What does it take to produce artisanal dry pasta in an Italian Pasta Factory? How are these products made? Why do we use different ingredients for industrial pasta and artisanal pasta?

Introduction to Artisan Pasta

Artisan pasta is a celebration of tradition, hand-craftsmanship and high-quality ingredients. Unlike industrial pasta that is made via a batch process, artisan pasta is made by hand, in small quantities, with a deep knowledge of the raw materials that goes into it: this makes each batch different from the other, a reflection of the local culture and culinary tradition. In Italy, pasta making is not only a culinary art, but a way of life, passed on from generation to generation, from region to region.

Welcome to the Italian Pasta Factory

When you walk inside an Italian pasta factory, you might feel as though you’ve stepped into the pages of a history book. You feel the pleasant smell of the fresh product, hear the rhythm of the machines and the sound of caressing fingers. Making an authentic pasta is a long process that begins with selecting the raw materials, particularly the ingredients for the dough, which should always be the best durum wheat flour.

Understanding Durum Wheat Flour

Durum wheat flour is the backbone of Italian pasta production. Known for its high protein content and gluten strength, it produces pasta that is firm and resilient, allowing it to hold its shape during cooking. The specific characteristics of durum wheat contribute significantly to the texture and flavor of the final product.

Artisan pasta best uses durum wheat. Many of the original grains used in Italian pasta are long gone, so most of the Italian pasta factories blend local grains with imports. The blend is to achieve the right taste and the right al dente texture on the palate.

The Dough Making Process

The magic starts with the dough. Durum wheat flour and water are weighed with the same intensity slowly and steadily. The 100 parts flour to two parts water of simple tomato sauce is also the rule for this dough. Too little water and it is too dry. Too much and it is overly sticky. It is kneaded to perfection, developing gluten, the substance in wheat that gives the pasta its structure.

The dough could then be left to rest — another vital aspect of the process, allowing la gluten to relax a little and be more pliable before shaping the dough. Conscientious bakers might touch the dough to help assess it: la patissiere could use their intuition to feel if the dough was ready to move on to the next step.

Crafting Dry Pasta: The Production Steps

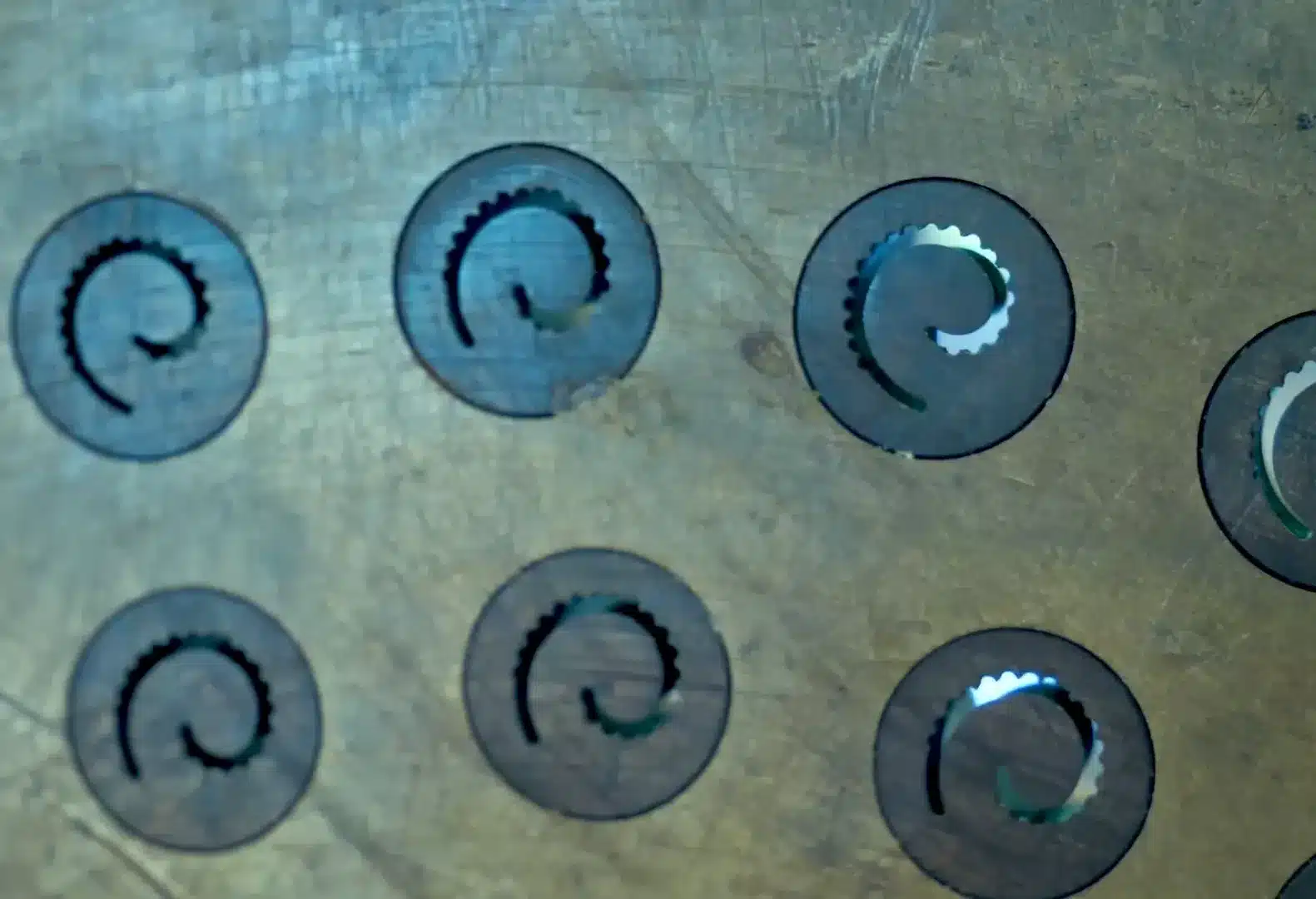

The production process for each one involves numerous steps, and affects the quality of the finished product. Dry pasta is extruded through bronze dies.

Then, shaped by the machine, it is slowly dried at controlled temperatures. Only through slow drying at controlled temperatures can the quality of the pasta be preserved. In many Italian pasta factories, the drying time is as long as 24 hours.

At last, the dried pasta is packaged and ready to be shipped to markets around the world. This is the product of a committed process, experienced craftmanship and cunning. This hard work means that artisan pasta is a culinary treasure. For those who wish to understand the process of making pasta, the transformation of dough into dried pasta is (for want of a better word) fascinating.

For more information about Italian pasta and the various production lines involved, you can visit our other pages, such as Spaghetti Production Line.

The Drying Process of Pasta

This is when the most important change to the material occurs, and getting it right is what sets apart the high-end Italian pasta with its characteristic ‘al dente’ bite, from the more processed forms of pasta. In an Italian Pasta Factory, we see how this is carefully controlled so that the pasta retains its integrity and edibility. The drying takes place at low temperatures, allowing water to evaporate more slowly, which is important both to preserve the taste of the pasta, and to make sure that it cooks evenly.

It usually takes 12 to 24 hours to dry completely, although different pastas require different times (the thicker pastas might take longer). This process creates a deep flavour while the pasta is drying.

Importance of Temperature Control

Controlling the temperature is especially crucial: if it is too high, parts of the product may dry before others, leading to a brittle crust and a soft interior that might impact both the texture and cooking properties of the final product. Drying at a lower temperature allows the pasta to retain its moisture content more evenly, leading to a product that cooks perfectly to al dente.

Not only that, keeping an eye on the humidity in the drying environment is also important; too much humidity will also lead to spoilage or the growth of mould. Drying pasta in a well-ventilated drying room with hygrometers is a common practice in Italian Pasta Factories.

Quality Control in Pasta Production

Quality control is one of the most important steps in the production of pasta, since the Italians pay great attention to its excellence. A thorough testing and inspection procedure takes place at every stage of Italian pasta production, from the choice of raw materials to the packaging of the finished product at the Italian Pasta Factory.

To determine these, the producer runs durum wheat flour through a machine to test its protein, gluten strength and moisture content: all factors that affect the pasta’s texture and cooking properties. But first, the wheat is cleaned to get rid of any impurities such as stones and leaves, and is passed through an optical machine that inspects it visually. There, it is compared against the ideal form of a grain in terms of size, shape and colour. The same visual inspection is later performed on the pasta to ensure that it is uniform in shape and that no pieces are bent or broken.

Testing for Cooking Quality

A further aspect of quality control relates to cooking tests. Pasta will be cooked under formalised conditions and its texture, flavour and cooking time will be tested to ensure that it meets the desired standards, as well as to ensure that consumers will be satisfied with what they receive. Only after the numerous quality checks is pasta suitable for packaging and retailing.

Furthermore, they are always soliciting feedback from chefs and other culinary professionals to hone and enhance the pasta continuously. This way the pasta maintains its authenticity and high level of quality.

Artisanal vs. Industrial Pasta: Key Differences

The distinction between artisan or handmade pasta and industrial pasta is real and is linked to different approaches to pasta making. Romagnoli argues that, when pasta is made the artisan or handmade way, the way it is produced is in line with quality and flavour, while preserving the craftsmanship involved in pasta making. When it is produced industrially, faster and with volumes that are unthinkable in artisan-type craftsmanship, there are always some quality parameters that must be sacrificed for speed and cost reduction.

Craftsmanship in Artisan Pasta

All of these steps are accomplished by hand, or at least with attention to detail by skilled artisans who tend to leave only a minimal amount of mechanical assistance in certain steps (eg, the dough is mixed and kneaded by hand or with the bare minimum of help from a mechanical mixer, the pasta is extruded through bronze dies which give it a rough surface which helps sauces adhere better, and the drying process is slower and more controlled). This leads to a more nuanced taste.

On the other hand, pasta produced on an industrial scale can be ready in significantly smaller amounts of time and with the help of high-speed machines that require very little labour, as well as very little time. The timescale and machinery used in industrial pasta production mean that the product tends to be fairly uniform in shape and size, but it often lacks the characteristics of al dente wheat – a rough texture and above all, taste. Using Teflon dies, industrial pasta often has a very smooth surface that may not adsorb sauces as successfully as its artisanal cousin.

Cooking Techniques for Artisan and Industrial Pasta

The cooking techniques also differ between artisan and industrial pasta (eg, the rougher surface and denser texture of the artisan product require specific cooking methods to achieve ‘al dente’).

For artisan pasta, I recommend always cooking in plenty of salted boiling water in a large pot, with enough space so that it can swell properly without sticking together and cook evenly, to maintain its flavour. Never boil it for less than the cooking time written on the package, as it will require around three minutes longer than industrially produced pasta, because of its greater density.

Industrial Pasta Cooking Techniques

On the flip side, the smoother, finer surfaces of industrially produced pasta cook quickly, often in less than half the time of an artisan product (so make sure to watch the clock, and, most definitely, don’t overcook, when you’ve bought dried pasta). Many chefs suggest checking it a minute or two before the package directions say it should be done, so you can produce an al dente product without an overcooked one.

But whatever type, the secret of good pasta is to boil it in masses of water with salt. This not only improves the flavour, it ensures that the pasta cooks properly. You must also keep back some of the pasta water to add to the sauce, which will help to unite the dish and draw the flavours together.

Enjoying the Final Product: Time to Eat Pasta

Once it has been dried, inspected and cooked, pasta makes its way to the table: al dente spaghetti with olive oil and garlic, or fettuccine with an Alfredo sauce maybe. Whatever. But pasta is the epitome of communal eating.

What’s more, in the Italian kitchen, pasta is often prepared as a primo, or first course of a meal, accompanied by an array of sauces, vegetables and proteins. The beauty of pastas lies in their versatility — it’s light and simple and adaptable to virtually any taste, any time.

For those looking to explore more about Italian pasta and its production, we invite you to visit our website for additional insights and resources, including details on pasta production lines and industry trends.

The Importance of Ingredients in Pasta Quality

It’s the ingredients that make the pasta, and nothing will beat the product of an Italian Pasta Factory made from the best quality durum wheat available. The very best wheat is vitally important when you are making pasta. This is because of its amylose/amylopectin ratio – more so than any other factor. Durum wheat has the highest protein content of all wheat varieties and a very strong gluten structure, which is formed via the combination of amylose and amylopectin. This gluten structure is very important for the elasticity and strength of the pasta, which is what allows it to maintain its shape and not break, giving us the al dente texture that pasta should always have.

Secondly, the quality of the water is essential, not only for the cultivation, but also for the formation of the dough. According to tradition, mineral content and pH of the water can influence the consistency of the dough and, consequently, the texture of the pasta in the end. Local sources are traditionally used by the artisanal producers for this reason: because water characteristics are specific to a given territory, they might align with the flavour and the quality of the pasta.

Choosing the Right Ingredients

Italian Pasta Factories mix different varieties of durum wheat to create the exact flavour profiles and dough-quality they’ve honed over centuries or even millennia, sometimes adding in ancient grains such as Senatore Cappelli, which are full of flavour and nutrients.

Furthermore, due diligence with end ingredients goes further than wheat: pasta made with eggs uses only fresh and quality eggs, while the few additives (if any) are kept to a minimum. This purity enhances taste but also supports the growing trend of clean-label products.

The Role of Quality Control in Pasta Production

Quality control (a cornerstone) of production process in Italian Pasta Factory is essential. From moment ingredients are sourced to final packaging stage, strict protocols are in place to ensure consistency and quality. Each batch (however) undergoes rigorous testing to meet established standards; this is crucial. Although it may seem tedious, the process is vital because it guarantees the product’s integrity.

One of the first quality control checks involves evaluating the durum wheat. This could include checking for protein, moisture content and gluten strength, all of which help determine the quality of the pasta on the plate by affecting its cooking quality.

Continuous Monitoring and Testing

Continuous testing happens throughout the whole process: the consistency of the dough is checked, and the flour dosage might be amended if necessary in order to keep the dough at the perfect texture. Pasta is periodically taken out for cooking tests in order to assess texture and flavour, until it can be given the green light to proceed to packaging.

This high level of quality control, not just because it ensures a product that meets customers’ expectations, but also because it helps to identify how the product can be further refined. The feedback of chefs and culinary critics is integrated into the production line so that the pasta is still handmade yet accommodates evolving tastes.

How Pasta is Shaped and Cut

Cutting and shaping are two stage which are important contributes to look and cooking property of the product.In an Italian Pasta Factory, there are traditionally hand made by skilled artisan are now also partially replaced by modern machine and by traditional technique. This is to make various pasta shapes, from long strands of spaghetti to cut pasta of thick, short shapes such as fusilli.

The action begins when the dough is made. It is fed into an extruder where it is pushed through bronze or Teflon dies. Bronze dies give a rough surface which facilitates the adhesion of sauces, whereas the Teflon finish will give a smoother surface. The choice of die used may well make or break the finished pasta.

Cutting Techniques and Their Importance

Finally, the extruded pasta is cut into the appropriate lengths. This is typically achieved with automated cutting machines, but can also be done by hand when making pasta with a more artisanal bent, such as fettuccine and tagliatelle, for example.

Once cut, the pasta is laid out to dry. This is an important step in the process, as drying brings out the flavour of the pasta and ensures a longer shelf life. Thicker shapes require longer drying times to ensure the dough is evenly dried all the way through.

Exploring the Nutritional Benefits of Artisan Pasta

Artisan pasta not only tastes better and has better textures, it also has several nutritional benefits. Made essentially from durum wheat, it is high in protein and general nutrients, making it a great addition to any balanced diet (containing, in whole grain varieties, lots of fiber).

Furthermore, slow-drying entails greater nutritional stability, since the traditional method of drying promotes preservation, keeping intact the nutritional qualities of goodness offered by the wheat cultivars. The end result is a stellar product from a taste perspective – but also in terms of health.

Understanding Glycemic Index and Satiety

As a result, artisan pasta generally has a lower glycaemic index than its industrial counterparts – which can be good news if you’re managing blood sugar levels, or simply trying to even out your blood sugar highs and lows over the course of a day.

More importantly, the same protein and fibre can help keep you feeling full, and therefore aid in weight control. Paired with vegetables and healthy fats, artisan pasta can be a nutritious meal, gut-friendly and delicious all at once.

Frequently Asked Questions About Artisan Pasta

What makes artisan pasta different from industrial pasta?

Artisan pasta is made the traditional way, by artisan producers concerned with quality and taste, while industrial pasta is purpose-built for mass production, with quality often compromised to achieve economies of scale. Bronze dies and longer drying times produce a rougher texture and greater flavour.

Is artisan pasta healthier than regular pasta?

True, the protein and fibre content of artisan pasta, as well as its glycemic index, tend to be higher than that of mass-produced pasta – which benefits from being stripped of nutrients – and this is due to the high-quality ingredients and traditional methods of production that are remarkably efficient at preserving nutrients.

How should artisan pasta be cooked?

When cooking artisan pasta, it is important to use a large, heavily salted pot of rapidly boiling water. Cooking times may be slightly longer than what is indicated for industrial pasta – usually requiring a few minutes longer, depending on the variety or shape – but test it a minute or two before the package indicates that it is al dente to the bite.

If you want to learn more about Italian pasta production and machines, please visit our website, where the world of pasta production lines setups and systems can be discovered.