Corn Flakes Production Line

Home » Food Machine » Corn Flakes Production Line

Learn about the Automatic Corn Flakes Production Line, featuring advanced corn flakes extrusion technology for efficient cereal production. Discover key Corn Flakes Manufacturing Equipment and connect with trusted corn flakes production line suppliers to find the right solutions. This fully automated system ensures consistent, large-scale production of high-quality breakfast cereal.

Get Information on Corn Flakes Production Line Manufacturers

Find Your Corn Flakes Production Line

The Corn Flakes Production Line is engineered for high efficiency, with production capacities suitable for both small-scale and large industrial operations. The line includes key components such as a raw material mixer, a twin-screw extruder, a flaking machine, drying ovens, and a coating unit. Utilizing an advanced corn milling and flaking process, this system ensures consistent quality throughout each stage—from cooking and flaking to drying and flavoring—making it ideal for high-volume breakfast cereal production.

Corn Flakes Processing Line for sale

Discover high-efficiency solutions from trusted Corn Flakes Processing Line factories, offering automatic systems designed for large-scale cereal manufacturing. These high-capacity corn flakes manufacturing equipment ensure consistent quality and streamlined production for your business needs.

- Small-Scale Corn Flakes Line

- Entry-Level Cereal Production

- Ideal for New Manufacturers

- Mid-sized Corn Flakes Processing Line

- Balanced Output and Efficiency

- Suitable for Regional Distribution

- High-Efficiency Corn Flakes Line

- Scalable Cereal Production Solution

- Ideal for Growing Businesses

- Large-Scale Corn Flakes Manufacturing

- Advanced Automation for High Output

- Consistent Quality at High Capacity

- Industrial-grade Corn Flakes Processing Line

- High-volume Cereal Manufacturing Solution

- Designed for Large Distribution Needs

- Maximum Capacity Corn Flakes Line

- Fully Automated for Mass Production

- Industrial-Grade High Output

Corn Flakes Manufacturing Equipment Technical Parameters

| Model | Capacity (kg/hour) | Power Consumption (kW) | Machine Components | Applications |

|---|---|---|---|---|

| 100 kg/hour | 100 | 75 | Mixer, Extruder, Flaking Machine, Dryer, Coating Unit, Packaging System | Small-scale corn flakes processing |

| 300 kg/hour | 300 | 120 | Mixer, Extruder, Flaking Machine, Dryer, Coating Unit, Packaging System | Mid-sized corn flakes production |

| 500 kg/hour | 500 | 180 | Mixer, Extruder, Flaking Machine, Dryer, Cooling & Coating Unit, Packaging System | Growing businesses and regional distribution |

| 800 kg/hour | 800 | 250 | Mixer, Twin-Screw Extruder, Flaking Machine, Multi-Stage Dryer, Coating Unit, Packaging System | Large-scale industrial corn flakes manufacturing |

| 1000 kg/hour | 1000 | 320 | Industrial Mixer, Twin-Screw Extruder, Flaking Machine, Multi-Stage Dryer, Cooling Unit, Coating Unit, Packaging System | High-volume cereal production for large markets |

| 1500 kg/hour | 1500 | 400 | Industrial Mixer, Twin-Screw Extruder, Flaking Machine, High-Capacity Dryer, Cooling Unit, Coating Unit, Automated Packaging | Mass production for international distribution |

Corn Flakes Manufacturing Equipment

Raw Material Mixer

Twin-Screw Extruder

Flaking Machine

Drying Oven

Cooling System

Coating Unit

Vibrating Sifter

What is the Process of Making Corn Flakes?

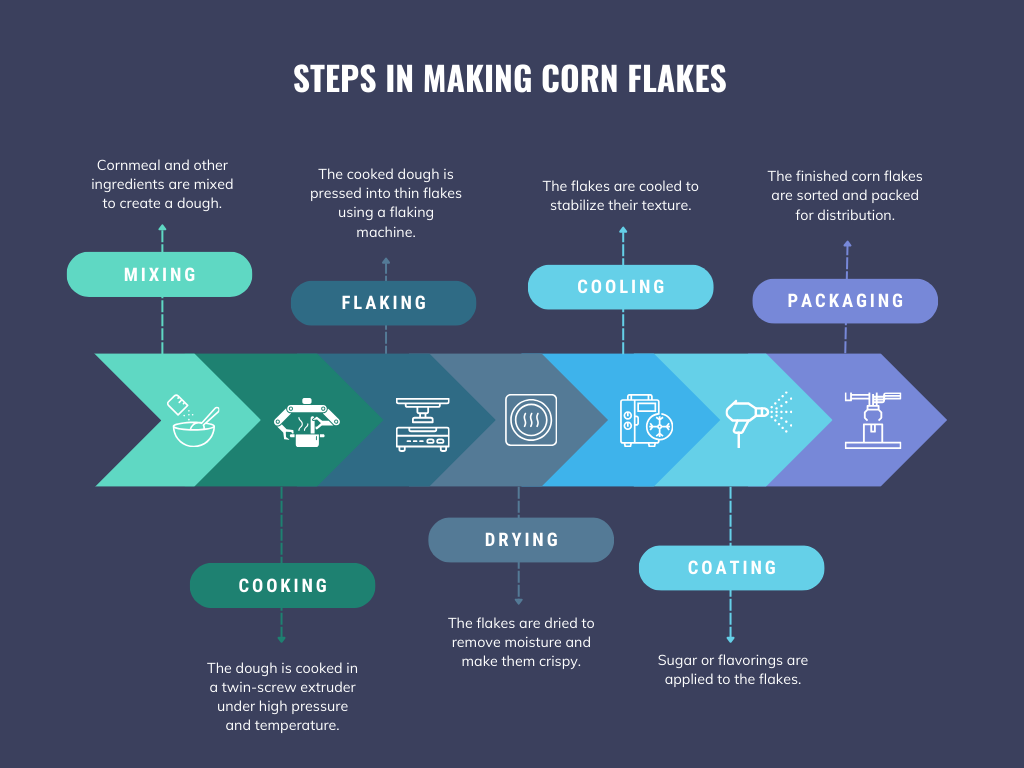

The process of making corn flakes begins with mixing cornmeal, water, and additives to create a uniform dough. This dough is then cooked in a corn flakes extruder, which shapes and prepares it for flaking. The dough is passed through rollers in the flaking machine, where it is pressed into thin, even flakes. These flakes are then dried to remove moisture, ensuring they remain crispy. After drying, the flakes are cooled to stabilize their texture and then coated with sugar or flavorings to enhance taste. Finally, the corn flakes are sorted, packed, and sealed for distribution.

Frequently Asked Questions

A corn flakes processing line is a set of automated machines designed to produce corn flakes efficiently. It includes processes like mixing, cooking, flaking, drying, and packaging, ensuring consistent quality and high production capacity.

Corn flakes extrusion technology involves cooking cornmeal under high temperature and pressure in a twin-screw extruder. This process shapes the dough and prepares it for the flaking stage, ensuring the right texture and consistency for the final product.

A typical corn flakes production line includes equipment such as a raw material mixer, corn flakes extruder, flaking machine, drying oven, cooling system, and packaging machine. Each part plays a crucial role in ensuring high-quality corn flakes processing.

When selecting corn flakes production line suppliers, consider factors like the supplier’s industry experience, the technology offered (such as corn flakes extrusion technology), production capacity, and after-sales support. Reliable suppliers ensure smooth installation and efficient production.

The production capacity of a corn flakes manufacturing equipment varies based on the model, ranging from 100 kg/hour to 1500 kg/hour. The right capacity depends on your specific production needs and market demand.

Yes, many corn flakes line suppliers offer customization options. You can tailor the equipment to suit different production capacities, ingredient types, and additional features like flavor coating systems to meet your business requirements.