Magic, isn’t it? Hosting spectacular professional hockey matches and mere ice burning, ice rinks have that magic. And yet, have you ever wondered how you can keep that shine and smoothness off that ice? One word- Zamboni. Zamboni. And not just because any skating event would be incomplete without a Zamboni, but because it is what allows skaters to achieve a flawless glide. This paper examines the history of the Zamboni machine, explains what a Zamboni machine is, and discusses the various innovations that went into creating this equipment and its unique role in providing irreplaceable service around ice surfaces. Are you a person who enjoys ice sports enough to appreciate this ingenious creation or a truthful interest in a known creation? Read on to“ski’’ where it all began and who rose to this angry maintenance challenge that ice presented.

History of the Zamboni

Have you ever wondered what a Zamboni machine is, who invented it, and when it was first introduced? Well, the Zamboni machine was invented by Frank Zamboni in 1949 for ice resurfacing. Frank Zamboni had an ice rink—an ice skating rink in Southern California —and he wanted to make resurfacing the huge patch of ice easy for everyone at the same time. This would be possible by a single machine that shaves the ice, collects it, and provides the facility with the ability to store it, thus transforming the way ice rink maintenance is done. The very first model, informally called Model A, was made possible with materials obtained from old cars and farming tools. Eventually, the Zamboni machine, as a piece of technology, was redesigned to add specific features and is now found in almost every ice rink today.

Invention and Early Development

The ice resurfacing machine, invented by Zamboni in 1949, was revolutionary for the ice rink industry. The first working prototype, Model A, was constructed from parts salvaged from automobiles, including jeeps and surplus military equipment, as well as a 1940s-era chassis. The mechanization process was designed to reduce the arduous task of ice rink resurfacing. It worked by shaving the thin layer of ice, collecting the ice shavings, and spreading a thin layer of water that would freeze into smooth ice.

In the process of continuous improvement, the Zamboni Company perpetually developed and perfected its machines. By 2023, the iconic Zambonis will have covered millions of surfaces and will be used in over 60 countries. Modern Zambonis utilize state-of-the-art technology, with many of them relying on electric motors for environmentally friendly and emission-free operations. The more sophisticated models are outfitted with precision control and GPS-assisted technologies for fully automated resurfacing. The electric Zamboni 650 Series can service and resurface a rink in under 10 minutes, while substantially reducing the noise level compared to gas-powered units of the past.

Not only did the invention revolutionize the maintenance of ice rinks, but it also developed an iconic status synonymous with ice sports, whether it be local recreational rinks or major events like the Winter Olympics or North American hockey games. The Zamboni legacy embodies the lasting impact of the ingenious minds of the Zamboni and his spirit of innovation.

Key Milestones in Zamboni History

|

Year |

Milestone Description |

|---|---|

|

1901 |

Frank J. Zamboni born in Eureka, Utah |

|

1940 |

Iceland Skating Rink opens in Paramount, CA |

|

1942 |

Frank Zamboni begins developing ice resurfacer |

|

1949 |

Model A Zamboni Ice Resurfacer debuts |

|

1950 |

First Zamboni sold to Pasadena Winter Garden |

|

1964 |

HD Series introduces industry-standard design |

|

1978 |

500 Series modernizes ice resurfacing |

|

1988 |

Frank Zamboni passes; family continues legacy |

|

1997 |

Zamboni Merchandising Co. established |

Impact on Ice Rink Maintenance

- Time Efficiency

Zamboni machines resurfacing the rink can take up to only 10 minutes; hence, downtime during events and recreational use is kept to a minimum. This makes for better use of rink schedules and gives a satisfied edge to the crowds.

- Improved Ice Quality

Zamboni machines shave the ice surface evenly and spread a thin layer of water over it. This water freezes to provide the athletes and skaters with top-of-the-line ice quality and maximum consistency, thereby reducing the hazards of uneven ice surfaces.

- Noise Reduction

Modern electric Zamboni machines have a significant advantage in that they generate little noise. This makes the place almost more pleasant for rink operators and spectators alike than the old gas Zamboni models.

- Reduced Environmental Impact

With the introduction of electric- and propane-powered versions, fuel emissions have been reduced to create a more sustainable operation. These developments pave the way for reducing our environmental footprint.

- Versatility and Durability

The Zamboni machines are designed to accommodate rink specifications of all sizes and environments, ranging from small community arenas to large Olympic ice pads. Very durable and reliable, these machines are widely regarded as an essential tool for ice rink maintenance worldwide.

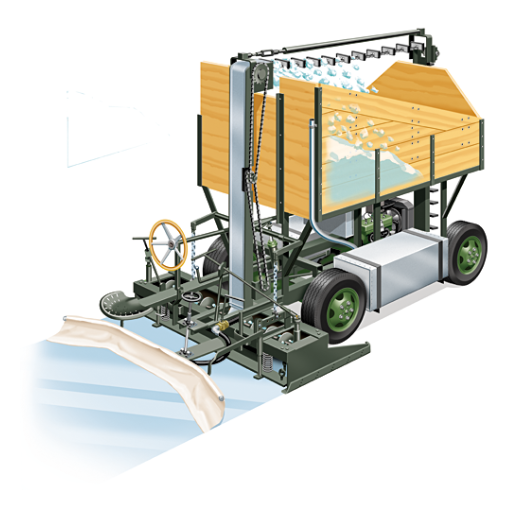

How a Zamboni Works

By slicing off a shallow layer of ice from the surface with a razor-sharp blade and depositing the shavings into a storage hopper, a Zamboni smooths the ice surface by spraying warm water that settles into grooves and irons out imperfections. This water freezes to form a new, even layer of ice. The meat of the Zamboni also involves removing excess water and detritus from the surface, ensuring a clean rink for the user. Its design, however, allows for precise and efficient resurfacing of the ice, making it an absolute necessity for keeping ice conditions of the highest standard.

Primary Function of the Zamboni Machine

The Zamboni machine plays a crucial role in maintaining ice rinks and ensuring ideal conditions for skaters. There are five key functions:

- Shaving the Ice Surface

It would use a razor blade to shave off uneven and rough layers of ice, creating a proper skating surface.

- Collecting Shaved Ice

Shaved ice is then collected in a hopper, preventing it from remaining on the rink and causing imperfections.

- Applying Warm Water

The thin layer of warm water is sprayed by the Zamboni over the ice to fill in the grooves and crack before freezing to provide a perfect surface.

- Removing Debris

It is a perfect method for quickly removing excess water, snow, and debris that could lower the quality of the ice.

- Efficient Resurfacing Design

Efficient resurfacing is achieved through the exact mechanics and design of the machinery, thereby saving valuable maintenance time and depression, and jeopardizing the quality of the ice.

Step-by-Step Process of Ice Resurfacing

|

Step |

Process Description |

|---|---|

|

1 |

Shave ice surface with a sharp blade |

|

2 |

Collect ice shavings into the snow tank |

|

3 |

Spray warm water to fill grooves |

|

4 |

Squeegee water for even distribution |

|

5 |

Lay a fresh water layer for a smooth finish |

The Role of the Zamboni Driver

The Zamboni driver is a crucial position for maintaining the highest quality ice for sporting, recreational skating, and professional-level zonal competitions. The operators operate this machine with smooth gestures, ensuring the surface of the ice formed is immaculate. Having more skills than simply “driving the machine” entails knowing how to maintain, fix, or operate the Zamboni.

Maintaining an ice rink in proper condition ensures safety and consistency. Zamboni drivers have to work against tight deadlines, especially during professional events, where they often have less than 15 minutes to resurface between periods. The industry claims that the Zamboni can clean and resurface approximately 17,000 square feet of Olympic-size rink ice in under 10 minutes. Uneven and poorly prepared ice is a recipe for disaster during a game, or, worse, a hazard to the skater; hence, being precise and efficient is of utmost importance.

In addition, Zamboni drivers frequently walk the rink to examine potential issues, such as cracks, ruts, or other surface irregularities, and then address these defects by feeding water from the Zamboni machine. Such painstaking care softens the ice, allowing it to serve as a smooth, level playing field for the athletes. Furthermore, with the advent of modern Zamboni machines featuring up-to-date technology, such as GPS-guided operation or electric motors, the driver’s job is made easier, and it lends a bit of green tint to the entire activity.

Technology Behind the Zamboni

Efficiency and precision typify Zamboni technology in ice resurfacing. Zambonis have a sharp blade that shaves the ice surface, and while the conveyor system brushes off coarser shavings, finer shavings are washed off with a light spray of water. Hot water then fills in scratches and forms a thin, smooth layer, which freezes quite rapidly and restores the ice’s entire beauty. Today, electric motor drives are available for Zambonis to reduce pollution and allow for the preheating of water and auxiliary melting snow systems, controlled by GPS technology, to maximize performance while considering site-specific ecological footprints. These processes guarantee excellent work and the highest quality of ice to be resurfaced.

Mechanics of Ice Resurfacing

In specific modern ice-resurfacing machines, a thin layer of ice is shaved off, collecting the shavings. It then applies hot water to fill in the scratches and features advanced technology, including GPS and temperature control, to produce smooth, high-quality ice surfaces.

Innovations in Zamboni Design

Over the years, the Zamboni design has undergone significant evolution, with the introduction of modern technologies and improvements in its efficiency, sustainability, and performance. A significant development is the electric-powered system comprising the Zamboni 450 and Zamboni 552AC. This machinery offers an enjoyable alternative to propane or gas-powered models, thereby conserving the environment through its zero-emission technologies.

Water management systems have been introduced to advance, enabling precise control of the water used in ice resurfacing. For example, newer models utilize a dual-blade system to smooth surfaces evenly, allowing for optimal use of hot water recycling technology.

Modern Zamboni machines are now equipped with digital monitoring systems. Armed with GPS technology and sensors, operators track their machines’ working conditions, correct their paths to maximize efficiency, and automatically perform key tasks. This has dramatically reduced the amount of energy required and time spent on ice resurfacing. According to data from the International Ice Hockey Federation (IIHF), arenas may be saving approximately 20 percent in operational costs by switching to these innovative Zamboni systems.

In the future, Zamboni hopes to harness AI and machine learning to achieve a level of resurfacing that is incredibly automated and precise, ensuring that ice quality is consistently maintained in arenas ranging from small local rinks to large Olympic venues. In turn, these developments imply that better conditions for skaters are underpinned by a rising awareness of ecological good within equipment design.

Different Models of Zamboni Machines

|

Model |

Key Features |

|---|---|

|

Model A |

First Zamboni debuted in 1949 |

|

Model B |

Improved design, used by Sonja Henie |

|

Model C |

Elevated driver seat for better visibility |

|

Model E |

First mass-produced Zamboni model |

|

Model HD |

Introduced a hydraulic snow-dumping system |

|

Model 500 |

Liquid-cooled engine, modernized design |

|

Model 552 |

First electric-powered Zamboni |

Importance of Zamboni in Modern Sports and Recreation

Zamboni machines have their place in maintaining the quality and safety of ice surfaces intended for sports or recreation. Efficient resurfacing results in a smooth, even surface, which is essential for athletes participating in hockey or figure skating. High-quality ice also corresponds to decreased threat amplitude, the threat of being injured on uneven or unlevel surfaces. The dependability and efficiency of Zambonis have since made them a must-have piece of equipment in arenas and ice rinks worldwide, catering to professional sports, community events, and recreational skating alike.

Enhancing the Ice Experience for Players and Fans

The modern technologies in ice resurfacing have offered a new experience to both players and spectators. Zambonis today are said to smooth out the ice perfectly and have also been equipped with environmentally friendly technologies to reduce their carbon footprint. For instance, many modern Zambonis have systems powered by electricity or operate as hybrids, which fare better environmentally than the old fuel-guzzling Zambonis.

Statistics state that, on average, a Zamboni performs one run by resurfacing the ice of an area measuring 10,000 to 15,000 square feet, hence delivering ice surface quality from which its perceptions are shaped, catering to the various sizes of the kitchen. Ice thickness is maintained very precisely, typically ranging from about 1 to 1.25 inches for hockey or figure skating, creating predictable conditions that enhance athletes’ performance and mitigate the risks of accidents.

Innovative technologies such as GPS and data analytics are integrated for real-time monitoring of ice conditions by operators. They can adjust water temperature, resurfacing frequency, and blade calibration to further perfect ice conditions. These technological advances help ensure excellent playability from both the players’ and the audience’s perspective, as they guarantee uninterrupted and dynamic games or performances.

Through technological innovation, the synergy of sustainability, precision, and productivity continues to set new standards for ice rinks, supporting lively sporting events and recreational activities.

Zamboni in Professional vs. Recreational Rinks

Several key differences and considerations arise in the employment of Zambonis between professional and recreational rinks. The following represents a detailed breakdown of these distinctions:

- Frequency of Use

- Professional Rinks: The Zambonis operate frequently, resurfacing the ice after every period of a game or after all performances, ensuring the ice quality maintains its superior standing.

- Recreational Rinks: Resurfacing is less frequent, and the standard time intervals for resurfaces may be every few hours or between sessions, depending on user levels.

- Ice Thickness Requirements

- Professional Rinks: The ice is kept at a thickness of around 1 inch, carefully calibrated for uniformity and optimal performance for the players.

- Recreational Rinks: Ice thickness tends to vary; sometimes, it is kept slightly on the thicker side, ranging from 1.25 to 2 inches, to withstand general wear and tear.

- Resurfacer Technology

- Zamboni machines at professional rinks are typically technologically advanced and feature GPS, automation, and environmentally friendly components, such as electric engines.

- They are essentially basic Zamboni machines with manual controls and minimal automation features at recreational rinks.

- Air Quality Standards

- Professional Rinks: Zambonis are more demanding from an air quality perspective, especially in indoor arenas, requiring maximum protection for players and spectators, which can be achieved by using electric or low-emission Zambonis.

- Recreational Rinks: Although air quality standards may exist for recreational rinks, they are generally not as stringent, allowing some facilities to employ fuel-powered models still.

- Surface Area and Time Efficiency

- Professional Rink: Typically of NHL or Olympic size, the Zambonis in these arenas are designed to do an excellent job of resurfacing within 10 to 15 minutes.

- Recreational Rinks: Surface areas vary in size. It is not critical to adhere to the resurfacing time, which is often longer, depending on the equipment and the operator’s skill.

Attributing and assigning differentiation of view to these factors ensures that Zamboni countermeasures and operations are adjusted to the individual requirements of every type of rink, thereby facilitating efficacy, lifetime, and experience further.

Future Trends in Ice Resurfacing Technology

An intriguing future development in ice resurfacing technology is the further evolution of electric-powered Zambonis. The machines are considered environmentally friendly, in keeping with a general trend toward eco-conscious innovation. Other improvements to consider include automating more processes with self-driving machines, which, in theory, could increase efficiency and reduce human error. I see that smart technology with IoT sensors may become more prevalent, enabling on-site monitoring of ice conditions and equipment performance to fine-tune resurfacing operations. What all of this spells out is a big leap forward toward a sustainable and more efficient ice resurfacing process.

References

-

Smithsonian Magazine: The article on the history and innovation of Zamboni machines is detailed and reliable. Smithsonian Magazine

-

Forbes: A comprehensive article on the Zamboni story and its impact on ice sports. Forbes

-

The Hustle: A detailed narrative on the invention and cultural significance of the Zamboni machine. The Hustle

Frequently Asked Questions (FAQ)

What is a Zamboni machine?

A Zamboni machine, invented by Frank Zamboni, is an ice resurfacing machine used to clean and smooth the surface of ice rinks. It removes the top layer of ice and adds a fresh layer of water to create an ideal skating surface for sports like hockey and figure skating.

What does a Zamboni driver do?

A Zamboni driver operates the ice resurfacing machine to maintain the quality of the ice surface during and after hockey games or figure skating events. They ensure that the ice is clean, smooth, and safe for skaters by shaving the ice and adding a layer of fresh water.

How does driving a Zamboni work?

Driving a Zamboni involves operating the machine’s controls to adjust the speed, direction, and functions, such as shaving the ice and dispensing water. The driver must navigate around the rink while ensuring the machine collects snow and distributes a new layer of water evenly across the ice.

What is the purpose of a Zamboni?

The primary purpose of a Zamboni is to resurface the ice, which improves the skating experience by providing a smooth and level surface. It helps maintain the integrity of the ice, preventing ruts and bumps that can occur during hockey games or figure skating performances.

How does a Zamboni machine resurface the ice?

A Zamboni machine resurfaces the ice by shaving off the top layer of ice and collecting the shavings in a snow tank. It then dispenses a thin layer of warm water from its water tank, which fills in imperfections and freezes to create a smooth ice sheet.

What types of Zamboni models are available?

The Zamboni company offers a range of ice resurfacing machines, each designed for specific rink sizes and types. Popular models include the Zamboni 520 and Zamboni 440, which are known for their efficiency and ease of use for Zamboni drivers.

Why is the Zamboni important in ice sports?

The Zamboni is crucial in ice sports as it maintains the quality of the ice surface, ensuring safety and optimal performance for skaters. Without regular resurfacing, the ice would become rough and uneven, negatively impacting games in the NHL and performances in figure skating events.

Where did the Zamboni machine originate?

The Zamboni machine originated from an auto repair shop in California, where Frank Zamboni developed the first ice resurfacing machine in the 1940s. His innovation has since become a staple in ice rinks worldwide, including facilities in Iceland and the Hockey Hall of Fame in Toronto.

What are the components of a Zamboni ice resurfacing machine?

A typical Zamboni ice resurfacing machine consists of several key components, including a sharp blade for shaving the ice, a snow collection tank for ice shavings, a water tank for dispensing warm water, and a vertical auger that helps distribute the water evenly across the surface.