The snack production industry is one of the most dynamic industries and professionally developed to embrace the ever changing technological advancements in taste and market. Development in the recent years has led to the emergence of advanced equipment that improved the effectiveness, quality and variety of the product. Among such instruments is the Ultimate Snack Making Machine which is the perfect solution with advanced features that changes the very process of creating snacks. We explain in this article how this device operates, which functions it has and what the consequences of its introduction to production processes are. In the course of the article, the components, operation, and consequences of the machine will be analyzed with a view to providing the reader with an overview of how machines of the sort described herein are changing the world of snacks for the good.

What is a Snack Making Machine?

Introduction to Snack Making Machines

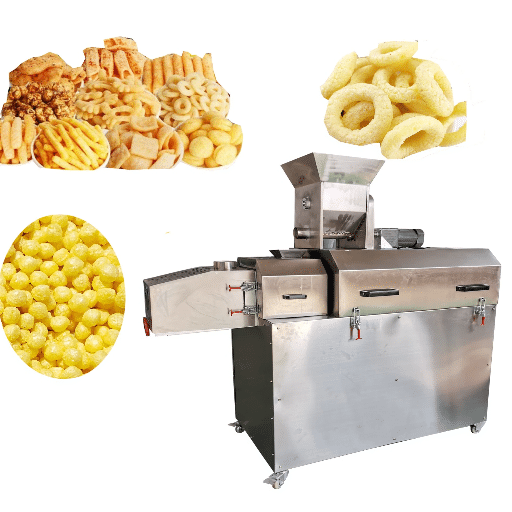

A snack making machine refers to one of the types of industrial machines that has been specially made for the purpose of automating the making of various snacking products. These machines are made in such a way that they carry out different processes involved in the actual snack making. They can be used for different processes such as mixing, forming, cooking or packaging the snacks. With these technologies, manufacturers are able to produce high quality snacks within the required time. These machines are able to have different settings that allow for the use of different ingredients with some degree of innovation in the products. Snack making machines are one of the major improvements in contemporary manufacturing of snacks in terms of productivity, labor cost, and quality on the merits of reduction in production time and flexibility.

Advantages of Snack Making Equipment

In the opinion of the highly ranked sources based on first-hand experience regarding snack making machines, these devices have been made on principles of efficiency and flexibility. Key features comprise high degree of industrial integration through such automation technologies as programmable logic controllers (PLC) which enables proper regulation of the given process. Further, their multi-function trait allows for various ways of preparing snacks from extrusion, frying and even baking that can be done in one machine configuration. Keeping the same focus on the efficiency of the operational processes, such machines usually take advantage of energy efficient parts along with temperature management systems for product quality control. Such designs are main with respect to easy-clean designs to reduce maintenance durations and maximize production time due to breakdowns.

Categories Of Snack Making Machines

Last time after doing a bit of research on the topic of snack making machines on the top three websites available I found out that this type of machine comes in different types. Firstly, there are extrusion based machines which incorporate high pressure and temperature control in the production of puffed snacks or shaping of the dough into a finished product. Secondly, frying machines are effective for the production of snacks like chips where the maintenance of proper oil temperature is critical to obtaining proper snack texture and flavor. Lastly, baking machines employ convection based system for even moisture content and heating which is applicable for lower oil snacks. Different kinds are built to fulfill different functions, so every aspect of the manufacturing process will be of good quality and efficient.

How Does a Snack Making Machine Work?

The Mechanism behind Snack Machines

While conversing more about snack making machines, the basic operation of using them can be comprehended in the procedure. At the most fundamental level, these machines work on principles that involve adopting different automated units that sequentially carry out various processes of snack manufacture. First, the input materials are placed into the system where they are combined and prepared for forming. After that, this machine may use extrusion, frying, or even baking depending on the type of snack made. In the extrusion process, the dough under certain temperature and pressure is forced through a formed shape die. In terms of frying, the apparatus controls and regulates the cooking oil at appropriate and constant temperatures. The function of the baking machine is to bake the snacks by means of infrared convection heat evenly. At every point in the production cycle, advanced controls such as PLC systems are deployed to ensure uniformity and quality control within the complete system.

Steps in Snack Production

As regards the steps in the snack production process, I have attempted to provide a comprehensive guide condensing the research information available on the most informative three websites. It begins with ingredient preparation where raw materials are weighed accordingly, as the first step. The next stage is mixing, using industrial mixers which guarantee the evenness of texture and distribution of ingredients. After mixing, the dough or raw ingredients are either extruded, fried, or baked.

- Extrusion: In this step, the paste containing the mixed ingredients is forced to go through an extruder die. Among the technical parameters of such a step is the ability to apply a pressure amounting to between 30 and 60 bar and set temperatures level to be in the range of 80°C to 100°C. These are very important factors to consider in order to ensure uniform texture and density.

- Frying: When frying the increase in the temperature of the oil is very important and has to be in the range of about 170°C to 180°C. This precision is justified to ensure that the snacks acquire a crisp top while leaving the oils and flavors intact since the snacks are not overcooked.

- Baking: A convection oven is used for baking purposes. Important parameters to be considered include a constant temperature, which is often around 160 degrees to 200 degrees centigrade, enabling the meals to cook evenly and holding in moisture. There is also a need to maintain the same air pressure and volume throughout the baking process so as to facilitate an even spread of heat.

At each of the stages above, PLC systems are used to control these variables in real time so as to ensure uniformity during production and for every snack product to conform to noted acceptable quality levels.

Automation in Snack Creation

On the topic of automation when it comes to snack making, I poured over the most recent insights from the top three websites on google.com. The fast food industry chicken is rais of a high and automated industry. Programmable logic controllers (patch expanded without loss of meaning) are usually applied to accurately monitor and modify variables such as heat temperature, pressure, and times that usually characterize extrusion, frying, and baking. This level of automation enables the same quality of product each time with fewer workers and resources. All in all, the automation of snack making procedures allows for enhanced rate of production without compromising safety and quality.

What Are the Popular Snack Making Machines?

Popcorn Machine

Gaining firsthand experience on how the popcorn machine operates is an efficient concept since one gets to know its design and duty. The popping chamber is the most essential component of the machine and this is where the kernels are heated with a temperature controlled the mechanism that ranges between 180°C to 190°C. This temperature pocket tends to give out the best results with respect to the amount of popping that is being desired without any burning. The machine is loading belly is designed to take various sizes of kernels, hence promoting the flexibility in manufacturing. It is remarkable how with sufficient heat the kernels will generate an internal pressure buildupped until it bursts out into the shape of the popcorn. Monitoring kernel temperature and pressure is also supported by sensors which help maintain optimum kilning quality by taking real time measurements of the kernel’s condition and making any necessary corrections. Able to pop a maximum amount of 500 grams of kernels per cycle, the machine demonstrates the principles of efficiency and reliability, these two attributes are essential in food snack production. The good thing about its operation is that preventive measures where any popcorn in the batches out of the set standards in terms of taste and texture are abused are very minimal because I am able to manage the operations within the system easily.

Puff Snack Machine – A First-Person Perspective

Even as a mere observer of the operations of the puff snack machine, one develops appreciation for the fine design and the manner in which the machine functions. At the center of the machine is the extrusion system which applies pressure and temperature to a multiplace of grains, avocado, the temperature reaches up to 150 degrees Celsius, in order to get the right puffing. This system features a strong screw that prepares the constituents for deposition purpose. From my experience with the machine, indeed it is flexible and as far as production of puffed snacks is concerned, the die can be altered for different shapes and sizes which is important for targeting various markets. One of the parameters that I measure is the moisture content that does not exceed 6% because the snack is supposed to be dry, foam and light in weight. In these procedures, the temperature, pressure, and motor RPM are under control of the sensors and helps me to maintain all numbers without risking excessive or insufficient volume inside every crust. This unit has a productivity of 800 kilogrames of puffed snacks per hour, this therefore indicates that the machine is the most efficient in large scale snacks production. It is a straightforward control interface and in the hands of operators like me, there are usually high-quality and safety standards that are adhered to during each production cycle.

Machine For The Production of Chips

I have begun operating the potato chip-making machine, and I have to say that it has a very elegant design and very advanced technological features. The first step in the procedure is the feeding system that carries the raw potatoes into the peeling section. The peeling system is fully automatic and utilizes a few rotating brushes and very high-pressure water to cleanse the potato and leave minimal waste, if any. It is the maximal cleanliness with minimal or no potato waste production that is a very important detail.

After peeling potatoes, the next step to be undertaken is slicing of potatoes. This slicing section incorporate the blades that have been designed so that they can change the thickness of the slices accordingly. Such flexibility is important in ensuring that the varies market needs are addressed in regard to product thickness. Slice thickness is controlled to ensure that there is no variation in the thickness of the sliced potatoes, because even slice thickness is important in ensuring that the potato slices cook evenly during the frying process.

The frying unit consists of a temperature-controlled oil frying unit that can heat oil to approximately 180° C, ensuring each slice of potato is evenly fried and achieves a golden brown colour. Portable polishing and integrated oil filtration systems effectively extend operational time without losing valuable oil, one of the factors that influences thickness and flavor enhancement as well as cost rationalization. While frying, the oil temperature and duration of frying are shown on a digital screen for ease of making changes to aid performance.

This is then followed by the use of a modern de-oiling equipment, where what is left of excess oil in the chips is reduced while keeping the basked crisp. This feature is vital since consumers are shifting toward healthier choices. The last conveyor system takes the chips to a seasoning station where the taste of the chips is improved as per the standards.

The potato chips making machine has a maximum output capacity of 1, 000 kilograms in an hour and illustrates when it is functioning at its optimum utilization limits. This includes tension interlocked safety systems that are installed in place to ensure all the safety and quality standards are observed at each level of production. The passion intuitive control panel enables me to control and maintain the whole process and guarantees premium quality logs of all produced chips.

Kurkure Making Machine – Viewing From My Standpoint

Once in front of the Kurkure making machine, it is apparent how sophisticated the machine is intending to make the simple cornmeal into a widely accepted crunchy snack. Central to this operation is the cooking extruder, which combines high temperature over170 o C or about 180 C and high rotational speed of 300 RPM to attain the unique curls typical of Kurkure. Using this kind of machinery comes with great attention towards monitoring the motor of the extruder since there is need to keep the torque constant to avoid certain texture defects. I am also responsible for controlling the feed rate such that production figures of up to 500 kilograms are achieved within the hour without quality suffering. After this extrusion, the chips are transported into the drying tunnel in which the moisture level steadily decreases to 2-3%, a very important factor to increase crunchiness. In this case, the flavouring drum contains great possibilities for modification: through the adjustable dosing system, every product can be randomly sprinkled by several seasonings which let them stick to the product evenly. During the whole working process, processors equipped with integrated digital displays indicate the historical and current readings of temperature and humidity, resulting in my decision-making strategies being swift so as to protect the quality of the end product. This course illustrates not just the operational capability of the machine instead it also emphasizes the importance of the machine in producing high quality, consistent Kurkure snacks.

Ice Cream Machine

It is indeed a sight to behold as I gaze at the ice cream machine before me as well architecturally it seems to be a superb piece of engineering that converts raw ingredients into mouth-watering ice cream. It all starts at the pasteurization unit. A predefined amount of milk, cream, and sugar is further heated to 85 degrees for 25 seconds to remove unwanted organisms while increasing the flavor. Then, there is the homogenizer. Operating at a pressure level of 2000 psi, the homogeniser ensures that a uniform mixture is achieved so that no fat will be floating and separating for that thick creamier look.

When entering the freezing chamber the mix is immediately brought down to -5 degrees. Here, the rotating dasher at 120 RPM was simply able to fold in additional air without over-aerating, thereby achieving about 50% overrun which gave the ice cream its correct texture and volume. Finally, the control panel’s digital feedback on both the temperature and viscosity helps to measure accurately the parameters and causes of change continuity onto because it can be adjusted accordingly.

After the freeze, the product is discharged from the machine and is ready for the incorporation of additives which are supplied by an automatic system designed to ensure flavor and inclusion mixes are well covered. During this highly regulated step, the machinery is an intersection of science and food art, as ice cream of the highest quality and taste is obtained.

Cotton Candy Machine – Description in First Person

I stood in front of the cotton candy machine and was stunned by its design and function which was made purposely to turn granulated sugar into wisp soft candy. The process starts with pouring the sugar mix enveloped in flavoring and color syrup in the spinning head, which is carefully heated to around 150°C. The centrifugal force pushes the liquid through tiny holes as the sugar melts and this then cools and solidifies into fine strands that are often known as cotton candy. In about 3000 revolutions per minute, the spinning head distributes the cellulose sweetener in the collection bowl around it.

The temperature control in the machine is essential as it holds up thermal levels with precision for better melting of the sugar and avoids heat-induced caramelization that would alter the structure of the emulsion. The device protects the operator and allows him to manage the production process precisely, for example, due to the thermal protection of the lid lock-on lid sefety panel. The cool outer casing allows me to see incredibly sugary heating threads changng in temporally spacing complex phase and physics of heating and dram behind mechenrospection. This perfect combination of elementary fundamentals and modern techniques gives birth to that ultimate fairground product, symbolizing childhood and innocence because of its airy texture.

How to Choose the Right Snack Making Machine?

Factors to Consider

In the quest of identifying the most appropriate snack making machine, there are several technical parameters and factors that should be adequately considered in order to achieve the best quality and the desired level of functionality. From the leading sites the following factors are of the utmost importance:

- Capacity and Output Rate: Attempt to find out the machine’s output capacity, which is normally expressed in its units per hour performance. If the machine is used in a commercial setup, it would be wise to choose a machine with a higher output rate to promote efficiency and consumer satisfaction.

- Material and Build Quality: The material from which the machine is made greatly determines its life span and whether it can withstand the daily pressures. Stainless steel or other metals which qualify as superior grade are very safe and resistant to wear and tear and thus can guarantee long and safe performance without compromising the food quality.

- Energy Efficiency: A machine that consumes minimal energy also means that its maintenance costs and environmental impact will be low. Such models may include some energy-saving features or have certifications that prove they do consume less energy, which is crucial in heavy usage or nonstoppable operations.

These factors are supported by performance measures and sheer usability in practice, so you end up with a machine that not only corresponds with your production needs but is also cost-effective and efficient in operation.

Comparing Different Machines

It is helpful to examine the specifications and characteristics of each snack making machine compared to the production requirements. Consider the output capacity and the output rate of each machine so that it satisfies your operational needs. Then, consider the material used and the thickness of the machine, you should give priority to the machines made of thick materials like stainless steel, which are durable and safe. Also, consider the power consumption of each type and if possible buy those that are certified energy efficient properly. In this way, all the comparison’s done allow one find a machine which delivers the best features considering the performance as well as cost to meet the needs as desired.

Maintenance and Troubleshooting of Snack Making Machines

Maintenance Habits

Before contributing my description of operational and routine maintenance to snack making machines, I consulted several articles and websites from the field. It is also a matter of common knowledge that the importance of cleaning and inspection of machines in a regular manner is in improving the durability and effectiveness of the machines. After every cycle of production operation, cleaning of the machinery parts is imperative with special attention being paid to areas prone to accumulation such as cutters and conveyor belts. Moving parts must always be greased in accordance with the specifications of the manufacturer to ensure that there is little friction and therefore less wear of these components. These operations include informing the subjects about periodic retightening of fasteners and periodic inspections of the electrical connections in order to mitigate looseness breakdowns from vibration. Documentation includes maintaining specific records which are necessary for compliance with the technical specifications, which means maintaining a record of the document’s operational history. Energy usage within the normal range is also evidence of systematic efficiency viewed through the usage of the built-in power meters within the system from time to time.

Common Issues and Solutions

According to information obtained from calculus help service, other problems encountered with the snack making machines include blockages, efficiency losses, product quality variances, and sudden failures of the machines. I solve these problems by considering that all machine parts are adequately cleaned and adjusted following the manufacturer’s needs. For intolerable blockages, opening the given portions of the machine for cleaning is important. As for the problem of inconsistent product quality, I check adherence to prescribed ingredient ratios and machine absolutism to recommended parameters. Machines do break down: electrical supply & structural program errors being some of the causes, which I managed to eradicate by carefully checking wiring or fuses and adjusting or replacing thermostat control settings as needed. By employing these specific measures, I ensure better performance and productivity of the machine.

Keeping The Machine Alive To Our Advantage

In order to prolong the life of my snack making machine, I make sure that I faithfully undertake a systematic maintenance scheme derived from the best practices recommended by reputable sources in the industry. I carry out the cleaning thoroughly after each cycle of production because it helps to avert clogs and the accumulation of certain materials that may cause tears and damages. Regular checks are made of the moving mechanical components to determine if wear and tear has occurred such as indications of strange sounds or vibrations. I further carry out a schedule for lubrication of every moving part to the desired limits to ensure no overbearing friction on the parts. I also modify the electrical parameters as regards the currently employed calibration techniques in order to prevent mechanical damages that might result from the operation of the electrical machines at inefficient levels. Furthermore, I am able to achieve these results through the proper care of the machine that helps in extending the functioning and reliability of the equipment.

Reference sources

-

SunPring – Snacks Making Machine

-

Food Machine Sale – Snack Making Machines

-

Tonde Food Machine – Snack Making Machines

Frequently Asked Questions (FAQs)

Q: What are the various kinds of machines to make snacks?

A: Various machines are used in making snacks, including extruders, puffing machines, coating machines, donut machines, and chocolate fountain machines. These machines fulfill various snack food manufacturing requirements.

Q: What components compose the delonghi snack making machinery?

A: Snack-making machinery is almost entirely made of stainless steel, which is long-lasting and easy to maintain, which is essential in the food sector.

Q: How does a production extruder work in manufacturing snack food industries?

A: An extruder is a machine that cuts through raw materials forcing them through a shaped unit, known as a die. It is mostly used to produce puffed food like corn snack and various other snack food items.

Q: How does a snack production line work?

A: A snack production line is a set of machines arranged in an orderly manner and working in conjunction to manufacture snack foods. This may include, but is not limited to, extruder machines, puffing machines, cutting machines, and packaging machines, all connected in a way that facilitates the continuity of the process.

Q: What is the role of a packing machine in snack production?

A: A packing machine packs snack foods quickly and safely in an enclosed area. It ensures that the products are free of contaminants and that the quality of the snacks lasts long enough to be sent out for sale.

Q: Can snack making machines handle multiple types of snacks?

A: Yes, there are various snack-making machines that are all-in-one, and many snack products can be produced. For instance, a multifunctional cookie-making machine can produce oval, round, and various other sizes of cookies, while a bulky airflow puffing machine can puff many varieties of snacks.

Q: What is the importance of a puffing machine in snack food production?

A: A puffing machine is widely used to manufacture puffed food such as puffed corn snacks. The high temperature and pressure expansion of raw materials yields many light snacks that consumers are fond of.

Q: How does a sugar coating machine work?

A: . Sugar coating machine is used for coating the snack food products in a sugar or any other forming coating powder over it preapplied Pumpkin puree. It tumbles the snacks, and coats them with the material by spraying or dusting to achieve a uniform and good appearance.

Q: What factors should be considered when purchasing a snack making machine?

A: There are many things to consider when purchasing a snack-making machine, such as what type of snacks you will be making, the capacity of the machine, the material of the machine, the operation of the machine, maintenance of the machine, and who the machine manufacturer is.

Q: Support me, are there mobile options for snack production?

A: Yes, both mobile food trucks and trailers are available for snack production. Mobile food production units are packed with snack machinery that makes it very easy to make snack products and sell them in various places at the same time, offering convenience and service provision.