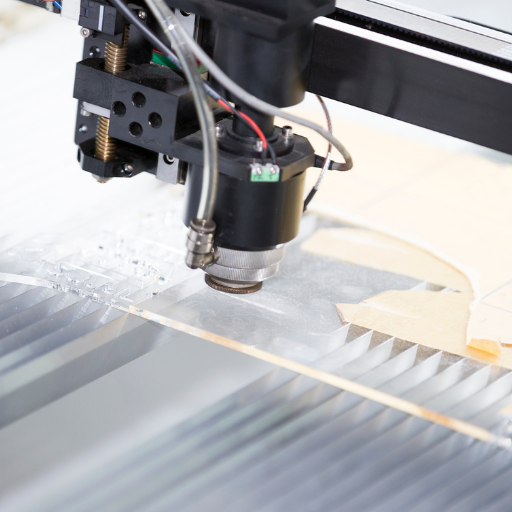

A versatile choice for non-metal materials, it excels in cutting wood, acrylic, leather, and paper with smooth, intricate detail and minimal waste.

Designed for high-clarity cuts, this machine ensures polished edges on acrylic sheets, making it ideal for signage, displays, and artistic designs.

Combining automation with precision, CNC-controlled lasers optimize efficiency, allowing for high-volume production with minimal material loss.

Built for industrial fabrication, it cuts stainless steel, aluminum, and titanium with pinpoint accuracy, making complex metalworking effortless.

Turn leather into works of art—laser engraved creates fine patterns, logos, and custom designs that are both sharp and lasting.

Designed for textiles, this system delivers clean, sealed edges on fabric, eliminating fraying and enabling precise cuts for fashion and upholstery.

Compact yet powerful, this portable system brings laser precision to large or irregular surfaces, making on-site metal and plastic cutting effortless.

Advantages of Laser Cutting

Precision, efficiency, and versatility make this cutting method a preferred choice across industries. Compared to traditional techniques, it offers superior edge quality, faster processing, and reduced material waste, optimizing both production speed and cost-effectiveness.

- Exceptional Accuracy – The highly focused beam ensures intricate details and sharp edges, making it ideal for complex designs and fine patterns.

- Wide Material Compatibility – From metals and plastics to wood, textiles, and ceramics, this technology adapts to various applications with precision.

- Non-Contact Processing – Without direct mechanical force, materials remain intact, reducing stress, tool wear, and deformation.

- High-Speed Performance – Advanced automation enhances productivity, delivering fast, efficient results for both mass production and custom fabrication.

- Smooth Edge Quality – Cuts are clean and precise, eliminating the need for extensive finishing work like sanding or deburring.

- Optimized Material Use – Smart software minimizes waste by maximizing material efficiency, reducing production costs.

- Automation & Repeatability – CNC-controlled systems ensure uniform results across every piece, making them ideal for large-scale manufacturing.

- Eco-Friendly & Low Maintenance – With no need for consumables like blades or inks, operational costs remain low while minimizing environmental impact.

What Materials Can a Laser Cut?

| Material | Fiber Laser Cutting Machine | CO2 Laser Cutting Machine |

|---|---|---|

| Stainless Steel | ✔️ | ❌ |

| Carbon Steel | ✔️ | ❌ |

| Aluminum | ✔️ | ❌ |

| Copper | ✔️ | ❌ |

| Brass | ✔️ | ❌ |

| Wood | ❌ | ✔️ |

| Acrylic | ❌ | ✔️ |

| Plastic | ✔️ | ✔️ |

| Leather | ❌ | ✔️ |

| Glass | ❌ | ✔️ |

| Fabric | ❌ | ✔️ |

| Stone | ❌ | ✔️ |

| Rubber | ✔️ | ✔️ |

| Paper | ❌ | ✔️ |

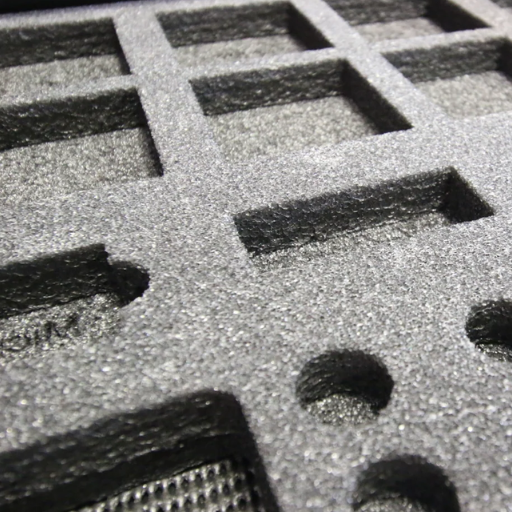

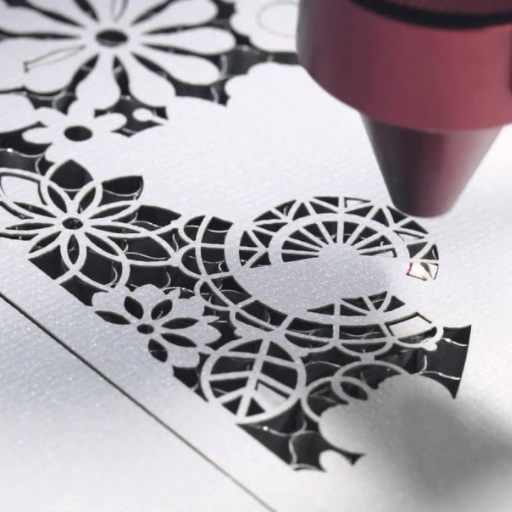

Laser Cutting Examples for Various Materials and Projects

Laser Engraving Cutting Machine Related Articles

Related Topics About Laser Cutting Machine

Frequently Asked Questions

What factors should I consider when choosing the right laser for cutting machine?

Selecting the right system depends on material type, thickness, cutting speed, and precision requirements. CO2 models are better for wood, acrylic, and fabrics, while fiber systems excel at metal processing. Additionally, factors like machine power, work area size, and software compatibility should align with production needs.

How does a fiber laser differ from a CO2 system?

A fiber-based system is optimized for metal, offering higher efficiency and lower maintenance, while CO2 versions are ideal for non-metal materials like wood, glass, and acrylic. Fiber technology delivers faster processing speeds with reduced energy consumption, whereas CO2 models provide smoother edges for organic materials.

Is this technology suitable for high-volume manufacturing?

Yes, many systems are designed for industrial-scale operations. With CNC automation and advanced motion control, they ensure precision and repeatability, making them ideal for mass production across industries such as automotive, aerospace, and signage manufacturing.

What are the maintenance requirements for long-term performance?

Regular upkeep includes cleaning optical lenses, checking alignment, and monitoring cooling systems. Fiber-based options require less maintenance compared to CO2 versions, which need periodic gas refills and mirror adjustments. Keeping the system in optimal condition extends lifespan and ensures consistent performance.

Can this technology be integrated into an automated production line?

Many models support integration with conveyor belts and robotic systems, streamlining workflow efficiency. Advanced software allows for real-time adjustments, ensuring seamless operation within smart manufacturing environments. Custom configurations may be available through a laser cutting machine supplier to fit specific automation requirements.

What safety measures should operators follow?

Proper protective eyewear is essential to prevent exposure to high-intensity beams. Additionally, well-ventilated workspaces help control fumes and particulate emissions, especially when processing materials like plastics. Many systems also feature safety enclosures and emergency stop functions for added protection.

How does cutting precision vary across different materials?

Metal surfaces require higher power settings and fine-tuned beam adjustments to achieve clean cuts without excess heat distortion. For materials like acrylic and wood, settings must be optimized to prevent charring or melting, ensuring smooth edge quality and minimal material loss.

Where can I purchase a reliable system for my business?

Working with an experienced laser cutting machine supplier ensures access to high-quality models, expert support, and customization options suited to different production demands. For recommendations and sourcing details, feel free to contact us today.