Ice resurfacing is both an art and a science, and at the heart of this process lies the trusted Zamboni machine. These remarkable machines have revolutionized ice maintenance for decades, delivering precision and reliability that ice rinks worldwide depend on.

Understanding the intricate components that make up a Zamboni machine is crucial for anyone involved in ice rink management, whether you’re a hockey enthusiast, figure skating fan, or simply fascinated by specialized machinery. This comprehensive guide explores the essential parts that work together to create perfectly smooth ice surfaces.

Standard Zamboni Machine Parts Overview

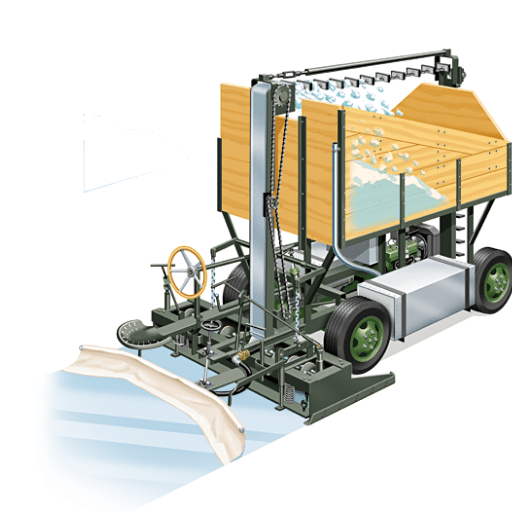

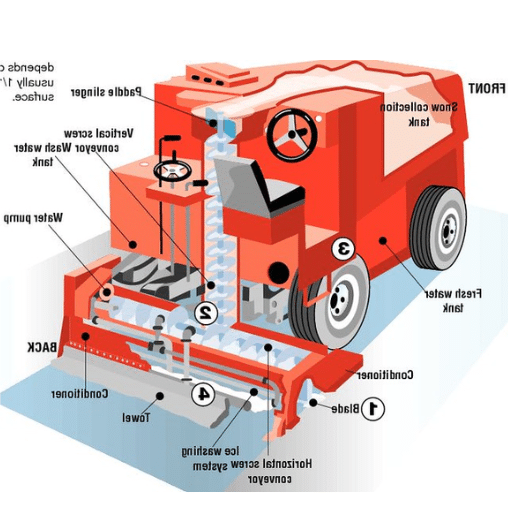

🔪 Blade

Skims the surface layer off the ice for smoothening purposes, creating the foundation for a perfect ice surface.

🌀 Augers

Push finely cut ice shavings to the collection tank, ensuring efficient removal of scraped material.

💧 Water Tank

Contains the water that fills and covers the cut channels in the ice, creating a smooth new surface.

🎯 Conditioner

Ensures uniform distribution of water while polishing the ice to professional standards.

🗂️ Collection Tank

Stores shaved ice removed during the resurfacing process until disposal.

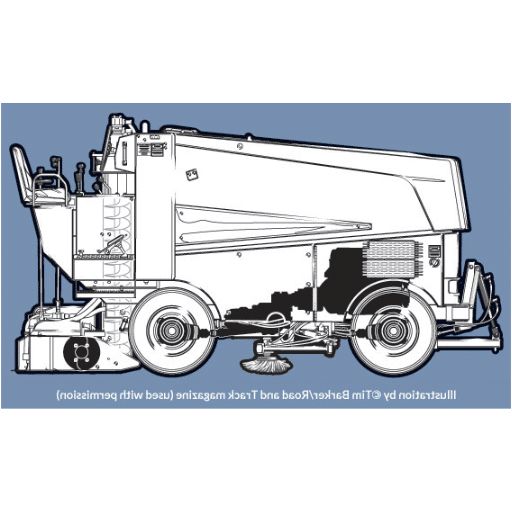

🛞 Tires

Specially designed for optimal traction on ice without disturbing the surface.

🔧 Engine

Provides the power necessary for all machine operations and movement.

Key Component Functions and Technology

Water Distribution Mechanism

The conditioner and water distribution system work together to distribute hot water evenly across the ice surface. This hot water application helps maintain smooth, long-lasting layers by properly bonding new ice to existing surfaces.

Collection Tank Features

Advanced collection tanks significantly impact resurfacing efficiency, especially in high-capacity arenas. Modern designs optimize storage capacity while reducing resurfacing time between cleanings.

Specialized Tire Technology

Zamboni tires are engineered with specialized materials to provide maximum grip on ice surfaces without causing damage during the resurfacing process.

Detailed Component Analysis

| Component | Primary Function | Key Features | Maintenance Frequency |

|---|---|---|---|

| Augers | Collect and transport ice shavings | Double auger systems for seamless operation | Daily inspection |

| Blade | Cut and level ice surface | Precision-engineered for smooth cutting | Weekly sharpening |

| Water System | Clean and resurface ice | Separate tanks for wash and resurface water | Monthly cleaning |

| Conditioner | Distribute water evenly | Integrated with blade and water system | Bi-weekly inspection |

| Snow Tank | Store scraped ice and snow | High-capacity storage design | After each use |

Popular Zamboni Machine Models and Their Specifications

Model 552 Electric

- Type: Fully electric, zero emissions

- Capacity: 25-30 resurfacing sessions per charge

- Features: Dual electric motors, advanced battery system

- Best For: Indoor arenas prioritizing environmental impact

Model 650

- Type: Hydrostatic transmission

- Capacity: 100 cubic foot snow tank

- Features: Advanced water management system

- Best For: Large rinks with frequent resurfacing needs

Model 446

- Type: Compact design

- Capacity: 85 cubic foot snow tank

- Features: Propane or gasoline engine options

- Best For: Smaller rinks and facilities with space constraints

Advanced Features in Modern Zamboni Machines

🚀 Latest Technological Innovations

- High-Efficiency Augers: Double auger systems for enhanced ice cutting removal

- Advanced Filtration: Water purification systems for superior ice quality

- Alternative Energy Options: Electric, LNG, and hybrid power systems

- Smart Monitoring: IoT integration for real-time performance tracking

Maintenance Tips for Optimal Performance

📋 Essential Maintenance Checklist

- Regularly Check Fluids: Monitor oil, hydraulic fluid, and coolant levels according to manufacturer specifications

- Inspect Blade Condition: Check for damage or wear, replace when blunt

- Monitor Tire Pressure: Maintain proper pressure for optimal performance

- Clean Collection Systems: Remove ice residue from snow tank and augers after each use

- Battery Maintenance: For electric models, check battery condition and charging systems regularly

Common Issues and Troubleshooting

⚠️ Common Problems

- Water tank leakage

- Battery performance issues

- Auger and blade wear

- Conditioner malfunctions

- Tire traction problems

✅ Solutions

- Replace seals and gaskets as needed

- Implement proper charging techniques

- Follow scheduled replacement schedules

- Perform regular system inspections

- Use proper tire maintenance procedures

Best Practices for Equipment Longevity

💡 Pro Tips for Zamboni Maintenance

- Follow Manufacturer Guidelines: Adhere strictly to recommended maintenance schedules

- Use Quality Parts: Invest in genuine or approved replacement components

- Train Operators Properly: Ensure all operators understand proper machine handling

- Stay Updated: Keep current with technological advances and industry best practices

- Implement Preventive Care: Address small issues before they become major problems

Finding Reliable Replacement Parts

Where to Buy Authentic Zamboni Parts

| Source | Advantages | Considerations | Best For |

|---|---|---|---|

| Official Zamboni Website | Guaranteed authenticity, expert support | May have higher prices | Critical components, warranty coverage |

| Authorized Distributors | Local support, competitive pricing | Availability may vary | Regular maintenance parts |

| Specialized Equipment Suppliers | Expert knowledge, comprehensive service | Limited geographic coverage | Complex repairs and installations |

| Online Marketplaces | Wide selection, competitive prices | Authenticity verification needed | Common replacement parts |

Part Compatibility and Selection

Zamboni machines feature highly modular and backwards-compatible designs, allowing parts interchange across different models within the same series. For example, Models 500 and 700 share many core mechanical components, simplifying maintenance and reducing inventory requirements.

Industry Trends and Future Innovations

🌱 Eco-Friendly Developments

- Electric Power Systems: Zero-emission machines gaining popularity

- Hybrid Technologies: Combining efficiency with environmental responsibility

- Biodegradable Lubricants: Reducing environmental impact of maintenance

- Smart Monitoring Systems: IoT integration for predictive maintenance

- Energy-Efficient Components: LED lighting and improved insulation

Future of Ice Rink Maintenance

The ice rink maintenance industry is evolving toward more sustainable and efficient practices. Advanced sensor networks enable proactive maintenance, while energy-efficient systems reduce operational costs. These innovations help facilities maintain high-quality ice surfaces while minimizing environmental impact.

Cost Considerations: Price vs. Quality

When selecting Zamboni parts, balance initial cost against long-term value. While genuine parts may cost more upfront, they typically offer:

- Superior durability and longevity

- Optimal performance and efficiency

- Warranty coverage and support

- Reduced maintenance frequency

- Lower total cost of ownership

References

-

Zamboni Official Website – Authentic Parts & Service: Provides detailed information on authentic Zamboni parts and authorized distributors.

-

J&C Ice Technologies – Zamboni Replacement Parts: Lists recommended spare parts and maintenance items for Zamboni machines.

-

All Star Arenas – Common Zamboni Parts: Offers a comprehensive catalog of common Zamboni parts with specifications.

Frequently Asked Questions (FAQ)

Which are the most important parts of the Zamboni machine?

The zamboni machine parts that are essential are the Ice resurface’s blade and water tank, augers’s’ and the electrical circuitry that controls the design of the machine. The parts are imperative in that they help with the management of the functionality of the machine in the ice making.

Where is Zamboni parts for sale worldwide?

The sale of Zamboni parts can be found throughout the world, being attained through Zamboni authorized distributors. The access to these distributors will guarantee you access to genuine components along with accessories to make your piece of equipment function without any problems.

How to find Zamboni parts for the machine?

Usually, the list of Zamboni parts available is provided on their official website or through any authorized representative. You will be sure to find these lists with much information on part/descriptions and also the part number making it easier to know what is needed for repairs or maintenance.

What are the Zamboni machine fuel requirements of the Zamboni machine?

The Zamboni Machining Application differ from model to model depending on the fuel type required. This is due to the fact that most of them rely on either propane or gasoline. These considerations are very crucial especially when referring to the manual of the product regarding fuel this is for the purposes of effective use of the equipment.

How about Zamboni mechanics, how do they play in performance evaluation?

Zamboni regular practice is very essential in improving the efficacy of the machine in question. Maintenance schedules, if adhered to, will minimize machine stoppages due to failures, equipment parts will be working properly, life of equipments will be extended and most importantly the ice rink will be in perfect condition.

What are some of the Zamboni parts that need frequent replacement?

Majority teams have discovered that there are certain Zamboni parts that need replacement especially the ice blade, water hoses and tires. Such appendages are prone to damages due to their day today utility hence the prompt help comes in when wear of such components occurs.

What would be the next step if parts for the Zamboni machine are not available?

If parts for the Zamboni machine are not available, turn to Zamboni authorized dealers for help. They may have information on the availability of the parts or offer alternatives on how they can be acquired.