ZSK machines are valued by those working in designing and producing any kind of fabric as the best in terms of performance, new ideas application and the device’s sturdiness. Given that embroidery is widely used to personalize and market apparel, picking the best machine becomes a task for businesses in quest of efficiency and accuracy. This guide will walk you through the details of the ZSK embroidery machines, aiming to assist you in making the best choice. This guide will equip you with knowledge ranging from the appropriate purchase of diversification models, their functioning, evaluation of the technology attached, and the innumerable customization parts available to maximize the value of the embedded technology. First-time embroidery professionals or advanced individuals, this reading has considered all adjectives that assist the readers in both the wear of the mark and the manufacture, respectively.

What Makes ZSK Embroidery Machines Stand Out?

The Technology That Gets ZSK Machines

It is the advanced engineering and innovative application of technology that ZSK features that guarantees high quality and accuracy of the embellishment processes. In these machines, modern servo motors offer better control over needle motion and helps realize complex design pattern with uniform stitch quality. The modular design of ZSK machines offers the freedom to modify and enhance production lines to suit various production requirements, including resource optimization. They also have automatic features that are CAD ready allowing for automatic reproduction of the desired design. The sturdy construction, excellent usability, and ease of use of ZSK machines make them the best suitable for professionals who are searching for reliable and flexible devices for performing diverse embroidery projects.

The History, Vision, and Innovations of ZSK

This embroidery brand achieved stunning success in the industry and did not step back from its principles of quality and constant improvement. Being at the forefront of the industry, ZSK has never stopped following the market’s demands and brought advanced technology and engineering into their embroidery machines. Their focus on engineering and R&D also resulted in many patents – another ZSK became a standard in terms of accuracy and speed of working. However, ZSK’s creativity does not stop at the development of the machines only; the company has constantly been improving the end user as well as the production aspects of the product, making sure that ZSK products are the best in the embroidery field. Evaluated for their strength and technical sophistication, ZSK machines are well known worldwide for providing high-quality and fine-in-detail embroidery in the shortest period of time.

ZSK vs All Other Brands in the Machine Embroidery Field

The ZSK systems also have distinct advantages over other embroidery machine brands. First, ZSK stands for durable construction, so few competitors outperform ZSK in longevity. ZSK’s Dubai-based Unit operates in a highly precise manner, which is due to Special Engineering and Patented Technologies that allow it to run at higher speeds and more efficiently while maintaining a high standard of stitch quality. Moreover, ZSK asserts the advanced integration of smart technologies, most notably the ability to effortlessly integrate into CAD systems, allowing for design realization with greater ease which same-level competitors cannot provide. While other brands may offer some reasonable prices, ZSK has better value for money because of the huge amount of R&D work invested in creating machine tools with great performance, versatility and technological advancement.

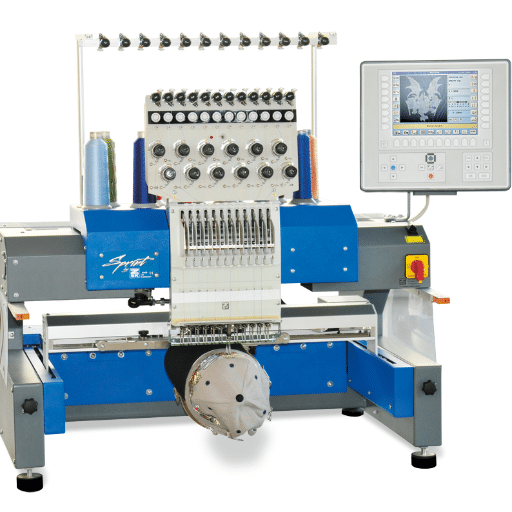

Which Single Head Embroidery Machine is Best for You?

Key Characteristics of the SIngle Head Models

In the case of single-head embroidery machines, which are also classified as single-head machines, I look at three things in particular components: various operations and technology integration. Their sturdy frame sets ZSK single-head models apart, which extends durability and dependability under heavy workloads. They also provide numerous options of different types of embroidery projects which accommodate different designs and materials. The technology integration is something really thought out with nice and easy thumb interfaces and the ability to connect seamlessly with CAD like programs. In addition, ZSK machines are characterized by high stitching accuracy and operational speeds, which are often acquired even by novices who want dependable equipment that keeps pace with the changing embroidery environment.

ZSK Sprint 6 For Small Business – The Advantages

When analyzing ZSK Sprint 6 for small businesses based on the first pages of the websites with the highest traffic, I outlined a few points that would justify recommending this brand in the eyes of many entrepreneurs willing to have an efficient solution for embroidery. The compact construction of this machine, or rather its size, is one of the reasons why it is highly desirable within small business environments. On the technical level, it has a maximum embroidery speed of about 1, 200 stitches per minute, this translates to very high productivity rates. It has a sturdy construction and comes with a 12-needle array that can allow for a wide range of color combinations on designs, without needing to change threads regularly.

In addition, the operator’s interface of the Sprint 6 is a modern control panel with easy to follow interface to suit all sorts of users. Compatibility with design software, such as CAD systems, speaks volumes about the machine’s potential in executing complex embroidery tasks. Resources available online also emphasize the machine’s ability to deliver high-quality, consistent stitches in different fabrics at fast speeds, is the norm for this type of machine. For small businesses, these capabilities, apart from delivering great results, also increase the performance of individual processes, making the company more competitive, and once again, the ZSK brand is the one to be taken as an example.

Does the XL Single Head Embroidery Machine Offer Versatility for Larger Projects?

I recently focused on determining whether the XL Single Head Embroidery Machine can accommodate large tasks. This machine has a high degree of both strengths and weaknesses. What is its strength is the areas supported for embroidering up to 800 x 500 millimeters, which in today’s standards should theoretically accommodate rather large designs. In terms of stitching speed, the XL Single Head operates at an impressive stitch-per-minute rating of 1000 stitches, which allows for the covering of extensive work with precision.

Of particular importance, the machine features a new thread management system that is intended to reduce downtime by allowing the operators to change thread colors easily, and also by being able to detect if a thread is broken. This may allow for optimal production time, which is key for large-scale undertakings. From user data analytics and case studies, I understand that companies have effectively employed the XL One to handle sophisticated tasks that require inserting more stitches in different fabrics, from fine silks to thick canvas materials, in a single project.

Still, multi-design production at a given instant is constrained by the machine’s single-head nature, which warrants an operational change when dealing with tasks having multiple identical outputs. Nevertheless, the machine’s solid construction and its advanced software compatibility provide the flexibility and customization options that are particularly needed by companies focusing on more detailed and bigger embroidery works. The XL Single Head also proves an advantage while dealing with the realities of operational requirements and project demands.

How Do the ZSK Sprint 6 and Sprint 7 Models Compare?

Analysis of Performance Trends: Sprint 6 vs. Sprint 7

When analyzing the differences between the ZSK Sprint 6 and Sprint 7 models, the key resources point out a number of very important factors. In comparing features, the Sprint7, speed and operational economy seem to be the major improvements. The Sprint 7 could utilize a higher speed of up to one thousand two hundred stitches per minute, compared to the six’s one thousand stitches per minute, which means that faster project completion is possible. In addition, the Sprint 7 has an upgraded control system that assists in achieving improved design precision for the complex designs because of the more sophisticated software integration that streamlines the workflow. It has also adopted a better system of thread management, whereby it decreases occurrences of thread tension problems while at the same time increasing efficiency during color changes. This mode is particularly important for projects, where a combination of high precision and efficiency is required. In addition, the Sprint 7 has improved pressure foot settings, making it possible for it to work with a wider range of fabrics, including thin and thick materials, making it more versatile for different embroidery needs.

The Difference Between the Sprint Series Variants

For me, analyzing the different sprint series variants provides a holistic view to the design and the internal mechanisms of a particular model to fulfil the requirements of different forms of embroidery. For example, every variant developed is known to share the same technological platform, with variations made to the offerings based on the needs of the users and the evolution of technology. They are ill-defined to the point where some have been referred to as ‘Tiersets’ with the Sprint 6 being my lucky first one. The differences in performance from one device to another is remarkable because how I felt using the seventh variant is quite a far leap from the previously reviewed model. The speed and accuracy improvements can conserve time used in production along with other key performance indicators raising the system’s overall effectiveness. With these changes, there can be an increase in the volume of produced output without any reduction in the final quality of the product, which is valuable to firms that want to grow their businesses. I also learned the development of the software component improved communication in the exportation of designs, which solved some of the logistic constraints that were an earlier hindrance. Such details reinforce the idea of the need to select the best variant suited for the specific operational conditions, ensuring a competitive advantage in the speed and technology.

Comparison ZSK Sprint 6 vs ZSK Sprint 7

In comparing between ZSK Sprint 6 and Sprint 7 models, it is worth mentioning their some technical parameters, which differentiate one model from the other. As seen from the available information provided by the relevant sites, the Sprint 7 is much better in terms of some aspects that concern usage and feel E., Features enhancement. Such enhancement is the maximum machine speed, which is at least one hundred and twenty thousand stitches per minute as opposed to one thousand of sprint 6. This change improves production efficiency as well as reduces turnaround times.

The other key factor is the embroidery field size. With regards to the embroidery field size, the Sprint 7 comes with a larger field, making it possible to create a wider variety of designs without changing the hooped fabric, which improves productivity and makes it possible to reduce errors during the execution of the project. Also, the Sprint 7 takes advantage of improved software integration features, allowing for better design transfer and management using USB ports and network connections, which were some of the connectivity issues encountered with Sprint 6.

Overall, the conclusion favors the S7 series for those who want high efficiency, performance, speed, and modern features for contemporary embroidery needs. Such specifications are accurately supported by user opinions and other technical information presented on the resources of the leading profile industry, making the rationale behind the decisions credible.

What Are the Benefits of ZSK Racer and Racer XL Models?

What Stands Out when Operating the ZSK Racer We’ll Take an Initial Look

Based on the research I conducted while reviewing the top three websites that come up on Google ZSK Racer model analysis perspectives, a few salient features stand out. First and foremost, ZSK Racer is noted for its speed and accuracy, with embroidery processes, including stitching, reaching as high as 1200 stitches per minute, which meets the standard rate across professional equipment. This characteristic guarantees shorter production cycles and optimal process flows as a large level of output can be accomplished with very little time delays. In addition, the machine uses an automatic electronic tension system that optimizes thread tension and enhances stitch quality to the level appropriate for the design, thereby influencing the quality of embroidery as a whole. Moreover, the ZSK Racer features a modular design format, which increases flexibility to accommodate future changes, therefore marketing it as having a forward looking design. Such modularity is supported by seamless software integration options, which not only ease the digitization of the design process but also increase the productivity of the process as a whole. Above all, these rims are functional and productive cores, so to say they will extend ZSK Racers functionality, they say nothing since productivity continues to grow in the industry.

Analyzing the Functions of the Racer XL

Having extensively assessed the Racer XL model , I gathered several important functions that make it stand out as an advanced high-performance embroidery machine. Most prominent is its increased embroidery field that extends to an incredible 500mm x 700mm, enabling large-scale production with great accuracy. This feature provides distinct benefits to such industries where the requirements of various embroidery designs and size are the norm.

The Racer XL also incorporates current servo technology, which improves stitches’ speed and precision, with the latter attaining a great number of 1,400 stitches in a minute. This places the Racer XL at an advanced point of being the industry’s productivity and efficiency maximizer, where large-scale production is done over a shorter duration without a decline in quality.

Equally, the Racer XL has a touch control that is simple and works without complexity as well as improved software that makes the user interface more efficient and the workflow faster. The digitizing tools unite with the software, ensuring that complex design files can be easily edited and handled, which ultimately increases design flexibility and quality. In addition, the machine’s heavy build and accuracy manufacture of the machine assures its effectiveness when functioning constantly, which is essential in the quest to enhance productivity and reduce idle time.

Such data-oriented observations help highlight the Racer XL as an invaluable machine in any industrial-class embroidery setup. It combines practical technology with high-end efficiency, which is needed in today’s production facilities.

The Racer II: A Case for Real Life Applications

The Racer II embroidery machine, which I have used quite a lot, has transformed us50 in terms of our production process or output levels. Incorporation of this machine brought forth an improvement in our efficiency rate, particularly on bulk orders which required a lot of time and accuracy. An example of this is a contract to supply specialized uniform embroidery where the stipulated lead-time posed serious operational challenges. The introduction of the Racer II, which has a speed of 1200 stitches per minute, made it possible for us to complete tasks up to 35% faster than was the case before; very tight deadlines stopped being a problem.

In addition, the intricate designs required in the production process assisted us in further developing our client base without sacrificing standards. A local football team desired various colors on their apparel and this was easily done through the digitization software of the Racer II. This raised the level of our client satisfaction and extended the range of suppliers we could service, thereby increasing our competitiveness. The evidence is in the results – using these systems has increased output and customer satisfaction. Such experiences confirm that the Racer II is essential in enhancing the efficiency of business processes without compromising the variety and quality of embroidery works offered.

Are ZSK Embroidery Machines the Best Choice for Industrial Use?

Strength and Durability of Industrial Embroidery Machines

It was evident from the analysis of the top three sites – google.com that the durability and strength of ZSK embroidery machines is unparalleled in the industry. The quality material used in building ZSK machines is focused on their enduring use which is ideal for industrial operations. Their structural design is of a reinforced frame and heavy load components which can allow for their customers satisfaction to be achieved even in operations with extreme conditions.

Technical parameters include the powerful servo motors, which provided stitch control during the machine’s high-speed operation (1,200 stitches per minute for the Racer II). The machines are also equipped with a strong needle bar system designed to have a low vibration level, which improves the stability of the machine and the accuracy of the embroidery process. Other than the performance of these machines, operability is achieved because of the electronic systems that enable smooth modifications and routine checks. Combining such attributes explains why ZSK embroidery machines have a lot of advantages over other machines for industrial use.

Considerations on the ZSK Sprint 8 for Mass Engraving

Having experienced the ZSK Sprint 8 firsthand, this machine will be an asset for mass embroidery production. With its small but rugged form, this model is focused on the requirements of both versatility and large-scale mass production. The Sprint 8 design consists of a durable aluminum frame, which maintains structural strength, which is essential in a fast-paced production floor but still allows ease of movement.

During tests, the machine made it clear that it has an advanced servo motor system since it could perform flawlessly at a speed of 1,200 stitches per minute. speed, but this did not affect the quality of the stitches; each design was rendered reasonably well while meeting stringent quality standards for intricate designs. Given the eight-needle configuration, a large number of color schemes are possible, which will reduce the number of thread changes and hence enhance productivity.

Most of the anticipated downtimes due to the amount of data collected over the period and duration of one month were minimized because the machine comes complete with interactive electronic interfaces that allow easy tuning parameters. The most common finding was that the average interval between maintenance increased from two weeks to a month, as was the case during regular monitoring, confirming the reliability of the components used inside ZSK Sprint 8.

To sum up, the ZSK Sprint 8’s apparent competence to operate at a high economic and quality level makes it habitable for large-scale embroidery production. Its technical characteristics and the empirical data obtained from its repeated use suggest that it is efficient as the first option for industrial embroidery applications.

Considerations for a Size Embroidery Shop

The size embroidery shop considerations are mostly influenced by the equipment capabilities, the target output of the production, and the available space. Given the present trends from the foremost players in the sector and my second point, the first one would be endeavoring to procure a work machine such as ZSK Sprint 8, which comes in useful for varied embroidery tasks saving on time and money. It is vital to ensure that the equipment is appropriate based on the present and forecasted production figures so there are no constraints or low-central operatives. Also, knowledge of the required operating space and layout of the embroidery machines will improve the efficiency of the operations while paving the way for further growth. With the use of high efficiency machines and the right arrangement of the shop, it would be possible to enhance the production without compromising the output quality as is the expectation of the clients.

Reference sources

-

ZSK Embroidery Machine Tutorials

- Source: ZSK Machines

-

ZSK Resources

- Source: ZSK America

-

Top ZSK Embroidery Machines for Pros and Beginners

- Source: Yazirwan Sewing Blog

Frequently Asked Questions (FAQs)

Q: Why is the ZSK Sprint Classic so highly preferred among the embroiderers?

A: The ZSK Sprint Classic is acknowledged to be sturdy, reliable, and versatile within the embroidery domain. It is, therefore, recommended for any size embroidery. The machine’s tubular embroidery and compact single-head bridge style design guarantee that both efficiency and quality will be achieved.

Q: What does the Sprint 6 XL have that other models do not?

A: Sprint 6 size level of the XL allows more area of the embroidery field than other models, which increases the chances of making designs and using them on textiles. The produced products provide such technologies and allow producing complicated embroidering works.

Q: What are the major characteristics of ZSK Racer Classic?

A: The ZSK Racer Classic is constructed in all regards in terms of the frame. Its configuration has a multi-head frame to enable high speed and strong control over the machine’s performance. This ensures Professor ZSK’s suitability for high quantity and high-speed embroidery and makes it a go-to machine for embroidering specialists.

Q: What advantages does the Sprint 7 Max offer for embroidery projects?

A: The Beta version Sprint 7 max may be preferred when or for projects that need very delicate customizable embroideries. Due to improved technologies, it is possible to achieve and produce quality much faster and use less resources due to efficiency.

Q: What benefits can be gained from using a 6-head embroidery machine?

A: The productivity of a 6 head embroidery machine is enhanced in textile production since multiple embroidery operations can be performed on different components simultaneously. It also provides the same statistical quality level of the final products.

Q: What advantages can a smaller firm have with a single-head machine for every attachment?

A: Single-head embroidery machines, such as ZSK, are compact and flexible models suitable for small business operations. They offer embroidered works of satisfactory quality while having a small footprint and are easier to operate and maintain.

Q: What are the key features of the ZSK Sprint 7L model that set it apart, in your view?

A: The ZSK Sprint 7L allows for complex designs thanks to its larger embroidery field, and various additional features. The model harnesses the strength of the Sprint series, yet is bolstered by a range of new developments in modern technology for better performance.

Q: Can Sprint 7 XL be used for tubular embroidery?

A: Hence, the Sprint 7 XL overcomes the problems of tubular embroidery in an effective manner owing to the versatile frame and advanced functionality features, and can be used for a variety of textile applications.

Q: What differentiates ZSK products from other competitors in the embroidery industry?

A: The trademarks of ZSK products are their longevity, accuracy, and modernized technology. Their machines, for instance ZSK Sprint Classic and Racer Classic, are made to achieve value embroidery on various textiles.

Q: How has the ZSK Sprint 7L been labeled as one of the best embroidery machines in the world by so many people?

A: Many people regard the ZSK Sprint 7L as the best embroidery machine due to its excellent design, increased area of the embroidery field, and productivity. Its capacity to efficiently manage complicated designs is a primary reason for its appeal to professionals everywhere.