Rice is a staple food for billions of people worldwide, and its journey from paddy to polished grain is a fascinating process that involves several stages of sophisticated machinery. This blog post aims to unravel the intricacies of the rice processing machine, providing readers with an in-depth understanding of the entire process. We will explore the essential stages, from the initial cleaning and dehusking to milling and polishing, highlighting how each step contributes to the transformation of raw paddy into ready-to-cook rice. Additionally, this article will shed light on the technological advancements that make these machines more efficient and sustainable. By the end of this post, you will appreciate the complex yet efficient system that ensures the availability of this vital grain, making it a cornerstone of cuisine worldwide.

What is a Rice Mill Machine and How Does it Work?

A rice mill machine is an industrial device designed to efficiently convert paddy into polished rice by removing husks and bran layers. The process begins with cleaning, where impurities like stones and dust are eliminated. This is followed by dehusking, which involves removing the outer husk to reveal brown rice. The subsequent step is milling, where the bran layer is polished off, resulting in white rice. Modern rice mill machines incorporate various technological advancements that enhance the precision and efficiency of each step, ensuring a higher yield of quality rice while minimizing grain breakage. The integration of features like automated control systems and efficient energy use makes these machines both sustainable and productive.

Understanding the Basics of Rice Processing

The primary steps in rice processing start with cleaning, which removes impurities like stones, straw, and dust from the paddy. Next, dehusking occurs, stripping away the tough outer husk to reveal brown rice. The rice then undergoes milling, where the bran layers are polished off to achieve the desired whiteness. Each step is crucial for producing high-quality rice, and the efficiency at each stage impacts the overall yield. Modern machines utilize advanced technologies to enhance accuracy and reduce grain breakage, integrating automated controls and optimizing energy use to ensure a sustainable and productive operation.

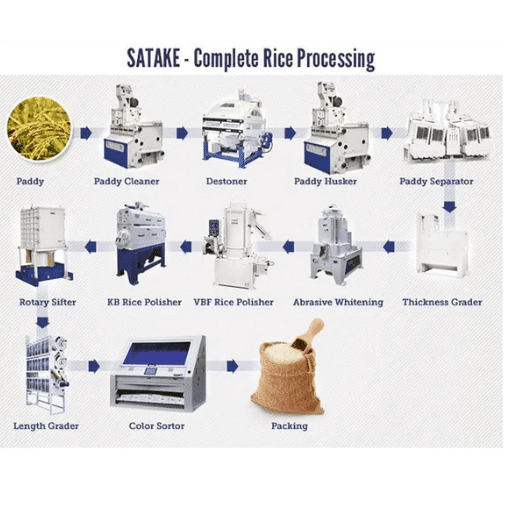

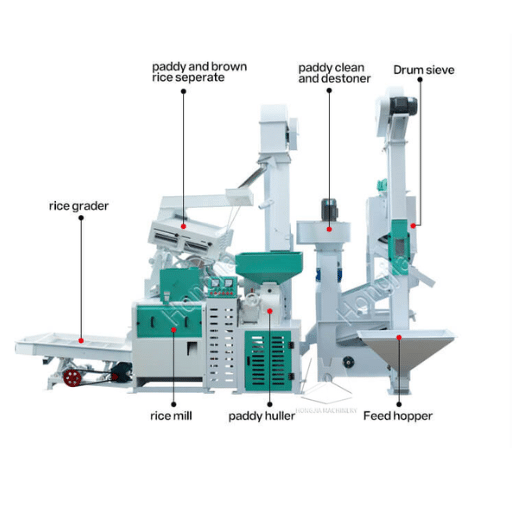

Components of a Rice Processing Machine

First, the paddy cleaner eliminates impurities like stones and dust. Next is the dehusker, which removes the rice husk. After that, the paddy separator segregates whole grains from brown rice. The next vital component is the milling chamber, where the rice gets polished. After milling, the whitener refines the rice, creating a uniform appearance. Finally, the grading machine sorts the rice by size and quality. Each part plays a key role in the process to increase efficiency and reduce waste.

The Role of a Rice Polisher in the Milling Process

The rice polisher enhances the finish and texture of milled rice, improving its appearance and market value. It removes any remaining bran layers, producing a smooth, glossy surface. The polishing process reduces the chance of spoilage by eliminating residual oils, extending shelf life. Polishers use gentle friction and minimal water for maximum efficiency, maintaining the integrity and length of the grains.

How to Choose the Right Rice Milling Equipment for Your Needs?

When choosing the right rice milling equipment, start by assessing your specific production needs, including the volume of rice you plan to process and the space available for installation. Consider the types of rice you process most frequently and ensure that the equipment is compatible with these varieties. Evaluate the efficiency of the machines by reviewing their energy consumption, processing speed, and yield rate to ensure they align with your operational goals. Look for equipment that includes features like automated controls and user-friendly interfaces to streamline operations. Finally, consider the company’s customer support, warranty offers, and the availability of maintenance services to ensure long-term reliability and performance.

Types of Rice Milling Equipment Available

Paddy separators are the first category of rice milling machines and they work to separate the rice from all its undesired elements; these examples are import machines in preserving the quality of the final product. Hulling machines or husking machines do the third and crucial step of rice milling these remove the husk of the rice which contributes towards the improvement in the overall efficiency of the process. The bran layer of the rice is then processed using whiteners which plays the final role of producing white rice out of the grain. Grading in size is one more step applied to the rice, with the help of milling graders it is possible to obtain rice of varying size as per the market requirements. The equipment you select also depends on your needs in terms of production and energy consumption and lastly on usability and maintenance.

Factors to Consider When Selecting Grain Processing Machinery

When selecting grain processing machinery, I first evaluate my specific needs, like processing volume and available space. Understanding the types of grains I process ensures compatibility with the equipment. I prioritize energy-efficient machines with high processing speeds to align with my operational goals. User-friendly interfaces and automated controls are crucial for streamlined operations. I also consider the company’s customer support, warranty offers, and maintenance services for long-term reliability and performance.

Benefits of Using a Modern Rice Milling Machine

First, they enhance efficiency by increasing processing speed, enabling large volumes of rice to be milled quickly. These machines ensure consistent product quality by integrating advanced technologies that reduce grain breakage and improve yield. Modern machines often feature energy-saving designs, minimizing electricity consumption and reducing operational costs. Their user-friendly interfaces and automated systems simplify operation and reduce labor requirements. Furthermore, many come with comprehensive customer support and maintenance services, ensuring optimal performance and extending machine lifespan. These advantages make modern milling machines a valuable investment for rice producers aiming for competitive markets.

What is the Importance of a Color Sorter in Rice Processing?

A color sorter is a crucial component in rice processing due to its ability to enhance product quality and value. These machines employ advanced optical technology to detect and separate discolored or defective grains from the batch. By ensuring a uniform and visually appealing end product, color sorters elevate rice quality, which is essential for meeting market standards and consumer expectations. This machine reduces the labor-intensive task of manually sorting grains, significantly improving efficiency and throughput. Ultimately, incorporating a color sorter into rice processing operations contributes to consistent product quality and higher profitability by minimizing wastage and maximizing yield.

How Sorting Machines Enhance Rice Quality

Sorting machines use cutting-edge technology to improve rice quality. They quickly identify and remove impurities, such as stones or foreign materials, from the rice. This process ensures a clean, high-quality product that meets market and consumer standards. By automatically separating unwanted items, these machines replace manual labor, speeding up processing times and reducing costs. Additionally, sorting machines enhance rice consistency by maintaining uniform size and appearance, thus increasing consumer satisfaction and market competitiveness. Through their efficiency and precision, sorting machines play an indispensable role in delivering premium rice products while maximizing yield and profitability.

The Technology Behind CCD Rice Sorters

CCD rice sorters utilize charge-coupled devices to capture detailed images of rice grains as they pass through the sorter. These devices operate with high precision, analyzing each grain based on set criteria for color and size. Upon detecting defects or impurities, the sorter swiftly removes them via a targeted jet of air. This technology significantly boosts sorting speed and accuracy, enhancing both product quality and processing efficiency. Compared to manual sorting, CCD rice sorters handle larger volumes with higher consistency, ensuring that only premium-quality rice reaches consumers. Additionally, the efficiency of CCD sorting contributes to cost savings and increased profitability for rice processors.

What are the Benefits of a Complete Rice Milling Solution?

A complete rice milling solution provides a fully integrated process that streamlines the various stages of rice production. The primary benefits include improved operational efficiency, as the integration of all necessary equipment and processes reduces the time and labor required for milling. This cohesive system also enhances product quality by ensuring consistent processing, minimizing breakage, and optimizing yield through precise control at each stage. Moreover, it increases profitability by lowering overall production costs and reducing waste. Additionally, a complete solution offers flexibility, allowing adjustments in processing to meet specific market demands and accommodate different rice varieties, thus helping processors maintain a competitive edge.

Efficiency of Automatic Rice Mill Systems

An automatic rice mill system provides me with several advantages due to its high-efficiency features. By fully automating the milling process, I am able to significantly reduce the labor and time required, ensuring a swift and cost-effective operation. The precision of these systems allows me to minimize rice breakage and improve yield consistently, which boosts both my product quality and profitability. By adjusting effortlessly to different rice varieties and market demands, I can maintain a competitive edge while ensuring that I meet the diverse needs of my customers. With enhanced integration, I also experience reduced waste, leading to lower production costs overall.

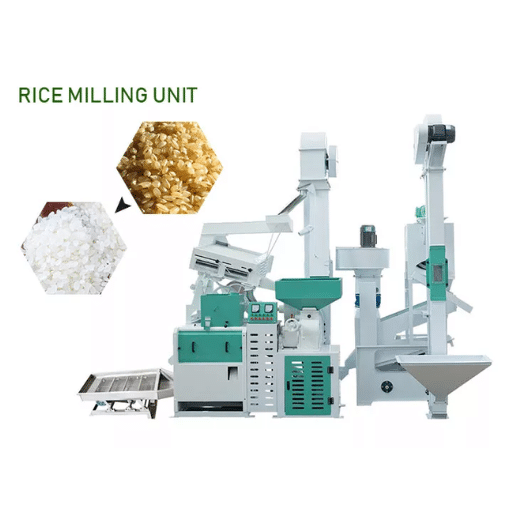

Streamlining Operations with a Combined Rice Milling Machine

A combined rice milling machine enhances operations by integrating multiple functions into a single unit, significantly reducing labor and processing time. These machines efficiently perform multiple stages, including dehusking, whitening, and grading. With this all-in-one system, I achieve higher productivity by minimizing manual intervention, which streamlines workflows and cuts costs. Additionally, consistent control over each stage improves the rice quality, delivering a premium product that meets market standards. Ultimately, adopting a combined rice milling machine maximizes efficiency, produces less waste, and adapts flexibly to varying demands.

Integration of Rice Grader and Destoner in Processing Plants

The rice grader accurately separates grains based on size, ensuring uniformity and improving the final product’s appearance. Meanwhile, the destoner efficiently removes stones and other impurities, safeguarding the mill’s equipment and ensuring a cleaner grain output.

How Does Paddy Processing Differ from Other Grain Processing?

Paddy processing differs from other grain processing mainly in the initial steps required to convert paddy into consumable rice. Unlike other grains, paddy has a husk layer that must be removed. This unique process begins with parboiling or soaking to partially cook the rice inside the husk, which loosens the hull and enhances nutritional value. Subsequent drying and husking stages follow, where machines separate the husk from the rice kernel. After husking, the rice is polished and graded for quality, a step less complex or not required in the processing of some other grains like wheat or maize. These distinct stages ensure the preservation of the rice grain’s nutritional value and overall quality, distinguishing paddy processing from the processing of other grains.

Steps in Paddy Processing

Cleaning stage is where workers use mechanical cleaning devices in the first treatment of paddy. The aim here is to eliminate foreign material like stones and dust existing within the paddy.

Soaking and steaming the paddy follows. This in turn allows better nutrient retention as well as an easier time removing the husk, which is done during the Parboiling stage.

After that, paddy must undergo parboiling before any solar drying or the use of mechanical dryers. This step allows achievement of desired moisture content.

Next, the coarse paddy husks get removed using dawsoning machines at the dehusking stage which exposes the brown rice.

At the polishing stage, bran, which forms a cover around the rice, is removed to improve its texture and shape.

After this, the rice is sorted by grain length and other quality aspects during grading, It also helps to pack the rice without any spoiling.

The Role of a Rice Huller in Removing Impurities

A rice huller plays a critical role in the rice processing chain by efficiently removing the outer husks to reveal whole grains of rice. This machine separates the inedible outer layers, ensuring cleaner rice free of impurities. The huller works by applying pressure, causing the hulls to burst open without damaging the grain inside. Advanced hullers often feature systems to suck away loose husks and dust, maintaining cleanliness throughout the process. By operating swiftly and precisely, hullers minimize grain breakage, enhancing the overall quality and yield of the processed rice.

Transforming Paddy into White Rice

The first step I take when working with paddy is to clear it of foreign materials such as stones and dust. I shuck or incise the paddy, parboil it, and then soak it in warm water so that I am able to easily remove the paddy husk. The warm water soaking also helps in removing moisture from the paddy thereby making the grains easier to dry. To reduce the moisture content of the paddy, I use paddy dryers as well as taking advantage of natural sun rays. The husked paddy becomes brown rice; I then further polish the rice to improve its appearance and texture. The final step in the process is to have the rice uniformly classified based on grain size and quality level before owing to the need to efficiently pack the paddy.

References

-

Hindustan Abrasives – Rice Mill Machinery & Rice Milling Processing Guide: Provides a comprehensive overview of rice milling processes and machinery.

-

Bühler Group – Rice and Paddy Processing: Covers the full range of rice and paddy handling technologies, from pre-cleaning to polishing.

-

Alibaba – Your Ultimate Guide To Selecting Rice Mill Machines: Offers guidance on selecting the right rice milling machines, including energy sources and power requirements.

Frequently Asked Questions (FAQ)

Q: What is a rice mill plant and how does it function?

A: A rice mill plant is a facility where paddy rice is processed to produce polished white rice. It functions by using various processing equipment, such as huskers, rice milling machines, and rice whiteners, to remove the husk and polish the rice grains for consumption.

Q: How does a mini rice mill machine differ from a commercial rice mill?

A: A mini rice mill machine is smaller in scale and is typically used for small-scale operations or personal use. In contrast, a commercial rice mill is larger and capable of processing a higher volume of rice per hour, making it suitable for industrial use in the rice industry.

Q: What is the role of a rice whitener in the rice milling process?

A: A rice whitener is a critical piece of processing equipment used in the rice milling process. It polishes the rice grains by removing the bran layer, resulting in high quality rice that is ready for cooking and consumption.

Q: Why is grading important in a rice processing line?

A: Grading is important in a rice processing line because it ensures uniformity and quality of the rice grains. This process involves separating rice into different grades based on size, shape, and quality, which is essential for meeting market standards and consumer preferences.

Q: How does a paddy cleaner contribute to the rice milling operations?

A: A paddy cleaner is used to remove impurities such as dust, stones, and straw from the paddy rice before it enters the milling process. This step is crucial for ensuring that the rice milling machine rice operates efficiently and produces high quality rice.

Q: What is a rice color sorter and how does it work?

A: A rice color sorter, also known as a color sorting machine, is used to detect and remove discolored or defective rice grains from the batch. It uses advanced optical technology to identify grains that do not meet quality standards, ensuring that only the best rice is packaged and sold.

Q: Can you explain the significance of the rice husk in the rice processing plant?

A: The rice husk is the outer protective coating of the rice grain that is removed during the milling process. In a rice processing plant, the husk can be repurposed as a fuel source for energy generation or used as a raw material in other industries, contributing to sustainable practices.

Q: How does the capacity of a rice processing machine impact its efficiency?

A: The capacity of a rice processing machine, often measured in tons per day or rice per hour, directly impacts its efficiency. A machine capable of processing a larger volume of rice can meet higher demand and improve overall production efficiency, making it suitable for larger rice mill plants.

Q: What advantages does a full automatic rice milling machine offer?

A: A full automatic rice milling machine offers several advantages, including reduced labor costs, consistent processing quality, and increased production efficiency. It is an ideal machine for large-scale rice processing operations where automation can enhance productivity and product quality.