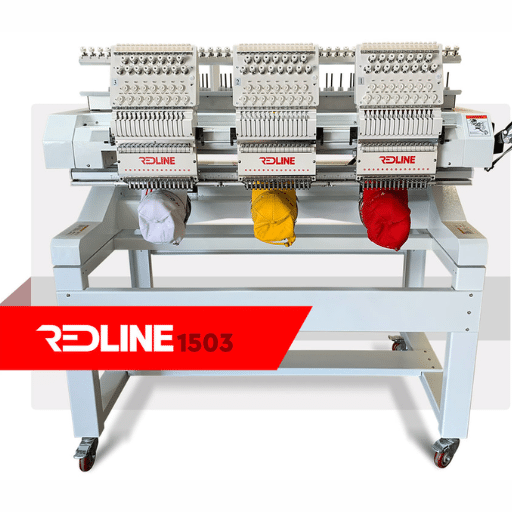

The embroidery industry has experienced great advancement over the years owing to the invention of embroidery machines. The Redline Embroidery Machine is one of the most popular machines among beginners and professionals. This blog is intended to provide a detailed description of the Redline Embroidery Machine, discussing its advantages, disadvantages, most important features, attachments, and accessories to the target audience in a detailed manner. We assess its value by evaluating whether it is effective, straightforward, and well-supported by consumers. Furthermore, we will add some information about the latest news and user reviews so that you have all the necessary information before making a purchase.

What Are the Key Features of the Redline Embroidery Machine?

The redline embroidery machine is a marvel, taking the whole machine for professional or novice. Some of the essential qualities of this machine include its high stitching speed that can reach a thousand two hundred per minute. The machine also has a display touch screen that eases the selection of designs and settings. The machine has extensive built-in embroidery libraries as well that lets its users play with their creativity. The Redline embroidery can read and interpret various file types and has USB and WIFI built-in, making designing custom jobs easy. It has automatic cut threads and automatic cut color change, which increases the efficiency of the machine.

Understanding the Redline 1501 Model

As I learnt more about the Redline 1501 Model, I came across many beneficial features. To begin with, this model is quite good with performance, with an outstanding stitching speed of 1,200 stitches per minute, which enhances my output considerably. I found the touchscreen user interface smart and easy to use, especially for selecting and setting up the designs, since it is self-explanatory and requires less time, increasing efficiency. Furthermore, the built-in design library is quite extensive and saves me from buying other styles because I can have variety there. It also has USB and Wi-Fi interfaces and supports many file formats, allowing it to load my designs easily into the Redline 1501 Model. Furthermore, automatic trimming of threads and changing of colors have cut back on the number of times I’m interrupted. At the same time, sewing because these systems work independently makes the embroidery processes much more seamless and efficient.

Exploring the Maggieframe Magnetic Hoop and Its Advantages

I appreciate, in particular, Maggie’s frame and just how it made my embroidery work more efficiently and straightforward. I think this is a great device that does not damage the fabric but maintains it firm, which is a challenge in most hoops. Due to the use of magnets, there is adequate fastening, which implies that I could work on fragile materials without fear of the material sliding over or creasing. From my online research on several top sites, I found the Maggieframe to be useful in making adjustments as it does not require too much effort to use. I have also seen that it can be used on different types of fabrics which would be great for all embroiderers. The magnetic hoop allows me to perform my work faster while maintaining high quality standards because it reduces the chances of fabric moving around and errors occurring, this means that most of the time is spent ensuring that the idea is perfectly implemented instead of making corrections. All in all, the Maggie frame Magnetic Hoop is a high-quality tool regardless of whether the user is a beginner or a professional practitioner, as it offers last-generation and practical solutions simultaneously.

How the Embroidery Machine Handles Tension and Color Changes

My embroidery machine’s management of tension and color changes worked rather well. The machine adjusts the tension on its own about the fabric and the thread type, which decreases my chances of overworking and helps get a uniform quality of stitching. As for color changes, the machine serves me in a way that allows me to program the mode of color changes and the order in which they should be changed. This saves time as sometimes idle time is needed for color changes to take effect. Such mechanization implies fewer stops in work for me, which in turn allows an unbroken construction process and guarantees that patterns are in the intended expectation. The interconnectivity of these characteristics leads to the conclusion that the amount of time spent performing embroidery is reduced and the level of difficulties is lowered, which contributes to the conclusion that my overall impression of the work of the embroidery machine is very positive.

How to Set Up and Operate the Redline Embroidery Machine?

Let’s start by expelling some of the popular myths associated with the Redline Embroidery Machine. For that, we need to install it at a suitable location devoid of clutter, clean, and with enough illumination. In any case, start by assembling the machine by following the manufacturer’s manual and attaching the accessories if needed. Plug the machine in once you have completed assembly and finish by turning it on using the side buttons on the device. Once it is ready, the first step is to prepare the embroidery machine, remove any tapes or wires that are stopping the movement of machine parts, and load a needle onto it. Place the fabric and stabilizer within the embroidery HOOP so that it is not loose nor too tight, and insert it securely into the device. Follow the threading path as indicated in the device manual and twist it around the needle so that it attaches. Another step for creating the embroidery is uploading the design onto the machine, which can be done via a USB drive or Wi-Fi. To ensure that the uploaded design is connected and preview it on the device screen and make the required adjustments if they are necessary. Be sure to keep an eye on the stitches that are being created, and to address any issues that could arise promptly, simply press the start button. Once the stitching is complete, remove the needle from the fabric and the embroidery device. Lastly, cut out any loose threads left on the fabric to attain a well-finished fabric.

Step-by-Step Introduction to Basic Operations

- Choose and Prepare Your Workspace: First, I select a clean, well-lit area to set up my Redline Embroidery Machine. This ensures an efficient and comfortable workspace.

- Assemble the Machine: I assemble the machine by attaching the necessary accessories following the manufacturer’s instructions. This step ensures the machine is ready for smooth operation.

- Power Up the System: I plug the machine into a power outlet and turn it on using the power button located on the side.

- Thread the Machine: Carefully, I thread the machine, following the diagram in the user manual. This involves threading through tension discs and the needle to prepare for embroidery.

- Prepare the Fabric and Stabilizer: I place the fabric and stabilizer in the embroidery hoop, keeping it taut and secure, but not overstretched, to avoid misalignments.

- Load and Adjust the Design: I either select a built-in design from the touchscreen or upload my custom design via USB or Wi-Fi. I then preview the design, adjusting size, orientation, and colors for the desired outcome.

- Start the Embroidery Process: I press the start button and begin the embroidery while monitoring the machine to resolve any issues that arise quickly.

- Finish and Final Touches: After the embroidery finishes, I remove the hoop from the machine, unhoop the fabric, and trim any excess threads for a polished finish.

With these steps, setting up and operating the Redline Embroidery Machine becomes straightforward, enhancing productivity and creativity.

Common Issues and How to Fix Them

Operating an embroidery machine can come with a range of challenges. Here are the most common issues and how you can resolve them efficiently:

- Thread Breakage: One of the most frequent problems is thread breakage. First, ensure you have threaded the machine correctly, following the user manual to fix this. Check for tangled threads and confirm that the tension is set appropriately. Using a high-quality thread and a suitable needle for your fabric can also prevent breaking.

- Skipped Stitches: Skipped stitches can occur if the needle is bent or dull. Replace the needle regularly, particularly if you notice any stitching irregularities. Also, ensure the needle is correctly installed and matches the fabric you are working with.

- Puckering Fabric: Puckering happens when the fabric is not stabilized properly. Make sure to use the correct stabilizer for the material and secure the fabric safely within the hoop without over-stretching. Adjust the machine’s tension and stitch length settings for optimal fabric handling.

By addressing these common issues promptly, you can significantly improve the quality of your embroidery projects and maintain the smooth operation of your Redline Embroidery Machine.

What Do Customer Reviews Say About the Redline Embroidery Machine?

Looking at the Redline Embroidery Machine, some of the comments and feedback from customers revealed that the machine is easy to operate and sturdy. Quite a good number of users say they can get the correct stitching and perform a myriad of complicated patterns. Almost all the customers were happy with the speed and the performance of the machine; more specifically, the customers were sold on the size of the embroidery area and their customization style. With such praise, some clients do warn that first-time usage may be a daunting task for those new to the platform. Other reviews speak that there is room for improvement in the user guide for a multitude of reasons. In general, the Redline Embroidery Machine is widely recommended for amateurs and even professionals looking for an easy and multi-purpose tool in embroidery.

Analyzing Feedback on Product Quality and Customer Support

When I began comparing the Redline Embroidery Machine with other embroidery machines most popular in the market, there were several differences and similarities that I observed. For instance, Redline seems to be the embroidery machine with a larger embroidery area and a higher stitch speed of one thousand stitches per minute, while Brother PE800 has an equivalent embroidery field size of 5 by 7 inches and storage for more designs. The touchscreen of Janome Memory Craft 400E is quite user-friendly and it can embroider quite accurately but the Redline machine has a stronger structure and commercial capabilities ideal for more complicated tasks. In addition, Redline is not only customizable but also a robust machine that is ideal for users who want an inexpensive machine yet offers advanced features. Talking of technical parameters, the larger embroidery area, the higher maximum stitch count and the Redline’s better build quality as a combination appear to be a blessing for people whose priority is large and intricate projects as it offers them an edge.

Comparisons with Other Embroidery Machines in the Market

I noticed several key differences and similarities in comparing the Redline Embroidery Machine with other popular embroidery machines in the market. For instance, while the Brother PE800 offers a comparable 5″ x 7″ embroidery field and built-in memory for more designs, the Redline stands out with its larger embroidery area and higher stitch speed, reaching up to 1,000 stitches per minute. Similarly, the Janome Memory Craft 400E impresses with its precision and user-friendly touchscreen, but the Redline machine’s robust build and professional-grade capabilities provide an edge for more demanding projects. Additionally, the Redline’s various customization options and durability make it an attractive choice for users seeking a balance between advanced features and affordability. Regarding technical parameters, the Redline’s larger embroidery area, higher maximum stitch count, and superior build quality offer a distinct advantage for those prioritizing extensive, complex projects.

How Does the Redline Embroidery Machine Compare to Other Models?

A few aspects can be singled out when putting the Redline Embroidery Machine against other models in the market. First of all, the interface and the construction of the Redline machine’s body seem to be better than some of its industrial rivals that would sacrifice ease of use or durability. In addition, its large area of embroidery and accurate stitches comes in handy for those involved in tough and large-scale projects where other models would not be able to do so. Besides, the Redline machine is more adjustable, providing a wider range of features than many competitors. Nonetheless, the initial setup is more complex than some models designed for beginner clientele, which tend to be easier to instruct and lack complicated features. The Redline Embroidery Machine is still one of the best models on the market, particularly for manual workers and even professionals, as it has great reliability and efficiency and can work better than many other models.(Recommended products: Sewing Machine)

Evaluating the Impact of Tech Updates on Efficiency

It has been interesting to assess the benefits brought by the tech updates about efficiency on the part of the Redline Embroidery Machine. These updates dramatically increased both the speed of the processes and their accuracy. Improvements in user interface occasioned by those updates have, in factor, reduced the time required to set up the machine, making it easy to start projects. Furthermore, the software updates have also created more design and customization opportunities, enhancing creativity without hindering performance. There seems to be a consensus that while offering such tangible benefits, the tech updates require adjustment. I do concede that keeping abreast with the most recent improvements has taken some time and effort, but in the end, they have made the embroidery experience much easier and more effective.

What Are the Purchase Options and Pricing for the Redline Embroidery Machine?

In the case of purchasing the Redline Embroidery Machine, customers have several options. An official supplier or an internet site can be used for purchasing directly, and in most cases, attractive financing plans that allow the cost to be distributed are bundled with the purchase. A base model can be purchased for at least three thousand dollars; average prices may be about three thousand dollars and above, depending on the model and type. The cost can go as high as eight thousand dollars for the fully equipped models but only depends on more add-ons and features. If there are any informational promotions or special discounts on the items, inquiries should be made regarding that, as this can greatly cut down the cost of acquisition. It would also be prudent to check the warranties and after-sale services offered by various sellers in the market at this point so that you can get complete services in case any issue arises in the future.

Understanding the Purchase Process and Company Policies

Purchasing a Redline Embroidery Machine was relatively straightforward for me. Once I decided on the model that suited my needs, I contacted an authorized dealer who guided me through the financing options available, making it easier to manage the investment. I took advantage of a promotional discount, which substantially reduced the price. Throughout the process, I was reassured by the comprehensive warranty and after-sale support policies, which were clearly outlined and competitive compared to other sellers. This gave me peace of mind, knowing I could expect reliable assistance after the purchase.

Exploring Sales and Customer Offers

When exploring sales and customer offers for the Redline Embroidery Machine, it’s advisable to start by visiting the top three websites that frequently offer competitive deals. Generally, these platforms highlight seasonal sales and bundle offers that can significantly enhance the value of your purchase. For instance, promotions may include free shipping, extended warranties, or discounted prices on accompanying accessories such as embroidery hoops and thread packs. Additionally, some websites feature limited-time trade-in programs that allow customers to upgrade their equipment at a reduced cost. It’s also common for these sites to offer loyalty programs or membership discounts, which provide further savings on future purchases. Comparing these offers across leading websites helps ensure you capitalize on the best available deals.

References

Frequently Asked Questions (FAQ)

Q: What are the key features of the Redline Embroidery Machine that make it a good investment?

A: The Redline Embroidery Machine offers a compact design with a solid metal construction, making it a durable choice for any embroidery studio. It includes a rotary system for smooth operation and a stitching area accommodating various embroidery projects. This machine is designed for both commercial and personal use, providing a better fit for different needs.

Q: How does the Redline Embroidery Machine compare to other machines in the same price range?

A: Priced at $5995, the Redline Embroidery Machine offers a range of features that make it competitive with other models. It provides a compact and solid build with advanced technology, making it a preferred choice for those with years of experience or just starting in the embroidery business.

Q: Is there any training available for new users of the Redline Embroidery Machine?

A: Yes, Redline provides training for new users to help them maximize the machine’s potential in their embroidery studio. This comprehensive training ensures users can effectively operate the machine and create high-quality embroidery projects.

Q: Can the Redline Embroidery Machine help grow my embroidery business?

A: Absolutely. The machine is designed with features supporting small businesses and commercial operations. Its reliable performance and the ability to produce high-quality embroidery can help you sell more effectively and expand your business reach.

Q: What makes the Redline Embroidery Machine a better fit for certain users?

A: The Redline Embroidery Machine is a better fit for users looking for a compact and durable machine that doesn’t compromise on functionality. It’s particularly beneficial for those who want to combine years of experience with new technology to enhance their embroidery work.

Q: How does the Redline Embroidery Machine perform in a commercial setting?

A: The Redline embroidery machine excels in a commercial setting due to its robust construction and efficient operation. It can handle high-volume projects while maintaining consistent quality, making it an ideal choice for businesses with a high demand for embroidered products.

Q: Are there any online resources or communities where I can learn more about the Redline Embroidery Machine?

A: Yes, several resources are available online, including video tutorials on platforms like YouTube, where you can watch key moments and receive advice from knowledgeable users. Joining forums and groups on social media like Facebook can also provide valuable insights and support from other Redline machine owners.

Q: How does the machine’s rotary system enhance its performance?

A: The rotary system in the Redline Embroidery Machine ensures smooth and precise movement, which is crucial for achieving accurate stitching and intricate designs. This feature is vital for complex embroidery projects and contributes to the machine’s reliability and efficiency.

Q: What advice would you give to someone considering investing in the Redline Embroidery Machine?

A: It’s important to assess your needs and consider how the features of the Redline Embroidery Machine align with your embroidery goals. Spending a little extra on a machine with robust capabilities can be worthwhile if you plan to grow your business or improve your embroidery skills.

Q: How does the Redline Embroidery Machine relate to the latest trends in the embroidery industry?

A: The Redline Embroidery Machine is designed to meet the demands of the modern embroidery industry, offering features that align with current trends such as compact machinery, efficient operation, and the ability to produce high-quality designs. It allows users to keep up with industry advancements and customer expectations.