The transition of raw potatoes into tasty chips is a detailed and complex activity within the boundaries of the snack manufacturing arena. The paper explains in detail the difficult path that a common potato follows inside modern production facilities. We take every stage into account, starting from the selection of raw materials – best quality potatoes, all the way to placing the ready–made chips on the shelves – to present our readers with the full scope of technology employed, processes undertaken, and control of quality which make sure that bags of chips always crunch. We begin with technical processes and innovations shaping the food manufacturing process. Each crisp, savory morsel has its own distinctive place and time in this well-rehearsed soothe.

What is the Potato Chips Manufacturing Process?

How Do Potatoes Reach the Manufacturing Unit?

The process of bringing the potatoes to the manufacturing unit involves first sourcing them from certain farms that grow the potatoes to set quality standards. The harvested potatoes are then loaded into temperature-controlled trucks, to ensure that they remain fresh and hard throughout the shipping period. After arriving at the plant, the potatoes are sorted and checked for size, weight and overall condition to determine their suitability for the required processing. These measures are vital to ensuring that the next steps in the chips manufacturing process will only use high quality materials.

What are the Main Processing Steps?

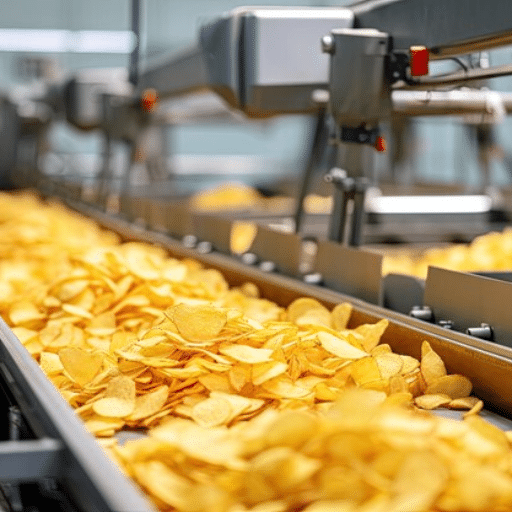

All the processing steps employed in potato chip processing can be divided into different stages. To begin with, the potatoes are cleaned or washed to remove any dirt substances, and after that they are peeled in order to maintain uniformity of texture as well as appearance. Then, the peeled potatoes are manufactured into equal chips by being sliced with high-speed slicers, which allow the desired size and shape to be achieved. All of these slices are then immersed in a blanching process that entails brief exposure of the slices to hot water or steam so as to remove excess starch and improve their color. Then, after the blanching processes, the slices are taken to the frying stage, where they are toasted in refined vegetable oil, which is maintained at a high temperature until the chips obtain the desired degree of crispness and flavor. Later on, chips are prepared by adding various spices and flavors, followed by cooling and packing the chips in sealed pouches that inhibit air movement. Quality control measures are implemented throughout the whole packing and processing to avoid inconsistency in taste with every batch.

What Elements or Strategies Contribute to the Completion of the Final Product?

Through various methods, potato chips are manufactured in bulk, and the end desired product must go through a 100% quality control inspection process. Previously mentioned processes such as washing, peeling, cutting, and steaming the potatoes follow with frying, which requires optimal control of parameters. The frying process usually ranges from 350°F to 375°F (175°C to 190°C) at a duration that is controlled to ensure a crunch texture and a golden brown color. Infrared radiation also helps rapidly cool down the fried chips after cooking to avoid the problem of excessive oil content in the chips.

After chips are cooled, seasonings are automatically applied using machines to ensure consistency in flavor throughout all the potato chips. After this, the chips are vacuum packaged and inserted in bags with nitrogen gas. The functions of this procedure are important to avoid oxygen exposure and keep the potato chips fresh for a prolonged period. Electronic sensors or automated vision systems detect all these operations, and only those products that satisfy the requirements for geometry, consistency, and taste are released on the market. All these steps are proven by applying research and continued technology improvement to the best-known industry standards.

How Does the Frying Process Work?

In What Manner Are Potato Slices Ready For Deep Frying?

In preparing potato slices for frying, I first do hands-on research and focus on identifying which potatoes should be selected, and in most circumstances, certain varieties which are rather more starchy and much less sweet will do the trick. After washing the tubers in clean water to remove dirt and other unwanted materials, I peel the potatoes, although in some cases, the potatoes are not peeled depending on the intended outcome. Next, I cut the potatoes with the needed thickness by placing them on a special slicer designed to cut them into consistent and evenly shaped slices. Cutting the potatoes into equal slices is important so as to allow for even cooking when being fried. Blanching and preheating are part of the last steps I recommend, where I dip the slices into boiling water and then follow it with rapid cooling. This helps to eliminate most of the sugars and starches, which after frying will help to ensure an even hue and avoid the overbrowning or uneven texture of the chips.

What Role does Frying Oil Perform?

In the frying process, fried oil enhancement and control are necessary to produce the desired quality of the finished potato chips. Some information and reliable sources from known sites provide that frying oil is the medium in which heat is transferred to potato slices, enabling their conversion into chips. Since high-quality oils are more expensive, potato chips are most commonly baked with sunflower or canola oil with a smoke point of around 400°F (204°C) to 450°F (232°C), which helps preserve their taste and nutritional value. Oil content with the right amount of oil in a potato chip that will result in its crispiness is limited Im generally looking for a 35% content in the final product. In addition, oils are regularly checked and swapped for a new batch to prevent the generation of odd tastes and maintain quality throughout the entire process. There is a more emphatic demand on oil in terms of oil’s antioxidant content in order to improve resistance against oxidation and extend oil current usage.

With Fryer, how do you deal?

Operating the fryer, in my opinion, is all about particulars. It starts with the heater settings. I usually set it up to 350°F (177°C) so that there is no oil and potato slice burning. I utilize a digital thermometer to constantly monitor the temperature. Usually, the thermoregulator instability does not exceed 5 Fahrenheit Degrees. I perform oil filtering every eight hours of use. Particulate residues deteriorate the initial quality of oil and have to be removed. While carrying out this procedure, the oil is pumped with a mesh filter to get rid of small fragments and extend the oil useful life. Once every 40 work hours, the oil is completely changed, though it might be less due to free fatty acid and polar substance content that should not exceed 0.5% and 25%, respectively. Such quantitative chemical monitoring guarantees the safety of the oils used. Finally, the fryer is also cleaned with other components, or the machine itself is checked for any kind of mechanical interference or safety issues using a very detailed checklist in the machine’s user manual to prevent anything from damaging the environment of great mass production.

What Raw Materials Are Used in Potato Chips Production Line?

Which Potato Varieties Are Best?

In my experience, it is important to choose superior potatoes and other qualities to achieve the desired texture and flavor characteristics in chips. It is a well-known fact that Russet Burbank and Atlantic varieties are the most preferred because they yield a biscuit with a high starch and low moisture content. This makes the final product crisp, which is what customers seek after all. Russet Burbank has a starch level of approximately 20 – 22%. This means it is great for frying, which allows for a crunchy texture and golden color.

On the other hand, the Atlantic variety is a little lower on the starch content, around 18 – 20%, yet has a more uniform spheroid shape that comes in handy for slicing and frying evenly. I ensure that such batches are selected so that the best frying outcomes are expected by conducting tests and monitoring the specific gravity of these potatoes, usually above 1.070. Adding those considerations to routine monitoring of sugar content below 0.1% ( cheaper than darker chips ) allows breaking the production line to make the chips more attractive.

How is the Seasoning Done?

In industrial terms of potato chips making, seasoning is done in a consistent way using a sprinkle application to achieve the desired end flavor of the chips. To begin with, the chips, together with those that have been fried and cooled to the required temperature, are pushed through a tumbling or rotating drum. In this case, a reasonable amount of the seasoning mix is conveniently injected into the treats through the tumbler mechanism equipped with an auger or shaker, which delivers a preset amount per batch. The key is the controlled and smooth tumbling motion of the chips to ensure that each chip is coated without disintegration. QL Menu parameters such as drum rotation, the angle of inclination, and per seasoning particle size are well set to ensure that the chips have an almost uniform combination of the several flavors added. Meanwhile, the seasoning quality is stringent, and alterations to it are made throughout the run where the desired atmosphere has already been predetermined to suit the consumers.

How Are Potato Chips Packaged?

How Does the Packaging Machine Work?

Working with sophisticated packaging machines outlined in some of the leading websites in the industry, these machines operate in pairs of machines that are automated and designed with precision to enhance efficiency and protect the product. At first, the packaging process starts with its last feeding part, the device that pushes the potato chips into the rotary-type filling machine. This step is crucial, as it eliminates the risk of chip breakage and ensures the constant flow of the product. Then, the machine introduces the form-fill-to-seap method, whereby laminated pouches or bags are produced to contain chips, and the packs are filled with chips and sealed. This is done by heat sealing, where the individual containers are sealed tightly, allowing them to preserve the content for a long time.

The conveyor belt speed used in the packaging process, which can vary from 30 to 60 meters per minute, the temperature to which the seal is applied which normally varies between 130°C and 160°C depending on the material to be packaged, and the sealing pressure, which should be within specified material parameters in order to avoid leakage or tearing, are some of the technical parameters that are important for the packaging process. These parameters are scientifically confirmed through controlled testing conformities to predefined quality and safety levels. As the industry is adopting cutting edge technologies, these modern machines integrate various sensors and feedback mechanisms that allow these machine parameters to be adjusted on demand for better consistency and performance in meeting classification standards of packaging materials and packaging quality assurance.

What is the Specific Function of a Metal Detector?

While carrying out observations on actual the activities of packaging plants, I have come to learn that metal detectors are among the most vital parts of the whole product packing process. The most common use of a metal detector is to locate and eliminate any metallic impurities in a product before its sale in order to protect the consumer. This is important because metal flake can be ingested and could lead to causalities. In my case, these detectors are usually located in a position after the product has been packaged and just before the product is finally delivered.

Metal detectors are thoughtfully designed to identify metal objects of various sizes and types, including ferrous, non-ferrous, and stainless steel pieces. The sensitivity of these devices can be adjusted, depending on the product’s nature and the package’s materials, with the average detection threshold for ferrous materials being 0.5mm and slightly greater for non-ferrous materials. Counting is done with additional data analysis that tracks specificity and sensitivity rates, contamination sources, and machine efficiencies. This information is essential for furthering the blended controls and the quality of requirements of the FDA and other agencies. Metal detectors’ installation on the packing line enables manufacturers to achieve a contaminate-free product since they practice a no-contamination policy. Such practices ensure the highest level of consumer safety and the integrity of the manufacturer’s brand.

What is the Suitable Packaging Size for Selling One Package of Chips?

The evidence provided by the key industry sources suggests that the volume of chips to be incorporated per package depends on market outlooks and the likely expectations of consumers, among other factors. On average, this target market is likely to use around 2 ounces of chips in a single serving package. This quantity is regarded as the most appealing in relation to prices and the volume that consumers expect and are willing to spend on the product. However, packages may be affected by the level of demand in the particular market or the level of awareness and promotion of the product, which might be intended to improve consumer satisfaction and product loyalty.

What Challenges Exist in Potato Chips Processing?

What If If Exceeding the Allowable Limit Set by the Company?

When we find ourselves in situations where the weight of a batch of our potato chip packets surpasses the predetermined weights, this calls for investigation into our production strategies. To begin with, we start by looking into the calibration of the shapes of the weighing equipment used. It is required that this calibration be as accurate as possible, because any variations, small as they may be, will translate into most variances in the weight of individual packets when total deliveries are huge. In this regard, sophisticated data analytics tools specify the times when deviations occur so that possible equipment malfunction or operator error is recorded.

We also conduct tests on our loading system for the materials to prevent overloading as a cause of variation in the raw material. Such variations involve retrieving the required volume of material from a silo, which is done according to the feedback provided about the time such volumes are expected to be retrieved. There is no doubt that such tactics are implemented to ensure compliance with regulations while simultaneously efficiently minimizing giveaways in terms of cost. To improve the quality of our products and our customer’s satisfaction level, we conduct a series of inspections using detailed process analytics. Each time a unit is packed onto the production line, such inspections will enable regulators to ensure that a certain parameter, weight in this case, will not be exceeded.

How Are Starch Levels Controlled?

The restoration of starch levels when processing potato chips is accomplished through a combination of corrective and control processes important for achieving the desired taste and texture properties. As noted by authoritative writers, a review of industry practices geared to these challenges can deduce some key tactics.

Strong quality control must be employed to begin with. At various stages of production, procedures involving measuring the starch content using instrumentation based on the color or enzymatic activities of the sample are applied and tested. Such ISM systems are essential in eliminating the time delays in offline measurements and the need for sampling while still enabling control of the starch level throughout the production run.

Other technical parameters, such as moisture content and fryer temperature, are strictly controlled. Physical foam characteristics should be kept in the order of sulfur dioxide. Frying temperatures allow for fluctuations but should range from 160°C to 180°C so that starch gelatinization is optimal with minimum unfavorable browning reactions and chip quality is retained.

Following these good agricultural practices defends the accuracy required in ingredient management, improving the quality and total uniformity of the potato chips while still achieving regulatory and consumer satisfaction measures.

Reference sources

-

How Chips are Made

- Source: Ontario Potatoes

-

Full Automatic Potato Chips Production Line

- Source: Potato Chips Machine

-

- Source: youtube

Frequently Asked Questions (FAQs)

Q: In what manner are raw potatoes processed to make potato chips?

A: The first step involves washing the raw potatoes and then peeling the outer layer, which is one of the crucial steps in making standard or ridged potato chips.

Q: Why must peel a potato before making potato chips?

A: Peeling is done to maintain a consistent flavour and smooth texture of the final product. To avoid oxidation and improve quality, potato slices are placed into water tubs after they have been peeled.

Q: How are machines used to manufacture ribs on potato chips?

A: A ribbed cutting blade grooves a potato on one side, resulting in a wavy shape. These blades are used to make ridged potato chips appealing and tasty, and the marketing for these chips focused mainly on the texture and crunch.

Q: What changes occur to the potato during the frying of potato chips?

A: The potato slices are fried at controlled temperatures until they reach the appropriate colour and crunch. Their weight is also observed for uniformity so that it does not exceed the allowable weight set by the company for that specific chip.

Q: What measures are taken in a chip factory to protect snack food products from contamination?

A: A chip factory uses metal detectors to scan the chips for metallic impurities. This step is necessary to ensure that the snack food is fit for human consumption.

Q: How do the post-cooked chips ayes?

A: Thereafter, the chips pass through a chute, receive seasoning and cooling, and subsequently transfer to an automated packaging machine. This prevents the chips from losing their freshness and crispness on the way to the end consumer.

Q: What’s the process for packaging these chips?

A: Potato chips are packaged by a machine that places them into sachets. Packaging assures that the chips do not lose their quality and freshness during transportation.

Q: Why do people control the amount of glucose in potatoes while they are being processed?

A: Glucose content has to be controlled as excessive levels may contribute to chip discoloration due to browning, which loses a significant quality feature of the chips. The chips are ready to be served without further modifications as every aspect is considered.

Q: Which marketing strategies do firms adopt to portray their chip products as natural?

A: Natural chip products have little to no additives, and the focus is on good-quality ingredients. Their campaign is directed towards maintaining the taste and texture of the chips within the health parameters.