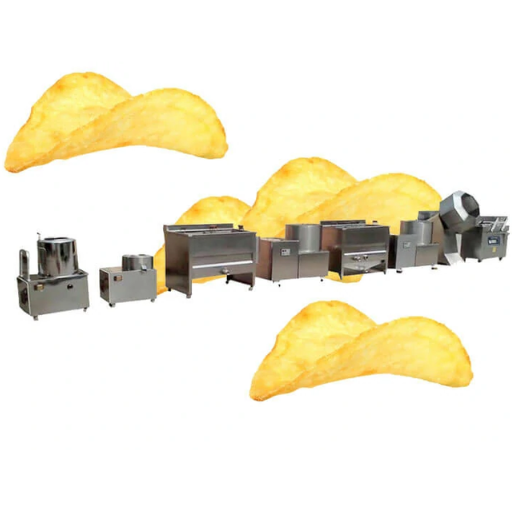

This article aims to examine each stage of a fully automatic potato chips production line, focusing on how the technology transforms a raw potato into an end product, the final chips ready for the package. Through this blog post, readers are familiarized with the basic components of modern lines and the processes that make it possible to turn ordinary potatoes into appetizing snacks with the help of numerous automated systems. Different technological aspects of the production line include washing and peeling machines, slicing of potatoes, frying of the potato slices, and seasoning of the finished product for packing. Moreover, the paper will also highlight other advantages of automated production processes including; high throughput, uniformity of end product quality, and safety of production activities. This guide is therefore useful to both an industrial expert seeking insights on how to upgrade his or her production line as well as any snack lover interested in the miracle behind the creation of the potato chip snack.

How Does a Potato Chips Production Line Work?

Automated production of potato chips starting from fresh potatoes and ending with delicious crispy chips can be described as a combination of many well-coordinated steps. This process begins with the intake and selection of raw potatoes and proceeds to washing and peeling to remove contaminations and the outer skin. Such operations also include putting peeled potatoes into slicing machines which can cut them into certain thicknesses to allow uniform cooking of the chips. Controlled Fractionation technology is utilized to fry potato slices while precise temperature, oil residues, and circulation are key to frying with the desired texture. After frying, chips are subjected to de-oiling before flavorings are applied with the aid of seasoning machines. After this step, the chips are ready for the extensive automated packaging which ensures quality is maintained right up to distribution. Automation enhances speed in every step, reduces labor costs, and ensures constancy in the output.

What is the Process of Potato Chip Production?

Potato chip manufacturing is a multiphase process that begins with choosing good potatoes. The first step of potato preparation includes washing and peeling the potatoes to get rid of any impurities or surface blemishes. Slicing is done after the peeling has been done, with the aid of relevant equipment to enhance the uniform thickness of the chips. The slices are then washed to eliminate surplus starch, which is essential for necessary crispness. After washing, the slices are extended fries for a time and temperature-controlled execution to get the right crunch and coloration. After frying, excess oil is removed from the chips in a quick step to stop sogginess. The fifth stage is adflavoreding where the prepared dyes with apprehensible anthropoid functions inside a coating of a variety of flavors are placed on the chips before they are packed. Afterward, the chips are packaged in moisture-proof bags sealed tightly and subsequently stuffed into cartons to preserve the chips’ freshness and avoid breakage during movement. This automated work reduces time, and labor costs level of competitiveness builds an automatic system regarding the product’s ordering.

How are Potato Slices Prepared?

To produce potato crisps, I start with a selection of quality potatoes from which I prepare the raw materials by washing and peeling them clean. I cut the potato tubers with specialized devices that ensure that they are of uniform thickness to promote uniform cooking. So that the slices can attain the desired crispness, I soak them in water to remove the excess starch. There is no room for lapses in any step of the process to promote efficiency and maintain the desired quality of the potato chips.

What Role Does the Frying Machine Play?

The frying machine is pivotal in the potato chip production process as it uniformly cooks the potato slices to the desired crispness and color. It operates by heating oil to a precise temperature, typically between 320°F to 375°F (160°C to 190°C), which is crucial for cooking the chips evenly without burning. The duration for which the slices remain in the frying machine is carefully controlled, often ranging from 3 to 5 minutes, to achieve the perfect crunch. Additionally, the machine maintains consistent oil circulation and temperature, ensuring that each batch of chips is uniformly fried. This not only enhances the chips’ texture and flavor but also improves the efficiency and safety of the production process by minimizing human intervention.

What Equipment is Essential for an Automatic Potato Chips Line?

To produce high-quality chips and run smoothly automatic potato chip lines must be equipped with specific machines. To begin with, preconditioning requires the use of a washing and peeling machine – one that eliminates both dirt and skin from the potatoes. Next, ensuring uniformity in slice thickness across potato slices becomes important; this is done using a slicing machine. Then the next, the blanching machine comes into play, which assists in removing excess starch which would otherwise affect the texture and color of the chips unfavorably. Of utmost importance is the frying machine, which cooks the slices to the required precision to make them crisp. An oil filtering system is also required to protect the quality and consistency of the frying oil. A seasoning and a packaging machine finally come in line adding flavoring and stuffing the chips for distribution. Each piece of equipment is essential so that the production line does not stall and all products meet quality requirements.

What are the Key Features of a Potato Chips Machine?

It would be incorrect to consider any one feature of the potato chip machine in isolation from the underlying process instead of an integrated machine. The first feature is the deceiving thickness of potato chips. Inconsistent slicing can affect cooking time and the resulting crunch. Any commercial potato chips machine for sale will be equipped with thermostatic controls to keep frying temperatures at an ideal level for better taste and texture. Moreover, the robust design incorporates suitable oil filtration, which promotes extended oil life and the quality of the chips. Automation means less reliance on human resources which further increases the general output. Today’s machines have come with smart configurations and built-in safeties to avoid manual interactions. These days, consumers also prefer machines that are easy to maintain because they reduce running costs over time. In a simple statement, those working with chip frying machines do expect a significant increase in productivity and decent quality. The truth is, that those machines are designed to meet certain expectations without compromising efficiency.

How Does a Slicing Machine Operate?

To operate a slicing machine efficiently, I analyze all equipment and their location and characteristics as well as their cleanness at first. I then make adjustments in the thickness settings which is crucial for uniformity, as it ultimately dictates the final piece size. Following that, I place the potatoes into the machine’s hopper, which automatically delivers them to a rotating blade system. With this system, the potatoes are cut to the right size, which is essential to make sure the cooking process is not uneven. I also grasp the measurement of the machine, during which, I check the blades and the accuracy of cuts. It is also significant to make routine maintenance checks to make sure the machine is in order and that there are no malfunction lumbar issues. The appropriate ones make sure that not only the quality of the final product is up to standard but also me while using the equipment.

Why is a Flavoring Machine Important?

The flavoring machine is a significant aspect of the making potato chips process since it weighs different flavors and applies them to the chips evenly and tastefully. The machine’s feature of evenly applying seasoning helps in preventing waste or a disappointing product in case of excessive or insufficient flavor respectively. Related to the flavoring machine are its key technical parameters such as the capacity for adjustable drum rotation speed which controls the rate of tumbling, the capacity for controlled dispensing for seasoning in which case the amount of flavor is regulated, and the capacity for adjustable settings for various flavors. All these aspects are meant to protect the integrity of the taste and quality which is very essential in the satisfaction of the customers and the thriving of the market.

What are the Benefits of a Fully Automatic Potato Chips Production Line?

The fully automated potato chip production line has great benefits in efficiency, productivity, and quality of the products. The first advantage is related to automation of work processes which in turn makes labor costs lower since there is less need for manual work as well as it minimizes human errors in producing the products. Such a system guarantees that the quality of the end product is maintained because a computerized machine will control every process from washing the potatoes to the placement of the bags on the shelves. Furthermore, an automatic line provides a higher production speed and volume which is crucial when the manufacturers need to satisfy greater demand. Also, the accuracy of automatic machines optimizes the usage of resources by allowing the reduction of raw material shortages and ensuring compliance with hygiene requirements so that the clients get clean and great-quality products.

How Does it Improve Production Capacity?

A fully automatic potato chip production line significantly boosts production capacity through streamlined operations and advanced technologies. By automating each step, from peeling and slicing to frying and packaging, the production line operates continuously with minimal downtime, optimizing throughput. The integration of high-efficiency components, such as rapid cutting systems and high-capacity frying units, allows for greater output in shorter time frames. Additionally, real-time monitoring systems and data-driven adjustments improve operational efficiency, ensuring all machines operate at optimal speed and performance. This level of automation minimizes bottlenecks, allowing manufacturers to respond quickly to increased demand and maintain a consistently high production capacity.

What are the Advantages of Potato Chips Manufacturing?

Taking into account the potential of implementing a completely automated potato chip production line, I see the merits to be quite numerous. To start with, the efficiency of operations is significantly increased as manual and repetitive tasks are automated which leads to time savings and reduces the need for labor. The quality of the products is guaranteed as the automatic technology can control every stage of production right from the peeling of potatoes to packaging. In addition to that, the pace and the volume of the production line naturally make it easier to satisfy the most variable customer preferences on the market. With these sophisticated systems in place, waste will be reduced and resource use better managed which will lead to lower costs. Last but not least, automated machine processes contribute to food safety as high levels of hygiene are maintained throughout the production processes, which makes consumers confident in the quality and safety of the products they purchase.

How Does it Enhance Food Processing Efficiency?

It is an Automated system that has remarkably improved food processing efficiency by lessening the manual input and increasing accuracy. Increased throughput is a result of Automation as it allows activities to be performed continuously at constant speed resulting in less downtime and variation. For example, the production cycle is streamlined by high-speed cutting systems and effective frying units ensuring that all stages of processing are uniform and fast. Examples of these lines are often imposed technical parameters such as cutting speed (about 400 slices per minute) and frying volume (about 1 ton in one hour). Predictive maintenance is enabled by real-time monitoring and data analysis, thus eliminating delays due to equipment failure. Moreover, the consistent temperature and cooking time during frying allow for consistent quality of the final output. These optimization technologies improve operational efficiency in addition to maintaining important quality and safety requirements which in turn enhance cost efficiency and customer satisfaction.

How to Choose the Right Potato Chips Plant?

The selection of a potato chips plant fulfills two issues a business and organizational tactic. First, determine the shift or the amount of output that you’ll have to generate to respond adequately to the needs of the market, making certain that the plant’s output is in line with the set expectations. Second, assess the technology and equipment you so plants with a high degree of modern automation can be relied on to increase the efficiency and quality of the products. Look into the adaptability of equipment for different potato types as well as chip types to provide variety in production. Third, look into the credibility of the plant, particularly the credibility of the maintenance service as well as the level of customer care and these will determine the long-term performance of the organization. Finally, verify the effort of the plant towards green and energy-retaining practices to minimize the carbon footprint and meet particular market expectations. With the correct balance of these factors, it will be possible for one to choose a plan that not only helps in the production objectives but also facilitates expansion plans in the future.

What Factors to Consider in a Processing Line?

About the key aspects of a processing line for potato chip production, a few points come to the fore. First, one needs to make sure that all the plants allow the use of modern technologies and automation to lessen the labor input. Slicing, drying, and frying are very important for the quality of the final product. Second, stability and the potential of the line; it should not only be able to satisfy your present requirements for production but it should also be able to be expanded as the needs of your business get higher. Third, give more emphasis on the machines which are designed in a way that the energy consumption would be minimal which minimizes the operational costs and protects the environment. Furthermore, assess the maintenance requirements and the availability of services related to the equipment to ensure minimal downtime and smooth operation. Finally, examine in detail of conformance to safety and quality requirements to ensure that this particular line does not hamper your purpose of quality and customer satisfaction. Taking into account these factors will help you design an effective and flexible processing line to match the future changes in the marketplace.

How to Evaluate a Machine Manufacturer and Supplier?

The first thing I do when looking for this type of company is check its background and whether it has been in this line of business long enough. I seek endorsements from businesses who have procured their products as it gives a good insight into their dependability and quality. Other considerations are the number of products as well as the degree of personalization available. I make room for the specific type of machines I need while also checking if the company has room to customize the machines to my specific needs. I also examine their customer service and the conditions of their warranties to understand their maintenance mode. There is no doubt that the client ought to be satisfied with the service rendered, and therefore there has to be a competent support team in place to deal with problems as they come up. Another thing I take into account is their ability to observe the rules governing the industry, and more specifically, the rules containing all the requirements for the safety and quality of the equipment. It allows me to avoid potential pitfalls and expect more from the manufacturer and supplier in a way that is in line with my operational objectives and beliefs.

What are the Differences Between Small Potato Chips Production Lines and Large Scale Lines?

A small potato chip production line is more suitable for start-ups or niche markets that are aimed at local distribution since it has a lower production capacity. Such lines require less initial investment and also allow room for greater variability in the types and flavors of snacks produced. , On the other hand, large-scale lines are constructed for mass production, aimed at catering to the needs of a country, or even a continent. They usually have a high capital outlay since they entail a more automated system which is meant to enhance productivity and reduce the labor requirement. Large lines are capable of producing high quantities per cycle with high-quality assurance throughout the process. Therefore, small lines are flexible and cost-saving whereas large ones can provide volume and extensive reach to the market.

How Does Production Capacity Vary?

The output of potato chip production can be quite different concerning some determining factors: the type of equipment, the organization of the technology, and even possible measures of сlasses. Small-scale production lines may be able to produce hundreds to a few thousand pounds of chips per hour, using manual or semi-automated moulder production machines designed for specific limited editions. Such a strategy allows a quick change of the product type, which is necessary on a small scale. In contrast, such quantities are only possible through large-scale production lines which are capable of churning out more than twenty thousand pounds in an hour using fully automatic sophisticated equipment specifically designed for large-scale production with minimal downtime. These plants attempt to optimize processes and produce an output of homogeneous quality and therefore often use modern technology for process supervision and control. Therefore, the decision on what type of production line to use small or large depends on the intended market, the amount of capital available for investment, and the firm’s objectives.

What are the Cost Implications of Small Potato Chips?

Since these smaller operations rely on simpler or comparatively smaller equipment, they do not require a huge amount of initial capital. This makes the production process more flexible so that adjustments to consumer demand can be made without a lot of fixed costs being incurred. However, small productions may have higher average costs than large-scale production because the latter enjoys economies of scale. Also, procurement costs may be more unstable because small businesses do not have the bargaining power to buy raw materials in bulk. Despite these concerns, a considerable number of small potato chip manufacturers can sell their products at premium prices by serving target markets that are less competitive or utilizing superior quality and thus managing to offset some of the cost pressure.

References

-

Pre-Feasibility Study – Potato Chips – A document aimed at helping potential entrepreneurs with project identification for investment.

-

Tanzania Pre-Feasibility Study of Potato Chips Industry – Provides a macro and micro view of the snacks food market for potential investors.

-

Potato Chips Manufacturing Plant Project Report 2023 – Offers in-depth market analysis and information on unit operations, raw materials, and infrastructure requirements.

Frequently Asked Questions (FAQ)

Q: What is the basic process involved in potato chip making?

A: The basic potato chip process involves selecting quality potatoes, washing and peeling them, cutting them into slices, blanching, frying, and finally seasoning and packaging. The process can be enhanced with the use of a potato chip-making machine for efficiency.

Q: How does a fully automatic potato chip production line work?

A: A full automatic potato chips production line includes a series of machines that automate the entire potato chips process from washing, peeling, slicing, blanching, frying, to packing. This setup ensures high efficiency and consistent quality in producing potato chips.

Q: What are the differences between potato chips and potato crisps?

A: Potato chips are typically thin slices of potato that are fried and seasoned, whereas potato crisps can refer to a variety of snack products that may include reconstituted potato dough formed into thin, crispy shapes.

Q: What role does a frying line play in potato chip production?

A: The frying line is crucial in potato chip production, as it determines the texture, taste, and overall quality of the chips. It involves the use of a potato chips frying machine that controls temperature and frying time.

Q: What is involved in a french fries production line?

A: A french fries production line involves processes such as washing, peeling, cutting into strips, blanching, drying, frying, and freezing the fries. Specialized processing machinery is used to ensure quality and efficiency in frozen French fries production.

Q: How important is the potato chips packing machine in the production plant?

A: The potato chips packing machine is essential as it ensures the chips are packed in a way that maintains freshness and extends shelf life. It efficiently seals the chips in bags, controlling portions and protecting them from external factors like moisture and air.

Q: How does the potato chip cutting machine affect the final product?

A: The potato chip cutting machine determines the thickness and shape of the chips, which significantly influences their texture and frying time. Consistency in cutting is crucial for achieving uniform quality and mouthfeel in the final product.