Biscuit Production Line

Home » Food Machine » Biscuit Production Line

Explore comprehensive information on automatic biscuit production lines that cater to large-scale biscuit and cookie manufacturing. Learn about the key processes, from dough mixing and molding to baking and packaging. Find trusted biscuit making machinery manufacturers and get the latest biscuit production line prices to help you make the best decision for your business.

- Price Range: $12,000 - $75,000

Get Information on Biscuit Production Line Manufacturers

Find Your Biscuit Production Line

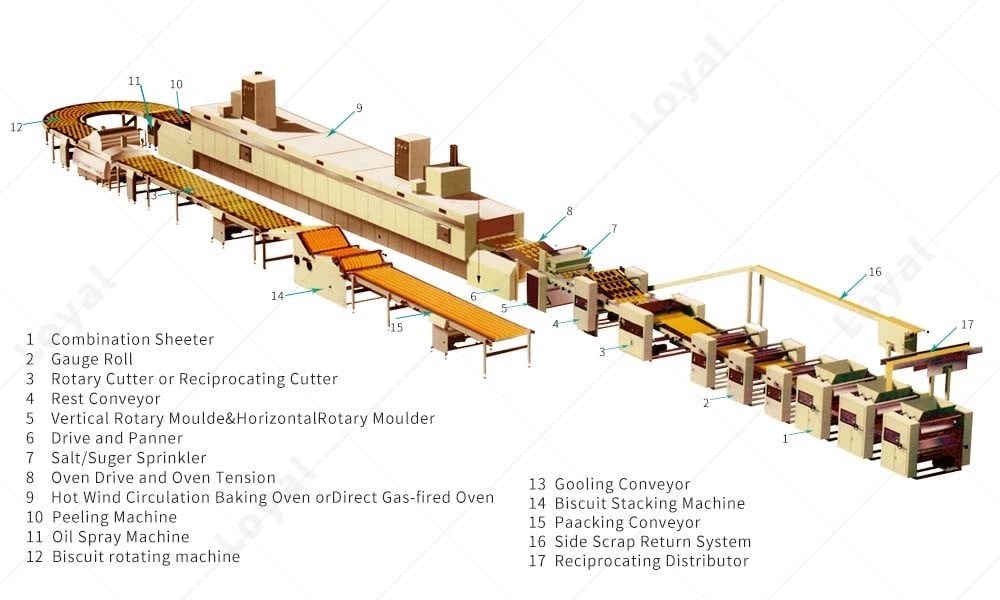

The Biscuit Production Line is designed to handle large-scale biscuit manufacturing, with production capacities ranging from 100 kg/hour to 1000 kg/hour. This line features essential Biscuit Making Machinery, including a dough mixer for preparing the dough, a roller or sheeter for shaping, and a cutting machine for precise biscuit formation. After shaping, the biscuits are baked in a specialized oven, followed by a cooling conveyor that stabilizes them before packaging. The system concludes with an automated packaging machine that seals the biscuits, ensuring they are ready for distribution. These components ensure efficient and high-quality production for various biscuit types.

Biscuit Production Line for sale

Discover flexible solutions for both hard biscuit production lines and soft biscuit production lines designed for high-efficiency manufacturing. Our comprehensive information on automatic biscuit making machinery connects you with trusted suppliers to find equipment tailored to your production needs and scale.

- Compact Soft & Hard Biscuit Manufacturing

- Sandwich Biscuit Processing

- Suitable for Small-Scale Operations

Price: $12,000 – $15,000

- Small-Scale Biscuit Making Line

- Soft, Hard, and Sandwich Biscuit Capabilities

- Ideal for Startup and Regional Manufacturing

Price: $18,500 – $22,000

- Soft Biscuit and Hard Biscuit Processing

- Sandwiching Biscuit Capabilities

- Medium-Capacity Biscuit Processing Equipment

Price: $22,500 – $25,500

- High-Capacity Soft & Hard Biscuit Manufacturing

- Sandwiching Biscuit Integration

- Efficient for Industrial Processing

Price: $30,500 – $42,500

- Large-Scale Biscuit Manufacturing System

- Soft, Hard, and Sandwich Biscuit Production

- Fully Automated Biscuit Making Process

Price: $42,500 – $55,000

- Maximum-Capacity Biscuit Equipment

- Soft, Hard, and Sandwich Biscuit Line

- Ideal for Large-Scale Manufacturing Operations

Price: $60,000 – $75,000

Biscuit Production Line Technical Parameters

| Production Line Model | Power Consumption (kW) | Machine Components | Applications |

|---|---|---|---|

| 50-60 kg/hour | 30 | Dough Mixer, Sheeter, Cutter, Baking Oven, Cooling Conveyor, Packaging Machine | Small-scale soft and hard biscuit production |

| 100 kg/hour | 50 | Dough Mixer, Sheeter, Rotary Cutter, Baking Oven, Cooling Conveyor, Packaging Machine | Regional biscuit production for small businesses |

| 150-200 kg/hour | 70 | Dough Mixer, Sheeter, Rotary Moulder, Baking Oven, Cooling Conveyor, Sandwiching Machine | Medium-scale production of soft, hard, and sandwich biscuits |

| 400-500 kg/hour | 120 | Dough Mixer, Sheeter, Rotary Cutter, Tunnel Oven, Cooling Conveyor, Packaging System | High-capacity industrial biscuit manufacturing |

| 600-800 kg/hour | 180 | Industrial Mixer, Rotary Cutter, Tunnel Oven, Multi-Stage Cooling Conveyor, Sandwiching Machine | Large-scale biscuit production with advanced automation |

| 1000 kg/hour | 250 | Industrial Mixer, Rotary Cutter, Tunnel Oven, Multi-Stage Cooling Conveyor, Automated Packaging System | Maximum capacity biscuit production for industrial-scale operations |

Biscuit Manufacturing Equipment

Dough Mixer

The dough mixer is a crucial part of the biscuit processing line, designed to mix ingredients like flour, water, sugar, and fats into a uniform dough. This machine ensures consistent dough quality, which is essential for producing high-quality biscuits. Whether for small-scale or industrial biscuit production, the dough mixer can handle various batch sizes efficiently.

Sheeter

Rotary Cutter or Moulder

Baking Oven

Sandwiching Machine

What is a Biscuit Production Line?

A Biscuit Production Line is a fully automated system designed to streamline the process of making biscuits, from raw material preparation to packaging. The process begins with a dough mixer that blends ingredients into a uniform dough. The dough is then passed through a sheeter to form thin, even layers, which are shaped into biscuits using a rotary cutter or moulder. The shaped dough is baked in a baking oven to the desired texture, followed by cooling on a cooling conveyor. For sandwich biscuits, a sandwiching machine applies fillings between two biscuits. Finally, the biscuits are packed using an automated packaging machine. This entire process ensures high efficiency, consistent quality, and large-scale production of both soft and hard biscuits.

Frequently Asked Questions

An automatic biscuit production line offers numerous benefits, including increased production efficiency, consistent product quality, and reduced labor costs. Automation ensures precise control over each step, from dough mixing to baking and packaging, which helps maintain uniformity in biscuit size, shape, and texture. Additionally, automatic lines can be customized for soft, hard, and sandwich biscuits, making them ideal for high-volume and diverse product demands.

A biscuit manufacturing equipment can produce various types of biscuits, including soft biscuits, hard biscuits, and sandwich biscuits. The flexibility of the line allows manufacturers to adjust the production process for different biscuit shapes, textures, and fillings, depending on customer demand.

The capacity of a Biscuit Processing Line can vary widely, typically ranging from 50 kg/hour to 1000 kg/hour, depending on the size of the production line and the type of biscuits being produced. Small lines suit startups, while large-scale lines cater to industrial biscuit manufacturers.

Key biscuit making machinery used in a production line includes a dough mixer, sheeter, rotary cutter or moulder, baking oven, cooling conveyor, and packaging machine. For sandwich biscuits, an additional sandwiching machine is also used to apply fillings between the biscuits.

In a biscuit production line, the baking oven plays a critical role by baking the shaped dough into biscuits. The oven’s temperature and baking time can be controlled precisely to achieve the desired texture for different types of biscuits, ensuring consistent results in every batch.

Yes, many manufacturers offer customization options. You can choose different machine capacities, types of ovens, and configurations to meet your specific production needs, whether for soft biscuit production, hard biscuit production, or even specialized sandwich biscuit production.