The right kitchen appliances can indeed be a game changer in terms of saving time when performing various kitchen tasks. Topping that up are the electric potato peelers that are made for those who would like to achieve time Wan while still keeping the quality. Potato peeling machine is a kind of food machinery in potato chips production line.This blog seeks to assist you in traversing the jagged world of the numerous of potato peeling machines, their effectiveness, usability and other salient features. Hopefully, this will help you know what to look for in electric potato peelers whether you simply want to avoid the hassles of meal prep at home or are a professional chef working in a high volume environment requiring consistency. In this case, we will compare different models analyzing their advantages and disadvantages in order to assist you in making the best choice according to your requirements. Let’s peel away the hype and the veneer to show the best options that the market has to offer today.

How Does a Potato Peeling Machine Work?

Elucidating the Working Principles of Peelers

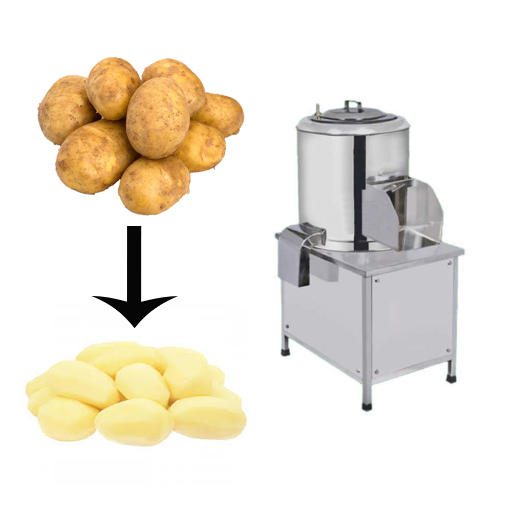

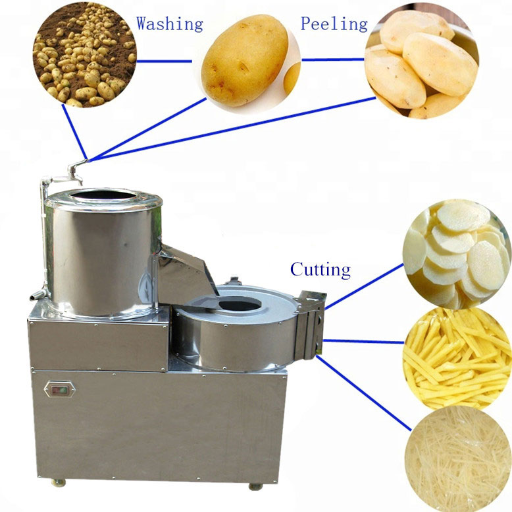

Potato-peeling machines utilize their rough surfaces and rotating parts for peeling. Electric peelers normally incorporate a round disc or cylinder armed with coarse material which revolves around and tumbles the potatoes so that skin is abraded off. Water is also used in this process since it is capable of flushing out the detached peel off spores. Machines are made to sustain different sizes of the potato as well as the time and energy consumed in operating them as compared to hand peeling is quite low offering uniformity and accuracy in preparing large number of tubers.

The Place of Electric Motors in Peeling

Electric motors make a remarkable contribution in the efficiency of small-scale potato peeling machines. These motors contribute to rotation of the mechanisms so that the rough surfaces keep on rubbing the skin of the potatoes for easy peeling. With electric motors, the operations run smoothly since there is constant speed and force, which results in uniform and faster peeling of the potatoes thus minimizing the workload and enhancing accuracy in large scale operations.

Why Choose an Automatic Peeler?

Opting for an automatic peeler comes with a number of benefits, among them are increased efficiency, faster means of operation and time savings. Through the mechanization of the peeling function, these machines reduce the manual effort needed significantly while allowing large quantities of potatoes to be prepared quickly and with more accurate end results. Waste is also reduced in automatic peelers by removing the potato skin only, thus more of the vegetable is preserved. Such machines are, therefore, very suitable for use in commercial kitchens or any other individual who regularly does a lot of batch cooking as they improve efficiency and reduce strain.

What Are the Benefits of Using a Commercial Potato Peeler?

Efficacy in Potato Processing

In potato processing, the application of commercial potato peelers greatly reduces the time allocated for the manual peeling of potatoes which increases the overall efficiency of the vegetable processing. Their large volume receptiveness contributes to productivity levels in busy kitchen spaces. They provide a consistent peeling action that serves uniformity in the ‘cooked quality’ and reduce peeling losses through exact removal of tank skins, which increase the yield and quality of potato products.

Efficient Timesaving Devices Ideal for Large Cookhouses

Kitchens that serve large quantities of meals can hardly be without using commercial potato peelers as they allow for the fast and uniform processing of vast amounts of potatoes. These devices take away some of the physical workload, increase efficiency, and guarantee that the peeling is done with maximum efficiency – i.e., the unnecessary parts of the potatoes are eliminated more effectively, and greater quantities of potatoes are utilized in large-scale cooking activities.

Capacity and Output of Industrial Peelers.

The performance of these industrial peelers is excellent in terms of both the capacity and output and can easily handle large quantities of potatoes within a short period of time. This translates to the ability of large kitchens to handle the busy requirements of serving meals quickly and smoothly. Because of the strength of the construction, these machines can sustain their level of productivity and quality consistently which makes them a must have in the preparation of food in bulk.

How to Choose the Right Potato Peeler Machine for Your Kitchen?

Examining The Sources For Blades And Their Materials

While trying to select the most appropriate potato peeler machine for your kitchen, take note of the options for blades as well as the materials from which they are made in relation to the expected usefulness and durability of the device. Stainless steel blades are the most preferred since they are resistant to corrosion and sharp and thus can accomplish effective peeling for a long time. Furthermore, ‘dig deeper into potato peelers that have other configurations such as depth settings or adjustables that can be used on different sizes and thicknesses of potato skins,’ increasing the scope of use for different culinary purposes as well.

Important notes on the construction of stainless steel

In the case of a potato peeler machine, it is worth choosing a machine designed with high-quality stainless steel in its construction because such machines are durable, easy to maintain. Such characteristics make sure that the working tools of the machine last for a long time, which allows the machines to operate with high levels of efficiencies across large kitchens. Furthermore, steel is easy to maintain as well as hygienic which petrifies risks during food preparation.

Assessing kitchen requirements against potato peeler machine capacity

First, when considering the capacity of a potato peeler machine, compare the number of potatoes the kitchen uses on a standard basis. Get one that corresponds with the working load of the kitchen in terms of peak performance during the busiest moments. Scale up: while smaller kitchens may use compact models, large, high output kitchens should purchase machines that are able to cope with higher volumes of outputs without compromising performance.

Can an Electric Potato Peeler Handle Other Vegetables?

Adjustment of Operations for Carrot and Beetroot Peeling

Indeed, there are many models of electrical potato peeler that can be used for other vegetables like carrot and beetroot provided these appliances have the options or attachments suitable for such works. Also consider looking for models that have adjustable blades or those that have several functions that complement other designs. That said, in order not to break the machine it is critical to follow the supplier’s instructions.

Versatility of Vegetable Peeler Machines

The scope of the term vegetable peeler machines, in particular the ones having adjustable features and advanced settings, can certainly go beyond potatoes. They can peel vegetables with varieties in shape and texture like carrots, beetroots and others because of the use of various devices and or attachments. It is advisable to observe the manufacturer’s instructions to avoid conflict between the tool and the type of vegetables that are to be processed, with the aim of conserving the machine’s functionality.

How to Maintain and Clean Your Potato Peeler?

Regular Washing Tips and Techniques

In case it is required for cleaning and sanitizing purposes, an operator may go a step further and further detach the potato peeler from the main unit. Observe how the skin and starch deposit are areas that remain even when rinsed under warm, soapy water, and are bound to remain too when such cleaning measures are undertaken, apply a soft brush look to those areas too, while they can be scrubbed. Apply a soft, damp cloth to the hatch of the main unit, but do not submerge any electrical contacts in water. After wiping all sections, as a final step, allow some time. This is done to ensure the whole set is thoroughly dry, which will help to prevent rust accumulation and damage to the entire set. Usually the maintenance will guarantee hygiene and maximum performance with minimum failures.

Brush and Blades Maintenance and Preservation of their Useful Life

With the goal of extending the lifetime of the brush and the blades of the potato peeler, regular inspection of the components for any damaging or wearing out should be performed. In order to avoid the accumulation which could blunt their sharpness, wash them immediately after use. Dry places should be used to keep the machine such that rust is avoided. Measure amount of time between sharpening or changing out blades, and perform blade maintenance as well as changing out blade components per the manufacturer’s directions.

Maintenance of the Automatic Peeler: Maintenance Practices

It is advisable to wash and dry all components of an automatic peeler after operations in order to maintain its hygiene. Monitor the condition of wear on brushes and blades frequently and if necessary, sharpen or replace these cutting tools. It is preferred to store the appliance in a location away from humidity to reduce the chances of rusting; maintenance recommendations and replacement tokens of the manufacturer should always be followed.

Are There Innovative Features in Modern Electric Peelers?

Technologies in the Kitchen requiring less Force during Cutting Operations

Today’s electric peelers are equipped with new features that aim at making one’s work in the kitchen more efficient and hassle-free. Such devices usually include more advanced cutting methods such as an automatically adjusting blade with its geometry to different fruits and vegetables. Certain models have principles of control which are the speed adjustable, and settings specifically geared for soft or hard producers, which reduces waste and increases the flesh of the food retained. Moreover, smart features and sensors enable self-activation while also protecting the user from jamming. In this way, the operations performed are much faster and require little effort on the part of the user as they are more adaptable to various cooking needs.

Integration of Peeler Electric together with Smart Kitchen Implements

The new generation of electric peelers can be integrated with other smart kitchen devices, thus making work easier and adding functionality. Bluetooth and app control features are also gaining popularity as users can control and monitor the electric peeler remotely. Consequently, the peeler can be used in a smart kitchen set up which enhances the cooking processes and improves overall efficiency. The ability to voice activate the electric peelers through devices such as smart speakers makes these gadgets both modern and ideal for the present day kitchen setting.

Reference sources

-

TOPCHANCES Multifunctional Automatic Electric Potato Peeler on Amazon

-

Mechanization & Development of Potato Peeling Machine (IJEIT)

-

Design and Performance Testing of Semi-Automatic Machine for PotatoPeeler-Cutter

Frequently Asked Questions (FAQs)

Q: What is a potato peeling machine, and what’s the procedure involved in using a potato peeling machine?

A: A potato peeling machine is a piece of equipment that is used for the purpose of removing the skins off potatoes in a very effective manner. The operation utilizes abrasive surfaces or blades, which peel the skin of the potatoes as the latter is rotated, manually or automatically, depending on the type of machine. Some models also have a washing function whereby washing and peeling is done at the same time.

Q: For other vegetables, can a potato washing peeling machine be applied?

A: Yes, many potato washing peeling machines are relatively multipurpose in that aside from potatoes, they can also wash and peel other vegetables like carrots, beets and turnip. However, these variables are best considered after confirming from the manufacturer specification instructions to avoid damage.

Q: There is an effortless cutting auto feature to the potato peeler how would this make the peeling of potatoes easier?

A: With the potato peeler effortless cutting auto feature, the peeling of potatoes can be done without intervention by hand. Manual effort and time exposure are also minimized when this feature is employed. For this function, a rotating blade or an abrasive surface is typically utilized to enable faster and more efficient peeling of potatoes thereby making it convenient to process potatoes for both domestic and industrial purposes.

Q: What are the strengths of an electric potato peeler automatic rotating model?

A: An Electric potato peeler automatic rotating model provides comfort as it makes the process efficient by eliminating the need for hands to peel the potato. It minimizes manual work labor as well as the danger caused by peeling chisels and specifically aids those in the food industry or those factories that deal with bulk processing of potatoes.

Q: Is it possible to find automatic potato peeling machines free of slippage?

A: Yes, a good number of potato peeling machines come fitted with non-slip bottoms so as to add stability to the machine during operations. This avoids the movement or slanting of the machine during the peeling operation thus increasing the effectiveness and safety of the whole peeling undertaking.

Q: As far as don’t forget to wash hands, how do I maintain my potato washing and peeling machine?

A: First, there are basic operational procedures that should be followed while using the potato washing and peeling machine, reasonable cleanliness should be maintained in line condition specifications. Over time, however, it is crucial to clean any clogs of working parts and the housing of the device. Maintenance done right will assure the continued efficacy and elevates the working time.

Q: Is it possible to make use of machine kitchen peeling tool for the purpose of producing potato chips?

A: Yes, a machine kitchen peeling tool can be used in a potato chips line in preparing the potatoes for slicing and frying processes. In that sense, the machine for peeling can be used to prepare potatoes for slicing into chips and proceeding to the chip making process according to your specific potato chips recipe.

Q: Are large scale potato processing peelers used by commercial potato processors available?

A: Yes, commercial peelers are available for large-scale potato processing. These devices are manufactured in consideration of extensive use in high volume of potatoes and industrial food processing is therefore feasibly possible. Materials for these products are usually of quality, size, and geometric shapes that are durable and provide advanced peeling techniques.