A CO2 laser is one of the most efficient and precise lasers utilized in multiple industries for cutting, engraving or marking tasks. Its main operating principle consists of creating a high-energy light beam penetrating the material, allowing for accurate and clean cutting. This article analyzes the main aspects of how CO2 lasers work, including the functions of its parts, the physics applied in the laser cutting process, and the reasons behind its variability of effectiveness. When readers finish this article, they will understand how CO2 lasers operate, and how precisely they are used in modern manufacturing and fabrication systems.

What is a CO2 laser and how does it work?

A carbon dioxide laser or CO2 laser is a type of gas laser that implements carbon dioxide as the main component. It excites a mixture of gases: CO2, nitrogen, and sometimes helium, with an electric discharge that puts the CO2 molecules into a higher energy state. While in this state, the molecules eventually cool down and go back to their base level. As they cool down, they emit infrared light at a wavelength of roughly 10.6 microns. This light is amplified by mirrors in the laser cavity to form a coherent, high power beam. This beam is ideal for cutting, engraving, and welding materials due to its energy and precision.

Learning the basics of CO2 lasers

CO2 lasers convert electrical energy to optical power using a carbon dioxide gas medium. The process starts with electric excitation of the gas molecules, which causes them to activate in an excited state. These molecules then emit their energy in the form of infrared light, which is used to create an exceedingly high-energy focused beam. This beam can be utilized for manipulating materials due to its precise and constant power and short wavelength.

How Carbon Dioxide Affects Laser Generation

Carbon Dioxide is a fundamental component of operation in CO2 laser, as it acts as the main lasing medium. Under an electrical field, CO2 molecules are excited to specific vibrational energy states called asymmetric stretch and bending modes. These transitions give off infrared radiation at 10.6 micrometers, which is the operational output of the laser. The efficiency of this process is influenced by the gas mixture containing about 10-20% CO2, 10-20% nitrogen (to increase excitation), and a small proportion of helium (to assist in thermal dissipation). Overall laser efficiency is typically around 10-20%, and power outpAccounts for some watts to several kilowatts depending on the system design and intended purpose. Collectively, these parameters guarantee the delivery of a stable high energy beam suitable for industrial and medical applications.

Main Parts of A Laser Cutting Machine

- Laser Resonator: The laser resonator contains the gas mixture (CO2, nitrogen and, helium), and the electrodes that ionize the gas molecules. It is the main feature where the laser beam is produced, assuring the constant energy output and stable beam quality.

- Cooling Systems: Unlike other components of a cutting machine, a laser cutter’s cooling systems prevent overheating by controlling the temperature of the resonator and other components sensitive to heat. Methods like water cooling are the easiest to incorporate.

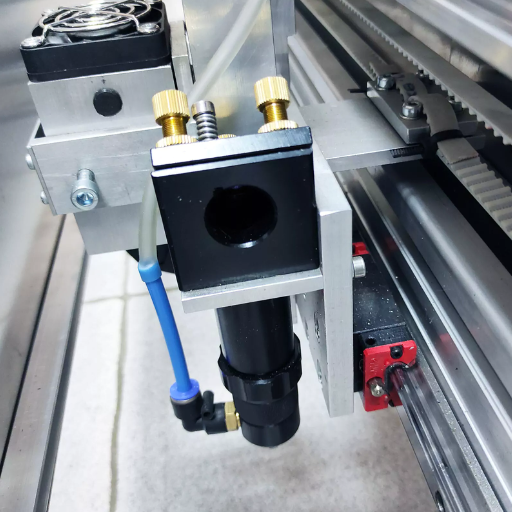

- Cutting Head: With the cutting head, the focusing lens aims the laser beam into a defined area (spot laser) on the material. It has an opening that releases inert gases, such as oxygen, nitrogen, or argon, to remove molten material and enhance the cutting process.

- Beam Delivery System: A beam delivery system consists of mirrors and lenses that accurately focus the laser into the cutting head. Coaxial alignment of these elements ensures proper fitting of all parts into the laser cutting machine for maximum energy efficiency and precision during work.

How does the CO2 laser cutting process actually work?

A beam of infrared light created in a laser’s resonator is focused and released, beginning the CO2 laser cutting process. This focused beam is directed through a beam delivery system and aimed at the material through the cutting head. The pointed laser burns melts or vaporizes the material while concentrating light to create extreme heat. At the same time, inert gases are released through the nozzle to remove any molten material and ensure the cuts are clean and accurate. In order to adapt to the kind and thickness of material being cut, gas flow, cutting speed, and laser power must be precisely controlled.

The Journey of The Laser Beam: From Generation to Material

The generating process of the laser beam starts when the mix of gasses, usually CO2, nitrogen, and helium, is placed inside the resonator cavity. The mixture then receives an electrical discharge for energizing and light is produced. The generated light reflects back and forth between the mirrors placed inside the resonator which again amplifies the light. The laser beam already received a lot of energy while reflecting back and forth, but further energy increases while exiting the beam delivery system. From here, the mirrored lenses and other components will help maintain the precision of the beam. Once the laser beam is formed, it can be focused by the cutting head on to the material. At this point, the intensity of the laser beam is sufficient to vaporize, oxidize, or melt the material.

Using a laser beam to achieve precise cutting: The process explained

Cutting with a laser beam requires one to focus the beam first. This simply means concentrating the beam’s energy on the material of focus. For this procedure, a lens or a curved mirror resides in the cutting head to assist in placing the focal point. The focal point is placed specifically on the surface of the cut material. It helps to determine whether the material is, melting, oxidizing, or vaporizing. When working with different material thicknesses, adjust the alignment and focus accordingly. There is always a hope for high kerf quality edge with proper adjustments. A few factors that affect the precision include lens quality, beam diameter, and the distance between the lens and the material being focused on

How different materials react to CO2 laser cutting: The Science behind it

Other physical and chemical properties of the materials determine how a material would react to CO2 laser cutting. Things like energy absorption, thermal conductivity, and melting point will differ for various materials. Take metals as an example. Due to their high reflection strength and conduction, most metals demand a higher laser power output. Non-ferrous metals like copper and aluminum are on the more advanced side of the cutting spectrum. To slice these metals oxygen needs to be used as an auxiliary gas to improve energy absorption via oxidation.

By and large, plastics and polymers can absorb energy and therefore have good compatibility with CO2 laser cutting. In comparison, cutting thermoplastics such as acrylics results in nice, clean edges; in other words, these edges are free from jagged parts. Materials like PVC, however, are dangerous because they may emit poison fumes during the cutting process, making them difficult to cut.

CO2 lasers achieve the required accuracy on organic materials like wood or paper by rapidly putting in energy, which evaporates the material with as little burning as possible. Essential factors for achieving cutting accuracy are laser power, which for moderately thick materials ranges between 100W and 400W; cutting feed, speed, beam focus, and assist gas like nitrogen or oxygen that might be required for the special material. Proper calibration ensures a high-quality cut while minimizing thermal swell for the surrounding area.

What materials can be cut or engraved with a CO2 laser?

CO2 lasers offer great versatility because they can engrave or cut several materials. Commonly used materials include wood, paper, leather, and acrylic, all of which allow the CO2 lasers to process non-metals quickly. Some fabrics and glass can also be worked with, but the engraving on glass needs special attention to temperature settings to evade cracking. Some plastics, including polycarbonate, can be processed but need particular parameter settings to avoid burns. Furthermore, polished metals, ceramics, and composite materials can be engraved easily, making CO2 lasers an ideal choice for different industries and artistic endeavors.

Best materials for CO2 Laser Engraving and Cutting

- Wood: All kinds of wood are efficient materials for CO2 lasers. Wood can be cut precisely with a lot of sharp details and engraved as well. Different types of wood, like plywood, hardwood, and MDF, need different power settings and laser timings for best outputs.

- Acrylic: Cast and extruded acrylic can both be used with CO2 lasers; however, cast acrylic is superior to extruded acrylic when it comes to engraving. Acrylic is very popular when people need the CO2 laser because it is easy to cut and engrave the edges with a polished finish.

- Leather: Both synthetic and natural leather can be cut and engraved easily with CO2 lasers, providing the precision needed. Leather can be utilized in fashion and upholstery, making very customized designs. Moderate power needs to be supplied to avoid scorching the leather.

- Fabrics: Cotton, polyester, and felt are well suited for intricate designs and laser cuts as they do not fray. Different lasers have different power requirements, so the settings should be able to be increased or decreased depending on the thickness of the fabric.

- Paper and Cardboard: These materials are perfect for fine engravings and artistic cuts and are also useful for packaging boxes and other craft projects. Low-level lasers must be utilized to avoid melting the material too quickly.

- Glass: Glass cannot be cut but can be frosted or textured into a design by engraving with the correct speed and power settings. Special coatings can enhance engravings even more.

- Plastics (e.g., ABS and polycarbonate): Some types of plastics can be cut and engraved with CO2 lasers as long as the parameters are set carefully. Thin sheets of plastic can be cut with CO2 lasers and the surface can also be engraved without burning or discoloring it.

- Coated metals: CO2 lasers can engrave on painted, anodized, or coated metals. These are usually used for ID tags, signs, and other decorative purposes.

- Ceramics: CO2 lasers can engrave ceramics as long as the engravings are deep enough to have fine lasting surface etching. The material does not sustain much damage as the CO2 laser is set at an optimal power level.

- Composite Materials: CO2 lasers can edit composite materials like fiberglass by cutting and engraving at an industrial or prototyping level.

Limitations: Materials you should not use CO2 lasers with.

- Metals (Uncoated or Bare): CO2 lasers have issues with uncoated metal because it tends to deflect sunlight, which leads to improper engraving and cutting. These materials might need coating before use or require fiber lasers. For these materials, coating is optional, but most likely essential.

- Polyvinyl Chloride (PVC): PVC is considered hazardous and has a high temperature propensity. A cooling factor would only release chlorine gas, which is dangerous to the operator and corrosive to the machines.

- Polytetrafluoroethylene (PTFE): When cutting or engraving, PTFE, also known as Teflon, emits dangerous fumes. The time it takes to engrave and cut poses material challenges in the long run by causing great health risks and slowing the degrading of equipment.

- Glass-Reinforced Plastics (Certain Types): While some fiberglass-based composites can be utilized, super dense specialty glass-reinforced plastic have the possibility of molting and releasing poisonous particles and fumes at the sight of a CO2 laser.

- Food Items: Edibles can never fall in the range of CO2 usage since they pose a contamination risk while lacking food grade endorsement.

- Reflective Materials: Some alloys and mirrors are highly reflective, so they can reflect a laser beam back into the machine. This can potentially cause serious harm to the optics and laser source.

Cutting Capabilities Comparison Between Thick And Thin Materials

There is a difference in the performance of CO2 lasers while cutting both thick and thin materials due to differences in the beam’s incorporation and the thermal effect. In CO2 lasers, thin materials which include sheets of metal or plastic up to a few millimeters thick can be provided with precise and clean edges alongside minimal heat-affected zones (HAZ) managed. When cutting the thin materials, the highly concentrated beam will almost instantaneously vaporize the thin layer, reducing the materials’ deformation. In contrast, the speed must be reduced to cut thick materials, and the power settings must be increased. The greater depth of the material uses up the heat, thus increasing the chances of a larger HAZ creating rougher edges and melting and warping into these materials. When working with different material thicknesses, focusing on the laser power and cutting speed is important for consistent quality.

What are the advantages of using a CO2 laser cutter?

CO2 laser cutters are exceptional in their ability to cut and etch materials. Their focused laser beam is able to reach a tolerance of 0.001 inches. This outstanding precision in detail makes them ideal for cutting complex shapes and patterns on wood, leather, acrylic, and even engraving stainless steel. Furthermore, their operational cost is low compared to other cutting technologies, and the maintenance is minimal, which increases their practicality and value in an industrial and artistic setting. With the speed at which CO2 lasers carve patterns, intricate designs can be crafted quickly, allowing bulk production. Non contact cutting guarantees no harm to materials and ensures quality and longevity throughout. Having high-edge quality CO2 lasers does not require any post-processing, which saves a great deal of time.

Ability to cut and etch on a wide range of materials

Carbon dioxide laser cutters are perfect for cutting materials like wood, metal, leather, glass, and acrylics. Their operational functionality employs focus lenses for lasers that allow sharp focus when etching or cutting into materials. A standard CO2 laser cutter has a wavelength ranging from 10.6 micrometers, which is effectively absorbed by non-metallic materials like wood, greatly enhancing efficiency while trying to accomplish such tasks. Overall effectiveness is improved because loss during processing is reduced.

The diversity in the range of materials like wood with 0.5-inch thickness, acrylic with 0.6-inch thickness, and even thin metals that can be coated, for example, allow for engraving versatility. By tweaking the power of the laser, the engraving depth and cut quality can be modified. The majority of commercial machines usually have anywhere from 30 to 150 watts. For instance, lower power levels (30-50 watts) are useful for delicate pieces, while intricate detail cuts (100-150 watts) can go deeper into thicker pieces.

Cutting speed, commonly between 10 and 300 mm a second, depending on the material, is supplied consistently, while adjustable parameters like frequency enhance output. The CO2 laser lenses focus and expand automatically, allowing for the ability to easily handle a range of material thicknesses without sacrificing edge quality. CO2 laser machines are well known for their precision, adaptability, and versatility, making them sought after for both industrial production crafting and artistic use.

Efficiency and speed in the industrial applications

CO2 laser cutters increase speed and efficiency in an industrial setting by automating high-precision and repetitive processes. Their high-speed material cut and engraving processing is further augmented by being able to set their working speed to when and where it is needed most, whether it is in a micro or macro working environment. Moreover, with the use of automated systems and software, human work is minimized, enabling reduction of time and mistakes made. This efficiency is furthered by the constant quality of the engravings and cuts, which reduce the need for secondary processing and boost productivity in demanding industrial settings.

Cost efficiency in different scales of production

By improving precision cutting, lowering energy usage while working, and needing less frequent maintenance, CO2 laser cutters are a cost effective solution at any output scale. Their ability to use different materials without much refitting makes them economical for micro-scale projects and large-scale manufacturing. In addition, automation, together with CAD integration, makes production highly efficient, which saves money on labor and lowers operational costs.

How do CO2 lasers compare to other laser technologies?

One of the major advantages of CO2 lasers over fiber or diode lasers is specific applications where CO2 lasers are much better. For example, CO2 lasers cut and engrave non-metal materials like wood, glass, acrylic, and textiles exceedingly well thanks to efficient edge smoothening and high precision provided by the lasers. CO2 lasers are more versatile than fiber lasers, which are more common for metal processing because of their wavelength and high efficiency in reflecting metals. Moreover, fiber lasers often consume more energy to complete a specific task than CO2 lasers, which makes these technologies optimal based on the material being used and production demands. The initial investment to acquire CO2 laser systems is significantly lower, making it more appealing for businesses focused on non-metal parts manufacturing.

CO2 vs. Fiber Lasers: Primary Differences and Uses

The technical parameters and applications of CO2 lasers and fiber lasers vary from one another, and this sets them apart from each other. The wave length of a CO2 laser is 10.6 microns. They are widely known for cutting and engraving nonmetal materials such as wood, plastic, and glass. Fiber lasers, on the other hand, use a wavelength of approximately 1.6 microns. This makes them very efficient for metal cutting, marking, and welding for steel, aluminum, or other sheath metals.

Fiber lasers usually have a higher energy transfer rate than CO2 systems, making them faster, reducing maintenance costs, and costing less in the long run. Their compact design elevates their value in industrial applications focusing on metals. As a result, fiber lasers are much more helpful and appealing than CO2 systems. On the contrary, CO2 lasers are less effective on reflective metals, such as aluminum and copper.

In terms of power efficiency, CO2 lasers have an everyday wall-plug efficiency of about 10-20%, in contrast to fiber lasers which can achieve 30-40%, creating a remarkable difference in long-term energy savings. Even so, CO2 lasers still possess advantages in industries with non-metal materials because they are more versatile and effective in these applications . The decision between the two systems questions production, materials, and money.

CO2 Laser’s Comparison with Other Gases Laser

Due to their robust output and cutting, welding, and engraving efficiency, CO2 laser are industrial workhorses. Compared to gas lasers such as HeNe or Argon Ion, CO2 lasers achieve much greater power levels- typically in the kilowatt range while the others are usually power limited to milliwatt ranges. This showcases the industrial utility of CO2 lasers as opposed to HeNe and Argon Ion lasers used in alignment, holography, and laboratory work due to their precision but lower power. Furthermore, CO2 lasers emit 10.6 micron light which is unmatched in intensity by the visible light output of other gas lasers, making it infrared light. The large difference in penetration eliminates the difficulty of using different materials as substrates for cutting and welding compared to the other gas lasers. Their operating conditions suit it best for various materials and more complex industrial processes.

When to choose a CO2 laser over other cutting methods

I mainly focus on precision laser work while working with non-metal materials such as wood, acrylic, glass, or textiles. I consider a CO2 laser the most efficient for achieving versatility and precision. Since CO2 lasers output infrared light, which is very efficiently absorbed by the substrates, they perform exceptionally well in contour cutting and achieving intricate designs. Additionally, they perform best when it comes to offering smooth, high-quality finishes. It’s more efficient and cost-effective than mechanical contact cutting because it doesn’t require physical contact, thus reducing a major risk of tool and material damage. Overall, CO2 lasers are ideal for tasks that require precision.

How to choose the right CO2 laser cutter for your needs?

In order to find the best CO2 laser cutter for your needs, you have to check several vital aspects, such as the type of materials that will be used, power output, and applications. First start with the type and thickness of the material you will use because that will determine the laser power. For delicate or thin materials, lower powered lasers are sufficient, but for dense or thick materials, higher power is necessary. Then, evaluate the cutting precision and speed of the various models on offer so that you can choose a model that corresponds to the detail and size of your work. Moreover, bed size, software, and maintenance must suit your operational processes. Budget and operational costs like energy use and replacement parts are also crucial for long term sustainability. In the end, buying this type of CO2 laser cutter increases efficiency and improves output quality.

Considerations: Power, bed size and the cutting space defined above

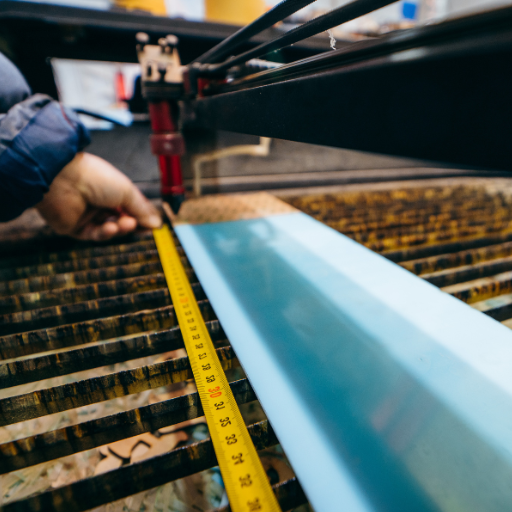

When assessing power demands, matching laser peak output to the specifications of the material and project is vital. For instance, a 40-60W CO2 laser cutter works fine for engraving and cutting thin materials like acrylic, plywood, or fabric. However, thicker materials like hardwood or metal usually need more powerful machines, often exceeding 100W, to make fast, clean, efficient cuts.

Bed size and, by extension, the cutting area determine the machine’s ability to accommodate larger materials or multiple items simultaneously. Common choices in the market for small-scale projects or confined work areas have a bed size ranging between 12″x8″ and 24″x12″. For large-scale commercial applications, larger cutting areas such as 48″x36″ or even 60″x40″ become necessary to accommodate extensive designs or batch processing.

These parameters, alongside build quality and precision range, define the machine’s efficiency, making the selection process critical for sustaining both immediate and long-term project needs. It is always advisable to verify if the parameters meet the expected workload for optimal performance and scalability.

Tailoring laser specifications to your intended use

Selecting the right machine tool for a project requires considerable thought about the type and thickness of material you will be cutting as well as the speed and accuracy of cutting you want. For example, engraving usually uses about 30-60W of power, but thicker materials like hardwood or metal may require over 100W. Also remember, large projects will require beginning with larger cutting areas, whereas small projects are initiated in compact cutting areas. Other important factors are the machine’s life, maintenance, and availability of software features that fit the project’s requirements. If all these specifications match the correct laser, application efficiency, long-term value, and others can be achieved.

Finding a sweet spot in cost and features without sacrificing quality

When balancing cost and features to achieve optimal performance, it is essential to prioritize functionality and efficiency without overextending the budget. Begin by identifying core requirements and focusing on features that directly impact performance. Avoid unnecessary extras that inflate costs without adding measurable value. Compare options to ensure scalability, reliability, and quality align with the desired budget constraints. Evaluating maintenance and long-term operational expenses is also critical, as lower upfront costs can sometimes lead to higher lifecycle expenditures. This strategic approach ensures a cost-effective solution while maintaining essential performance standards.

Reference sources

Frequently Asked Questions (FAQs)

Q: How does a CO2 laser work?

A: A CO2 laser, or carbon dioxide laser, works by electrically stimulating a gas mixture containing carbon dioxide. This stimulation causes the CO2 molecules to emit infrared light, which is then focused into a powerful beam. The laser beam is guided by mirrors to the laser head, where it’s concentrated onto the material being cut or engraved. The intense heat from the laser beam vaporizes or melts the material, creating precise cuts or engravings.

Q: What are the main applications of CO2 lasers?

A: CO2 lasers have a wide range of applications. They are commonly used for cutting and engraving various materials such as wood, acrylic, leather, and fabric. In industry, they’re used for cutting metals, welding, and marking. CO2 lasers are also used in medical applications, such as laser skin treatments and surgical procedures. Additionally, they’re popular in hobbyist and small business settings for creating custom products and artwork.

Q: How does a laser cutter work with a CO2 laser?

A: A laser cutter using a CO2 laser works by directing the focused laser beam onto the material placed on the work bed. The laser head moves along X and Y axes, guided by computer-controlled motors. As the laser beam interacts with the material, it vaporizes or melts it, creating cuts or engravings according to the design input. The power and speed of the laser can be adjusted to accommodate different materials and achieve various cutting or engraving depths.

Q: What is the difference between CO2 laser and fiber laser cutting?

A: The main differences between CO2 and fiber laser cutting are the wavelength of the laser and the materials they can effectively cut. CO2 lasers produce a longer wavelength (around 10.6 micrometers) and are better suited for cutting non-metal materials like wood, acrylic, and fabric. They can also cut thinner metals. Fiber lasers have a shorter wavelength (around 1.064 micrometers) and are more efficient at cutting metals, especially reflective ones like aluminum and copper. Fiber lasers generally offer higher precision and faster cutting speeds for metals.

Q: How does a CO2 laser machine handle engraving and cutting?

A: A CO2 laser machine can perform both engraving and cutting by adjusting the laser’s power, speed, and focus. For engraving, the laser beam is set to a lower power and moves quickly, removing only the surface layer of the material to create an image or text. For cutting, the laser power is increased, and the speed is typically reduced, allowing the beam to penetrate through the entire thickness of the material. The machine’s software controls these parameters, allowing for seamless switching between engraving and cutting tasks.

Q: What safety precautions should be taken when using a CO2 laser machine?

A: When using a CO2 laser machine, several safety precautions are essential. Always wear appropriate safety goggles to protect your eyes from the laser beam. Ensure proper ventilation to remove fumes and particles generated during cutting or engraving. Never leave the machine unattended while in operation. Use materials approved for laser cutting to avoid generating toxic fumes. Keep the work area clean and free of flammable materials. Regular maintenance of the laser machine, including cleaning optics and checking alignments, is also crucial for safe operation.

Q: What materials can be cut with a CO2 laser?

A: CO2 lasers can cut a wide variety of materials. They excel at cutting non-metallic materials such as wood, acrylic, leather, fabric, paper, and cardboard. They can also cut thin metals like stainless steel, mild steel, and aluminum (though not as efficiently as fiber lasers). Materials like glass and stone can be engraved but not cut. It’s important to note that some materials, like PVC, should never be cut with a CO2 laser due to the release of toxic fumes.

Q: How does the power of a CO2 laser affect its cutting capabilities?

A: The power of a CO2 laser directly affects its cutting capabilities. Higher-powered lasers can cut thicker materials and work at faster speeds. For example, a 40-watt CO2 laser might be suitable for cutting thin materials and engraving, while a 100-watt laser can handle thicker materials and perform cuts more quickly. The laser’s power also influences the depth of engraving and the ability to cut through denser materials. However, power isn’t the only factor; the type of material, focusing lens, and cutting speed also play crucial roles in determining cutting capabilities.