The introduction of laser technology into the engraving world has changed the industry entirely. This is particularly true for rotary attachments, as these advancements have significantly enhanced the ability of precision laser engravers to execute detailed engraving on irregularly shaped objects. This post will clearly describe the functionality and benefits of a rotary attachment, especially its use in custom glassware, metal tumbler engraving, and even in some promotional products. By the end, you will be able to grasp how rotary attachments profoundly affect the world of laser engraving and why it is crucial for craftsmen, manufacturers, and even hobbyists during streaming, bending, and laser cutting design.

What is a rotary laser engraver, and how does it work?

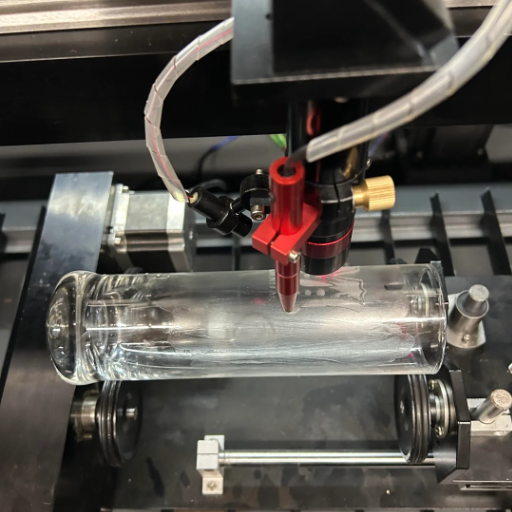

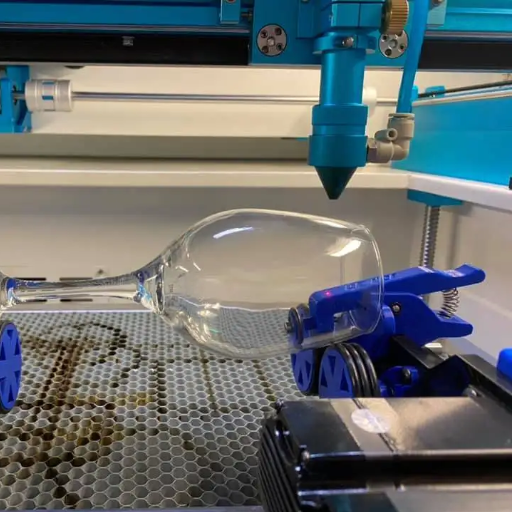

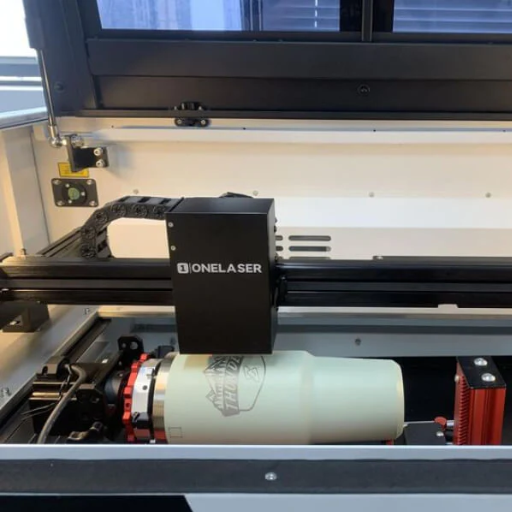

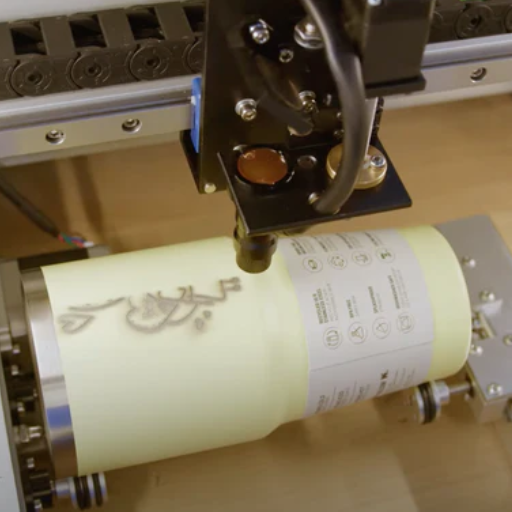

Rotary laser engraver attachments enable precise engraving on cylinders or curved surfaces. During engraving, the rotary engraving attachment rotates the object to ensure the laser consistently contacts the surface. This attachment usually features adjustable rollers or a chuck to clasp the object securely. The laser can also move freely without the risk of hitting the object while its movements remain in sync with the laser. This is essential for wine glasses, bottles, mugs, and other non-flat surfaces. This helps improve both the efficiency and precision of the engraving.

Understanding the basics of rotary laser engraving

Engraving a shaped surface using a rotary laser engraver attachment is known as rotary laser engraving. The engraving begins by converting a digital design into laser-friendly instructions. During the mesmerizing process of rotary engraving, the engraving attachment rotates the item in a linked motion with the laser beam. This method removes the possibility of the engraving becoming distorted over the curved shape since the laser moves synchronously.

Several elements need to be considered to maintain quality output throughout. First, the object’s material composition will determine the laser’s setting, such as the power and speed, since glass, metal, and ceramics have specialized parameters. Second, a rotary attachment must be appropriately calibrated to remain stable and minimize movements while engraving. Lastly, software integration is also essential because it can control sophisticated design software that allows the manipulation of complex geometries and patterns.

Many businesses, such as gift shops, marketing companies, and manufacturers, use rotary laser engravers. This technology allows for effective marking of graphics, identifiers, and inscriptions on cylindrical surfaces, which is superior in quality and durability to the other marking techniques.

Key components of a rotary laser engraver

Rotary laser engraving machines typically have key parts that work together in a synchronized way to engrave accurately on curved or cylindrical surfaces. First, the rotary axis is essential in gripping and rotating the workpiece in its place while engraving. This axis is connected to the machine and allows it to rotate in a smooth and controlled manner. Second, the laser source is the main component of the machine since it mechanically rotates and focuses the laser beams on the surface to be engraved. This can be a CO2 laser, fiber laser, or diode laser. Lastly, control software is also essential because it sets the engraver’s speed, intensity, design, shape, alignment, and more so that the results for details and patterns are accurate.

The science behind laser engraving on cylindrical objects

Laser engraving on cylinders is an exacting procedure needing sophisticated systems that serve optics, mechanics, and software all at the same time. The cylindrical shape has difficulties; the laser must remain focused while adjusting to the object’s curve. Therefore, a rotary attachment or unique axis is conventionally utilized to rotate the object and move the laser, keeping the laser on the object at all times during the engraving. The way the laser beam interacts with the material differs in intensity and wavelength, which are preset to the specific surface properties, whether it is metal, glass, or plastic. This refined setting pulls away or color changes the material on which the heat is aimed, but without disrupting the rest of the surface.

The intricate calculations for handling control over curved surfaces require control software. It offsets the relations of laser focus and its placement to the object’s geometry. To add on, power settings, speed, and resolution need to be optimized; otherwise, it will be unclear and lose detail, especially on sophisticated designs. By integrating these components, laser technology, rotational mechanics, and computer software, modern systems can engrave cylindrical shapes quickly and more accurately than ever for any industry, from automotive to gifts and advertising.

How to choose the best rotary laser engraver for your needs?

Evaluate the right rotary laser engraver by discerning the materials you will work on and your requirements on size and precision. Ensure that the laser’s power and wavelength work with the materials you chose to engrave on, be it glass, metals, or plastics. Check how long and how wide the workpiece the engraver’s rotary attachment can hold, and see if it fits within what you need for your project. Look at how the software works to make sure that there would be minimal interruptions to productivity because workflow integration is essential. Check further for the durability of the system, maintenance needed, and customer support to ensure that it is helpful in the long run. Finally, there is always a trade off between cost and features, evaluate them to get the best value for your money.

Comparing CO2 and diode laser engravers with rotary attachments

While examining CO2 and diode laser engravers with rotary attachments, I have concluded that CO2 lasers have greater versatility because they have higher power output and can engrave and cut metals, acrylics, and wood much more efficiently than other lasers. This makes CO2 lasers much faster and more precise for professional projects. At the same time, diode lasers are compact, energy-efficient, and inexpensive, making them ideal for hobbyists. However, Diode lasers have drawbacks, like limited material and cutting depth. Regarding specific project parameters, CO2 lasers win regarding versatility and power, but diode lasers are preferred when portability and cost are concerned. This is true for both devices, as they need careful consideration of rotary attachment usability about the application.

Essential features to look for in a rotary laser engraving machine

When choosing a rotary laser engraving machine, I look for precision, compatibility, and ease of use. Precision is necessary because it means that all details of the pieces are captured accurately, which is essential for professional-level results. It is also required to consider the range of materials that can be used, enabling me to apply it to wood, glass, and metal. Ease of use is the last criterion, including user-friendly software and a setup that is not complex. This is important in optimizing workflow and minimizing downtime. Machines that offer all these features while still meeting the exact specifications for my projects are always the best.

What materials can be engraved using a rotary laser engraver?

Rotary laser engravers can engrave many materials accurately and quickly. These devices handle basic materials like wood, acrylic, leather, glass, metal, and various plastics. They are especially effective with cylindrical-shaped items, allowing detailed engravings on glasses, bottles, and cylindrical metal pieces. Engravers with a rotary feature can engrave intricate designs into soft materials like wood and leather or even more complex materials like metals and glass, as long as the right laser power and settings are used.

Engraving on glass, acrylic, and metal tumblers

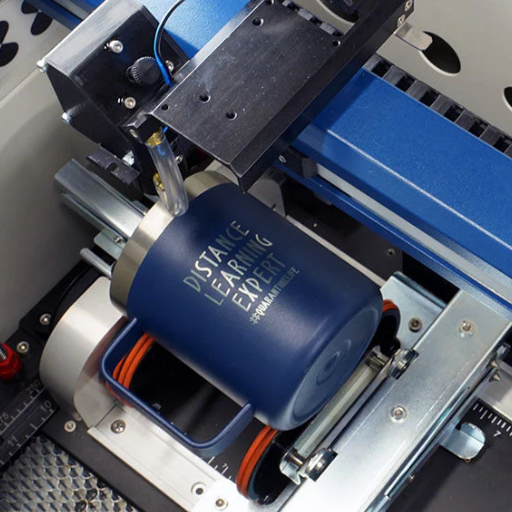

Cutting different patterns on a glass or metal tumbler mug needs time, specific settings, and a focus to get precise work done. The lower laser frequency is often preferred for glass tumblers to avoid cracking or chipping the glass. When glasses are being engraved using a laser, a rotary device is used to stabilize the glass. Acrylic tumblers are more prone to scratches, so they engrave more easily. Depending on the design, they can also be used for vector engraving and raster cutting. For metal tumblers, marking the surface of the tumbler is easier with a high-fiber laser-powered system. Some metals get high absorbance of the leader marking agent, which is used on these metals’ surfaces to enhance contrast and other character properties. Focus, speed, and other settings must also be calibrated for all the materials.

Working with wooden cylindrical objects

While working on cylindrical wooden pieces, I pay special attention to precise registration and well-marked fixation for proper engraving. A rotary device is essential to provide continuous movement and prevent lateral slippage. My laser power and speed settings are moderate to avoid burning and excessive engraving on the wood, as its porosity and grain structure will dictate the level of detail in the engraving. To achieve a better result, I always first rough sand and test on a scrap piece to adjust the fine settings for better accuracy and sharpness in detail.

Exploring unique materials for rotary laser engraving

Rotary laser engraving enables personalization for materials other than just metal or wood. For example, cylindrical glass or bottles are often chosen; however, the power of the laser must be low during the engraving process to avoid cracking or chipping the surface. Wrapping the piece in a wet paper towel or using an appropriate coating helps remove heat for better results. Another flexible material is acrylic since it is very easy to engrave into. Changing the laser’s speed and power to limit the melting or warping of the specified acrylic makes engraving smoother. Leather is less popular for rotary engraving but can produce interesting textures and patterns. With leather, the high speed and low power settings are essential; otherwise, scorching might occur. Every material requires testing and precise adjustments to reach optimum results. Therefore, flexibility is a very important factor for engravers.

How to set up and use a rotary attachment for laser engraving?

Let’s consider what we need to engrave; with the rotary attachment, the laser technique will differ from the step engraving technique. Engraving with rotary attachment starts by removing the standard engraving bed and connecting it to the correct port on the laser machine. Next, make sure the machine is powered off. Align the object in the rotary chuck first, ensuring it is well bound on both ends. The object’s axis needs to be ideally in the center of the rotation. The next step is to enable rotary mode on the laser software (it needs to be integrated as a plugin). Before running it, make sure to input the ideal diameter of the object for accurate calibrations. If the carving goes as planned, check the balance and alignment while rotating the object. I wish you good luck in achieving the best setting with the speed and power for your material to minimize the risk of covering the surface with damages.

Adjusting settings for different object sizes and materials

I put the object’s diameter into the software since scaling is critical in the engraving. I then set the borders by the diameter values. If I work on a smaller object, I decrease the laser speed a notch or two for better accuracy. In contrast, larger objects demand rotation adjustments to be precise. The type of material used is also of the utmost significance. Softer materials like wood and leather require me to lower the laser’s power to prevent overburning. In comparison, more rigid materials, like metal or glass, need speed increase alongside power boosts for a clean engraving. Finally, a small test area is utilized to confirm the settings.

Tips for achieving precise alignment and rotation

Accurate position and rotation are key; start with securely fastening the object to the rotary attachment or engraving tool to ensure minimal movement while engraving. Use alignment tools like lasers or guidelines to place the design properly on the object’s surface. Set the rotary attachment for cylindrical objects to ensure uniform rotation and constant contact across the contour. Select a center point or axis of rotation beforehand to increase the chances of correctly placing the design. Test runs must always be done using the low-power laser option to confirm placement along with the design, and macro adjustments can be made afterward. Keeping the workspace organized and aligned will ensure minimal error caused by shifting or miscalibration.

What software is best for rotary laser engraving projects?

Ideally, the most suitable software for rotary laser engraving projects should include design, output, and alignment controls integrated with a laser engraving device. CorelDRAW and Adobe Illustrator are some of the most preferred programs utilized for highly detailed designs because they are simplistic in using vector graphics. Also, direct software for the machine, such as LightBurn or RDWorks, is highly recommended since they work with the majority of laser machines and also allow for your detailed engraving settings to be controlled. These programs often have features for rotary attachments, such as rotation setup and preview simulation, ensuring accurate results on cylindrical objects. Please ensure that the programs in question work efficiently with your laser engraver for maximum efficiency and output quality.

LightBurn: A comprehensive solution for rotary laser engraving

LightBurn is a versatile software for laser engraving machines that use rotary engraving. It is incredibly easy to use and control. I selected it because it’s very user-friendly and works with many devices. Specific features include powerful pathing, rotary axis manipulation, and precise engraving alignment, which makes even tricky engraving operations straightforward. Also, the ability to import files from AI, SVG, and DXF makes it easy to integrate into existing practices. Those looking for perfect precision and efficiency in rotary engraving projects will find it excellent for all their needs.

Designing and preparing files for cylindrical engraving

Design work for cylindrical engraving is incredibly tedious. First, the design should factor in the curvature of the object. This means using some software to “unwrap” the design to the object’s dimensions. Software such as LightBurn is capable of mapping flat designs with the use of rotary tools, enabling the engraver to cover curves.

Second, choosing the correct file format is just as important. Common file types like AI, SVG, and DXF support scaling and precise reproduction of the design. Also, check if the design’s resolution is high enough to produce a quality image when scaled to the dimensions needed.

Lastly, the rotary attachment correctly positions the object in the engraving machine. This guarantees that the design fits appropriately on the cylindrical surface. Careful testing with scrap materials can avoid mistakes, and utilizing simulation tools in the software ensures that the design will be appropriately engraved. By efficiently merging the tasks of preparing the designs and setting the machine, accurate cylindrical engraving can be done consistently and efficiently.

How do you maintain and troubleshoot your rotary laser engraver?

To enhance the efficiency of your rotary laser engraver, I constantly perform essential maintenance and resolve issues that might arise. First, I ensure I wipe down dirt from the machine daily, especially the lens, mirrors, and rotary attachments, as they capture dust and grime that can hinder the engraving’s effectiveness. Additionally, lubricating the moving parts with the correct grease reduces the chances of excess friction. I also make sure that the device’s software is updated regularly.

Regarding troubleshooting, I understand that the design file must be adjusted to the proper scale before engraving. Whenever the alignment looks incorrect, I reset the rotary tool and ensure it is tightened. When a system is not performing consistently, I examine the physical parts for any damages and check the electrical connections for faults. Many common problems can be solved by looking at the user manual and the support provided by the manufacturer. These logical steps ensure that performance remains stable and that there is minimal downtime.

Regular maintenance tasks for optimal performance

Before anything else, remember that a rotary laser engraver works best when specific maintenance procedures are followed. As a rule of thumb, all optical components, such as lenses or mirrors, should regularly be cleaned with the proper cleaning agent. This ensures maximum precision during engraving. All mechanical components like belts, screws, and rotary parts should be checked frequently to see if anything is too loose or too tightly fitted, as this could lead to unstable operations. In addition, moving parts like rails and gears should also be lubricated, although be sure only to use the manufacturer’s recommended lubricants.

The laser beam path should be inspected and aligned for improved engraving precision. Regarding the machine’s software, compatibility with new design files and overall functionality is improved with frequent updates. Switching out worn cables or connectors to ensure electrical connections and power supply are working correctly is also necessary. Following this, regular maintenance can prolong the device’s lifespan and prevent issues from arising down the road.

Common issues and their solutions

One problem frequently reported about laser engraving machines is uneven engraving results on a single object. This problem can be easily solved by cleaning and realigning the lens and checking that the material is held securely. I would also recommend checking for dirt on the lens or mirrors if there are faulty nozzles or low laser power. Also, ensure that the laser tube has not reached the end of its useful life. Suppose the engraving machine stops working in the middle of the operation. In that case, I will first inspect the power supply and cables to ensure they are all connected properly and haven’t sustained any damage. To fix issues caused by the software, many clients report that upgrading the firmware and checking for compatibility between the files commonly solves these problems.

When to seek professional help for your rotary laser engraver

A qualified professional should be consulted for tasks requiring a unique approach. Software diagnosis would take much longer than needed in power issues, frequent software bugs, or alignment errors. On top of that, if there is a persistent problem of inaccurate results even after servicing and recalibration, the breakdown of the internal parts is likely, which is usually challenging to reach. In these situations, it is best to consult with a professional. If frequent issues with the laser tube or power concentration lead to a significant drop in power, replacement needs to be done to ensure no other damage is caused. If electrical issues result in blown fuses or constant power outages, attending to these would require immediate assistance from a professional. As for other problems, if everything that could be done to alleviate the issue has been tried, seeking a professional is best for the system’s integrity.

What are some creative projects you can tackle with a rotary laser engraver?

A rotary laser engraver makes it easy to perform complex designs on rounded surfaces for innovative ideas. Adding names, logos, or intricate engraving patterns, you can personalize pieces such as tumblers, mugs, or wine glasses. Rotary engravers are also great for branding unique pen barrels, small tools, or even flashlights as gifts. Moreover, you can design high-quality vases for businesses or engraved water bottles as marketing assets. The rotary engraver can transform intricate ornamented candles or wooden rolling pins into uniquely engraved household items. The agility and precision of a rotary laser engraver make it the perfect tool for various creative ventures.

Personalized gifts: Engraving mugs, wine glasses, and water bottles

A rotary laser engraver can effortlessly create monograms and add company logos on drink bottles, mugs, and wine glasses. Such engraving tools are excellent for professional and long-lasting results. With the precise craftsmanship of rotary laser engravers, I can transform ordinary cups and bottles into heartfelt gifts that perfectly suit any celebration, promotional need, or corporate gift. Streamlining the processes grants me enduring results that result in practical and valuable customized gifts.

Crafting unique cylindrical signage and decorative items

A laser engraver with a rotary attachment is an efficient way to beautifully engrave a design on wax candles, metal tubes, and vases and even create intricate signage while maintaining shape and avoiding distortion. Merging advanced technology with business makes it possible to etch logos, phrases, and highly detailed designs on wax and metal, making them perfect for theme parties and the ideal gift. The ability to engrave on rounded surfaces while maintaining alignment allows me to seamlessly customize and adorn interior spaces. These engraved items are an excellent way to promote businesses while making them an integral decoration.

Industrial applications for rotary laser engraving

In business, rotary laser engraving is valuable in marking cylindrical components like pipes, gears, and other mechanical parts. Due to its exactness and repeatability, this technology dramatically facilitates marking serial numbers, barcodes, logos, and other technical specifications directly onto the metal or plastic surface. Some cutting-edge industries, such as aerospace, automotive, and manufacturing, harness these capabilities as they enable proper traceability, improved product identification, and regulatory compliance. Using a rotary laser engraver eases the production processes while assuring precision and durability of the markings in harsh operational conditions.

References

Frequently Asked Questions (FAQ)

Q: What is a laser rotary attachment and how does it enhance a laser engraver?

A: A laser rotary attachment is a device that allows laser engravers to work on cylindrical objects. It enhances the versatility of laser engraving machines by enabling them to engrave and cut on round surfaces such as tumblers, glasses, and bottles. This attachment expands the working area to 360 degrees around cylindrical objects, opening new possibilities for engraving and cutting projects.

Q: What types of rotary attachments are available for laser engravers?

A: There are primarily two types of rotary attachments: chuck rotary and roller rotary. Chuck rotary attachments hold objects at one end, making them suitable for items with one open end. Roller rotary attachments, including the y-axis rotary roller, use rollers to support and rotate objects, making them ideal for a broader range of cylindrical items. Some advanced models, like the rotary Pro, offer enhanced features for more precise engraving.

Q: Can a rotary attachment be used with CO2 and fiber laser engravers?

A: Rotary attachments can be used with CO2 and fiber laser engravers. However, ensuring compatibility with your specific laser engraver model is essential. CO2 lasers are typically best for engraving materials such as wood, acrylic, and glass, while fiber lasers are ideal for metal engraving. Always check the specifications of your laser engraver and rotary attachment before purchase.

Q: What are the best laser engraver brands that offer rotary attachments?

A: Several reputable brands offer laser engravers with rotary attachments or compatible add-ons. Some popular options include xTool, Ortur, and Atomstack. The xTool F1 and other models from these brands are known for their quality and versatility. When choosing the best laser engraver with a rotary attachment, consider factors such as power (e.g., 20W), working area, and overall engraving experience.

Q: How does a laser engraver’s y-axis rotary roller work?

A: A laser engraver y-axis rotary roller is a type of rotary attachment that uses rollers to support and rotate cylindrical objects. It works by synchronizing the object’s rotation with the movement of the laser along the y-axis. This coordination allows for precise engraving around the entire circumference of the object. The y-axis rotary roller is handy for engraving larger or heavier cylindrical items.

Q: Can I use a rotary attachment to engrave tumblers and other drinkware?

A: Yes, rotary attachments are excellent for engraving tumblers, glasses, and other drinkware. They allow for seamless 360-degree engraving on these cylindrical objects. When using a rotary attachment for this purpose, ensure that you have the correct settings for the material (such as stainless steel or glass) and that the object is securely held in place to prevent slipping during the engraving process.

Q: What is the difference between a CNC machine and a laser engraver with a rotary attachment?

A: CNC machines and laser engravers with rotary attachments can work on cylindrical objects but operate differently. CNC machines use cutting tools to remove material, while laser engravers use a focused beam of light to etch or cut surfaces. Laser engravers with rotary attachments are typically better suited for detailed surface engraving on various materials, whereas CNC machines excel at three-dimensional carving and cutting.

Q: How do I choose the proper rotary attachment for my laser cutter and engraver?

A: To choose the proper rotary attachment for your laser cutter and engraver, consider the following factors: compatibility with your laser machine, the types of objects you plan to engrave (size and weight), the materials you’ll be working with, and your budget. Look for attachments that offer a suitable working area and can handle the dimensions of your typical projects. Also, consider whether a chuck rotary or roller rotary style would be more appropriate for your needs.

Q: Can hobbyists use laser engravers with rotary attachments, or are they only for professionals?

A: Laser engravers with rotary attachments suit hobbyists and professionals. Many desktop laser engravers now come with rotary capabilities or offer compatible attachments, making them accessible to hobbyists. These machines allow enthusiasts to explore cylindrical engraving on various materials, from wood to metal. However, more advanced rotary modules and higher-powered lasers may be geared toward professional use, offering greater precision and faster engraving speeds.

Q: What safety precautions should I take when using a laser engraver with a rotary attachment?

A: When using a laser engraver with a rotary attachment, follow these safety precautions: Always wear appropriate eye protection designed for the specific wavelength of your laser. Ensure proper ventilation to remove fumes and particles. Secure the cylindrical object properly in the rotary attachment to prevent accidents. Never leave the machine unattended during operation. Be familiar with emergency stop procedures. Lastly, ensure your workspace is free from reflective surfaces that could redirect the laser beam.