In this blog, we will take a look at the interesting process of making one of the most popular breakfast cereals in every household – Corn Flakes. It all starts with selecting the best corn, which is then cooked, flaked, and finally toasted, all of which ultimately results in a bowl of delicious, crispy cereal flakes. We will trace the history of its origins and look for the most important ingredients, paying special attention to the industrial processes used in its manufacturing today that allow the same quality and taste to be achieved throughout. If you are a cereal lover or have ever wondered how food is produced, all these questions will be answered in this article, taking you through the entire process of making this breakfast food.

What are the main steps in cornflake production?

Processing corn into its famous product, cornflakes can be divided into several main stages. The process of producing cornflakes starts with collecting high-quality corn, which is then cleaned. The corn kernels are then heated in large pressure cookers and some seasonings and vitamins are added. After soaking, the wet corn is pressed into thin flakes using large rollers. These loose cornflakes are then baked in an oven to give them a rich golden color and crispiness. Finally, the cornflakes are packaged and sealed to ensure freshness before shipping. Now, cereal lovers around the world can enjoy them.

How is raw corn prepared?

Corn procurement is the first step in corn flakes manufacturing, which begins with sourcing the best quality corn cobs. The corn is then cleaned of impurities such as dust, stones, etc. to ensure that the corn is clean and safe. After that, the cleaned corn is degermed to remove the germ from the endosperm. The corn kernels not only help enhance the flavor and texture of the final product but also prevent it from rotting and extend its shelf life. After that, the corn kernels gradually change from degermed corn to easy-to-handle particles that are rough and easy to cook for further processing into corn flakes. During these activities, strict quality control is always implemented to ensure that the corn is still suitable for grain production.

What does the extrusion process do?

As far as I know, extrusion is one of the important stages in corn flake production as it determines the texture and nutritional value of the product. During the extrusion process, corn grits are mixed with water and other ingredients such as vitamins and minerals, and passed through a machine under high temperature and pressure. This process helps to cook the corn, mold it into the desired shape, and improve the digestibility of the starch structure. Extrusion not only provides uniformity and quality in the form of grains but also helps to integrate other nutrients into the cornflakes, making the extruded cornflakes delicious and healthy.

How to bake cornflakes?

Toasting enhances the characteristic crispness and flavor of corn chips, which is critical to the success of this product. The process begins with the corn grits being transformed into flakes, which then pass through a drying and toasting system. Typically, the toasting method uses relatively moderate temperatures, 110 AF to 145 AF, for approximately 5 to 15 minutes. Exposure to heat in a controlled manner results in good color and flavor. However, if not properly monitored, overtoasting can result in a burnt taste, while undertoasting can result in tough flakes. In addition, many new production lines use horizontal screen toasters, which allow for uniform toasting while maximizing yields with batch-to-batch tolerances.

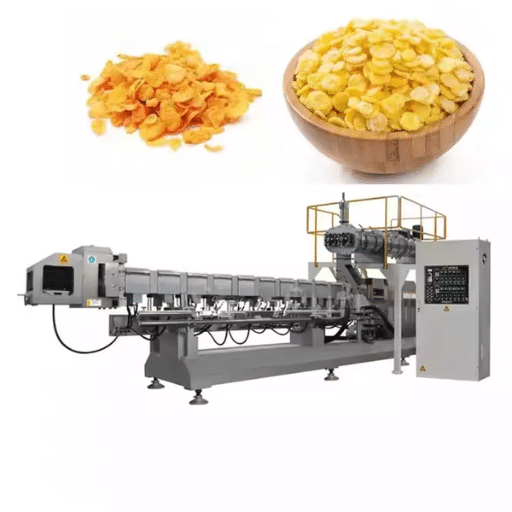

How does a cornflake production line work?

Corn flakes production lines use complex kitchen procedures that are time-sensitive and designed to produce high-quality products. First, corn grits are mixed with water and necessary vitamins and minerals. This mixture is then processed in an extruder under controlled temperature and pressure for cooking, shaping, and fortification. The cornflakes are then dried and baked in a unit, during which the appropriate texture and taste are developed. To complete the entire operation efficiently, the process ends with the packaging of the product, which is done via a continuous conveyor belt. The right machinery is also very important to ensure accuracy at every step in the grain processing process.

What is the function of a twin-screw extruder?

The twin-screw extruder is very important in the cornflakes-making process, as it performs several functions to ensure that the final product meets high standards and is uniform and consistent. Firstly, it mixes and cooks the corn flour slurry at high temperature and pressure, which not only provides starch gelatinization but also textural consistency. In the extruder, the screw can apply shear forces to the high-viscosity material, which facilitates kneading and conveying within a barrel of limited diameter. In addition, the extruder is also useful in the fortification process, as it helps to distribute the vitamins and minerals evenly throughout the mixture. Before the mixture enters the next stage of forced feeding, it is already used to cut the pieces, which will later be cut into flakes so that they can be dried and toasted. This British “machine” demonstrates the current trends in food processing – that is, allowing to obtain every batch of cornflakes that meets nutritional and textural specifications.

How to manage moisture levels?

However, in the beginning, to increase the production of cornflakes, I tried to ensure and address water control issues in all stages of the operation, from mixing to the finished product. First, during the mechanized mixing process, water is added in an amount that will give the corn flour mixture the best final consistency during the extrusion process. Careful water amounts and a careful water management plan are implemented at this point to ensure that the water present is in an ideal state for cooking and extrusion. After the forming and cutting tasks, it can be said that the drying and toasting unit is a very difficult task, but here I ensure a lot of temperature and time to eliminate excess water, but not too much to cause over-crispness. Good drying is important because it helps increase the texture of the product as well as the ultimate shelf life. This system of combining temperature, time, and machine efficiency ensures that each corn flake is not only perfectly crispy but also well preserved.

What quality control measures are in place?

As with all manufacturing processes, several quality control steps are applied during the manufacturing of cornflakes. First, certain parameters of the purchased raw materials, such as their quantity or concentration measurement, are well controlled. Control of extrusion performance parameters is also crucial to the production line, as it enables the reliable production of cornflakes with specific sizes and shapes. Samples from test batches are tested and analyzed for structure, moisture, and nutrition up to the specified acceptable limits. There is complete equipment to deal with whether there are defects or contaminations in the production process, and if product breakage or deformation occurs, it can be effectively handled. The system of this method is fully documented to achieve a high degree of clarity and traceability. This strong process of quality control measures is very useful to ensure the integrity, safety, and quality of the cornflakes produced.

How is the final product tested?

To inspect the finished product, I use a step-by-step process to maintain high quality. First, I conduct a sensory evaluation, which involves tasting the cornflakes to test their flavor, crunchiness, and other factors. In addition, I conduct laboratory tests to evaluate the nutritional content and moisture content according to our recommended health standards. I use state-of-the-art technical equipment to pinpoint the presence of any contaminants or defects in the cornflakes, which helps ensure that only the best quality products are supplied to the market. Finally, all results are documented in a structured and organized manner, as this also helps improve quality.

What ensures food safety?

To produce high-quality and safe cornflakes, certain important measures and technical parameters must be strictly followed. First of all, it is very important to comply with food safety, following standards such as HACCP to foresee and control hazards. The hygiene of the equipment is ensured through constant cleaning and disinfection. Parameters include controlled environmental safety characteristics, namely temperature and humidity to avoid any possibility of contamination. For example, the relative humidity in the production facility may be around 15% to prevent mold infestation. All raw materials are microbiologically checked for contamination and strict pest control measures are also taken. The batches produced in large quantities are recorded, which helps in traceability history and also facilitates recalls. These protocols, along with others, guarantee the ultimate safety and quality of cornflakes.

How do you add seasoning to nachos?

The addition of flavorings to cornflakes is a method that enhances the taste of cornflakes without reducing the nutritional value of the cornflakes. First, corn kernels are taken as raw materials and pre-cooked with flavoring substances, which can be natural extracts, sugar, salt, or a mixture of any substances, depending on the taste of the final product. They add the flavorings to the cooked corn kernels, which are then crushed and toasted. This process enhances the retention of flavors through the Maillard cooking process, thereby improving the taste. This quality is maintained through various processes, among which the desired quality is achieved through flavor retention measures. Finally, a mixture of flavor-coating materials and sweeteners is applied to the cornflakes before undergoing the final drying cycle.

What types of seasonings are commonly used?

In cornflake production, the most important flavors are honey, cinnamon, or vanilla. Honey flavor can be created by adding pure honey or honey powder, which adds flavor without being too strong. Cinnamon can be added to cornflakes as a powdered spice or cinnamon extract. Vanilla can be provided through vanilla extract or vanilla bean powder to add a sweet and floral flavor to cornflakes. In addition, flavors including chocolate or fruit can be created using cocoa powder, fruit flavors, and concentrates to increase the variety of flavors. The ingredients for these flavors must be precise: the amount of sugar is generally recommended to be no more than 10% to achieve the desired sweet but healthy composition, and the natural flavorings used should meet food safety standards regarding the content of “common additives”.

How does the seasoning process work?

The seasoning process in cornflake production is a carefully planned operation that begins with the preparation of a seasoning mixture that complements the basic flavor of cornflakes. First, some raw materials are used together with some flavoring substances such as sugar, salt, and malt extract, and carefully proportioned to ensure that the sensory properties do not vary from batch to batch. During this process, this mixture is emulsified into the corn grits and, due to the heat, the Maillard reaction occurs, which naturally enhances the flavor. After cooking, the cornflakes are further toasted to enhance the flavor and obtain a special crispness.

After the flavor base has settled, other flavors, such as fruit essences or chocolate, are added by spraying to achieve uniformity. Some of these parameters are optimized to avoid flavor deterioration; spraying pressures are typically between 20 and 60 psi, while room temperature is maintained between 70 and 85 degrees Fahrenheit. This is followed by a long steam contact drying phase, the main purpose of which is to fix the flavor; the drying temperature is fixed between 250 and 300 degrees Fahrenheit to achieve the best taste with minimal impact on texture. Nevertheless, at this stage and the next, there is a quality control system in which sensory and technical (such as chromatography) evaluations are used to maintain flavor texture and safety standards.

What is the final step in cornflake production?

The last stage in the production of cornflakes is the packaging stage. After the cornflakes go through a drying stage that helps preserve the flavor, they are cooled and moved to the packaging area. At this stage, the product is prepared for the market by being weighed, sealed in packs, and properly labeled. Therefore, this stage is not only the last stage of production but is also important in protecting the product from the factory to the consumer’s table.

How to package the baked flakes?

To maintain the quality of the baked flakes and extend the shelf life of the flakes product, the baked flakes are packaged. After the flakes cool, they are sent to an automatic packaging machine. Here, the flakes are divided into several portions and then sealed in bags made of multi-layered material that protects against moisture, air, and oxygen. The crispy taste and rich taste of the flakes are not affected by this material. After packaging, the sealed bags are placed in boxes, which are labeled with nutritional and marketing information about the product. During the packaging process, we implement several quality control measures to ensure that all packaged goods meet the specified standards.

How to ensure shelf life?

There are various ways to extend the shelf life of cornflakes and the quality of the product. Based on my practice and research, it is recommended to package the product in an airtight container. This packaging must be made of a material that is resistant to moisture and light. These two factors contribute to the presence of air and moisture, which are the main causes of cornflakes’ spoiling and deterioration. In addition, providing constant temperature and humidity levels during storage and transportation reduces the risk of both extremes. Quality control is regularly performed at each stage of production and packaging so that when the end user receives the cornflakes, they are processed and packaged to be fit for human consumption.

References

- Discovery UK – How to make cornflakes

- Spring – How do they make nachos?

- Making.com – Corn flakes production equipment

Frequently Asked Questions (FAQ)

Q: What are the main raw materials for producing cornflakes?

A: The main raw material for corn flakes production is corn, specifically corn flour made from whole corn kernels.

Q: How is corn cleaned before it is used in the cornflakes production line?

A: The corn is cleaned through a series of steps to remove impurities and ensure that the corn is suitable for human consumption when making breakfast cereals.

Q: What are the initial steps in the cornflakes process?

A: The initial step in the corn flakes process is grinding the corn into a fine corn meal, which is an essential part of the production process.

Q: How are cornflakes formed during the production process?

A: Corn flakes are made by extruding and puffing corn flour and then flattening it using a flattening machine to create the characteristic shape of cornflakes.

Q: What role do temperature and humidity play in the production of cornflakes?

A: Temperature and humidity are key processing conditions that affect the texture and quality of corn chips, ensuring they are crispy and ready to eat when they reach the final product stage.

Q: How are cornflakes dried during the manufacturing process?

A: Corn flakes are dried using a high-temperature oven and forced convection continuous tumbling method to achieve the desired bulk density and crispiness.

Q: What quality standards do cornflakes meet before packaging?

A: Corn flakes meet strict quality standards for flavor, texture, and appearance, ensuring they are a high-quality breakfast food suitable for human consumption.

Q: How are cornflakes transported within the production facility?

A: Corn flakes are transported through the production facility on conveyor belts, allowing each stage of the production process to be completed efficiently.

Q: What happens if the cornflakes production line is temporarily shut down?

A: If a cornflake production line is temporarily shut down, it may move to a new phase permanently, or adjustments may be needed to return to normal operations.