The fiber laser cutting process has greatly impacted different fields of precision manufacturing. This next-generation technique utilizes a laser beam created through an optical fiber, which provides unmatched precision, efficiency, and adaptability. Unlike traditional cutting systems, fiber lasers outperform in working with various materials, from metals and alloys to non-metals. This makes them very useful in the automotive, aerospace, construction, and electronics industries. We will evaluate the significant concepts of fiber laser cutting systems, their benefits, the innovations in their applications, and explain why these systems are a fundamental instrument in modern industrial processes. Whatever your level of interest, this article is crafted to focus on how fiber lasers impact the world of precision engineering.

What is Fiber Laser Cutting and How Does It Work?

A fiber laser cutter is a highly accurate and effective cutting machine for different materials like metals, plastics, or composites. The cutting is done by a laser beam generated and focused by fiber optics. The core mechanism works on the principle of light amplification through a doped optical fiber that contains the element ytterbium. The fiber works as the gain medium, where the Ytterbium is used to obtain an intense light source, which is then transferred to the cutting material using flexible fiber cables.

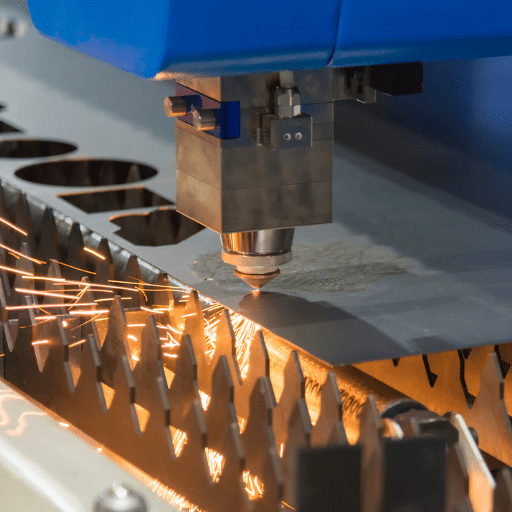

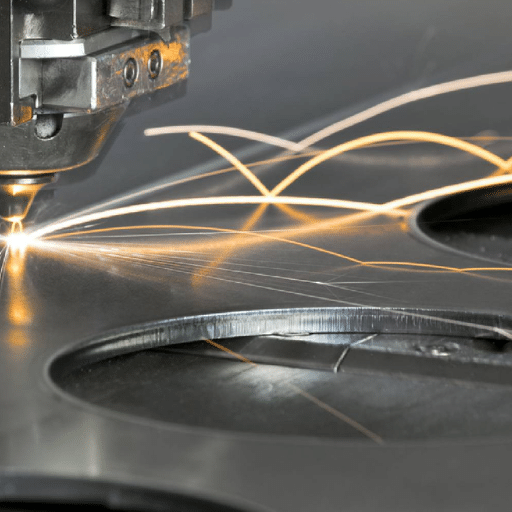

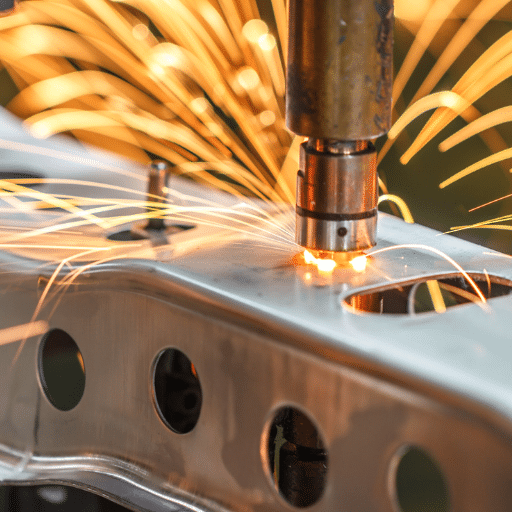

First, the laser source produces a powerful beam of light which is then passed through a collimating lens system to focus the beam on the material’s surface. The energy from the laser will melt, vaporize, or even combust the targeted materials, allowing the laser to make accurate and clean cuts. When cutting is done with fiber laser systems, assist gasses such as oxygen or nitrogen are usually used to boost the cutting. These gasses have specific functions like removing the molten materials, preventing oxidation, and reducing edge quality.

A fiber laser cutting system is appropriate for its speed and thermal distortion, along with the precise intricacy of the structure. Containing power from a few tens of watts to several kilowatts, fiber lasers are versatile because they are capable of fine engraving and cutting metal sheets. Their flexibility makes these lasers valuable in modern manufacturing environments.

Basics of Fiber Laser Technology

A fiber laser generates laser light from optical fibers containing rare metal elements like Ytterbium. A laser beam is guided into the optical system and is characterized by its high intensity and stable wavelength. This beam is then used to target items with precision, allowing efficient energy transfer during cutting or engraving processes. By using assist gases, cutting efficiency is improved because debris is cleared away, along with providing oxidization-free products. These features make fiber lasers more industrial-friendly.

The Fiber Laser Cutting Process Explained

The fiber laser cutting process entails focusing a laser beam on surface of a material, which is then used for cutting or engraving. The fiber laser cuts by delivering a powerful beam of light and uses its high energy to reflect against non-reflective surfaces such as steel, aluminum, brass, and copper. Fiber laser uses a lens to funnel the laser beam and cuts at the range of 1.06 µm to maximize its power. This range is perfect for cutting glass and provide extreme levels of focus accuracy. Fiber laser cutting lenses maximize the beam and capture it at a focal spot of 0.01 mm to boost efficiency.

Below are several technical parameters relevant to the cutting prpocess:

- Power Output: This parameter is somewhere between 500W to 50kW based on thickness of the material and the application.

- Cutting Speed: The type and thickness of material play a major role in cutting speed. Generally, however, weak metals cut between 10 and 60 per minute.

- Focal Position: The focal position cut has to be modified to accommodate each material. It is done by placing the point below the surface of the material, which enhances the level of cutting efficiency.

- Assist Gas Types:

- Oxygen (O₂): The most common gas utilized in cutting steel the increases oxidation, which leads to an efficient cut, but creates more slag.

- Nitrogen (N₂): Used in non-ferrous metal cuts that need to be clean and free of oxidation.

- Compressed Air: This is a thin alternative appropriate for less demanding, high-edged quality materials, where precision cutting is not necessary.

- Beam Mode (M² value): Having M² values near one means low M², which is a close approximation. This indicates that the beam can cut with high precision.

- Thickness Capability: Fiber lasers can cut through 40 mm of material, depending on the power and properties of the material prop.

Components of a Fiber Laser Cutting Machine

- Laser Resonator: The main component has the power to craft the laser by amplifying light. Optical fibers that have emitted rare elements like “Yb” are routinely used to generate the right intensity and wavelength.

- Beam Delivery System: This system consists of mirrors or optical fibers that transport the laser from the resonator to the cutting head with high precision and focus while losing as little energy as possible.

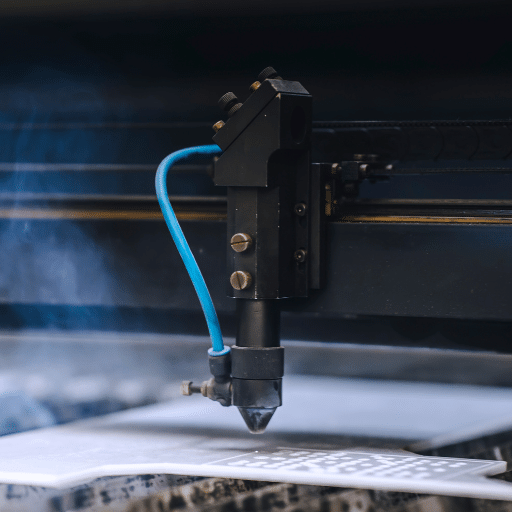

- Cutting Head: The nozzle systems that incorporate assist gas delivery. The lens and focus mechanism that the cutting does not miss and fogs up at optimal points for easier cutting.

- CNC Motion System: Every cut made with a CNC system fits within calculated numbers and precision lines. The system’s motion System refers to the framework that moves the cutting head and material table to the computer’s specified coordinates, enabling intricate and high-accuracy cutting patterns.

- Chiller Unit: This unit ensures stable performance while extending a machine’s lifecycle by regulating the temperature of critical components through the scattering of heat produced during laser operation.

- Assist Gas Supply System: This system supplies assist gas such as oxygen, nitrogen, or even compressed air to the cutting head to enhance cut quality.

- Control Unit: This provides a user with an interface to the machine’s software. Users can then manage and monitor the machine while customizing the required parameters, such as cutting, automating workflows, and performing real-time diagnostics.

- Material Support Table: This table enables the user to have a sturdy place designed to hold the workpiece securely while it is being processed. Often, slats or grids are incorporated into the platform’s design to ensure the material’s stability and collect waste materials.

What Are the Advantages of Fiber Laser Cutting Over Traditional Methods?

There are notable strengths in fiber laser cutting that make it preferable over traditional methods, no matter the materials used. Fiber lasers give the highest precision cuts while utilizing the least amount of material due to the focused laser beam and motion control systems. Additionally, fiber lasers offer support for various materials, such as metals, plastics, and even composites without needing any tool modifications. Unlike traditional mechanical methods, fiber lasers can operate at higher speeds and with thinner materials. This means a drastic reduction in production time. Lastly, there are no tools in contact with the materials while cutting is done, which reduces any additional wear and tear alongside the maintenance costs. The future and modern needs of a manufacturer are met with fiber lasers as they use up less energy and is also economical.

Higher Cutting Speed and Precision

Machining demands tight tolerances, where something needs to be crafted with high precision and in a limited time frame, making fibler laser cutting cut above the traditional means. Since fiber lasers focus a wide range of high energy into a small beam, a higher cutting speed with complex designs is provided on a variety of materials with minimal thermal distortion. Fiber lasers are the perfect solution for industries that need speed and precision, along with reduced material wastage and higher accuracy.

Enhanced Efficiency and Reduced Operational Expenses

Fiber lasers pose significantly lower energy consumption when compared to conventional cutting methods and less energy usage, reducing overall operational costs. The overall efficiency comes from advanced beam delivery and smart power modulation. Further, the expenditure is lowered through cutting down on various maintenance consumables such as spare parts, cooling, and other resources. This makes it a desirable option for long term usage in industrial settings.

Cutting Different Materials With Precision

Cutting a broad scope of materials with fiber lasers is possible because of their impressive efficiency and accuracy. These include stainless steel, plastic, ceramics, aluminum, copper, and brass. The power density of fiber lasers as well as their ability to produce clean cuts on both thick and thin materials makes them universal in some sense. In addition, fiber lasers can cleanly and reliably work with most reflective materials while having very low chances of back reflections. This makes them ideal for industrial applications, from automotive and electronics manufacturing, to jewelry making.

How Does Fiber Laser Cutting Compare to CO2 Laser Cutting?

Fiber laser cutting has numerous advantages over CO2 laser cutting. The major components of fiber lasers are solid state and they convert a greater portion of input power into a cutting power. Cutting speed is also greater than CO2 lasers, cutting thinner materials much more quickly, increasing productivity. In addition, fiber lasers have very low maintenance compared to CO2 systems, which have mirrors and lenses that require regular replacement. One of the best features of fiber lasers is their unmatched durability. They have a more robust design, enabling them to last much longer than CO2 lasers. While CO2 lasers still have their place in the industry, especially for the cutting of non-metals, fiber lasers are progressively being preferred due to their unmatched accuracy, speed, and cost effectiveness for industrial use.

What Makes Fiber and CO2 Laser Technologies Different

The most notable differences between fiber and CO2 laser technologies are their operation, use, and performance efficiency methods. A fiber laser design uses a solid-state configuration that procures energy from optical fibers that have been ‘doped’ with rare earth elements. This design configuration results in energy of a higher grade being emitted with a higher power fiber lasers severally outperform CO2 lasers in terms of energy conversion efficiency reaching 25-30% as opposed to CO2’s 10-20%. In addition to this, fiber lasers emit light in the ~1µm range, whilst CO2 lasers work with a 10.6µm range which leads to fiber lasers offering more precision and enhanced material absorption, significantly when cutting metals and demanding alloys such as aluminum, brass, and copper.

On the other hand, CO2 lasers are ideal for cutting nonmetallic materials in wood, plastic, and glass products since they benefit from the longer wavelength. Nonetheless, they require more attention as every part of the system needs maintenance; mirrors, lenses, and seals need replacement as they deteriorate. For fiber lasers, those are consumable parts so they require minimal maintenance leading to less expense in the total cost of ownership.

Fiber lasers outperform CO2 lasers when it comes to thin materials, as they can cut through metals with up to 5 mm of thickness at a speed that is 3-4 times faster than CO2 lasers. CO2 lasers are on par with fiber lasers in cutting non-metallic, thicker and more complicated substrates. In addition, fiber lasers are more durable and energy efficient, giving them an edge over their CO2 counterparts in industrial applications. This is why industry standards that clamp down on precision and speed are turning to fiber lasers.

Material Suitability: Fiber Laser Vs CO2 Laser

- Metals: Fiber lasers have a decisive advantage when it comes to metal processing, as their wavelength is better suited for reflective materials like Aluminum, bronze, and copper. This results in effective cutting while reducing the number of heat-affected zones, and CO2 lasers do not cut reflective metals directly. Specialized settings or coatings are needed to achieve substantial results.

- Non-Metals: CO2 lasers are most efficient in cutting and engraving wood, glass, acrylic, and plastics. Since these materials have a longer wavelength, they cut and engrave precisely. Fiber lasers do not provide efficient results for non-metals, as they can melt the material or fail to penetrate sufficiently.

- Reflective Materials: Fiber lasers are practical and efficient when dealing with reflective materials, greatly minimizing the chances of damaging equipment from beam reflection. CO2 lasers, however, must be used carefully when working with reflective surfaces, as improper alignment may reflect beams that can damage the primary laser components.

- Material Thickness: Fiber lasers, which are more efficient and speedy for materials under 5 mm, can tackle weaker materials. CO2 lasers, conversely, are more trusted with thicker materials and perform better in non-metals since their energy distribution is effective for deeper penetration.

- Surface Finish: With fine metals, fiber lasers can cut more sharply and craft better precision products while reducing dross on edges. For wood and plastics, CO2 lasers can provide smooth finishes, making them favorable for sculptures, signage, and decorative products.

Cost-Effectiveness and ROI Comparison

CO2 lasers serve non-metal wood, acrylic, and plastic applications, especially where thick cuts need to be made at a lower cost due to the lasers’ versatility. However, fiber lasers tend to work more efficiently when dealing with metals as they have a higher return on investment. Furthermore, fiber lasers also possess a lower need for maintenance, higher energy efficiency, and faster cutting speed on thinner materials. Ultimately, I determine what laser is cost effective based on the tasks to be done, types of materials to be worked on and overall expenses.

What Materials Can Be Cut with a Fiber Laser Cutting Machine?

Fiber laser cutting machines are incredibly flexible and able to cut several types of materials efficiently and accurately. They are mostly used for stainless steel, carbon steel, aluminum, brass, and copper because steels are easier to work with. Reflective metals are tough for other laser types to process, however, fiber lasers master this task without breaking a sweat. There are some non-metal materials, such as plastic, that fiber lasers can cut with specialized processes. Still, fiber lasers are seldom used in non-metal cutting compared to CO2 lasers. Their versatility in processing materials of differing thicknesses may makes fiber lasers more desirable for industrial purposes.

Metals Suitable for Fiber Laser Cutting

- Stainless Steel: Precision cutting machines using fiber lasers can provide clean edges and cuts on stainless steel, making them favorable for use in industries for both decorative and functional purposes. Completely effortless when dealing with thin sheets and heavy plates, fiber laser cutting machines excel in thickness variations while providing speed and accuracy.

- Carbon Steel: Carbon steel is a very versatile and strong metal, which makes it easy to work with even when fiber lasers are used. In addition, the technology cuts down the amount of burr that is formed, and the thermal distortion that takes place. This ensures that intricate designs and components can be created to esthetically please several industries.

- Aluminum: Fiber lasers cut aluminum sheets quickly despite their difficulty and reflectiveness. Advanced laser cutting technology makes smooth and accurate cuts in thin to medium aluminum sheets by reducing reflections during the cutting process.

- Brass: Fiber lasers easily cut brass sheets, unlike other types of lasers, which rarely work with this metal. These lasers have low cutting defects and high operational speed, which is perfect for processing small parts with detailed features efficiently.

- Copper: Fiber lasers are efficient when it comes to working with copper’s high reflectivity and thermal conductivity. Copper sheets can easily be used for electronics and other precision work due to the clean edges produced by fiber laser cutting.

Non-Metal Materials Suitable for Fiber Laser Machining Operatives

- Plastics: Fiber lasers can cut acrylic and polycarbonate plastics. Their accurate control means warping and discoloration are kept to an absolute minimum. Because of this, fiber lasers work perfectly for cutting components for consumer goods, packaging, and even sign making.

- Wood: This does fall under the umbrella of fiber lasers, but wood cutting and engraving are not usually done with fiber due to its lesser efficiency. However, high-precision furniture design, models, and decorative prototypes can be done with minimal charring and can be optimized with minimal charing at set parameters.

- Ceramics: Fiber lasers are capable of processing high-precision ceramics primarily for marking or engraving. Imprints in electronics and medical devices require clarity and durability of details. Lasers help achieve these criteria.

- Composites: Fiber lasers can cut and process composite materials for aerospace, automotive, and sporting goods. No fiber fraying or material distortion occurs, so clean, precise machining is available on these advanced materials.

- Glass: The power of the laser is precisely controlled, and glass surfaces can be wrought or engraved with no risk of splinters or cracks. Additionally, it is easier to make decorative features, serial numbers, and brands on glass products.

Limitations and Challenges in Fiber Laser Cutting

Fiber lasers are claimed to be more effective, but they do have limitations and challenges. For instance, specific sorts of aluminum, copper, and brass are highly reflective, which makes cutting them challenging. The laser beam may get reflected back into the system which could cause serious damage. The disadvantages also include the high investment required to set up fiber laser systems. This can be a disadvantage for smaller companies. Moreover, while fiber lasers are accurate, they are less effective than other types for thick material cutting. Finally, the need for routine maintenance and skilled operators, in addition to these systems’ operational complexities, could pose issues in fully utilizing a fiber laser system.

How to Choose the Right Fiber Laser Cutting Machine for Your Needs?

It is essential to evaluate primary aspects a fiber laser cutting machine must satisfy to ensure it fits your operational requirements. Start with the materials and thicknesses you intend to process, as it will affect the machine’s required power and ability. The level of detail, cutting speed, compatibility with various materials, and the machine’s reflective metal capabilities will also be influential factors. Analyze the software features, automation ease, useability, and optimization workflow. It is also essential to consider the technical support availability, maintenance services, and the machine’s durability to reduce downtime. lastor, check the alignment between the budget and the cost of the machine. Ensure the budget meets the requirements while achieving long-term cost-effectiveness.

Factors to Analyze Before Purchasing A Fiber Laser Cutter

A fiber laser cutting machine’s ideal power output must be gauged about the type and thickness of the material. For example, a 1kW laser is needed for stainless steel up to 6 mm thick. However, materials over 12mm will likely need 3kW to be cut with speed and accuracy. As for aluminum or copper, ensure that the machine can counter-back-reflection by including specialized beam delivery systems.

Precision is critical in industries with tight tolerances, and high-end machines offer an accuracy of ±0.03mm and a repeatability of ±0.02mm. Their build and motion control systems influence the precision that can be achieved, which is often in microns. Lastly, cutting speed is dependent on laser power. For example, a laser of 4kW can cut 1mm stainless steel sheets at speeds greater than 35m per minute.

Software integration has a huge role in boosting effectiveness. More advanced systems have nesting optimization, remote monitoring, and even CAD/CAM compatibility. Automation does have its limits, but material loading/unloading systems increase productivity, particularly in mass production settings. Reliability and durability also matter, as strong machines made from good materials ensure low maintenance cost and high operational lifetime. At the same time, technical support availability should also be considered to minimize operational downtimes.

The last step to solving the puzzle is matching all of these to your budget. This takes into account not only the sticker price but also the total cost of operating, such as energy usage, replacement parts, and maintenance, to find the perfect balance between investment and performance.

The Power of a Laser and Its Capacity to Cut

Power achieved in cutting is highly reliant on laser power; this means that the capability of cutting through various materials depends on the efficiency and speed achieved in the process. Laser tools with a configuration above 4kW are considered the most useful for industrial activities because they can cut thick metals like steel and aluminum quickly and efficiently. For example, one can effectively use a Mild steel with a thickness of 25mm, Stainless steel 20mm, and aluminum 16mm, all depends on machine setting alongside material type and quality. Precision cutting also shifts the quality of the beam, often termed beam parameter product (BPP); much lower BPP indicates sharper cuts.

The absorption characteristics of the material being cut is also crucial. For instance, metals such as Aluminum reflects more, hence higher intensities from the lasers have to be manipulated, failure to which will result in energy losses. Advanced pulse modulation techniques and nozzle designs stabilize the cutting process. Ensuring the appropriate gas pressure is essential. For stainless steel, nitrogen or oxygen are required to cleanly cut through the metal by assisting oxidation or preventing dross formation. Considering these parameters seriously ensures that performance is enhanced and production targets are met with less resources.

Evaluation of Automation and Software Features

Automation systems such as robotic loaders and unloaders should be considered to properly evaluate a modern laser device’s features. These advanced tools enable control software to increase the precision of laser cuts by continuously optimizing the cutting paths and adjusting other relevant parameters to real time material variations. Incorporating feedback hardware components enables thorough diagnostics and machine monitoring which aids in predicting machine maintenance, thus reducing machine failures. All these factors are classified as Integrated monitoring tools, which, when aggregated, lead to an increase in productivity and reduction in operational costs, all while maintaining high standards of cut quality. All these features are critical to contemporary manufacturing processes.

What Are the Applications of Fiber Laser Cutting in Industry?

Cutting with fiber lasers is popular in several sectors because of their accuracy and high speed. They are widely used in the automotive industry to cut engine parts, body panels, and complex structures. The aerospace industry is able to process super alloys such as titanium and aluminum with laser beams with unparalleled accuracy and precision. Fiber lasers are essential for metal fabrication in many manufacturing steps, where custom parts and complex designs are produced. This technology is additionally used in electronics for cutting thin slabs of other materials and in jewelry where very little heat is needed to work with delicate materials. Fiber lasers are crucial for many fields that require high repetition and exceptional edge quality.

Laser Cutting Through Fiber Lasers In The Manufacturing of Automobiles

Using fiber lasers in automotive manufacturing has improved the effectiveness and accuracy of the production process. Because of its cutting speed, fiber lasers can easily cut and shape components such as engine parts, exhaust parts, and even some structural parts of the automobile with very low material loss. This method is also beneficial for cutting and forming steel and aluminum, both critical for strong and safe automobile structures. In addition, fiber laser cutting can design and produce lightweight components critical for better fuel economy. The technology enables constant quality, shortened production time, and decreased costs which all prove to be pivotal in the current automotive production processes.

Applications in Aerospace and Defense

Laser fiber cutting is used in aerospace and defense sectors because of its ability to fabricate and process precise intricate components. This technology is deployed in cutting and contouring high strength alloys and advanced composites for aircraft and defense hardware. The capability to produce complex geometry with low tolerances guarantees optimal design and reliability for these applications. In addition, fiber laser cutting reduces scrap yield and cycle times, thus providing cost savings and greater efficiency. Its utilization aids the rigorous industrial requirements for quality and performance, making it an important instrument in these demanding technology areas.

Fiber Laser Cutting In Donation of Electronics And Medical Equipment

Due to its unmatched precision and flexibility, fiber laser cutting has emerged as a critical method for spectacle-making in the electronics and medical devices industries. High-powered laser beams intricately cut precise shapes into different materials like metals, plastics, and composites. Fiber laser cutting is highly valuable in the medical and electronics fields as it guarantees consistent quality while reducing unnecessary heat. Fiber laser cutting is highly useful in medical and electronic fields as it enables the production of microscale components such as circuit boards and connectors. The beauty of fiber laser cutting lies in its efficiency when used to craft surgical instruments, implants, or stents and the smooth finish that guarantees minimal risk of contamination. Moreover, fiber laser cutting can enhance scaling due to the easy prototyping and mass production of components needed in high demand industries.

Reference sources

Frequently Asked Questions (FAQs)

Q: What is a fiber laser machine and how does it work?

A: A fiber laser machine is a type of laser cutting system that uses a solid-state laser to generate a high-powered beam. It works by transmitting laser light through a fiber optic cable, which is then focused onto the material being cut. This technology allows for precise and efficient cutting of various materials, especially metals.

Q: What is the difference between a CO2 laser cutter and a fiber laser cutter?

A: The main difference between a CO2 laser cutter and a fiber laser cutter lies in their laser sources and applications. CO2 lasers use a gas mixture to generate the laser beam and are better suited for cutting non-metallic materials like wood and acrylic. Fiber lasers, on the other hand, use a solid-state laser and excel at cutting metals, especially reflective ones like copper and brass. Fiber lasers are generally more efficient and require less maintenance than CO2 lasers.

Q: What types of materials can a fiber laser cutting system handle?

A: Fiber laser cutting systems are versatile and can handle a wide range of materials. They excel at cutting various types of metals, including mild steel, stainless steel, aluminum, copper, and brass. Some fiber lasers can also cut certain non-metallic materials, though they are primarily used for metal cutting applications.

Q: How do cutting parameters affect the performance of a fiber laser machine?

A: Cutting parameters play a crucial role in the performance of a fiber laser machine. These parameters include laser power, cutting speed, focus position, assist gas pressure, and nozzle type. Adjusting these parameters allows operators to optimize the cutting process for different materials and thicknesses, ensuring the best possible cut quality and efficiency.

Q: What are the advantages of using fiber laser machines for cutting operations?

A: Fiber laser machines offer several advantages for cutting operations. They provide high precision, fast cutting speeds, and excellent edge quality. Fiber lasers can be game-changers in terms of energy efficiency, as they consume less power than other laser types. They also have lower maintenance requirements, longer service life, and the ability to cut reflective metals that are challenging for other laser types.

Q: How does the cost of a fiber laser cutter compare to other laser cutting equipment?

A: The initial cost of a fiber laser cutter is generally higher than that of CO2 laser cutters. However, when considering the total cost of ownership, fiber lasers can be more economical in the long run. They have lower operating costs due to their energy efficiency, reduced maintenance requirements, and longer lifespan of components. For businesses with high-volume metal cutting needs, the investment in a fiber laser cutter can often be justified by increased productivity and reduced operating expenses.

Q: What safety considerations are important when operating a fiber laser cutting system?

A: Safety is paramount when operating a fiber laser cutting system. Important considerations include proper enclosure of the laser to prevent exposure to the beam, adequate ventilation to remove fumes and particles, use of appropriate personal protective equipment (PPE) such as safety glasses and gloves, and training for operators on safe machine use. Additionally, implementing safety interlocks, emergency stop buttons, and following manufacturer guidelines are essential for maintaining a safe working environment.

Q: How do fiber lasers compare to CO2 lasers in terms of cutting speed and quality?

A: When comparing CO2 and fiber lasers, fiber lasers generally offer faster cutting speeds, especially for thin to medium-thickness metals. They also provide excellent cut quality with minimal heat-affected zones. For thicker materials, CO2 lasers may still have an advantage in some cases. However, advancements in fiber laser technology continue to improve their performance across a wider range of material thicknesses.

Q: Can fiber laser cutting machines be used for applications other than cutting?

A: Yes, fiber laser machines are versatile and can be used for various applications beyond cutting. They are effective for laser marking, engraving, and even welding with appropriate modifications. This versatility makes fiber laser systems valuable for businesses that require multiple processing capabilities from a single machine.

Q: What factors should be considered when choosing between different laser cutting systems?

A: When selecting a laser cutting system, consider factors such as the types of materials you’ll be processing, required cutting thicknesses, production volume, available space, budget, and energy efficiency. For primarily metal cutting applications, a fiber laser system is often the best choice due to its speed, precision, and ability to cut reflective metals. However, if you need to cut a wide variety of materials including non-metals, a CO2 laser or a combination of both technologies might be more suitable.