Ever wondered how ice rinks maintain those pristine, mirror-like surfaces? The answer lies in one of the most ingenious machines ever created for sports maintenance: the Zamboni. This revolutionary ice resurfacing machine has transformed ice rink operations worldwide, ensuring perfect skating conditions for everyone from recreational skaters to Olympic athletes.

Ice rinks are synonymous with smooth, shimmering surfaces perfect for skating, hockey, and figure skating performances. Behind these flawless sheets of ice lies the remarkable Zamboni machine—an invention that has revolutionized ice resurfacing for over seven decades. This comprehensive guide explores how Zambonis work, their essential components, and why they’re indispensable to ice sports worldwide.

The Rich History of Zamboni Machines

The Zamboni story began in 1949 when Frank J. Zamboni, a California mechanic and innovator, recognized the need for a machine that could resurface ice rinks faster and more efficiently than manual methods. His first creation, the Model A, was ingeniously built from a Jeep chassis combined with farm equipment parts.

The Birth of Innovation

Frank J. Zamboni invented the first ice resurfacing machine, forever changing ice rink maintenance and laying the foundation for decades of innovation.

Trademark Registration

The Zamboni name was officially trademarked, establishing the company’s rightful place as the leader in ice resurfacing technology.

Olympic Debut

Zamboni machines made their Olympic debut at the Squaw Valley Winter Olympics in California, bringing worldwide recognition to the brand.

Electric Revolution

The first electric-powered Zamboni was launched, addressing the growing need for environmentally friendly ice resurfacing operations.

Golden Anniversary

Zamboni celebrated 50 years of innovation, highlighting remarkable growth, technological advancement, and commitment to quality ice surface solutions.

Automation Integration

Advanced automated ice resurfacing capabilities were implemented, ensuring precision and efficiency while minimizing human error.

Impact on Ice Sports Excellence

The Zamboni has fundamentally transformed ice sports by providing consistent, high-quality surfaces. Its contribution to creating optimal skating conditions has enhanced athlete performance, reduced injury risk, and elevated the overall quality of hockey, figure skating, and curling competitions worldwide.

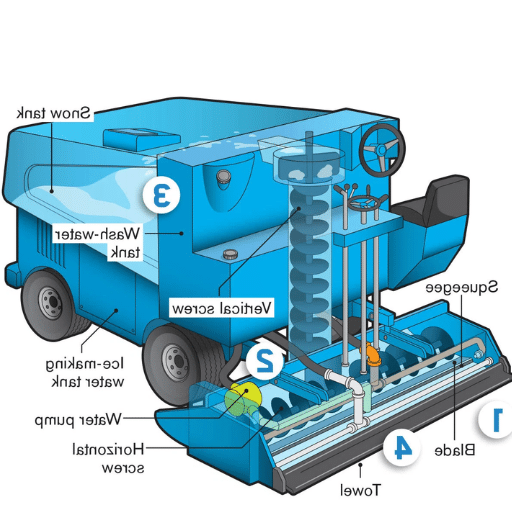

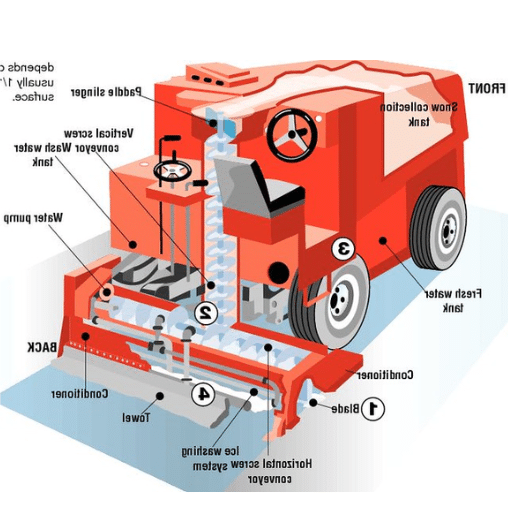

Essential Zamboni Machine Components

🔪 Retractable Blade

The precision-engineered blade shaves off the top layer of rough ice, creating a smooth, even surface. It’s carefully adjusted to remove just the right amount of ice without compromising rink thickness.

🌀 Auger System

Dual augers work in tandem to collect ice shavings and transport them efficiently into the snow tank. The horizontal auger gathers surface debris while the vertical auger lifts it upward.

💧 Water Tank System

Advanced dual-tank system containing both wash water for cleaning debris and resurfacing water heated to approximately 140°F (60°C) for optimal ice formation.

🎯 Conditioner

Located at the machine’s rear, the conditioner levels the fresh ice layer and distributes water evenly, ensuring uniform freezing and a flawless skating surface.

🗂️ Snow Tank

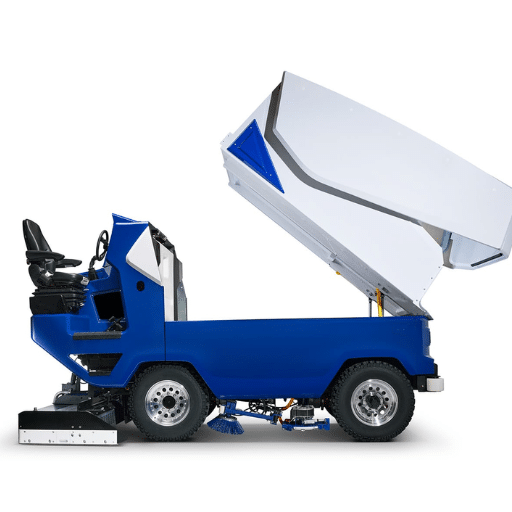

High-capacity storage compartment (60-100 cubic feet) that collects and stores ice shavings until disposal. Advanced models feature hydraulic dumping systems.

⚡ Power System

Modern Zambonis utilize either electric motors or fuel-powered engines, with electric models offering zero emissions and reduced operational costs.

How Zamboni Machines Work: The Complete Process

Ice Surface Preparation

The sharp blade removes a precise layer (approximately 0.004 inches) of damaged or uneven ice, creating a clean foundation for resurfacing.

Debris Collection

The auger system efficiently gathers ice shavings and debris, transporting thousands of pounds of material into the storage tank daily.

Surface Cleaning

Wash water is applied to remove any remaining debris, dirt, or impurities from the freshly cut ice surface.

Water Application

Heated water (140°F/60°C) is evenly distributed across the ice surface to fill grooves, cracks, and imperfections left from previous use.

Surface Conditioning

The conditioner ensures uniform water distribution and creates the perfect foundation for the new ice layer to form.

Final Freezing

The warm water bonds with the existing ice and freezes uniformly, creating a smooth, professional-quality skating surface.

💡 Why Warm Water?

Warm water creates superior bonding with existing ice surfaces and cools uniformly during freezing. This process eliminates imperfections and creates the ideal gliding surface for skaters.

Types of Zamboni Machines Available

⚡ Electric-Powered Models

- Zero Emissions: Environmentally friendly operation

- Quiet Operation: Minimal noise pollution

- Cost Effective: 85% reduction in operational costs

- Indoor Ideal: Perfect for enclosed rinks

🔥 Propane/Natural Gas Models

- Reliable Power: Consistent performance delivery

- Reduced Emissions: Cleaner than gasoline alternatives

- Efficient Operation: Maximum power delivery

- Versatile Use: Suitable for various rink sizes

⛽ Gasoline-Powered Models

- Traditional Reliability: Proven performance record

- Outdoor Applications: Ideal for external rinks

- High Power Output: Handles demanding resurfacing

- Wide Availability: Easy fuel access worldwide

🚛 Diesel-Powered Models

- Maximum Durability: Built for heavy-duty operations

- High Capacity: Handles large facility demands

- Long Lifespan: Extended operational life

- Industrial Strength: Commercial-grade performance

Performance Data and Industry Statistics

📊 Key Performance Metrics

Minutes to resurface Olympic-sized rink

Gallons of water per resurfacing

Emission reduction with electric models

Horsepower typical engine output

The Critical Role of Zamboni Drivers

Zamboni operators play an essential role in maintaining ice quality and safety. These skilled professionals must master precise driving techniques, understand ice conditions, and operate complex machinery to ensure optimal results.

Essential Driving Techniques

| Technique | Purpose | Key Considerations | Impact on Quality |

|---|---|---|---|

| Overlapping Passes | Complete surface coverage | Consistent overlap patterns | Eliminates gaps and uneven areas |

| Speed Control | Optimal ice thickness | Maintain constant, moderate speed | Prevents over-cutting or thin layers |

| Corner Navigation | Edge quality maintenance | Careful turns to avoid pressure variations | Ensures uniform corner conditions |

| System Monitoring | Real-time adjustments | Blade, auger, and water system checks | Maintains consistent surface quality |

Ice Maintenance: Quality and Performance Impact

Proper ice maintenance directly affects athlete performance, safety, and operational efficiency. High-quality ice surfaces provide optimal friction for skates, enabling precision movements, maximum speed, and superior control during athletic performances.

Resurfacing Frequency and Best Practices

- High-Use Rinks: Multiple times daily before each session or game

- Recreational Facilities: Every 4-6 hours of skating activity

- Competition Venues: Before every event and during intermissions

- Training Facilities: 2-3 times per day depending on usage intensity

Challenges in Modern Ice Maintenance

⚠️ Common Challenges

- Maintaining consistent ice quality with varying temperature and humidity

- Balancing energy efficiency with frequent resurfacing needs

- Managing increasing operational costs

- Equipment maintenance and repair scheduling

- Balancing safety with heavy usage demands

✅ Modern Solutions

- Advanced environmental control systems

- Energy-efficient electric resurfacing machines

- Predictive maintenance technology

- Smart scheduling and monitoring systems

- Improved safety protocols and training programs

Latest Technological Advancements

🚀 Recent Innovations in Zamboni Technology

Electric Powertrain Revolution

- Zero emissions for environmentally conscious operations

- Significantly reduced noise levels for improved user experience

- Lower operational costs and minimal maintenance requirements

Advanced Water Management

- Precision filtration systems for water recycling and purification

- Automated distribution systems for uniform ice layering

- Reduced water waste and improved ice quality

Smart Technology Integration

- GPS tracking and laser-guided leveling systems

- Real-time data analytics for performance optimization

- Predictive maintenance scheduling

- Automated pattern optimization software

Enhanced Precision Engineering

- High-precision blade systems for superior surface finish

- Improved ergonomic design for operator comfort

- Advanced sensor technology for ice condition monitoring

Environmental Considerations and Sustainability

🌱 Green Technology Leadership

Modern Zamboni machines have significantly reduced their environmental impact through innovative green technologies:

Renewable Energy Compatibility

- Solar and wind energy charging capabilities

- Reduced dependence on traditional energy sources

- Lower carbon footprint for ice rink operations

Water Conservation Features

- Advanced recycling systems minimize water waste

- Efficient filtration for water reuse

- Optimized application patterns reduce consumption

Emission Reduction Technologies

- Electric and hybrid models eliminate direct emissions

- Improved fuel efficiency in traditional models

- Biodegradable lubricants and fluids

The Future of Ice Resurfacing Technology

The future of ice resurfacing technology promises exciting developments driven by automation, artificial intelligence, and environmental consciousness. AI-powered sensors and real-time data analytics will enable machines to dynamically adjust to ice conditions, maintaining uniform surface quality while minimizing resource consumption.

Emerging Technologies

- Artificial Intelligence: Dynamic adjustment to ice conditions for optimal results

- IoT Integration: Connected systems for predictive maintenance and monitoring

- Advanced Automation: Reduced human intervention while maintaining precision

- Sustainable Materials: Eco-friendly components and biodegradable fluids

- Energy Storage: Advanced battery technology for extended operation

References

-

Zamboni Official Website – How It Works: Provides detailed illustrations and explanations of the Zamboni’s components and functionality.

-

Pure Hockey – How Does a Zamboni Work?: Explains the step-by-step process of ice resurfacing performed by a Zamboni.

-

Wikipedia – Ice Resurfacer: Offers a comprehensive overview of ice resurfacers, including Zamboni machines, and their operation.

-

Exploratorium – Science of Hockey: Making Ice & the Zamboni: Discusses the science behind Zamboni machines and their role in maintaining ice quality.

Frequently Asked Questions (FAQ)

How Does a Zamboni Work to Resurface the Ice?

A Zamboni machine works by resurfacing the ice in an ice arena, creating a smooth sheet of ice for skaters and hockey players. The process involves scraping the top layer of ice to remove rough spots and grooves, followed by laying down a new layer of water from the wash water tank. As the machine moves, a squeegee spreads this water evenly, filling in the remaining grooves and creating a fresh surface.

What is the Role of the Zamboni Driver?

The role of the Zamboni driver is crucial for maintaining the quality of the ice. They operate the ice resurfacer, ensuring that it collects ice shavings and applies a layer of water properly. Skilled drivers can navigate around the rink efficiently, especially during intermissions in hockey games, to keep the ice in top condition.

Who Invented the First Ice Resurfacer?

The first ice resurfacer was invented by American inventor and engineer Frank Zamboni. He built the Zamboni® machine in the 1940s, revolutionizing the way ice rinks were maintained. His invention allowed for a much quicker and more efficient way to keep ice smooth and clean, enhancing the skating experience for everyone.

What Features Make the Zamboni Machine Efficient?

One of the key features of a Zamboni machine is its self-propelled design, which allows it to move smoothly around the rink. It has a refrigeration system that helps maintain the ice temperature and a vacuum hose that collects dirty water and ice shavings. This efficiency is vital for large ice arenas that host events like hockey games or ice capades.

How Does the Zamboni Collect Ice Shavings?

The Zamboni collects ice shavings using a scraping blade located at the front of the machine. As the driver maneuvers around the rink, the blade removes the top layer of ice, which is then funneled into a hopper. This process ensures that the ice is prepared for the new layer of water, keeping the surface smooth and even for skaters.

What Happens to the Water Tank During Operation?

During operation, the water tank of the Zamboni dispenses ice-making water over the freshly scraped surface. The machine carefully regulates the amount of water applied, ensuring that it creates a thin layer that freezes quickly, resulting in a smooth ice surface. Proper management of the water tank is essential for effective ice resurfacing.

How Do Zamboni Machines Improve Ice Rinks?

Zamboni machines improve ice rinks by creating a layer of fresh ice that enhances the skating and playing experience. By regularly resurfacing the ice, Zambonis help maintain a smooth surface that reduces the risk of injury and allows for better performance from hockey players and skaters alike. This innovation has made ice rinks greener by optimizing water usage during the resurfacing process.

Can Anyone Drive a Zamboni?

While anyone can learn to drive a Zamboni, it requires some training to operate the machine effectively. Knowledge of how to resurface the ice, manage the water tank, and navigate around the rink are essential skills for a Zamboni driver. Many ice arenas provide training programs to ensure that drivers can maintain high-quality ice for all users.