Chicken Processing Machine

Home » Food Machine » Chicken Processing Machine

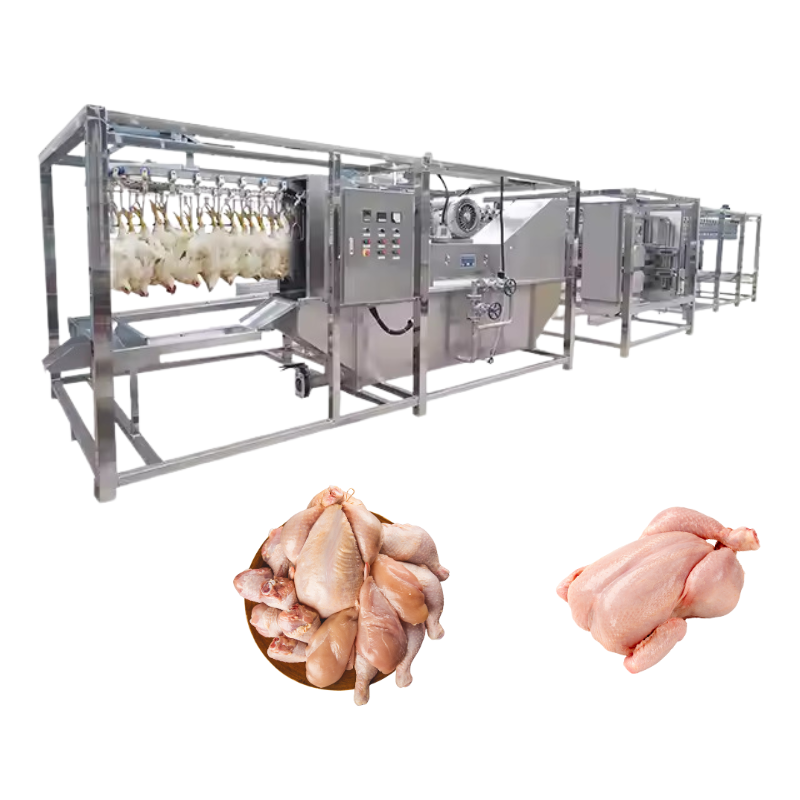

Chicken processing machines are essential for efficiently handling poultry at various stages, from slaughtering to packaging. Whether you’re looking for commercial chicken processing equipment or used chicken processing equipment, these machines help streamline production, reduce labor costs, and improve consistency. Reliable poultry processing equipment manufacturers offer a range of solutions tailored to meet the demands of small-scale operations to large poultry processors. For more details, contact us to discuss your specific processing needs.

- chicken processing machine Price: $12,000 - $45,000

Get Information on Poultry processing equipment Manufacturers

Find Your Chicken Processing Machine

When selecting a chicken processing machine, it’s important to consider key features such as processing capacity, automation level, hygiene standards, and the ability to handle various poultry sizes. A reliable chicken processor should offer flexible settings to accommodate different stages of processing, including slaughtering, defeathering, eviscerating, and cutting. Additionally, factors like energy efficiency, ease of cleaning, and compliance with food safety regulations are crucial in ensuring smooth operations. Whether you’re investing in commercial poultry processing equipment for a large-scale facility or upgrading existing systems, the right machine will optimize production efficiency, reduce waste, and maintain product quality.

- Compact equipment, suitable for small-scale production

- Typically semi-automated or manual operation, with lower initial investment

- Commonly used in local markets or for low-volume demand

Price: $10,000 ~ $30,000

- More automated equipment, suitable for larger-scale production

- Higher investment but significantly improves production efficiency

- Flexible configurations that can process different chicken parts (eg, breast, thighs)

Price: $20,000 ~ $70,000

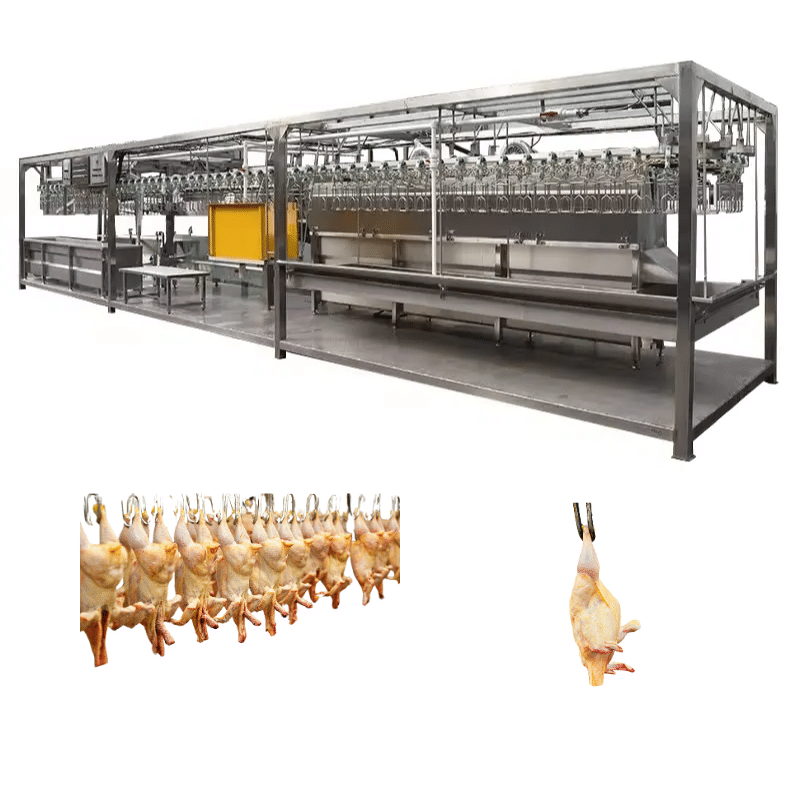

- Highly automated, capable of handling complex processing tasks such as slaughtering, splitting, deboning, and packaging

- High integration of production lines to reduce manual intervention and improve efficiency

- Ideal for large-scale batch production, with a significant investment required

Price: $50,000 ~ $120,000

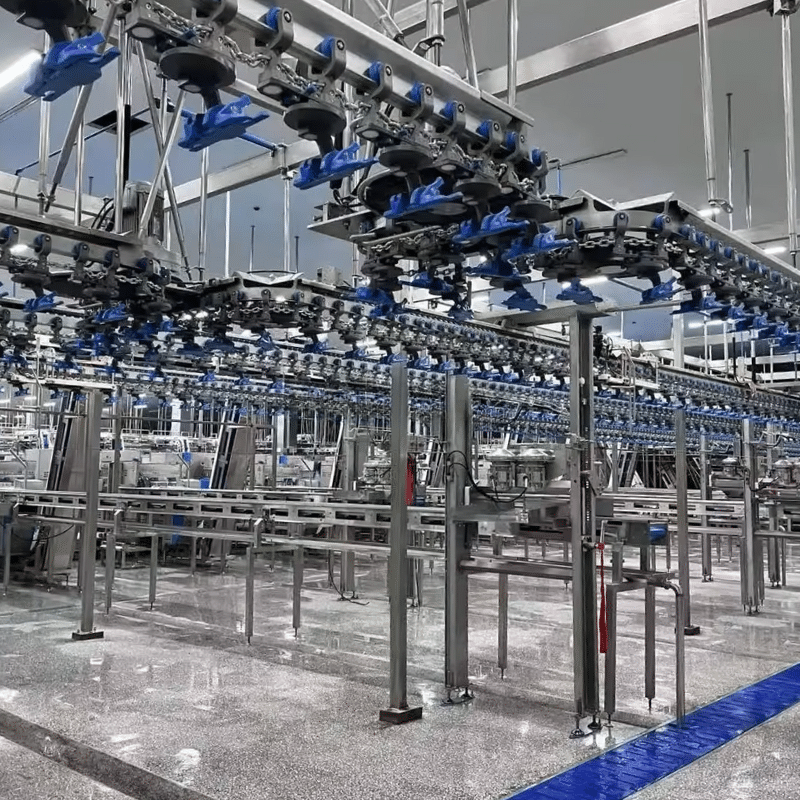

- Ultra-high automation and integration, covering all stages of processing from slaughtering to splitting, processing, and packaging

- Large-scale production ensures consistent product quality and stability

- Requires highly specialized equipment and customized solutions

Price: More than $70,000

Chicken Processing Machine Technical Parameters

| Equipment Type | Processing Capacity | Voltage | Power | Automation Level | Applicable Field |

|---|---|---|---|---|---|

| 500 Birds Per Hour Small Scale Chicken Processing Equipment | 500 birds/hour | 220V/380V | 7.5kW - 12kW | Semi-Automatic/Automatic | Small-scale commercial slaughter and processing |

| 1000 Birds Per Hour Commercial Chicken Processing Equipment | 1000 birds/hour | 380V | 15kW - 20kW | Fully Automatic | Medium-scale commercial slaughter line |

| 2000 Birds Per Hour High Capacity Chicken Processing Machine | 2000 birds/hour | 380V | 25kW - 35kW | Fully Automatic | Large-scale commercial production line |

| 5000+ Birds Per Hour Industrial Poultry Processing Line | 5000 birds/hour or more | 380V | 50kW - 75kW | Fully Automatic | Industrial-scale production, slaughter and processing |

Chicken Processing Equipment

Feather Removal Machine

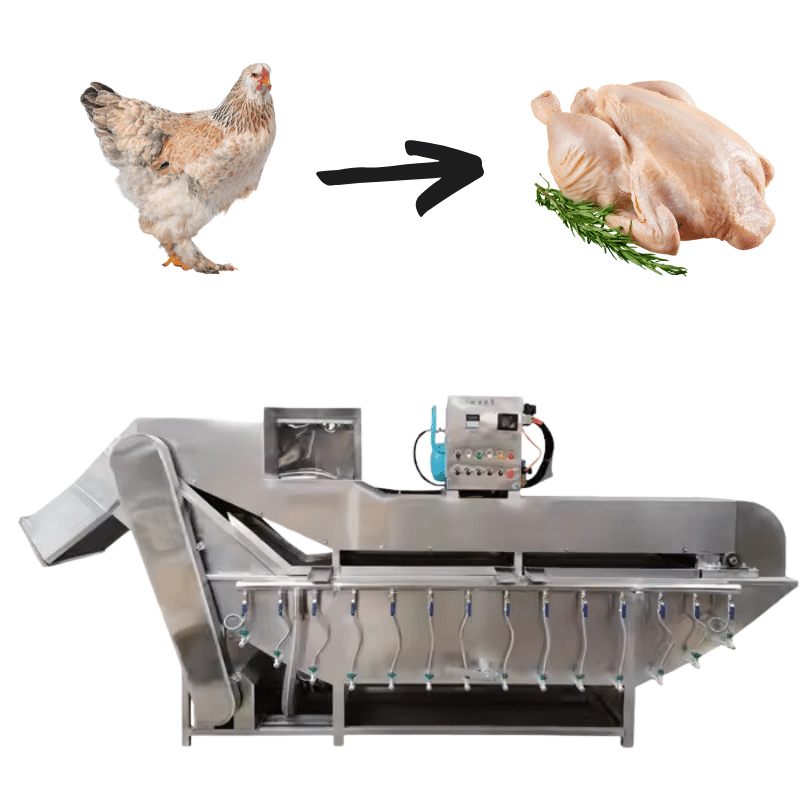

The feather removal machine is essential in the chicken processing line, efficiently removing feathers from slaughtered chickens. Using rotating rubber fingers, it gently removes feathers without damaging the skin, ensuring a clean and smooth finish. This equipment is crucial for achieving high product quality, providing fast and thorough feather removal that is vital for maintaining a consistent and high-quality output in chicken processing.

Scalding Tank

The scalding tank is designed to loosen the feathers and soften the skin for easier removal. Hot water or steam is used to heat poultry carcasses to the ideal temperature, aiding in the efficient feather removal process. As an integral part of any chicken processing machine system, the scalding tank ensures that chicken carcasses are clean and properly prepared for the subsequent stages of processing.

Eviscerating Machine

The eviscerating machine is used to remove the internal organs from the chicken after slaughter and feather removal. This equipment typically operates automatically, significantly enhancing processing speed and hygiene. It reduces manual labor and ensures that all internal parts are removed cleanly and efficiently. The machine can be configured in semi-automatic or fully automatic modes depending on the desired level of automation in the chicken processing line.

Cutting Machine

The cutting machine is designed to portion processed chicken into smaller, standardized pieces such as thighs, wings, breasts, and drumsticks. It provides precise cuts that meet specific size and weight requirements for different products. This equipment is vital in ensuring accurate and uniform portions, meeting product specifications and market demands within the chicken processing machine workflow.

Chilling Machine

After processing, chicken must be chilled to prevent spoilage and maintain freshness. The chilling machine rapidly lowers the temperature of chicken carcasses using cold water or air. This step is essential for preserving meat’s quality and safety, ensuring it remains fresh and suitable for storage, transportation, and further processing in the chicken processing machine system.

Frequently Asked Questions

A chicken processor refers to a machine or facility that processes chickens into various products, including fresh meat, cuts, and by-products. These machines are essential for poultry operations, automating key steps like slaughtering, defeathering, eviscerating, and portioning. From small scale poultry processing equipment to large-scale systems, these processors help streamline poultry production efficiently and consistently.

A chicken feet processing machine is designed specifically for processing chicken feet, which are often used in soups, snacks, and as export products. The machine typically involves cleaning, peeling, cooking, and drying chicken feet. This type of equipment is an important component of the chicken food processing machine range, ensuring minimal waste and maximizing the use of every part of the chicken.

Yes, a food processor can be used to prepare canned chicken salad in food processor. The machine can chop or shred cooked chicken and mix it with other ingredients such as vegetables, seasonings, and dressing. This results in a uniform texture and is particularly useful for food manufacturers looking to produce consistent, high-quality canned chicken salad in large quantities.

Chicken food processing machines include a variety of equipment designed to automate different stages of poultry processing. This may include machines for scalding, feather plucking, eviscerating, cutting, and packaging. Each piece of equipment ensures the chicken is processed in a hygienic, efficient, and safe manner, adhering to strict industry standards and requirements.

Yes, you can make canned chicken salad in food processor by shredding or chopping cooked chicken along with vegetables, mayo, and seasonings. The food processor helps to achieve a uniform texture, making it ideal for manufacturers of canned chicken salad who require consistency and efficiency in production.

Using a chicken processing machine offers numerous benefits, including improved efficiency, reduced labor costs, and enhanced product consistency. These machines automate key tasks in poultry processing such as slaughtering, defeathering, and cutting, allowing for quicker production times and more consistent results. Chicken processing machine also ensure a higher standard of hygiene and safety, which is crucial in food production.