The integration of automated batch retort systems into the technology of food processing is a definite working advancement. For these are the systems whose aim is to increase efficiency, uniformity, and safety in sterilization of food packages that are already sealed. Aimed at focusing on increasing batch production, automated retort mangles the whole process of it. Because a manufacturer will have total control over temperature and pressure, food will be effectively cooked and safe. This helps not only in the enhancing the quality of the product but also in increasing its shelf life as well as its safety. Retort machine is a kind of food machinery.But even before the article covers the aforementioned types of issues there is need to appreciate the impact that these kinds of systems come with. The paper will go through the positive aspects of these systems, highlights of how to incorporate them and the effect they have on the food processing industry in modern times.

What is a Retort Machine and How Does it Work?

Knowledge concerning the retort method

Retort technology, as one of the significant components in food sterilization, is essential in applying heat and pressure to the packaged food in airtight containers. In the retort method, food is reheated to high temperatures to eliminate most fatal microorganisms and enzymes and make it fit for human consumption and to increase its lifespan. The scope of retention is determined by three factors: temperature, pressure and time – these three together can be used to to engage pasteurization or sterilization processes in the respective food products. Such functions as batch retort systems automated food processing operation cuts down on the overhead of manpower while improving food quality and safety.

Parts utilized in Retort Machine

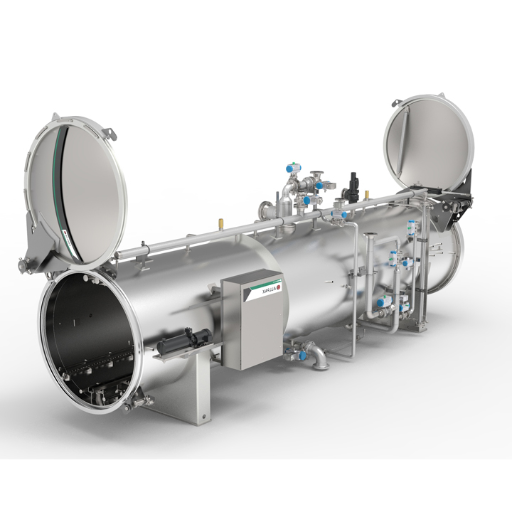

A retort machine has a few principal parts comprising those that are manufactured in a series for the purpose of sterilization of the food. The principal parts of this machine include the retort chamber in which the package containing food is placed for treatment; the heater tempering element which raises the temperature to certain limits; the pressure controlling element, which determines the pressure values to be employed; and the rectifying system that lowers the temperature of food to a safe level. These parts, with the aid of an empirical configuration, together appliances heat the food uniformly and systematically which serves to destroy any present organism within the product guaranteeing its safety and quality standards.

Applications in Food Processing

Retortases or retort machines find broader range of application in food processing e.g. canning, preservation of readiness-to-use food, sterilization of soft drinks, packed pet food products and many more. In terms of application, retorts allow food to be stored for long periods of time without risk of spoilage, guarantees the preservation of its nutritional content and ensures that taste and texture are not compromised. These devices enable manufacturers to meet high levels of safety and increase the expiration date of goods without any additional JSP.

How Does Retort Food Processing Ensure Safety and Quality?

The Function of Sterilization in the Retort Process

Microbial safety and quality of food products in retort food processing is mainly achieved by sterilization whereby food products are brought to high temperatures for sufficient time to eradicate potentially harmful microorganisms. This process destroys pathogenic and spoilage organisms which guarantees that the food will be Microbiologically stable. Retort processing maintains food safety while using heat and pressure control technologies to preserve food attributes such as vitamin content, taste, and surface characteristics. This procedure minimizes the requirements for preservatives to be incorporated into the products so as to maintain safety and extend the shelf life of the products.

Controlling the Quality and Storage Stability of the Product

In retort food processing, food safety and quality are ensured by high-temperature sterilization, which destroys pathogenic microbes and spoilage organisms, thereby delivering safe products. Such close control of heat and pressure conditions helps not only in extending the shelf life of such foods but also in retaining their nutritional content, taste, and texture, all without the need for chemical preservatives.

Controlling the Temperature and Pressure in Retort Systems

Controlling temperature and pressure simultaneously in retort systems is essential for food safety and food quality by incapacitating the contents. This control provides the benefit of destroying harmful microorganisms without jeopardizing the food’s nutrients, taste, or texture which results in a stable and secure product with better shelf life.

What are the Types of Retort Machines?

Looking at the Differences Between the Batch Retort and the Continuous Retort

For batch retort systems, food is processed in fixed or discrete units or amounts, which leaves allowances in the size and type of the products to be handled. They are best suited for small and medium scale operations. Oppositely, in continuous systems there is no pause in the process. Production is being done through a conveyor belt thus allowing better efficiency, uniformity and consistency at major productions. Sterilization is well achieved in the two systems and the selection between the two is usually based on scale of production, cost factors and processing needs.

Essential Provisions of Water Immersion Retort and Steam Retort

Water immersion retort systems heat and cook the packed food by submerging it in hot water, which prevents the hot spots and overheating of heat sensitive items. This technique is especially useful for low density products or containers of different materials. Steam retort systems, on the other hand, consist of superheated water steam which is used in the sterilisation of food products, thus high heating and energy efficacious. Steam retorts are for uniform product loads in which steam can easily infiltrate and also heat up, hence effective and fast sterilisation is achieved. Both systems are intended to ensure the that the products are of the desired quality and safety whilst increasing shelf life.

Advantages of Automated Batch Retort Systems

Large scale food manufacturing companies have turned to automated batch retort systems as they bring forth several advantages: First, introducing batch systems into the production processes, improves the consistency and accuracy of operations while reducing the chance of human error; Second, it makes operations more efficient by changing work processes and reducing a labor involved; Besides, automated systems ensure better control and monitoring of critical safety factors which leads to improving the quality of products and minimizing risk to health. Given this type of automation, the throughput is also enhanced and the whole process is more efficient and consistent.

How to Optimize Retorting in Food Processing?

Enhancing the effectiveness of food processing through automated retort systems

There are a number of elements in retorting that should be considered to maximize its efficiency in food processing. The first is the adoption of automated retorts which reduce the need for manual intervention hence improving efficiency. Better automation allows for better monitoring and control of critical parameters like temperature and pressure which are necessary for maintaining product quality. Also, maintenance and calibration of the equipment should be performed regularly to prevent idleness and ensure that the machines are operating at their best. The use of data analytics could help to highlight areas for improvement and help optimize the processes. The last is the training of employees who will be responsible for the advanced retort systems for easy and efficient adoption of the technology.

Best Practices for Achieving Uniform Temperature in a Retort and Ensuring Agitation as Required During Retorting Steps

To resolve the issue of temperature distribution and agitation during retorting, calibrating and maintaining the equipment for optimal heat distribution should be done. Retorts should be periodically validated to ensure uniform temperature levels during the retort. Introducing systems with rotational or reciprocating agitation can help improve the uniformity of temperature during the heating process. Employing sensors to monitor the process allows setting of parameters in real time eliminating deviations. In addition, inspect the condition and location of hung or mounted agitators on a regular basis to ensure reliable agitation which is critical for uniformity of the end product.

Maximizing Food Safety and Product Quality During Retorting

In order to maximize food safety and product quality during retorting, great emphasis should be placed on following the sterilization procedure with precision and monitoring critical control points effectively. Regular decontamination and calibration of all equipment should be carried out. Improper forced blanketing and uncontrolled temperature escalation during processing should be avoided, and effective control strategies should be established. All raw material and ingredient temperatures, pressures, and other relevant parameters need to be under more elaborate supervision and control to ensure that any adverse effects on food safety or quality are completely avoided. Furthermore, every affected employee should participate in a hygiene and emergency response refresher training in order to quickly eliminate any safety concerns.

Reference sources

-

JBT FoodTech – “Automated Batch Retort Systems”

-

Allpax – “Automated Batch Retort Systems for Efficient Sterilization”

-

ResearChgate – “Understanding retort processing: A review”

Frequently Asked Questions (FAQs)

Q: What is a retort machine and how is it applied in the food industry?

A: A retort machine is a food processing machine designed to kill microorganisms in food products rendering them fit for storage. It is mostly used in the food industry in the processing and sterilization of canned food, pouches and other retorted packs. This type of equipment applies heat and pressure to eliminate bacteria and make the food secure for eating.

Q: In which ways does a retort machine increase efficiency in retort food processing?

A: The advanced controls and automation in retort machines harness food processing efficiency and effectiveness. Since the retorting process can be fully automated, the dependence on human resources is reduced and the thermal processing remains uniform. All these contribute to having safer food products and enhanced quality.

Q: What are the different types of retort machines available?

A: There are different categories of retort machines such as rotary, basket type and autoclave retorts. Different types of machines are intended for different functions including pouch and tray handling in relation to the packaging form and thermal processes for food packed in specific forms.

Q: What role does water spray play in a retort machine?

A: Water spray is in some retort machines so as to help in the even distribution of heat during the sterilization process. This makes it possible for all parts of the food product are heated uniformly, which in turn allows for more efficient sterilization while ensuring food is not compromised.

Q: What is the purpose of overpressure in retort machines?

A: Overpressure is utilized in retort machines in order to prevent the destruction of the packaging during the sterilization. This is particularly critical for flexible packages such as pouches because it prevents them from rupturing high temperatures and pressure.

Q: What is the process of unloading when using a retort machine?

A: Upon completing the processing and sterilization cycle, the retort machine now discharges the already processed item. This may be done either manually or automatically, depending on the nature of the machinery in use. The unloading process has certain specifics which do not allow for the use of great force while unloading so as to avoid damaging the food products.

Q: Why is retort packaging significant in food production processes?

A: Retort packaging is very important in food production as it is a method of packaging which preserves ready-to-eat and commercially shelf-stable coated foods. It makes it possible to sterilize the food together with the package ensuring that the shelf storage period is greater and the nutrients are preserved.

Q: What does the fully automated retort equipment add in value for the food manufacturers?

A: Fully automated retort equipment adds value for food manufacturers through better productivity, high quality and safer food products. After all, automation of retort process implies low labor cost, less human mishap, and a standard for safety and quality output when it comes to food products.