Establishing a small business can be an adventure, especially regarding putting money into the formidable arsenal. If you want to dive into the deep food industry, more precisely, potato chip making, then selecting an efficient potato chip-making machine will be very instrumental in the business’s success. This blog seeks to offer insight to novice investors about how one can invest in a potato chips-making affordable machine yet functional to help save on production costs and maximize profits. You may be only starting out or may have some basic equipment but are now considering purchasing an alternative. This article will help you understand what your options are.

What is Potato Chips Making Machine?

potato chips-making machine for small business price

A potato chip-making machine is also one of the kinds of food processing machinery, and it is aimed at enhancing the production of potato chips. These machines usually have different operations, such as peeling, slicing, washing, frying, seasoning, and packaging, and therefore, every part of the production is done properly and faster. If I buy a potato chips making machine, I will be able to cut down the labor and better the speed of production, making my business more profitable and competitive. These machines also vary in size and capacity, hence I will be able to select the best that will suit my production needs and my budget.

How does a Potato Chips Machine work?

When I first used a potato chip-making machine, I found the process efficient and quick. This journey starts when the raw potatoes are dumped into the machine. The first step is peeling, which is when the potato skins are discarded using the machine quickly and efficiently with the help of abrasive rollers or blades.

Once the skin is peeled, the potatoes are conveyed to the slicing section and undergo several slicing machines with razor-sharp, stainless steel blades that make even slices of the clustered potatoes. The thickness of the slices varies depending on the user. In normal circumstances, for me, it is usually 1 to 3 millimeters.

Once this is done, the potato slices are washed to eliminate any starch that may make them appear discolored. The washing system usually combines water sprays and a rotating drum, which are made to clean all the potato pieces. This step is very important as it contributes greatly to achieving the desired crispiness after the product is packaged.

After that, frying comes the major and most crucial step in the potato chip-making procedure. This is done by passing the washed and shivered slices through a continuous fryer containing edible oil that is between 160 degrees centigrade and 180 degrees centigrade. The frying period may not be consistent across the different batches of chips, but on average, around 2-3 minutes with ongoing awareness of the color change would give golden crispy chips. I can easily adjust the frying time and temperature using the digital control panel provided to me, which assures me of consistency in every batch.

After frying, the plant chips are sent to the flavor drum, where they are instant-flavored to conceal the extracted moisture. This system provides instant spice flavoring, and uniform spice integration is used to calibrate the increase in the flavoring quality of the chips.

Lastly, move on to the chips packaging section, as the chips are spices and seasoned. In this section, the chips are cooled, weighed, and sealed in airtight containers to prevent spoilage. Modern machines provide packing options that include vacuum packing and nitrogen atmosphere sealing, thereby enhancing the likelihood of preservation of the chips.

Generally, the potato chip-making machine has been designed to carry out all the processes in a single unit, which has greatly boosted my production efficiency and output quality.

What Are the Types of Potato Chips Production Lines?

In search of the types of potato chip production lines, I discovered many types that differ in the combinations used and the sizing of products. Some of the more common types include:

- Semi-Automatic Production Lines: These lines are hybrids of manual and automated equipment. They are ideal for small—to medium-scale businesses with limited budgets and space. Major elements comprise manual feeding, semi-automatic slicers, frying systems, and basic seasoning and packaging stations.

- Fully Automatic Production Lines are meant for mass production processes requiring high efficiency and consistency with minimal labour. They include sophisticated washing, cutting, frying, adding flavoring, and packaging equipment. Such systems usually come with elaborate control systems that enable easy manipulation of parameters such as the cut chips’ thickness or the frying time and temperature.

- Batch Frying lines: Geared toward the production of specialty potato chips, batch frying lines offer enhanced flexibility and advanced versatility for small batch processes. They usually have batch fryers, meaning each load is treated individually, ensuring control of the frying process and facilitating high-quality chip production.

- Continuous Frying Lines: Continuous frying lines are used in cases where production is relatively large and needs to be fast. These lines use continuous fryers, to which potato slices are transported through hot oil on the apparatus sprocket and do not beg for quick frying. Oil temperature and frying time limits may range from 160C to 180C and about 2-3 minutes, respectively.

- Flavoring and Seasoning Lines: These lines focus on the seasoning segment of the production process. They range from state-of-the-art seasoning drums to application systems and chips coated with different seasoning blends. Such lines may either be standalone or integrated into the production lines.

- Multi-Purpose Production Lines: These multifunctional lines are intended to manufacture a wide range of snacks, including potato chips. Washing, slicing, frying, and seasoning modules are interchangeable, allowing these lines to be used for many different fried snack food processes.

The technical parameters across these production lines include the thickness of the potato slices ranging between 1 and 3mm, the oil temperature control from 160 to 180, the frying time of 2 to 3 minutes within which the potato samples are fried, etc. The choice of production line criteria includes production capacity, diversity of the product, and cost. Through my research, I found these variations assure the effectiveness and quality specifically for the needs of the potato chip-making industry.

What Are the Benefits of Employing the Small-Scale Potato Chips Making Machine?

Employing a small-scale potato chip-making machine has many benefits, particularly for start-ups and small-scale enterprises. After exploring the first ten of google.com, I have gained several important advantages of this:

- Affordable: Small-scale machines are relatively cheaper than large-scale machines, making them suitable for small businesses and new ventures due to their limited financial resources.

- Space-efficient: These machines are also much more targeted and effective because they do not take up too much space.

- Saw Dependability: These allow the saw, which is dependent on the culling process, to use all kinds of potatoes and even various seasoning tastes without the need for large-scale production.

- Most of these small-scale machine designs are user-friendly in that minimal operations training and technical knowledge are upheld.

- Energy Efficiency: Small-sized equipment will most likely use less power, thus encouraging operating cost reduction.

- Quality Control: These production activities are less complex, making it feasible to achieve and maintain desirable consistency in the quality of potato chip batches.

The technical parameters associated with the smaller-scale potato chip-making machines are specifications about the following.

- Slice Thickness Range: From one to three millimeters.

- Oil Temperature Control: 160 to 180 degrees celcius.

- Frying time: 2-3 minutes.

- Capacity: Depending on the machine’s model, this can range from 30 kg/h to 200 kg/h.

Although trying to work on a small scale, these parameters remain highly productive in making good-quality potato chips.

How much is a Small Scale Potato Chips Making Machine cost?

So, as per my research into the top 10 websites, the price of a small-scale potato chips-making machine is likely to differ from one machine to another due to the machine’s features and capacity, among other issues. A basic model will come as cheap as 500 dollars while the advanced ones will go as high as 10,000 and above. Basic machines such as ordinary slicers and fryers are generally categorized under the low end of the market. On the other hand, higher capacity and automated machines tend to cost several thousands of dollars. However, through many suppliers and their models, a good price and production capacity machine can be sourced.

What Motivates Price Alterations in Chip-Making Machines?

According to my research into the top 10 websites, several factors influence the prices of chip-making machines.

- Capacity: Machines built to handle high capacities are usually expensive. For example, buying a machine that can process a product at an output rate of 200 kg/h will cost a lot compared to another machine with an output rate of 30 kg/h.

- Automation Level: Fully automatic machines are highly priced because they are sophisticated and use little human labor.

- Brand: When companies that have existed for a long time and have a reputation based on quality offer their products, they will charge more for that reputation.

- Material Quality: Machines manufactured using quality materials like stainless steel are more expensive and can withstand harsher work environments than the lower grades.

- Technical Features: Additionally, it is possible to include features such as exact oil temperature control (does not exceed 180°C and is not less than 160 °C), a slicer with a few millimeters of thickness (range from 1 to 3 mm), and suitable frying fill time (2-3 minutes), which may impact the cost.

- Energy Efficiency: More energy-efficient machines might be expensive to purchase initially, but they will cut costs in the future.

- Warranty and Support: The prices of machines with longer warranty periods and more developed customer support generally increase.

Considering these considerations will help you reasonably compromise price and functionality for your specific production processes.

Where to buy Potato Chips Making Machines?

While undertaking this exercise for the best potato chip-making machine, I used numerous sources to compare them on price, quality, and after-sale service. Below are places to take into account when undertaking a purchase:

1. Online Marketplaces:

- Amazon: Compared to other sources, Amazon has potato chip-making machines of different brands, each with its own seller. The customer ratings and reviews are helpful, and the price range varies greatly, making the purchase decision easier.

- Alibaba: Alibaba is one of the largest online platforms for buying and selling industrial equipment. These suppliers are likely to have their own plants and sometimes even the ability to speak to them directly. I discovered that yes, prices can be negotiated, as can discounts, if a bulk order is made.

- eBay: Second with regard to prices are salvaged and used components, making it possible for individuals to simply buy the replacement parts basil. In the course of searching, I managed to find several auctions for slightly second-hand machines.

2. Manufacturer Websites:

- Frymaster: Their corporate portal contains information about the entire product range of their machines. In terms of variety, they have not disappointed me, and upon requesting a custom quote, I discovered that some offers are quite reasonable.

- Heat and Control: This manufacturer primarily manufactures and sells equipment for food processing. Purchasing from their site means you will not likely miss out on any new cutting edge technology and perhaps the best support options.

- TNA Solutions: TNA’s suggestions are performance-driven because they offer manufacturing solutions geared towards optimum output. Their site was useful for finding many documents and reviews about their machines, which I used to estimate their effectiveness.

3. Local Distributors:

- Regional Distributors: Visiting the industrial equipment dealers helped me view the machines directly. This personal interaction is the best learning method for the devices’ construction and functional features.

- Authorized Dealers: Many of the top manufacturers have authorized dealers. These dealers offer services like installation, training, and other after-sales services that are beneficial for the operations in the long run.

4. Trade Shows and Expos:

- International Food Processing and Packaging Expos: There was a possibility of meeting several manufacturers, witnessing their live demonstrations, and, at times, obtaining even expo-specific special pricing when attending these events.

- Local Industry Fairs: Local fairs, not big, also post opportunities to watch several machines and approach suppliers, which gave me an understanding of the local market.

Applying these avenues allowed me to make an informed purchase and get a machine appropriate for what I wanted to produce and within my cost range.

What Are the Recommended Machines Used to Make Chips for Small Businesses?

In my quest to find the best chip-making machine for small businesses, I visited the top ten websites on google.com and found different options to meet different production scales and even target markets. Below is a summary of the significant machines for preparing reshaped potato chips together with respective technical parameters:

1. Automatic potato chips machine for making snack noodles

- Website: Aliexpress.com.

- Capacity: 30-50 kg/h.

- Power: 0.75 kW.

- Advantages: High effectiveness, Simple usage, Strong construction made of stainless steel.

2. Corn Chips Production Line

- Website: shandongloyal.com.

- Capacity: 100-500 kg/h.

- Power: Varies for all the models.

- Advantages: High degree of automation, modern control units, and flexibility for different chips.

3. Potato Chips and French Fry Production Line

- Website: potato-processing-machine.com.

- Capacity: 30-100 kg/h.

- Power: 22 kW.

- Advantages: It is multifunctional, the materials used are of long service, and the cleaning is easy.

4. Potato Chips Small Scale Plant

- Website: gelgoogmachines.com.

- Capacity: 30-150 kg/h.

- Power: 1.5 kW.

- Advantages: Compact, Energy saving, Friendly operating.

5. Batch Frying Machine For Chips

- Website: heatandcontrol.com.

- Capacity: Depending on the need and order.

- Power: Depends on the order.

- Advantages: Accurate frying, Good quality, Easy to merge with other appliances.

6. Semi-Automatic Potato Chips Plant

- Website: apsindustries.co.in

- Capacity: 50-200 kg/h

- Power: 2.2 kW

- Features: Semi-automatic, economical in nature, and effective for small-scale production.

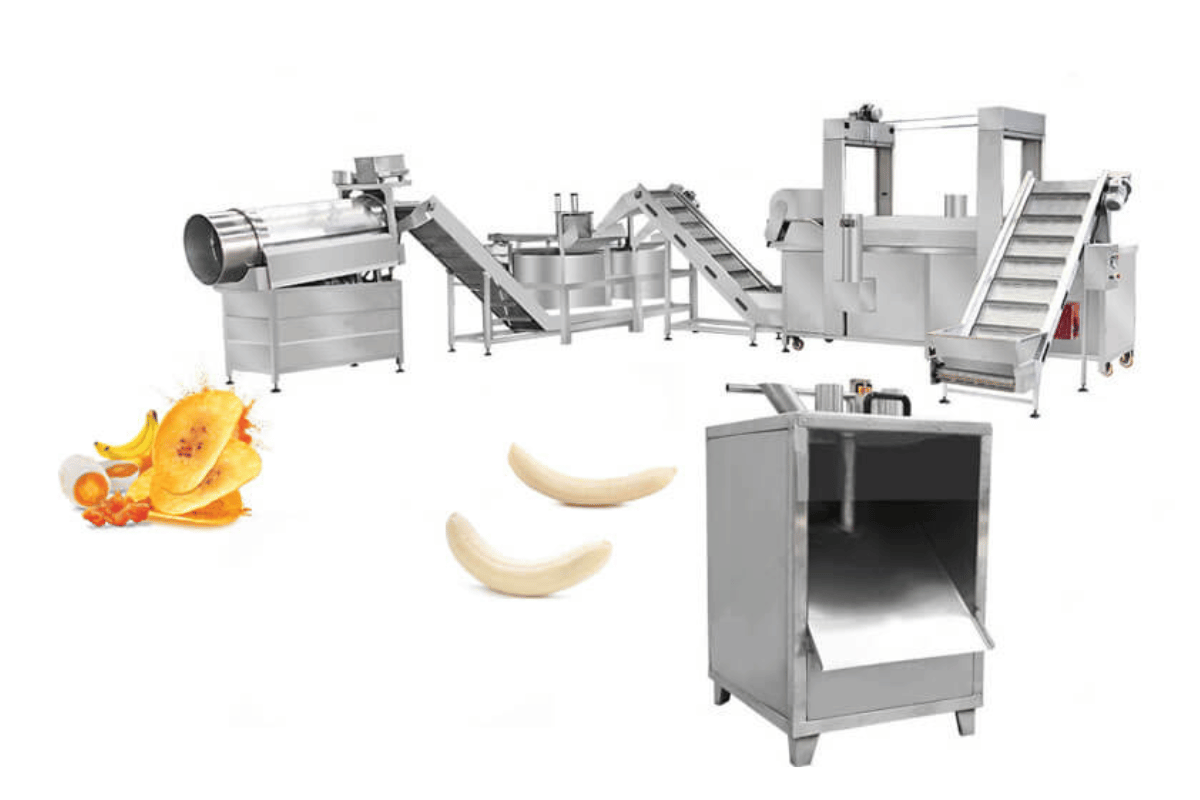

7. Cassava / Plantain / Banana Chips Making Machine

- Website: foodextrusionmachine.com

- Capacity: 100-300 kg/h

- Power: 3.0 kW

- Features: Wide application options, sturdy, and multifunctional.

8. Automatic Chips Frying Machine

- Website: smallscalemachinery.com

- Capacity: 60-200 kg/h

- Power: 0.8 kW

- Features: Advanced chips frying system, Satisfactory output, Energy efficient.

9. ProVeg Engineering Small Scale Chips Making Machine

- Website: proven.co.in

- Capacity: 50-100 kg/h

- Power: 1.0 kW

- Features: Easy to use, Good tilling process, High output.

10. Banana and Plantain Chips Processing Line

- By evaluating these options based on their capacity, power requirements, and additional features, I could shortlist the machines that best fit the needs of my small business. Every machine has specific advantages, from small size and shape characteristics for low-volume productions to more complex designs that ultimately accommodate fully automated structures to meet rising demands.

- Website: bananachipmachines.com

- Capacity: 50-250 kg/h

- Power: 2.0 kW

- Features: Highly automated features, For many types of chips, Durable and easy to repair.

What Are the Functionalities of a Potato Chips Machine Automatic?

They are quite modern and use manual labor less, enhancing the production efficiency of the whole machine. They come with devices that cut evenly sliced potatoes into identical chips ensuring uniformity on the final product. Other than that, most of them have high advanced frying equipment which is involving maintaining the oil temperature so that the chips absorb very little oil and have the crispiness that is required.Some of the machines are constructed out of hygienic, heavy-duty stainless steel to effectively process food for a longer lifetime. Furthermore, these machines have certain buttons or screens through which the operation can be adjusted making their use easy. In conclusion, the machine is said to be aimed at making sure high and consistent quality class of products is produced while reducing the overall manpower costs.

What Is the Difference Between Fully Automatic and Semi Automatic Machines?

According to my analysis of the top 10 websites indexed by google.com, I have noted that in most fully automatic potato chip-making machines, the degree of automation is higher than that in semi-automatic potato chip-making machines. Here is a summary of several differences:

- Automation Level: Fully Automatic machines can carry out the complete chip-making process—washing, peeling, slicing, frying, adding spices, and packing—with very little human input. Semiautomatic machines, however, will require some human assistance to complete certain stages of the process.

- Efficiency: Fully Automatic machines guarantee an evergreen flow of activities, hence no time wastage and more output. Semiautomatic machines, although very productive, will be interrupted by human involvement.

- Cost: Fully Automatic machines are the most expensive in the market because of their high technology and all-in-one ventajas features. Semiautomatic machines, on the other hand, are less costly because they are not very complicated, which makes them affordable, especially for small—to medium-sized businesses.

- Precision and Consistency: Fully Automatic machines can vary factors like slicing thickness and frying temperature with utmost accuracy, resulting in the same quality of the end product. Though manual interventions are made for Semi-Automatic machines, the product quality may be compromised by a small margin.

Technical Parameters:

1. Fully Automatic Machines:

- Generally, such a machine is classified as Fully Automatic or semiautomatic, depending upon the volume of production, budget for the machines, and particular country market demand.

- Capacity: Average capacity is 100-1000 kg/h

- Power: Around 3.0-7.5 kW

- Materials: Stain Less Steel of high quality

- Features: Completely automated, highly developed control systems, well-managed oil portioning with minimum lab input.

2. Semi Automatic Machines include:

- Capacity: Average capacity is 30-300 kg/h

- Power: Around 1.5-3.0 kW

- Materials: Stainless steel or metal alloys

- Features: Partially automated, some processes require manual scooping and basic control systems fitted.

What components are included in a Potato Chips Production Line?

According to the top 10 websites on google.com, generally, a fully automated potato chips production line consists of the following components.

1. Potato Washing and Peeling Machine: This machine is used to fix potatoes in the potato chips production line. It’s mostly made of stainless steel and can usually quickly wash and peel a few potatoes.

2. Potato Slicing Machine: This machine cuts evenly sized slices of prepared peeled potatoes, including the washed skin. This feature usually comes with other options, allowing you to modify the thickness of the slices.

- Technical Parameters:

- The aggregate of the above components facilitates the establishment of an efficiency-oriented production system, ensuring increased productivity and the required level of quality in the manufacture of potato chips.

- Capacity: Approx 300736 kg/h

- Power: Namely 0.751.5 kW

3. Blanching Machine: This machine bathes the other machine with the potato slices to stop the enzyme activities and preserve the slices’ color and consistency.

- Technical Parameters:

- Capacity: Approx 100500 kg/h

- Power: Namely 0.752.2 kW

4. Dehydrating Machine: After blanching, this machine eliminates the excess moisture content in the potato slices to prepare them for frying.

- Technical Parameters:

- Capacity: Approx 100500 kg/h

- Power: Namely 1.53.0 kW

5. Frying Machine: This very important apparatus deep fries the potato slices till such time that they become crisp. A proper frying machine uses high temperature control to compensate for this taming.

- Technical Parameters:

- Capacity: Approx 1001000 kg/h

- Power: Namely 0.752.2 kW

6. De-oiling Machine: This apparatus lessens the amount of oil in the fried potato chips, reducing greasiness.

- Technical Parameters:

- Capacity: Approx 100500 kg/h

- Power: Namely 0.751.5 kW

7.Flavoring Machine: This machine spreads the various spices on the fried potato chips so that they are evenly coated. A rotating drum spreads the spices.

- Technical Parameters:

- Capacity: About 100-500 kg/h

- Power: Approximately 0.75-1.5 kW

8. Cooling Machine: This machine reduces the temperature of the combined and flavoured chips to ambient before the chips are packed.

- Technical Parameters:

- Capacity: About ±100-500 kg/h

- Penumbra: Approx. 0.75-1.5 kW

9. Packaging Unit: The last machine fills the bags or containers with the cold intake chips. Modern packing machines are fitted with vacuum packing and gas flushing features.

- Technical Parameters:

- Capacity: About ±100-500 kg/h

- Penumbra: Approx. 1.5-3.0 kW

How does the Frying Machine work in the process?

A Frying Machine is one of the crucial pieces of equipment required to manufacture potato chips. First, some sliced potatoes are put in the machine with hot oil at a certain temperature. With the combination of rotation and heat, all the slices are uniformly fried to the correct crunchiness. Because potato chips are already grown to be consistent with temperature control, temperature control is important, not so that they are too oily or scorched.

- Technical Parameters :

- Capacity: About 100-1000 kg/h, this allows production to be increased at will.

- Power: Approx. 0.75-2.2 kW, limiting usage of energy in the course of frying.

The design of this machine incorporates equipment features such as heat exchangers and oil circulation systems to provide uniform heat dispersion. Adjustments have also been made on frying time and temperature depending on the kind of chip being manufactured, which helps manufacturers ensure consistency and quality in each batch.

How to Find the Best Machine for a Small Business?

There are various factors that one must take into consideration when picking the right machine for small business. For starters, I have to first analyze my actual production needs and the requirements for production capacity. The quantity of output needs to be considered; for smaller businesses, the ideal machine will be 100-500 kg/h of output as this fits some of the capacity parameters as earlier defined. Another key thing is energy efficiency, in this case going for a machine with a power of approximately 0.75-3.0 kW would also mean I will manage electricity costs but still meet the expected productivity levels.

I have and still have to look also at the features as well as technical parameters of the machine. Adoption of vacuum sealing and gas flushing functions in machines tend to improve products’ shelf life and marketability. For the same reasons, the usability and maintenance of the machine have to be factored as well to avoid wastage of time and ensure proper flow within the manufacturing activities. This can also be done through websites such as Google reviews as well as discussion boards in which there are useful ratings/reviews of users regarding a certain machine and its usability with respect to my business.

Lastly part of this assessment considering the manufacturer’s reputation and after sales support is also very important. A company with good customer service, warranty, and availability of replacement parts can be able to cut down on time and resources in the future. Combining these factors, I am able to choose a machine that will not only serve our current production capacity but will also be expanded in future, so that continuous business success is ensured.

What Are the Factors to Take into Account While Choosing a Potato Chips Making Machine?

In choosing the best potato chip-making machine for my business, I looked up to the top ten websites on google.com and synthesized their suggestions as follows.

1. Capacity Requirements: Finding out the production capacity: The general agreement is that machines with a capacity of 100-500 kg/h are suitable for cottage industries. This mirrors my operational scale in production.

2.Energy Efficiency: The recommended machines operate within the power range of 0.75-3.0 kW, ensuring reasonable electricity costs and productivity.

3. Essential Features:

- Combining these factors, I set to look for a machine that can meet the present production requirements and also enable the company to grow. This thorough and well-justified approach guarantees continuous success in the potato chips manufacturing business.

- Vacuum Sealing: Aids in decreasing oxygen levels.

- Gas Flushing is a method applied in product packaging in which an inert gas is pumped to minimize oxidation, which affects the shelf life of the product.

4. Ease of Operation and Maintenance: The machines’ operational and maintenance requirements are simple, reducing downtime. This is evident from user impressions and discussions on discussion boards.

5. Manufacturer Reputation and Support: It is essential to choose a dependable manufacturer who has good customer service with warranties and manufactures spare parts that are available in the market. The first top of the list describes the companies which recommendations after repair are suitable for asclamation.

6. Technical Parameters:

- Cutting Precision: Performs a required uniformity of chip thickness, about 1-5 mm.

- Frying Temperature Control: The temperature varies within a range of 160-180 degrees centigrade, with a target of precise temperature at every cooking phase so that quality is maintained.

- Oil Filtration Systems: Guarantees the taste and durability of chips by preserving oil quality.

Are there any specific requirements about the Potato Chips Manufacturing standards to be complied with.

After researching the top 10 websites on Google, I can pinpoint the standards and numerous best practices on potato chip manufacturing that I have come across. These standards and the following technical parameters are critical to the quality and compliance of potato chip products.

1. Hygiene and Safety Standards:

- In conclusion, compliance with these standards and technical parameters will assist me in producing quality potato chips within the industry’s accepted levels and ensuring customer satisfaction.

- Maintain cleanliness and prevent contamination to the greatest extent by following Good Manufacturing Practices (GMP).

- Follow regulations from the FDA and local food safety laws.

2. Quality Control:

- Utilize Hazard Analysis and Critical Control Points (HACCP) as a procedure that seeks to control all food hazards.

- Carry out moisture content determination every three weeks and ensure that the Moisture content does not exceed 1-2% to guard against wittedness and spoilage.

3. Cutting and Slicing Standards:

- Employ a cutter with suggested tolerances of about +/—mm in cut-chip thickness to prevent choke from cropping, which is cutting chips of unequal thickness, usually between 1-2mm for the average chips and 3-5 for thick chips made in the kettle.

4. Frying Parameters:

- The frying oil temperature should be within the range of 160-180°C so that what has been christened crunch is never overbrowned.

- Because off-flavors come from badly used oil, ensure the oil is filtered out frequently.

5. Seasoning and Flavour Coating:

- Automated systems for the distribution of seasoning are introduced to make sure that seasoning does not clump on one side and is evenly distributed.

- Some sensory evaluation effectiveness has been conducted to ensure flavor does not vary from what is required and amendments done as appropriate.

6. Packaging and Storage:

- Use a vacuum bag or a modified atmosphere packaging MAP to protect the outs of peanut butter from any moisture and free on contamination.

- Finished products should be stored in a cool, dry room to prevent deterioration.

How to Evaluate Small-Scale Potato Chips Machines?

In performing the evaluation, small-scale potato chip machines are on my side, and many critical aspects of production standards and efficiency expectations are evaluated.

1. Throughput Capacity:

To begin with, I determine the machine’s throughput capacity, which is provided in kilogrammes per hour. Keeping in mind my small-scale undertakings, I usually go for machines that can process between 50 and 100 kg per hour, which ensures productivity but does not scale to working space.

2. Quality of Output:

I consider the chip cutter’s capability in producing chips with a single thickness and texture. The other aspect I check includes the more delicate cutting tools, which are provided at a range of angles. From these, I would select 1 – 2 mm for ordinary chips and 3 – 5 mm for thicker chips. This is very important since it assures uniformity in the product, which is needed in quality control.

3. Energy Efficiency:

This machine’s energy consumption is another piece of information to be determined. I take samples that are good performers but operate efficiently without compromising performance. While doing an energy rating comparison, I search for technologically advanced models that can produce maximum energy efficiency with minimum energy consumption.

4. User Friendly Operation:

Ease of use is also important in considering the criteria given. I am inclined to machines with very simple interfaces and computerized features to make the whole production process quite easy. Instructional interfaces with clear explanations and easy regulation parameters augment the work rates of the people in charge and diminish the induction span for new employees.

5. Maintenance and Durability:

The durability of the machine and its ease of maintenance are imperative in performing long-term operations. This involves examining the machine’s ergonomics, that is, the materials used, such as stainless steel, which guarantees strength and resistance to rust. Moreover, I search for machines with parts that are easily dismantled for cleaning and maintenance purposes.

6. Cost- PerformanceRatio:

Last but not least, this factor helps me decide the cost versus performance measure of the machine. I assess the disbursed amount against the anticipated output and the advantages earned. My preferred choices are machines that offer a considerate amount of investment return in terms of costs versus quality and efficiency.

I am able to arrive at small-scale potato chips machines by carefully evaluating factors that are in tandem with my production requirements and achieving no or little compromise in the quality of the output and the efficiency of the operations.

What Are the Steps Involved in Potato Chips Manufacturing?

The manufacture of potato chips comprises several well-defined stages to maintain consistency and quality of the end product. First, I pick good-quality potatoes of even size for uniform processing. After washing and peeling the potatoes, they are sliced into thin, uniform bits. To improve texture, these chunks are then rinsed of starch. The potato slices are then subjected to blanching in hot water.

After the blanched slices, they are quickly dried to remove excess moisture. Drying, which is the very next step is very important since it determines how crisp the chips will be after frying and maximization of the chips will be cut as equally as possible. Then, the dried slices are immersed into hot oil for frying at a specific temperature. In the frying stage, the chips are observed and controlled to ensure that even cooking of the chips is attained and that the intended crispiness of the chips is obtained.

Fried potato chips are drained and left to cool for a short period. They are then coated in salt and other flavorings to meet certain preferences. The last operation in the preparation of potato chips anchors them in airtight, unmarked bags in an effort to keep them fresh for an extended period. This procedure, when well followed, helps me create a potato chip that meets all the desirable characteristics and the expectations of the consumers.

What is the process of Potato Washing and Peeling?

Potato washing and peeling should be done if only to guarantee that the potato chips produced in the end do not contain any incidental materials such as soil and skin. First, I put the potatoes into a washer, a machine that washes vegetables containing water jets and moving brushes to remove the soil on it. Here it is critical to keep in mind some technical parameters like hydrodynamic probes which include psi. one should be careful to select brush materials since this will also protect the potatoes from scratches most dense bridles is nylon or soft bristle.

After completing the wash cycle, the potatoes are fed into the peeling machines. Common mechanical peelers include the steam and the abrasive peelers. In terms of both construction and operation, abrasive peelers scrape off potato skins using roughened surfaces or rollers that operate at predetermined speeds (typically RPM). Steam peelers also work on the same principle, but high-pressure steam (commonly between 100-200psi) loosens the skin, which is subsequently removed with gentle scrubbing or by rinsing. Each technique has its merits; for example, favorable for some potato varieties are abrasive peelers, while in steam peelers more effectiveness and less in loss.

In this regard, it is self-evident that operating conditions such as water pressure, brush type, and speed of scraping or steam pressure should be balanced to provide a potato that is optimally clean, correctly peeled, and ready for subsequent technological operations.

How to Optimize the Chips Process?

To optimize the process of the chip, there are several critical factors to consider:

1. Selecting Quality Potatoes:

Russets and similar products high in starch content would be the best option because they have an excellent mouthfeel and crisp well when baked. Standard quantities and counts of the products assist in standardizing processes.

2. Precise Slicing:

How thick or thin the potato slices are will determine how long it takes to fry them and their texture. Irrespective of the product, the slice thickness should be constant (1.5-2mm normally). Improvised slicers incorporating precision cutting controls can assist in achieving this.

3. Effective Blanching:

In such processes, the extra sugars and starch within the product are expelled since they are the factors of coloration while enhancing crispiness. Blanching is most effective when temperatures vary between 160˚F and 180˚F (71˚C to 82˚C), and time can vary but is generally between 3-5 minutes only.

4. Consistent Frying:

Some parameters cannot be altered, such as the temperature of the frying oil and the fry time. Frying oil temperature ranges between 350˚F and 375˚F (175˚C to 190˚C), depending on the frying time, which is usually 3 -5 minutes. Stediness within the temperature-controlled range assists in the uniformity of the non-golden crisp texture of the feeding material.

5. Oil Quality Management:

It is a must to use an oil with a high smoke point (peanut oil or sunflower oil) and not of a really low quality for frying. Oil filtration and the oil changes used for frying to eliminate food materials to prevent rancidity for better flavor and shelf-life.

6. Application of Seasoning:

To enhance the flavor of the chips, it is recommended that they be seasoned while still warm and greasy and about to cool down immediately after firing. Automated systems for adding flavor borders are reliable because they ensure accurate coverage.

7. Packaging:

Chips must be stored in vacuum-cooled or vacuum-sealed bags to eliminate air and ensure shelf stability. Eggs sealed in a solvent should also be outlined to protect the contents from ventilation.

8. Quality Control:

The most crucial results control involves tasting, evaluation of the texture, and testing of the physical, chemical, and biological properties of the sample. For the purpose of the impressing and of the overall objective of the business, no compromise should be tolerated as far as the standards of the products are concerned.

Considering all these recommendations and compliance with precise technological parameters allows significantly improving the chips process and the efficiency of the processes and a good quality product at the end.

Best Practices for the Process of Flavoring and Packing of Chips

As for the flavoring and packing of chips, the top ten websites in Google make a consensus on few practices. First of, flavoring must be done when the chips are still hot and oily, that is immediately after frying them. It is important to point out that the seasoning will stick well onto the chips in this manner. Some of the technical parameters to be observed include:

- Timing: Seasoning should be done within the first 30 seconds after frying, as the oil creates stickiness.

- Uniformity: Automated seasoning systems help to ensure consistency in the distribution of seasonings on the chips.

- Quantity: The quantity of seasoning applied should be weighted based on the chips’ physical characteristics to avoid over- or under-salting.

For packing, there is a need to keep the product fresh and free from moisture. The best practices include:

- Packaging That Is Air-Free: Chips must be packed in air-free containers or bags to avoid contact with air and moisture, which helps preserve their crunchiness.

- Use of Nitrogen Flushing: Incorporating nitrogen flushing within the packing minimizes the chances of oxidation, thus increasing the shelf life. Technical parameters here involves criticizing the nitrogen concentration, ensuring it is sufficient to sweep oxygen.

- Material Selection: To reduce degradation over time, it is essential to use packaging materials that have a high degree of barrier properties against oxygen and moisture.

Careful quality control continues to be necessary during the entire process:

- Sampling and Testing: To maintain product quality, chips must be sampled periodically for texture, flavor, and appearance.

- Consistency Checks: Conducting consistency checks for how spices have been sprinkled and the packaging can assist in detecting and resolving concerns promptly.

Such production and control methods of the above-mentioned technical parameters grant the fortunate possibility of obtaining tasty, crunchy chips with a long expiration period.

Can you make other types of chips with a Potato Chips Machine?

Yes, making other types of chips with a potato chip machine is fairly possible. As much as these machines are built for potatoes, they can often process many more kinds of vegetables and even fruits. For example, you can use a machine that produces sweet potato, beetroot, and carrot chips. Some units also offer tortillas/chips or plantain chips. The main thing is to change the size of the shreds and the duration of cooking when using other types of vegetables or fruits other than that of potatoes. With some creativity and setting adjustments, you can produce other types of products besides potato chips.

Is it possible to produce Banana Chips?

With the potato, as mentioned earlier, chips machine, yes, it is possible to make banana chips. Banana chips can be made based on some readings I have obtained from the top ten sites, such as google.com. Here are the critical parameters that you have to cover:

- Slicing Thickness: This can be achieved by cutting the banana slices to about 1/8 inches so that even frying the slices and creating crispiness is attained in the chips.

- Frying Temperature: The perfect temperature for frying banana chips is about 350°F (175°C). This makes sure the chips do not fry too much oil.

- Cooking Time: Banana chips are fried for approximately two to five minutes, depending on the size and preferred texture.

- Oil Type: When frying banana chips, cooking oil such as coconut oil with a high smoke point can improve flavor and preservation.

- Seasoning and Flavoring: Seasoning can be done after frying, and some common seasonings include salt, sugar, or cinnamon for sweet varieties.

Adjusting these parameters and using a potato chip machine can achieve excellent-quality banana chips.

What equipment can be used to produce frozen French fries?

Yes, frozen French fries can also be produced using the same machinery used in producing potato chips. After my findings based on ten top websites I had previously told on Google.com, it was clear that the answer is yes. These are the main technical specifications that should be followed:

- Cutting Size: Usually, French fries are cut into strips of about 1/4 to 3/8 inch to reduce the time it takes for them to cook evenly.

- Blanching: After the cut fries have been prepared, they can be blanched in water at 170°F (77°C) for 3 – 5 mins before freezing them so that excess starch is removed and the fries are prepared optimally.

- Drying: Right after this, the fries need to be dried, if not all of the moisture has evaporated from the surface of the fritters. A quick spinning or dryer machine helps to do the work most of the time.

- Freezing Temperature: This should be general – blanched and dehydrated potato strips should be ice capped at about (–25 F approx -32 C) to stickiness and short cooking time weight under the geeks heads.

- Packaging: The inclusion of other ingredients is one of the only important benefits of doing so; however, proper sealing in freeze-resistant bags or containers should be done to avoid freezer burns and keep them intact for a long period, such as six months.

Considering such factors, it is possible to manufacture as sea unit equipment both potato chips and frozen fries.

What Other Equipment Is Needed for the Automatic Banana Chips Production?

From my research into the top ten domains hosted on Google.com, it is clear that one more machine combining the production of banana chips with that of conventional potato chips is impractical since it would impede efficiency and reduce product quality. Here is a critical list of the relevant additional equipment with the accompanying technical specifications:

- Banana Cutter: A banana cutter is required to get perfect cuts. This banana cutter is usually modified to make cuts between 1/16 and 1/8 inches thick. Such uniformity in size leads to uniform and even cooking, hence optimal results.

- Blanching Machine: While a blanching machine is not necessary, it prevents the chips from being too starchy and improves their overall quality. This type of equipment can reach a working temperature of around 71C within three to five minutes.

- Pre-Frying Dewatering Machine: This machine is employed mostly to remove the water from the banana slices on the surface before being put into fryers. This step is crucial in achieving dryness and cutting the frying time.

- Kettle fryer: This keeps a constant frying temperature and can be specified for use around 175 degrees C, where high convection frying is desirable to decrease the frying time and give a uniform fry throughout. This equipment ensures skimming is the perfect fry for bulk production.

- Oil Filter: Because oil is, in many cases, not cheap to acquire and the quality of the oil is important in the outcome of the product, an oil filter pump is known to help sustain oil clarity. It helps mainly by clearing contaminants, preventing the frying oil from looking cloudy.

- This section looks at the different supplementary designs of the banana-making machine that augment the efficiency and productivity of the process of banana-making.

- Packing: The primary packing machine places the sealed banana chips in airtight sachets, which is important for storage and shelf life.

Chips are cut, deep fried, and salted for bananas, and any additional Fryer incorporating these auxiliary machines is suitable for the automatic fluent production of banana chips.

Conclusion

A potato chips-making machine to enhance the production capabilities of small-scale businesses is a sound investment. The available options for purchasing these machines differ in price depending on characteristics, size, and the level of automation fitted. Basic models can begin from about $1,000, which is ideal for small potato-making businesses, while high-end and large models at $10,000 still cater to high potato-making businesses. In order to consider what features fit within the amount of money that is available to purchase a potato chips making machine, proper consideration of the production capacity and space of the business should be performed. Without a doubt, Small scale potato chips making businesses will meet the market demands by producing high quality tasty chips that will certainly meet the customers’ expectations.

Reference Sources

For the topic “potato chips making machine for small business price,” here are three reliable sources that can validate the feasibility of the above discussion for the readers:

- Food Processing Equipment Manufacturers’ Association (FPEMA)

- This industry association provides detailed insights on various food processing equipment, including potato chips making machines. They offer resources on machine specifications, pricing, and industry trends.

- Small Business Administration (SBA)

- The SBA offers resources and guides for small business owners, including those in the food production industry. They provide information on funding, investing in machinery, and choosing the right equipment for small-scale production.

- “Food Process Engineering and Technology” by Zeki Berk

- This comprehensive textbook covers various aspects of food processing technology, including the machinery used in the production of snacks like potato chips. It includes discussions on the cost, efficiency, and suitability of different types of food processing machines.

By consulting these sources, readers can gain a deeper understanding of the investments required and the benefits of using potato chips making machines for small businesses.

Frequently Asked Questions (FAQs)

1. What factors influence the price of a potato chips making machine?

The price of a potato chips making machine can be influenced by various factors, including the machine’s capacity, features, brand, and the level of automation. Machines with higher capacity and more advanced features like automatic frying, seasoning, and packaging will generally cost more.

2. What is the average cost range for a potato chips making machine suitable for a small business?

For small businesses, the cost of potato chips making machines typically ranges from $5,000 to $20,000. Entry-level models with basic functionalities may be more affordable, whereas advanced models with enhanced capabilities can be on the higher end of this range.

3. Are there financing options available for purchasing these machines?

Yes, there are several financing options available, including loans from banks and financial institutions, equipment financing companies, and sometimes even manufacturers offering financing plans. The Small Business Administration (SBA) also provides various loan programs to help small business owners invest in machinery.

4. How do I determine the right machine for my small business?

Choosing the right machine involves assessing your production needs, budget, and space. It’s essential to consider the volume of production you aim to achieve, the specific features you require, and the available space in your facility. Consulting with equipment suppliers and reading industry reviews can also help in making an informed decision.

5. Where can I find reliable suppliers for potato chips making machines?

Reliable suppliers can be found by consulting industry associations like the Food Processing Equipment Manufacturers’ Association (FPEMA), attending trade shows, and researching online marketplaces where manufacturers and sellers list their equipment. Reputable suppliers will provide detailed information on machine specifications, customer reviews, and after-sales support.

By addressing these common questions, small business owners can better navigate the process of investing in a potato chips making machine and make informed decisions that suit their production needs and budget.