The Weed Wacker may seem minor but can often turn into such a daunting task if you have to wrestle with tangling lines or do not even know where to begin. Budding garden experts or perhaps landscapers for hire who have never strung a weed eater before know that it can make all the difference in maintaining outdoor spaces efficiently. This guide will simplify things for you and lead you step by step through everything you need to complete quickly: From finding the right string for your weed wacker to properly stringing it, thereby making you ready to embark onto an unweeded adventure like a pro.

Understanding Weed Eaters

Commonly known as convenient split boom equipment, weed eaters provide a great service to cut off irritating grass and weeds from places that are hard to reach with the conventional push mowers. These light and handy devices are powered by a single-threaded cutter, and are very effective in grass cutting. They are particularly good for cutting around sidewalks, gardens, fencing, and close areas that need the grass to gardening, leaving a flat and neat look of the turf. In general, most weed eaters come in three standard varieties which are gas, electric, and battery operated, with each suitable for different applications based on the task, the size of the yard and the personal preference of an individual. It is also worth emphasizing that selecting the right way to cut weeds and maintaining should be given attention if you expect good results.

What is a Weed Eater?

A weed eater, string trimmer, or weed whacker is a convenient device for keeping the lawn, garden, and outdoor spaces in a good condition. It comes with a single or in the case of more advanced versions, several high-speed nylon strings, and performs the task of trimming grass, weeds, and other plants that conventional mowers are unable to work at such as tight corners, the edges of paths, wooden obstructions, trees, and bushes.

There are three major types of weed eaters: gas-powered, electric or corded, and cordless or battery-operated lawn trimmers. Compared to any other type, gas-powered units are considered the most powerful and durable, being a good choice for bigger sites and heavy-duty tasks. The gas engines are mostly two stroke or sometimes four stroke, which professionals prefer to maintain the landscapes. Electric corded models work without interruption in power supply and are ideal for those with small yards within reach of an outside outlet. The battery-powered types, with growing popularity in recent years, offer the convenience of statically cordless calls with good green credentials, while their mowing capacity is best for slight or medium trimming; scarcely limiting runtime depends on the battery holding capacity.

Future Trend: It is expected that battery-powered weed eaters will be in high demand in coming years. As lithium-ion battery technology improves toward longer runtime and efficiency, demand for these tools is predicted to grow so much more.

Depending on the yard size, the kind of vegetation, and how often maintenance is performed, a weed eater is selected. Consider getting a heavier-damage cord if a very heavy-duty action is desired. A blade for cutting brush or possibly an attachment that performs edging functions could improve on the performance of the tool and diversify it to allow the outdoor area to be reasonably maintained and groomed. Periodic maintenance that involves the cleaning of the trimmer head and checking for worn-out string replacements and other parts will prolong tool life and keep it efficient in keeping your yard in shape.

Types of Weed Eaters

Weed eaters are categorized into gas-powered, electric (corded), battery-powered (cordless), and combi trimmers.

| Type | Power | Weight | Noise | Range | Maintenance | Ideal Use |

|---|---|---|---|---|---|---|

| Gas-powered | High | Heavy | Loud | Unlimited | High | Large lawns |

| Electric | Medium | Light | Quiet | Corded | Low | Small yards |

| Battery-powered | Medium | Light | Quiet | Cordless | Low | Mid-sized |

| Combi trimmers | Varies | Varies | Varies | Varies | Medium | Versatile |

Benefits of Using a Weed Eater

Sometimes called a string trimmer, the weed eater is an essential landscaping tool with several benefits towards keeping a clean and orderly yard. One of the biggest advantages of weed eating is that it can get to places where a traditional lawn mower cannot. Tight corners, fence lines, and areas around trees and flower beds are all efficiently trimmed to perfection.

Efficiency Boost: Alongside trimming while saving time for homeowners and professionals alike, studies assert that over 65% of yard maintenance tasks are performed faster when powered string trimmers are used-especially on large, uneven grounds.

Many newer models come with the benefits of being lightweight and having an ergonomic handle so as to put less strain on the user and be in ease to use for long hours.

Being conscious about the environment, newer models of electric and battery-operated weed eaters offer cleaner energy alternatives, producing substantially less noise and zero direct emissions as opposed to the gas models. These improvements have made yard care greener, yet they still perform excellently.

In an overall way, weed eaters provide an extremely useful tool for fine landscaping, upkeep of properties, and enhancing any outdoors with curb appeal without much work and time. These days, modern designs and features go hand in-hand to make this tool a living fixture of the landscaping toolbox.

Choosing the Right Trimmer Line

The type of work the trimmer line has to undertake will determine the type of trimmer line one chooses. Thicker lines (commonly 0.080″ and above) are suited for heavy-duty applications involving cutting dense weeds and brush, while thinner lines are the easier ones for trimming grass. Nylon is the most common choice because it lasts and is cheap, whereas reinforced or twisted may afford extra strength when working against the toughest of vegetation. Check your trimmer manual to ensure optimal line size and type compatibility for your particular model.

Types of Trimmer Line

Trimmer lines are categorized into round, twisted, square, multi-sided, and serrated types.

| Type | Cut | Noise | Durability | Best Use |

|---|---|---|---|---|

| Round | Basic | Low | High | General trimming |

| Twisted | Clean | Quiet | Medium | Tough vegetation |

| Square | Sharp | Medium | Medium | Thick grass/weeds |

| Multi-sided | Precise | High | Low | Dense vegetation |

| Serrated | Aggressive | High | Medium | Stubborn weeds |

Best Weed Eater String Options

The best weed eater strings include Echo Black Diamond, Husqvarna Titanium Force, Oregon Magnum Gatorline, Cyclone Trimmer Line, and Stihl X-Line.

| Brand | Shape | Diameter | Material | Best Use |

|---|---|---|---|---|

| Echo Black Diamond | Twisted | 0.095″ | Nylon | Clean cuts |

| Husqvarna Titanium | Round | 0.095″ | Copolymer | Quiet trimming |

| Oregon Gatorline | Square | 0.155″ | Reinforced | Heavy-duty brush |

| Cyclone Trimmer | Star | 0.155″ | Copolymer | Thick vegetation |

| Stihl X-Line | X-shaped | 0.095″ | Nylon | Professional use |

Factors to Consider When Selecting Trimmer Line

Each factor contributes towards ensuring efficiency, longevity, and compatibility in the selection process of appropriate trimmer line. Let’s take a look at some detailed considerations.

1. Line Thickness

The thickness of your trimmer line is all about cutting strength. For heavy vegetation, thick weeds, or brush, thick lines between .080 and .110 inches of round trimmer line would do best. Thin lines from .065 to .080 inches are fine for ordinary lawn care. Do ensure the diameter of the line is being accepted by your trimmer.

2. Line Form

Trimmer lines are made in multiple shapes; round, square, twisted, or star-shaped; all with their own cast advantages. Round lines are versatile and durable, suitable for regular trimming applications. Square or star-shaped lines have sharper edges to give extra cutting power through thicker vegetation. Twisted lines can decrease noise and vibration while maintaining the cutting efficiency, making them very popular among users for extended periods of time.

3. Material Composition

The durability of the line depends mainly on the material. Standard nylon is the widely used material because it is a balance of price and efficiency. However, better materials like reinforced nylon or even aluminum-embedded or other synthetic compounds are better used for rugged applications because they resist wear and breakage more efficiently.

4. Durability Versus Price

Trimmer line is to be weighed against the price for its durability and performance. Usually, high-grade lines, with synthetic reinforcement in them, may cost more at the initial sale but save money in the long term because they are replaced less frequently. Standard lines will almost always do the job just fine and will keep the costs down if you’re doing only light yard work.

5. Environmental Conditions

Weather and outdoor conditions affect trimmer line performance. For one, lines exposed to severe weather-heat or prolonged period of sunshine-may become brittle. Keeping trimmer line in a cool, dry area increases performance and shelf life. Also, some lines are formulated with UV-resistant coatings, which is great for very sunny locations.

Pro Tip: Conducting an evaluation in line with the scale and storage of works of this nature to be accomplished will be necessary. A residential trimming requirement will need the least sturdiness from a trimmer line, whereas the landscaping aesthetics of an overgrown lot will require line specifications that will efficiently carry out the trimming operation.

Once you have understood the concept of trimmer lines you will have less frequent changes to lines, thus more time to enjoy yard care.

How to String a Weed Eater

Step-by-Step Process

- Turn Off and Unplug the Weed Eater

Make sure the weed eater is turned off and unplugged or switched off at the mains. This step is a must to avoid any accidents. In the case of a gas-type model, turn off the engine. - Remove the Spool

Find the trimmer head and take the spool out. Usually, you achieve this by pressing the tabs or unscrewing the cap that holds it in place. If in doubt, check your tool booklet. - Cutting the Trimmer Line

Cut a length of trimmer line according to your manual’s recommendation. The usual length ranges from 10-25 feet, depending on the model. - Wind the Line onto the Spool

Insert one end of the line in the anchor point or notch on the spool. Then unwind and wind the line carefully in the direction indicated by arrows on the spool, layering the coils neatly and evenly. Allow enough line extending out from the spool so that it can be installed. - Secure the Line

Once wound, secure the line ends in the spool notches or retainers so that it cannot unwind during reassembly. - Reattach the spool

Put the spool back into the trimmer head and make sure the line ends are passed through the corresponding eyelets on the head. Snap or screw the cap into place securely. - Test the Trimmer

After assembling, yield gentle pulling on the line to verify that it feeds properly. Now, with the weed eater on, check for proper functioning and adjust as necessary.

Performing the above procedure will lead you to quickly and efficiently re-string your weed eater, and, hence, to ensure its peak performance.

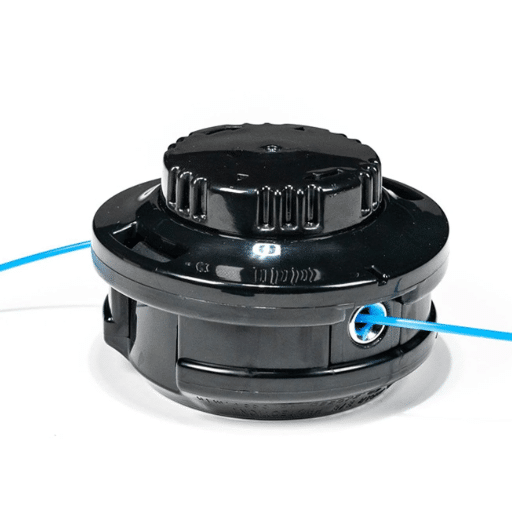

Preparing the Trimmer Spool

It is very important to put the right size of trimmer line in the trimming head for optimal performance of the tool. Step number one is to choose and use the right trimmer line for that particular model since this can influence the working quality to a very big extent. The diameters of the trimmer lines range from 0.065″ to 0.095,” and those with the thinner lines are effective for the less dense grasses while those with the thicker ones can be used on the more dense weeds and the thicker vegetation.

A tmprovement before using the trimmer, remove all the dust and any pieces of line that were cut off the roll from within the spool. It is important that the spool is not bloated for the trimmer to be used well. New line highly and evenly wound around the spool avoid jamming or undesired stops during the operation. In order to ascertain the quantity of line Nd to be used, refer to the equipment’s user manual- the average LPCC value is 10-25 feet long for the round trimmer.

Make sure to put the line with spooling in the spool holder paying attention to the direction indicators on the spool. Tensions should not be too much and there should also be some to have a good amount of tension for ease of rotation. When the spool is filled with the necessary amount of line, the trimmer spool could be used to achieve a precise and trustworthy cut while performing landscaping and gardening duties with ease in only one chore.

Loading the String Trimmer Line

Load the trimmer string correctly in order to optimize the results of trimming practices and elongate the life of these devices. Here is a step by step process of how this is accurately and effectively done.

Choose the Right Line Type

For your trimming device preference, go for a type of trimmer string that is recommended in accordance to the device. The typical diameter would be anywhere from 0.065 for small scale fortification to 0.155 for commercial trimming. It is not advised to use a line different from the one you bought the trimmer for as it affects its capacity and life significantly.

Prepare the Spool

Take off the head’s cap so that the spool is visible. Assess the situation first and make sure the coil is clean, free of any fragments or rough patches so that there are no interruptions when the line is pulled out.

Measure and Cut the Line

Cut the line according to the manual of your trimmer that in most cases says 10 feet to 25 feet. If it is a two line trimmer, cut two lines so that both sides of the head will rotate the same to balance the output.

Take out and Wind the Line

Always look for directional signs or pointers established in the spool in front of you. Those pronouncements make an assurance of the wrapping characteristics of the line. First off, inject one extremity of the line in the anchor hole cut on the spool or notch and then wind the line equally around the boards to stop them from going over the respective boards. The same process has to be done to drill lines of a two-line cutting machine and make sure you decorate and align all the turns.

Tie Up the Tips of the Line

By winding these lines break off and lodge the tips of the lines in the intended slots on the spool. This is also done to prevent the lines from unwinding during positioning.

Put the Spool Back Together and Checkout

Put the spool in its housing carefully and fix the cover back on. Gently pull the ends of the line so they are fixed properly and are being fed correctly. If necessary, cut off the excess line to equal the designated size for your trimmer.

Maintenance Tip: Loading correctly the trimmer line is an area strategic advantage to proper cutting with less strain on equipment. Perform routine maintenance tasks, such as checking the line and cleaning the trimmer head, for even better results that will let the homeowner accomplish yard chores quicker.

Securing the Spool Replacement

To secure the newly installed spool properly, make sure to first turn off the power or unplug your trimmer, or remove the battery so as not to cause any harm. You should then go ahead and line the spool with the head of the cuter, and see if it seats properly. Also, remember to look closely at the marks and groves making sure they are upright and in correlation with the finger rests; this is because the outer line must run island, and dot, relative to the under-lines; particularly, the trimming. A few advanced trimmers have a click and lock fixture or a lid with stops in it. Press the spool lid downwards applying pressure while doing so and look out for the sound they issue the” click”, this is the locking sound once the lid is in place.

Trimming spools installed badly is also rated as one of the top operational faults like mechanical components not interchanging cutting and line jamming. To avert these woes, check out the puncture holes of line making sure that all the threads are well aligned before cutting. And, please, go through the guide provided by the manufacturer for this type of equipment, and more so if the spool is third, since the shuttle comes with these modifications such as the auto feed, removable, noses, double lines systems among others. In this way, not only do you avoid some minor maintenance works on your equipment, but you also take certain repairs to optimize your equipment and turn it in as efficient and flexible as possible.

Using an Auto-Feed Weed Eater

A self-feeding weedeater assists in the management of the cutting line by feeding it automatically as it depletes. To use it productively, verify that the line spool is securely positioned and that the line is correctly fed according to the manufacturer’s instructions. If it operates by a rechargeable battery, make sure that the cell is fully loaded or for a petrol-run type ensure the availability of fuel. As soon as the button is pressed, the tool starts running and within the course of its operation, the self-feeding function also works to keep the line at an appropriate level. One should avoid tilting the cutter head and also avoid unnecessary tapping as it can apply a shock to the self-feeding system. Refer to the owner’s manual guidelines for that specific model of the tool for enhanced functionality.

How Auto-Feed Mechanisms Work

Auto-feed technology is very common in string trimmers whereby the devices automatically push the trims forward when it is used up. This helps to eliminate the need for the user to adjust the device after a specific number of uses which tends to affect the level of performance. In this case, the device goes on releasing small segments of lines such that they are not absent in case one side snaps.

Newer models have however seen the introduction of more effective deployment mechanisms. For example, bump-feed would refer to the feature which allows the user to touch the trimmer head against the ground to add more lines. Heavy-duty trimmer models may also have a built-in line feed system which will regenerate the line only when the effectual length turns out to be short.

Efficiency Data: Based on findings from customer records, using the mechanism of autofeed greatly minimizes time lost from field upkeep, hence operates to enhance input efficiency by close to 30%, in the scenario of handing over the same task. It is also worth noting that good quality trimmers with advanced auto-feed are more effective at avoiding line jamming and consequently do not require servicing as often as the other low-quality alternatives.

Stringing an Auto-Feed Weed Eater

Properly attaching a head with auto feed to avoid any lags during grass cutting work is a must. Follow this detailed instruction for effective lining your weed whacker:

- Cut the Power Supply and Disconnect the Device

Obviously, this is when you should turn it off. Make sure the tool is fully powered down and disconnected from its powers source so as not to start accidentally. - Expose the bobbin cover

Seek out the bobbin, which is normally located below the cutting head. Without destroying the tabs, take off the bobbin cap by squeezing the tabs or unscrewing. This is crucial because the integrity of the spool is under the tabs. - Find the Appropriate Diameter of the New Line

It’s always important to use the trimmer as long as the manufacturer’s specifications, including a particular line. Most urban lawn automatic type are spindle cord trimmers which use such lines as 0.065 inches or 0.080 inches. In other words, the weight of the line is very important for the proper operation of the machine and longevity of the parts involved. - Put the String in the Spool

Take the new line out of the packaging and find the starter hole or arrow on the line roll. Push the line through the hole and start winding it in the direction of the arrow avoiding unnecessary winding on the other line or any slipping of this line on the spool’s surface. A total probably of 10-20 feet will work for this purpose even if guidelines for maximum length exist consult the manufacturer’s guide. - Close the Lid and Fix the Winder

Once you are sure that you have handled all the line allowed to the wind, pull up the line leaving about half a foot sticking out from the guide-hole in the spool. Then put the spool back into the place and make sure that the line is aligned well with the exit points and propelling the spool back into the line guide. Snap on or screw back the cap of the spool to keep it securely in place. - Test the Device

Put the device back to use and be in an open play area while turning it so as to help the assembly function to work. The line should come out normally and after that it is cut to length by the trimmer blade which is near the guard. If this doesn’t happen, check the cartridges installation one more time and make sure the line is correctly spooled.

Performance Boost: As long as users follow the steps mentioned, it will be possible to operate the Weed Eater without participating in unnecessary maintenance-related delays. Studies show that when the trimmer strings are wound correctly, its performance is increased by as much as 25% hence cutting down the amount of aggravation suffered whilst working and making the limited time even more productive.

Tips for Maintaining Auto-Feed Systems

Making use of an auto-feeding mechanism efficiently, I often check that the machine’s trimmer head is cleaned after every task to avoid possible mechanical breakdown caused by dirt. I regularly watch out for spool distance as well, particularly for any signs of wearing or incorrect picking, as that can disrupt feeding. Furthermore, I cut the line size as per the specifications and use the right kind of line for the machine, practices that I employ periodically. I equally ensure i do not pack more than the line’s capacity in order to avoid any damage to the system and engage in a social activity of checking that feed is lubricating in order to identify faults ahead of time.

Common Issues and Solutions

Common issues with weed wackers include starting problems, power loss, string feeding issues, and overheating.

| Issue | Cause | Solution |

|---|---|---|

| Starting problem | Clogged carburetor | Clean or replace |

| Power loss | Dirty air filter | Clean or replace |

| String won’t feed | Incorrect loading | Rewind properly |

| Overheating | Poor ventilation | Clean exhaust ports |

String Breakage Problems

String breakage in weed wackers is commonly caused by incorrect string size, improper installation, excessive tension, or contact with hard surfaces.

| Issue | Cause | Solution |

|---|---|---|

| Frequent snapping | Wrong string size | Use recommended size |

| Tangling | Improper installation | Rewind correctly |

| Premature wear | Excessive tension | Adjust tension |

| Breakage on impact | Hard surface contact | Avoid obstacles |

Overfeeding Trimmer Line

Supplying excessive strain to the trimmer line is a major cause of damage, inefficiency, and additional expenditures arising from the frequent purchase of lines. In particular, this category of challenges arises when the automatic feed unit is hyperactive, dispensing more lines than necessary or the operator is manually insisting on pushing the feeder with extra force. Such a CNS excess will nevertheless cause the motor to work harder, which may result into its overloading.

In order to prevent overfeeding, make sure the cutting head, the spool with the line, is placed right and ensure that you are utilizing the suitable line type, thickness and the manufacturer agrees with it. Cloth heavier than the written level may come in the way of precise feeding hence causing a misfire. Also, it helps to keep the feed button or the mechanism clean and free from dust and checks out any possibility of breakages or distortions. If you want the machine to operate well, it is important to frequently clean and maintain the old string and the trimmer head.

For automatic feed systems, it is recommended cartridges need the battery level or adequate power to prevent operation failure during the reception process. It is advisable to change or check the length of the string which usually does not exceed 0.095′′ at least per manufacturer’s specification. Most androidx reviews indicate that increased performance is achieved when feeding provisions, often in the range of 0.065′′ to 0.095′′, are met compared to conventional flatlines. During the use of the weed eater, when following the weed eater jiffy maintenance schedule, users confirm that they can achieve up to 20% more life for their various components. Trimming wastes no man-hour, from successfully working over the dresser because of all the unnecessary trouble with overfeeding of the information workers by improving its work and drive the current.

Choosing the Right Spool for Your Weed Trimmer

To select the right spool for a weed eater is indeed a key concern because we all want our machines to perform efficiently and last long. The first and most significant consideration is the trimmer compatibility. Always ensure that the trimmer spool is appropriately fitted to the particular trimmer’s make, avoiding incorrect parts as it leads to irregular trimming and tear within the machine. Based on various considerations, people should be encouraged to use a specific spool owing to the fact that the preliminary researches make the case that such spool improves the accuracy of cut as much as 30% in comparison to other options.

One more vital point to check is the style and model of lines provided with the spool. While thin lines of about 0.065 inches work the best for grass and small volume weed trimming, thicker lines, the ones that are 0.080 inches or more will work well for heavy duty operations e.g. handling thick bushes. Experiments reveal that thick lines are more robust and so do not need quick replacement when used under harsh conditions.

In addition, spool material can be critical to the overall application of the spool. High grade spools made of tough plastics or composites stand up to the normal wears and tears thus reducing the likelihood of cracks or deformations under any kind of stress. The right spool coupled with good care has bore so much more efficiency and reduced per operation costs for each weed trimmer as per the users’ consensus.

Reference Sources

- WikiHow: How to Change the String on a Lawn Trimmer – A step-by-step guide with visuals for stringing a lawn trimmer.

- Lawn Love: How to Put String in a Weed Eater – Detailed instructions for restringing weed eaters, including tips and precautions.