Zinc plating is a very critical industrial process which is used to protect metal surfaces from corrosion and enhances their look and durability. In this detailed guide, we look at the process of zinc plating in deeper details by checking the machines involved and the procedures that have to be followed to complete the application. In this case, readers will appreciate first-hand the operational mechanisms of the zinc plating machines, the techniques available and how to attain the best outcome. We also outline the objectives of the article, namely, the equipment and tools available for metal plating, applications in practice, techniques of zinc plating and others. The information provided in this article should help metal plating professionals as well aspeople new to the world of metal plating to grasp everything needed to perform zinc plating.

What is a zinc plating machine?

The process undertaken in the zinc plating machine

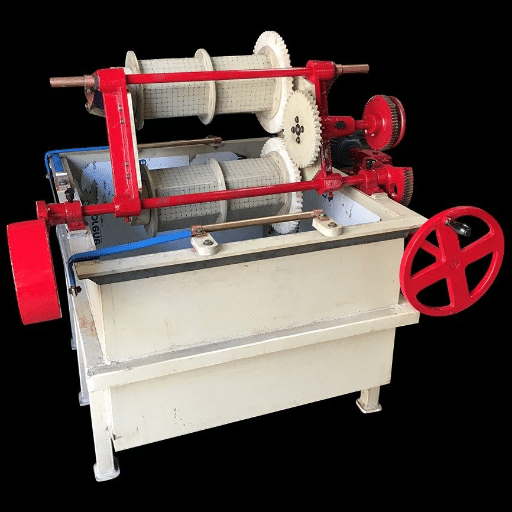

A Zinc Plating Machine is a specific tool whose purpose is to coat objects with a thin layer of metal, particularly zinc. This entails placing in a bath metal objects inserted into a solution with zinc ions and passing an electric current through this solution. The machine is capable of regulating critical parameters such as voltage, the flow of electric current, and the value of temperature. Due to the configuration of the zinc-plating machine, the electric current can be evenly distributed which results in the quality of the coil being uniform. The zinc plating machine is capable of improving the efficiency of rust and corrosion resistance of metal components.

Examples of zinc plating equipment

A zinc plating machine essentially compromises of important elements such as a power source supplying the necessary electric current, an electrolyte tank for the immersion of the zinc ion solution, electrodes through which current ion flow, control systems and so on, which enable one to control the voltage, current, temperature, etc. Other devices may also include agitation devices that help in distributing the zinc coat evenly and rinsing tanks for the metal parts before and after plating. These components serve together for the purpose of obtaining a uniform zinc coat on all area of the metal object being coated.

Zinc Plating Machine: Overview and Advantages

Using a zinc plating machine has many advantages such as increased resistance to corrosion, greater strength and longer life of metal components. It conforms to the contours of any metallic surface and ensures that there is an even and smooth surface finish. Furthermore, it is possible to obtain a zinc plating that enhances the subsequent attachment of coatings like paints while also providing an economical means of protection against environmental corrosion. Thus, zinc plating offers ease of fabrication and aesthetically pleasing protective finishes, making it a preferred option among manufacturers for improvement in their metallic products.

How does electroplating machine work?

The study of electroplating

The deposition process in electroplating involves the application of electric current in order to deposit one or more layers of a metal onto a conductive substrate. The equipment used includes a metal bar which serves as the anode in addition to the object to be plated, often known as the cathode. This is submerged into an electrolyte solution or electrolyte bath as it’s called containing metal ions. When the power supply is turned on, the current passes through the solution and metal cations from the anode go into the solution and will later deposit into the mouth. This allows for the even deposition of metal coating on the object thereby improving its functionality and aesthetics.

How To Use An Electroplating Machine – Step By Step Guide

In the initial step, the object must be cleaned thoroughly to remove all grease or dirt. Then the object and bar must be tempted into the electrolyte solution. Always check that the power supply is properly attached: a cathode to the negative terminal and an anode to the positive terminal. Connecting something to the power supply will switch on the flow of current, enabling metal ions to be deposited onto the object. The process has to be watched until the deposition of metal coating is which suffices the expectations and then the power will be switched off. Once turned off, the plated object is rinsed in water to remove any residual chemicals.

Barriers connected with electroplating

As with any process, electroplating also has issues which affect the properties of the end product. One of the most problematic is the concentration of coating due to the un-even distribution of the ions composing the metal. For example the presence of contaminants within the electrolyte solution, insufficient processing of the surface to be coated can lead to undesirable effects such as pinhole defects, rough surfaces or low bonding strength, to give a few. Furthermore, the deposition rate must also be controlled because rushing the process may lead to burning of the work surface or formation of nodules on the treatment surface. Overcoming these challenges is a matter of fine-tuning electroplating parameters, among them, current density, temperature and solution composition, among others, as well as ensuring that operational equipment is in good condition so as to enable seamless operation.

How to choose the right plating equipment?

Criteria that can assist in choosing the best plating equipment

When choosing plating equipment, some features should be taken into consideration, namely: the material of the object which is going to be plated and the thickness required, the dimensions and configuration of the objects, the number of items that will need to be produced, and the desired degree of automation. Moreover, check the compatibility of the equipment with a diversity of plating solutions and its maintenance. Equally important is the need to comply with regulations regarding energy consumption and environment protection by the equipment. Finally, consider the starting price of the equipment and the expected cost of its modification in the future as new production requirements will arise.

Evaluating various categories of plating equipment.

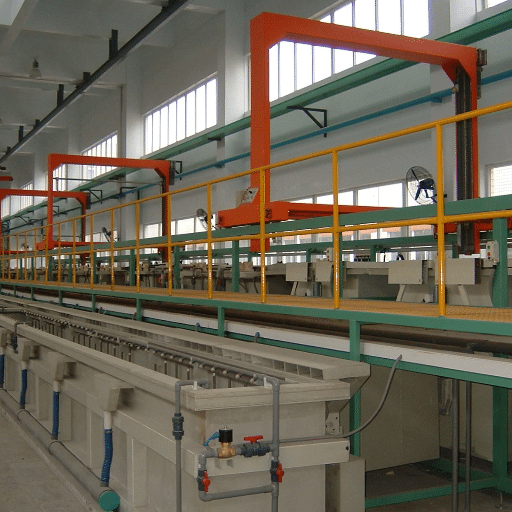

When evaluating various types of plating equipment, such factors can include usability, cost, and the intended purpose. Batch plating equipment is appropriate for medium & even small sized production runs or for making prototypes & allows for many different types of plating. While continuous plating systems allow for mass production, they also cut down operational cost and time. For small bulk components barrel plating is an excellent strategy, whereas rack plating is best for larger components which require their own dedicated effort. Determine your specific manufacture requirements because a distinct equipment type has certain inherent strength that is relative to the purpose.

Tips for Maintaining Plating Equipment

Regularly inspect plating equipment for damage and parts that show signs of wear. This testing allows most of the carburizing process to be accomplished while the tool is quite new. Create a cleaning routine to eliminate any residual accumulation throughout all pieces of equipment. Always check that electrical links, mechanical parts are tight and working properly. Schedule timely replacements of worn parts to minimize downtimes, and routinely adjust the equipment to ensure precision in plating. Keep detailed maintenance logs so that players can monitor the state of the equipment and define the moment for preventive measures.

How to achieve optimal zinc coating?

Improving resistance to corrosion with the help of zinc coating

When aiming for the best corrosion protection with a zinc coating try to emphasize on three aspects, i.e. surface preparation, quality control, and competent coating methods. For adequate adhesion of zinc in the protective coating a substrate should be properly degreased and clean. Specific treatments like galvanizing, electroplating or thermal spraying should be carried out according to given requirements and target attributes of the final product being produced. The layer of cover should be of the panel thickness and spread evenly, also malpractices should be checked on a regular basis.

Tips for the best possible outcome with the zinc-plating process

Prior to plating, make sure that the substrate is cleaned and all contaminants are removed. Select the most suitable method for zinc plating and control process parameters consistently. Check and maintain coating thickness regularly and perform quality control checks for a clean and even coating.

Problems Likely To Occur With Coating With Zinc And Their Solutions

One problem that is frequently encountered is poor adhesion, which in most cases may be remedied by thorough surface cleaning and preparation. Another one is too low a coating thickness which can be mitig against by efficient management of the plating process parameters. Non-uniform coating thickness can be caused by poor calibration of the equipment, inconsistent plating time, etc. Maintenance and process control are therefore essential. Also, removing the contaminants present in a plating bath will also help to prevent defects like blisters or pits on the zinc coating. Regular inspections and quality checks can assist in detecting and correcting such problems in a timely manner.

Reference sources

-

KDM Fabrication – The Complete Guide to Zinc Plating: All You Need To Know

-

Electroplating Machines – The Zinc Plating Equipment Process

-

Koch LLC – Plating Equipment

Frequently Asked Questions (FAQs)

Q: Explain what a zinc plating machine is and the working principle.

A: Zinc plating machine is a machine that applies a protective zinc layer over metals to avoid rusting. Zinc is always used in the form of a coating. A zinc coating can be deposited on a substrate through a process called zinc electroplating. The interaction usually involves a plating bath into which the metal object is immersed, so that the zinc ions can chemically attach themselves to the surface of the metal.

Q: What is the main function of a barrel plating machine that a normal zinc plating machine could not accomplish?

A: A barrel plating machine is used for mass production of small parts through electroplating. Commonly, unlike conventional zinc plating machines which plate one part at a time; the barrel machine actuates non-plates mounted on rotating or tumbling barrels within a plating solution while they are immersed there to guarantee that all pieces obtain an applying surface uniform coating.

Q: What are the critical features to keep in mind while selecting electroplating equipment for large scale operations?

A: Factors such as the type of metal to be plated, size and capacity of the electroplating equipment, degree of automation, energy consumption, and compatibility with various plating solutions like nickel plating or zinc plating kits should be taken into account.

Q: Describe the differences between zinc nickel alloy and zinc ingots in zinc plating.

A: Zinc nickel alloy plating has an increased corrosion resistance as compared to a plain zinc plated which can be useful for operations in high wearing conditions. It provides a nylon covering which gives longer life of metal components.

Q: What does the term copper plating mean, and what is the role of copper diffusing in plating of zinc?

A: Copper plating, as a process, involves covering a substrate with a thin copper coating, usually in order to improve the substrate’s electrical properties or in advance of subsequent deposition such as nickel chrome for example. The only purpose of zinc plating is to assist in isolation from air and moisture.

Q: What are the precautionary steps that must be observed when carrying out metal electroplating machine operation?

A: Some safety precautions include wearing gloves and goggles, avoiding fume inhalation which can be done by staying in a well-ventilated area, adhering to the specified safety requirements from the operators’ manuals, and performing scheduled maintenance for all equipment in order to avoid continuing leaks or faults.

Q: Can the anodized processes be combined with the zinc plating machine?

A: The anodizing process and the zinc plating process are two different processes, which anodizing is mainly used for aluminum for improved resistance to corrosion and surface hardness. While these are not combined, a facility may use separate facilities to carry out both processes on different materials.