Without a doubt, the first and foremost step to a well-kept yard with no grass is taking care of your lawnmower. For that reason, the first and most crucial step in maintaining any lawnmower is picking the correct motor oil. The wide variety of oils available might make this job quite confusing. Using an inappropriate oil for your engine can damage its internal parts, leading to inefficiency in the long run and unpredictable repair costs. To take the pain out of the process, a guide is provided for you. One goal of the blog is to make sense of the oil jungle by giving practical, concise, and straightforward advice. Apart from this equipment, if you’re an experienced gardener or a new lawnmower owner, you’ll find this blog a valuable resource for maintaining your lawnmower and ensuring its efficient performance at all times.

Understanding Your Lawn Mower Engine

The lawn mower’s engine takes in fuel and converts it into mechanical energy to power the blades that cut the grass in your lawn. Most of the time, push mowers use a four-stroke engine, similar to vehicle engines, which perform four distinct tasks—suction, compression, power, and exhaust—every cycle. To function at top performance, engines need three components in particular: clean air, the right fuel mix, and a lubricated system. The engine sucks in the air and fuel, mixes them, and then compresses them inside the cylinder. A spark plug fires the mixture, causing the movement of the piston. This specific motion produces energy, which is then converted into the force that turns the cutting blades. If the engine of the mower is maintained and kept clean all the time, it will work very smoothly, and the life of the mower will be extended as well.

The Importance of Proper Oil for Lawn Mowers

It is essential to use the correct type and required quantities of oil for the long-lasting and top-notch performance of a lawnmower engine. The use of good oil ensures that the engine is properly lubricated, resulting in less friction and wear. Lubrication failure can cause the engine to break down, leading to severe damage. Thus, the majority of lawnmower motors are meant to be powered by a specific type of oil, SAE 30 for warm weather or 10W-30 for engines that will have to withstand a broad range of temperature variations. Routine checking of the oil level and its replacement according to the producer’s agreements could significantly boost the machine’s efficiency and dependability. Furthermore, using clean and fresh oil prevents the formation of harmful deposits, which ultimately keeps the engine running well for many years.

How Engine Type Affects Oil Selection

Various kinds of lawnmower engines require unique requirements for the oil to operate at its optimum level and last longer. Generally speaking, four-stroke engines, which are one of the most common types in the large lawn mowers, call for standard motor oils like SAE 30 or 10W-30. In short, these oils have the appropriate viscosity to lubricate internal parts efficiently under various operating conditions. However, two-stroke engines, which are primarily found in small and handheld mowers, are greatly dependent on oil that they mix with fuel. The fuel-oil mixture ensures that the combustion is correct and, at the same time, lubricates the moving parts of the engine. Also, the newer engine models may recommend using synthetic oils that provide the engine with a more stable temperature and reduce deposit formation compared to regular oils. This means it is essential to know the type of engine and its special needs to select the right oil and maintain the mower’s peak performance.

Common Types of Lawn Mower Engines

| Engine Type | Fuel Type | Maintenance Needs | Key Features | Typical Use |

|---|---|---|---|---|

| Two-Stroke Engine | Gasoline + Oil | Moderate, oil mixing | Lightweight, simple design | Small-scale residential lawns |

| Four-Stroke Engine | Gasoline | Low, regular oil changes | Durable, efficient, quieter | Larger residential or commercial |

| Electric Engine | Electricity/Battery | Minimal, battery care | Quiet, eco-friendly, low maintenance | Small to medium lawns |

| Diesel Engine | Diesel | High, specialized repair | Powerful, long-lasting, fuel-efficient | Large commercial applications |

| Propane Engine | Propane | Low, refueling required | Cleaner emissions, steady power | Eco-sensitive areas or large lawns |

Choosing the Right Lawn Mower Oil

Picking the best oil for your lawn mower is a necessity if you want to ensure that it runs well and lasts a long time. The majority of the lawn mower engines work best with either SAE 30 motor oil when it’s warm or SAE 10W-30 if the temperature varies. Synthetic oils, on the other hand, perform better in both extremely hot and cold settings, require less frequent changes, and thus, not only save on overall costs but also benefit the environment. Make a habit of checking your mower’s manual for the brand’s reviews. Not only will you ensure proper usage, but you will also easily extend your equipment’s lifespan if you use the right oil. Mixing oil types, on the other hand, should be avoided; always opt for regular oil changes to maintain the engine of your mower and keep it running smoothly.

Synthetic vs. Conventional Oil

| Parameter | Synthetic Oil | Conventional Oil |

|---|---|---|

| Performance in extreme temperatures | Performs well in hot and cold climates | Less effective in extreme conditions |

| Engine protection | Offers superior engine wear protection | Provides moderate protection |

| Oil lifespan | Longer lifespan; requires fewer changes | Shorter lifespan; frequent changes |

| Cost | More expensive upfront | Less expensive upfront |

| Viscosity stability | High stability over various conditions | Less stable over time |

| Environmental impact | Lower emissions; eco-friendlier | Higher emissions |

| Additive content | Includes advanced performance additives | Basic additive formulas |

| Compatibility | Suitable for modern engines | Ideal for older engine models |

| Sludge buildup | Minimizes sludge and deposit formation | Higher risk of sludge formation |

| Fuel efficiency | Improves fuel efficiency | Average fuel efficiency |

Understanding SAE Ratings for Small Engine Oil

SAE ratings, set by the Society of Automotive Engineers, are a standardized system for measuring the viscosity of engine oil under different temperature conditions. Customers need to know these ratings so they can buy the right oil for their engine’s special needs and the conditions in which they are operating. People who live in an area where it is cold in the winter, for example, should probably use a 5W-30 oil that is very thin and provides good performance in cold weather conditions, thus smoother starts and proper lubrication in winter. On the other hand, the higher SAE grades (like 20W-50) provide strength through high viscosity for performance in warmer climates or under severe stress during engine operation. It is essential to keep the engine in good health, which involves preventing wear and tear and increasing efficiency through the selection of various oil grades. The area where the oil will be used might be the warmest in another case. Weather conditions can change sometimes during the day or in the same part of the country at the same time of the year and it can be the coldest. In both cases, the multifunctional oils will be the best solution in the consumer’s mind, as they can handle any conditions during temperature changes. The buyer needs to know all these; hence, the choice of a more informed small engine user, whether for lawn mowers, generators, or recreational vehicles, will result from that.

Best Oil Types and Recommendations for Push Mowers

To choose the most suitable oil for a grass cutter, the type of engine is just as essential as the operational temperature. SAE 30, primarily used for modern push mowers, is a regular and perfect oil. For this kind of climate, it is always good to have oil that performs similarly at 40°F as SAE 30. With this oil, the standard operation would be secured through constant lubrication.

Users who love flexibility can use the synthetic 5W-30 oil, which works well in both cold and hot conditions. The unique characteristics of this oil lead to less wear and friction, and, therefore, a push mower with it can be used in areas with rapid temperature changes. The cold starting is satisfactory if the selected oil is 10W-30, and the end of the season will provide the normal protection required.

Alternatives that have less of an impact on the environment, such as biodegradable or low-smoke oils, are gaining popularity and are effective because they do not contravene eco-friendly guidelines. You should always check the oil types recommended by the mower manufacturer in the user manual and be sure to carry out regular oil changes to increase engine life and maintain optimal efficiency.

How to Check, Drain, and Change Oil in Your Push Mower

Gather Your Supplies

To cover the sites, be sure to get with yourself all needed tools and supplies and that includes measuring and quality oil, a container or a drain oil pan, a funnel, a piece of cloth for cleaning, and gloves for protection.

Prepare the Mower

You should have the mower put on a level surface and let it cool for a while if it was on. At the same time, disconnecting the wire of the spark plug helps you avoid any sudden starts during maintenance.

Check the Oil Level

The oil stick is where you shall find it. Most of the time, it is located on the engine side. Take it out, clean it with a piece of cloth, and then put it back in. Pull it out again to see where the oil is. If the oil is below the recommended level or it is filthy and dark, this means you need to change the oil.

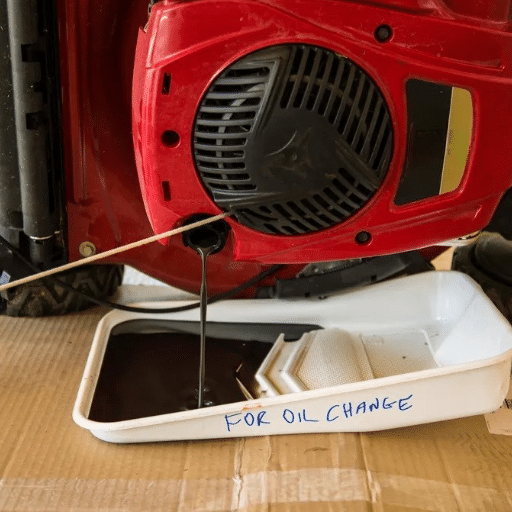

Drain the Old Oil

Under the mower is where the oil pan should go, and now remove the oil drain plug. It is usually positioned at the bottom of the engine. Alternatively, you can tilt the mower with the air filter on top and let the oil flow out from the dipstick tube. Then rinse until all the oil is gone.

Add Fresh Oil

Insert the plug firmly when completely done draining. Then, by utilizing a funnel, get the correct amount and kind of oil to proceed with oiling up the oil filler tube. Confirm the oil is at the specified level by pulling out the stick.

Final Check

Put back the dipstick, reconnect the spark plug wire, and wipe off any spills. Do not forget to take the old oil to the oil recycling center. Your mower is now ready to be filled with the new oil and work optimally.

Step-by-Step Guide to Checking Oil Levels

- Drain the Old Oil

The usual spot to find the oil drain plug is under the engine, so they remove it with a wrench and place the drain pan beneath. Wait for the oil to drain, and then close the plug totally. If you have a mower with no plug, you can use the tilt method, which involves carefully tilting the mower to pour the oil out through the fill spout. - Replace the Oil Filter (If Applicable)

Certain lawn mowers are fitted with oil filters. If your mower has one, simply remove the old filter and replace it with a new one, ensuring it is appropriately fastened. A thin layer of new oil should be applied to the gasket before the installation of the new one to prevent leakage. - Refill with New Oil

Pour the proper amount and kind of new oil through the funnel into the fill spout and be very careful not to overflow it. Check the oil level in the tank using the dipstick to ensure it is in the proper range. - Secure All Components

Put back the oil fill cap and reconnect the spark plug wire when everything has been finished. Clean up any oil spills so that there won’t be any problem with safety and the engine compartment will stay clean. - Dispose of Used Oil Properly

Change your oil with little effort by following the instructions in the user manual. Disposal of the oil is as essential as changing it and should be first on the list.

Determining the Oil Capacity for Your Mower

Oiling the mower should be done with care and deliberation and not after doing it one time, the whole process should be effortless and seamless if the capacity of the oil is well known and considered. The amount of oil required for most push mowers generally goes from 15 to 20 ounces, while riding mowers may use up to 48 to 64 ounces, depending on the size and type of the engine. Besides, the safest first step is to consult the mower’s manual for its oil capacity, and only then fill the mower’s tank to that point. Don’t use more than the recommended quantity, as it may lead to engine harm. People who lose their manuals can easily and quickly find all the information about their mowers’ makes and models. This includes details of oil and all other information available through the brand’s website. Always stick to the limits of the oil type. Additionally, some mowers require synthetic blends or a specific viscosity grade for optimal performance.

What Happens if You Use the Wrong Oil?

The incorrect choice of oil in the mower is the root cause of several problems that are harmful to the engine. If the oil is too viscous or otherwise inaccurate, it will make starting the engine more difficult and decrease its efficiency. On the other hand, using oil that is too thin might cause the lubrication process to reverse, leading to more friction and wear on the engine. Eventually, overheating will occur, which can lead to poor performance or, even worse, destroy the engine. The best suggestion to prevent this from happening is to follow the Manufacturer’s recommendation on oil type and grade.

Common Issues Caused by Incorrect Oil Types

Engine Overheating

The consequences of using oil of the wrong type or grade can also be seen in the engine’s cooling system. A thicker oil would not flow properly, failing to deliver heat evenly, while a thinner oil could not sufficiently lubricate, leading to increased friction and overheating. But this is just the beginning of possible engine damage, even to the extent of component warping due to prolonged, non-stop overheating.

Reduced Fuel Efficiency

Incorrect specification of the oil viscosity can put an additional heavy load on the engine’s operation, leading to a higher fuel consumption rate and a decrease in efficiency. This degradation may lead to higher overall operational costs and more frequent refueling incidents, which can be avoided by selecting the correct oil viscosity.

Excessive Wear and Tear

Improper oil viscosity results in a shortage of lubrication, which increases friction inside the engine. Consequently, wear and tear are severe on engine parts, such as pistons and bearings. This shortening of the engine’s lifespan may become more problematic if a replacement or repair has to be done.

Higher Emissions

When the oil loses its properties and quality, the engine may not work as intended, potentially leading to an increase in harmful emissions. Such a situation not only affects the environment but also may not comply with the regulatory requirements in some places.

Oil Leaks or Sludge Buildup

Surrounding not identical properties of oil can result in inadequate sealing, leading to leaks or sludge formation inside the engine as time passes. Among factors to be blamed for poor performance effectiveness is the heavy clogging of vital components due to the sludge presence, which may cause irreversible damage and may also result in locking down.

Signs of Oil-Related Problems in Lawn Mowers

Excessive Exhaust Smoke

When the exhaust pump of the machine emits a thick smoke—the white or blue kind—this may be a sign that the engine is burning oil. The issue is sometimes the result of overfilling, faulty seals, or worn-out engine parts.

Engine Knocking or Unusual Noises

The engine of the lawnmower starts making knocking or inconsistent noises? It may be caused by a low oil level or improper lubrication of the moving parts, preventing the oil from performing its function correctly.

Difficulty Starting the Engine

Poor startup of the mower can stem from oil problems, such as sludge clogging the internal parts or insufficient lubrication, causing higher resistance.

Oil Spots on the Ground

If oil appears beneath the mower, there may be leak problems due to damaged seals or fittings that are not tight enough, or it could be oil that is incompatible with the equipment.

Decreased Performance or Overheating

A sudden decrease in the mower’s performance quality or overheating could be caused by insufficient oil circulation or contamination, leading to severe friction and thermal stress on the engine parts.

By monitoring those indicators and performing necessary maintenance at the right time, mower owners can avoid these problems and keep their machine running efficiently for a long time.

Environmental Considerations and Oil Disposal

You have to ensure that your used oil goes through the proper disposal process, hence preventing contamination of the environment. It is the best practice to store used oil in a clean, tightly sealed container and then take it to a local recycling center or a sanctioned collection site for proper disposal. Pouring oil into drains, the ground, or water bodies should be avoided entirely, as it will pollute soil and waterways and harm wildlife and ecosystems. Many cities and vehicle services, which typically use such services, offer either free or inexpensive options for recycling oil, making oil waste management less of a burden. Ensuring compliance with local laws and regulations on the safe disposal of oil should be the top priority to guarantee the lowest possible environmental footprint.

Proper Disposal Methods for Used Oil

What most people would discard as merely a waste actually reveals great dangers when not disposed of properly. The U.S. Environmental Protection Agency (EPA) states that improper disposal of even a single gallon of motor oil can pollute about a million gallons of clean water. Moreover, used oil still poses hazards due to its heavy metal contents, such as lead, arsenic, and cadmium, which, if not properly managed, can penetrate the soil and damage the environment. Not only does recycling used oil help prevent pollution, but it also aids in conserving the environment. The process of re-refining used oil can produce lubricants, industrial oils, and power generation fuel, significantly reducing the need for virgin crude oil extraction. By ensuring proper waste disposal, individuals can directly contribute to creating a better world and a sustainable future.

Promoting Eco-Friendly Practices in Lawn Care

One of the most effective methods to promote green lawn management is choosing organic fertilizers and natural soil solutions. Chemical fertilizers not only harm but also significantly contribute to water pollution, as their runoff disturbs aquatic life in lakes, rivers, and the sea through algal blooms. Organic fertilizers, however, make the soil nutritious naturally and at the same time improve its structure and water retention more than chemical fertilizers. Home-made compost or eco-certified products are indeed excellent sources that promote long-term soil health and minimize environmental pollution. Plus, mulching grass clippings and planting native drought-resistant grass species are some of the sustainable lawn care practices. Additionally, there are various watering practices and chemical use reduction methods.

Sparing a few gallons not only saves the environment but also reduces the expenses you would incur to care for your lawn. Every step is taken to keep the grass green, such as watering when the temperature is relatively low or late at night, so that water does not evaporate and goes directly to the underground. The use of rain barrels is advised, as it leads to the cashew plant element, which is another effective way to keep the lawn well watered without depending on the municipal water supply. And finally, the third way to supply the lawn with cheap water is to purchase an intelligent irrigation system, which waters only when necessary by adjusting to weather and soil conditions, eliminating any worries.

Reference Sources

Development of Unilateral Obstacle-Avoiding Mower

This paper discusses the design and development of a mower capable of avoiding obstacles autonomously. It focuses on the integration of hydraulic systems to enhance the mower’s functionality and adaptability in complex terrains.

Putting the Yard and Garden to Bed

This document provides maintenance tips for lawn equipment, including the use of lightweight oils like gun or pneumatic tool oil for preserving metal parts. It emphasizes the importance of proper care to extend the lifespan of tools and equipment.

Frequently Asked Questions (FAQs)

How to Determine the Best Oil Type for My Push Mower?

To figure out what the best oil is for your push mower, you always need to take a glance at the owner’s manual since it often states the oil kind and grade that is of best quality. Most push mowers are happy with just SAE 30 or 10W30 engine oils. If your machine goes through a range of temperatures, a synthetic 5W30 oil might be the thing; it has no trouble operating in hot or cold conditions. The synthetic oil may be more expensive, but it also saves money in the long run. The operating manual gives the oil change intervals to follow and keep the engine in good working condition. Deep discussion on proper oil type detection helps prevent elevated oil consumption and extends the life of one’s mower.

What is the Oil Capacity for My Small Engine Mower?

The oil capacity range for mowers with small engines could vary significantly depending on the model and make of the machine. In most cases, the oil capacity of push mowers is about 15 to 20 ounces. It is essential to refer to the owner’s manual of your specific mower to determine the correct oil capacity and ensure you are not adding too much or too little oil. Adding too much can lead to increased oil consumption and engine damage. Moreover, using the correct type of oil and maintaining the oil level are essential for your small engine to keep performing well.

Can I Use Automotive Oil in My Lawn Mower?

Even though some people might be up for it, the use of a car engine oil in a lawnmower is generally not a good idea. This is because automotive lubricants are designed for different temperature ranges, and the small engines would not be able to utilize them properly. On the contrary, if a person uses the lawnmower oil recommended by Briggs & Stratton, the engine will get precisely what it requires. However, if you absolutely want to use a car oil, make sure the oil meets the correct engine type and properties. Otherwise, the lubrication process may vary, and issues such as engine problems, performance, and warranty issues could occur.