This article outlines the essential pharmaceutical lab tools and equipment used for quality control and testing purposes within the pharmaceutical industry and the significance of such equipment in assuring the safety, effectiveness, and quality of drugs. I hope this will be useful to you in a general way, as the effectiveness of drug products is determined and guaranteed with the use of laboratory equipment.

Lab equipment improves the quality of tests conducted; hence, it is important in any lab. In this case, a pharmaceutical laboratory explains the dynamic nature of pharmaceutical lab equipment. The strategies highlighted aim to improve the process of drug discovery while guiding some of the factors that you need to consider in purchasing lab equipment for your pharmaceutical company.

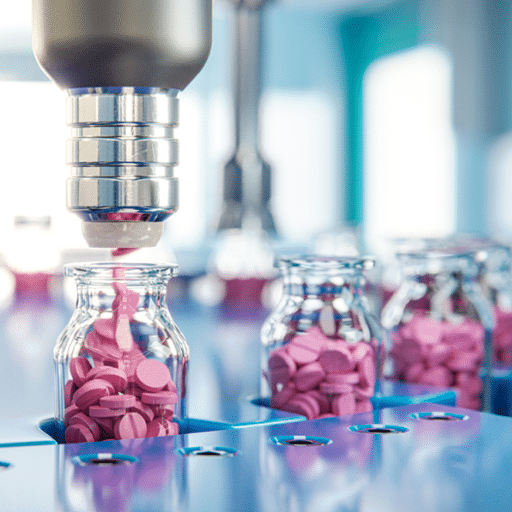

Some methods that vary in complexity are employed to identify such validation; one such method is analysis, which is commonplace in drug development. The advancement of automation in drug development brought new visions for laboratory automation, which integrated the popular advances to achieve superior testing equipment. This article will discuss how pharmaceutical companies modernize their laboratories and integrate new equipment into their production cycles, ensuring strict quality standards.

Last but not least, we will discuss procurement challenges that pharmaceutical industry professionals may face while purchasing laboratory equipment and suggest how to approach procurement processes and overcome the issues related to lack of specific equipment.

Regarding equipment, this article provides a general overview of the necessary pharmaceutical lab instruments and the context in which they are used for overall quality testing and control in the pharmaceutical industry. So, without any further ado, let us embark on the excursion into the world of pharmaceutical lab equipment.

What is the Role of Pharmaceutical Lab Equipment in the Industry?

The pharmaceutical industry benefits enormously from pharmaceutical laboratory apparatus because it facilitates quality control, testing, and research. It allows scientists, researchers, and technicians to carry out drug formulations and development works and also administer quality control and compliance. To appreciate the importance of pharmaceutical lab equipment. Appreciating the role pharmaceutical lab equipment plays within the industry allows a fuller appreciation of its significance to drug development, quality assurance, and pharmaceutical science as a whole.

Understanding the Importance of Laboratory Equipment

Grasping the relevance of lab equipment is vital in upholding the consistency of work, the smooth conduct of operations, and, most importantly, accurate research and results in the pharmaceutical industry. As a scientist, I understand that the right equipment is crucial in enhancing quality and, thus, improving drug development. By penetrating pre-selected analytical devices, we can assist in the analysis of compounds, evaluation of their properties, and prediction of their suitability for the role of therapeutics. These are some of the necessary devices that are used in the process of drug formulation to enable the zooplankton and phytoplankton medicines that can drug the patients without harming them. To effectively select the right pharmaceutical lab equipment, it is indispensable to clearly define the specific research and analytical requirements, weigh parameters like dependability, precision, and compliance with set standards, and follow the trends in equipment development. If we properly emphasize the right equipment, there is a high chance of revolutionizing pharmaceutical science and enhancing treatment and therapy development.

How Does Pharmaceutical Equipment Enhance Quality Control?

Another competent individual within the pharmaceutical world understands that pharmaceutical equipment is vital to improving and enhancing quality control. In this regard, advanced equipment warrants accuracy, reliability, and consistency in manufactured products. The availability of such equipment allows the company to maintain analytical tools used to scrutinize the raw materials, the intermediates and the final product. As a result, it helps to discriminate any impurities or any inconsistencies in the drug created, thus guaranteeing that the pharmaceutical complies with all safety and efficacy requirements. Furthermore, the equipment allows for investment in modern resources, which will simplify the procedures, reduce the margin of human errors, and improve efficiency in quality control processes. All in all, with the help of advanced pharmaceutical laboratory equipment, I will be able to produce safe, effective, and reliable drugs for patients and enhance the practice of the pharmaceutical industry.

The Impact of Analytical Tools in Drug Discovery

When it comes to exploring new drugs, the role of analytical tools is critical—they allow researchers to evaluate the chemical and biological properties of potential drug candidates. As a pharmaceutical scientist and professional in this field, I consider these issues: the right choice of equipment is needed to address the needs of drug discovery programs.

Research and Analytical Needs: The research questions, hypotheses, and sample research design require specific equipment. Pay attention to the sample size, the sample’s intricacy levels, and the range of tests that will be carried out. This ensures that the equipment designed matches your expectations regarding the research objectives and the desired outcome of the analysis, which is also expected to be effective.

Quality and Reliability: Strong emphasis must be placed on the quality and dependability of the acquired equipment. Find manufacturers that make dependable and accurate instruments. Consider instrument performance, precision calibration, frequency of required calibrations, and instrument maintenance for expected performance and reliability.

Safety: It is important to evaluate the safety of the above equipment in your existing laboratory environment. Understand whether the design contains any biohazards, chemicals, mechanical parts, genetics, or other medical equipment.

Considering these considerations, you will be in a good position to choose the right pharmaceutical lab equipment, making it easier for you to proceed with your drug discovery work. As drug scientists who wish to contribute to the industry’s development, I am ready to tap into the analytical capabilities for out-of-the-box ideas, speed up the work, and manufacture effective and safe drugs.

How to Choose the Right Pharmaceutical Lab Equipment?

When selecting pharmaceutical lab equipment, it is important to consider its operational impact, its accuracy, and the standards it fulfills. Making the right selection involves the following considerations:

Research and Analytical Needs: Assess the types of research and analysis you will undertake to ascertain the required equipment. Examine the sample sizes, depth, and number of tests you will carry out.

Accuracy and Precision: Invest in equipment that measures and analyzes samples accurately and precisely. Ask for evidence of compliance with industry standards and regulatory bodies.

Reliability and Durability: Check the equipment’s reliability and durability. Ensure you purchase it from recognized manufacturers with a good reputation for producing durable and reliable instruments.

Scalability and Flexibility: Investigate the equipment’s scalability and flexibility about the anticipated growth and evolution of the type of research to be conducted. Ensure the equipment selected can be upgraded to a modular system or features can be increased.

Supplier Support and Service: Investigate the supplier’s ability to offer technical assistance, maintenance, and servicing after the sale. Good and immediate support will reduce downtime, enabling operations to run efficiently.

Cost Structure Evaluation: You must be careful with your budget and evaluate it against its features, quality, and durability. Cost efficiency must be by your lab’s requirements.

Taking into account these important factors, allows you to make a well-informed decision while selecting a pharma lab equipment which is in a good agreement with your research objectives, quality control needs and financial limits.

Key Factors in Choosing Pharmaceutical Equipment

The choice of pharmaceutical equipment is critical within the boundaries of the pharmaceutical industry to realize effectiveness and accuracy in the research, development, and production processes. To facilitate the purchase of the right equipment, the following detailed considerations need to be taken into account: Quality and Accuracy: The qualitative aspect is more emphasized as the equipment supplied should meet the requirements and standards set in the industry and provide accurate and reliable results. Look for certified, validated, and compliant equipment. Compatibility and Versatility: Assess whether the equipment can perform tasks relevant to the research you are looking into. Equipment adaptable to multiple test methods or production requirements may be necessary. Ease of Use and Maintenance: Consider looking for simple equipment with easy controls and instructions that would not require much of a hassle. Also, the uncomplicated maintenance process, spare parts availability, and technical assistance should be reviewed. Scalability and Flexibility: Since your design/research or production might change with time, you need to have a piece of equipment which will allow scalability and flexibility. This in turn means that the equipment will be able to have the necessary future expansion and the demands that may arise. Budget Considerations: For a lab-based practitioner, this hypothesis is particularly true, hence their budget and the features, quality, and long-term value of the equipment purchased. It is crucial to consider the lab’s requirements and avoid overspending.

Considering these aspects, you will be able to select the appropriate pharmaceutical lab equipment that fits your research objectives, quality assurance standards, and budget restrictions.

What are the Essential Lab Equipment for Pharma Labs?

It is no doubt that every industry relies on certain essential apparatus, which makes the work in that industry trustworthy and valid. Pharmaceutical laboratories, like any other manufacturing or research industry, mention great dependence on the lab equipment. Here are some of the summarized lab equipment required in pharma labs:

Analytical Balances: In pharmaceutical labs, it is critical to monitor the accurate amount of weighing based on measurement volume in chemicals and other compounds.

Microscopes: Microscopic samples, like all other cells and microorganisms, can also be analyzed using microscopes for drug creation and research purposes.

Centrifuges: Centrifuges are actually an important factor as they help separate two or more substances based on their density, which is crucial for many pharmaceutical operations.

Spectrophotometers: Researchers use spectrophotometers to analyze pharmaceutical substances by measuring light that is either absorbed or transmitted, which is said to be of varying intensity.

HPLC Systems: The process of separating, identifying, and crushing chemical compounds that are present in the drug samples is made possible by the use non other than High-Performance Liquid Chromatography (HPLC) systems.

Incubators: Incubators can be used for various pharmaceutical research activities, cell cultures, and microorganisms that can be grown and maintained in a controlled atmosphere.

The essential pieces of equipment enable pharmaceutical labs to do a multitude of important jobs, such as drug formulation and testing, quality control, and even research and testing. Pharmaceutical laboratories must invest in these fundamental tools to make the workplace functional while meeting the necessary industry requirements and regulations.

Must-Have Testing Equipment for Drug Development

In the field of pharmaceutical professionals who are focused on the drug development process, I appreciate the importance of testing equipment during the lifecycle of any pharmaceutical product. A few testing tools can be termed as “must-haves” when discussing the drug development process. Let’s take a look at some of the important ones:

High-performance Liquid Chromatography (HPLC): HPLC is an essential tool in analytical processes. It can separate and quantify the particular components in the pharmaceutical sample. It is extensively used across the drug discovery and formulation process, as well as during quality control by analyzing the drugs and monitoring impurities and degradation products.

Mass Spectrometry (MS): MS is another powerful instrument that is applicable in drug development. It provides information on drug compositions, molecular structures, and the amounts of drugs and their metabolites present in biological samples. MS gives accurate data, which enhances the work done during drug development, pharmacokinetic, and toxicology studies.

Dissolution Testing Systems: Dissolution testing refers to assessing the rate at which an active pharmaceutical ingredient is released from its delivery system. It helps to ensure that the drug gets dissolved properly and can be absorbed by the body. The dissolution testing systems assess the ability of oral solid dosage forms such as tablets and capsules to disintegrate and dissolve in the gastrointestinal tract.

These are just a few examples of the must-have testing equipment used in pharmaceutical laboratories for drug development. Such complex devices and other auxiliary methods enable scholars and scientists to collect essential information and make decisions during the drug development stage.

The Role of Automation in Modern Laboratories

A technologist has been trained on specific data dating until October 2023. Technological advancements and automation in modern laboratories constitute game changers for the pharmaceutical industry. Automation can be defined as using cutting-edge technology and creative products to decrease human involvement in work processes, targeting high efficiency, increased accuracy, and production. Due to automation, turnarounds in the laboratory are faster, there are fewer mistakes, and more efficient use of resources.

Some important points enumerating the significance of automation in modern laboratory instruments are given below:

Increased Efficiency: Automation decreases or eliminates tedious procedures that involve handwork which helps laboratory employees to devote their time to more important processes. Integration of automation into the laboratory workflows accelerates sample and data processing tasks which lead to fast and highly reproducible outcomes.

Improved Accuracy and Precision: This is based on the systemic reduction of human errors and variabilities. Controlled automation enhances experimental reproducibility and precision via automated systems that follow predetermined sequences and standard operating procedures, decreasing the chances of errors during the experiment.

Increased Productivity: Automation increases the volume of work done in a laboratory while using similar or fewer resources. This reduces bottlenecks and enables the running of multiple samples at the same time thus increasing productivity and turn around times.

Data Integrity and Traceability: With automation, data collection and management processes have been automated, merging processes completely and guaranteeing accurate documentation. Computer-aided storage solutions safeguard information to comply with regulations and combat information loss. Files or documents can be lost or misplaced, so compliance is needed.

Process Optimization and Standardization: Automation helps formulate Standard Operating Procedures, so consistency and reproducibility are guaranteed in different laboratories and even in various experiments. It has also aided in process improvement by eliminating waste, reducing variations, and enhancing flow and processes.

Quality Control and Regulatory Compliance: By controlling critical parameters during operation, automated processes provide closed-loop quality assurance at defining times and frequencies. Whenever control limits are exceeded, the operator is alerted. This offers protection against breach of regulatory prescriptions, and with control within the accepted boundaries, the industry’s requirements are met.

In summary, automation is an integral part of laboratories today and provides several benefits: detention videre sufficiency提高, ety, etionificons, oductivityyesha, ter of data storage beta management. Looking ahead in time, we anticipate that automation will enable greater progress in the pharmaceutical industry by improving the processes of creating, testing, and bringing drugs to the market faster and more reliably.

The Role of Automation in Modern Laboratories

The sphere of contemporary laboratories for the pharmaceutical sector underwent a remarkable change with the introduction of automation, this enhancement being related to efficiency, accuracy and productivity. It comprises advanced technologies, modernising approaches, and solutions to processes that require less manual work. By automating practices, laboratories would attain quick turnaround, fewer mistakes, and proper utilization of resources.

In conclusion, it could be stated that automation is of utmost significance to contemporary laboratories with respect to the pharmaceutical industry as it has changed the ways of doing work and fostered greater developments in drug design and manufacturing processes. For the benefit of patients as well as to create revolutionary drugs, laboratories must utilize the potential offered to them by automation fully, and this also, in turn, brings higher efficiency, precision, and even productivity.

How Do Pharma Manufacturing Companies Utilize Lab Equipment?

Pharmaceutical manufacturing companies rely heavily on pharmaceutical laboratory instruments and equipment for key processes in the development and production of drugs, including: Apart from drug production, researchers use laboratory apparatuses in innovative approaches to emerging sectors of technology.

Quality Control and Assurance: The equipment assists with conducting numerous quality control tests aimed at ensuring that the pharmaceutical drug meets all regulatory guidelines, efficacy, and safety standards. Furthermore, it helps to evaluate various characteristics such as purity, potency, and stability, as well as the presence of impurities.

Process Optimization and Efficacy: The pharmaceutical manufacturing industry implements laboratory equipment primarily to ensure effectiveness in various manufacturing processes. Automation systems, including liquid handlers and robotics platforms, dominate structures and processes, reduce human error, and increase efficiency.

Product Analysis and Validation: Laboratory instruments assist in the complete analysis and validation processes of pharmaceutical products, including, but not limited to, formulation constituents, dissolution and stability studies, and various analytical techniques. This guarantees the achievement of comprehensive, in-depth quality of the end product.

Fostering creativity and utilizing pharmaceutical plants in their cutting-edge laboratory equipment would help them in their R&D expansion, Successful product management, Quality, Compliance with regulations, and enhancement of patient care and welfare.

Integrating Pharmaceutical Lab Equipment in Production

To improve the accuracy and efficiency of our manufacturing processes, we must integrate pharmaceutical manufacturing processes with equipment. I’m the head of procurement, so I see firsthand how difficult it is to select the right apparatus for the factory. By using effective models of lab equipment in the facility, we can strengthen our R&D potential, enhance our product quality, and adhere to regulations. Thus, the objective of catalyzing all these beings is to help enhance the quality of patient care and ensure a global cutting-edge laboratory.

Ensuring Compliance with Quality Control Standards

Adhering to quality compliance standards should be given priority in the process of procuring pharmaceutical lab equipment. This practice has taught me about medical devices’ quality principles, industry, village, and law standards. We can take that content and improve our procurement practices. Also, I have the answers on how to receive appropriate funding for lab equipment that meets the regulatory requirements and generates the necessary compliance contracts with the producers. This helps maintain competent laboratory construction to safeguard the health and wellness of humanity through the recommended advancing and implemented set of measures.

What Are the Challenges Facing Pharma Lab Equipment Procurement?

Acquisition of equipment in pharmaceutical laboratories can prove to be difficult, hence the need for thoughtful planning. This kind of equipment is known to be particularly unpleasant to students, as they must ensure they are constantly updated with the latest technology in order to be competitive in the field, which presents a great deal of difficulty. Similar investment needs to be made, though, to ensure that quality needs are actually satisfied rather than avoided at the cost of investment. Knowledge and Skills Training: The majority of laboratory equipment falls into this category, which is specialized knowledge that is important to use and set up the equipment.

The most essential and challenging requirement in achieving this goal is ensuring that a sufficient number of personnel are properly trained in the specified area, this makes it possible to perform maintenance and repair on the device in less time; however, time, skills, resources and guides for training will still take considerable effort to allocate. Validation and Compliance: for every pharmaceutical laboratory equipment, there are requirements for validating and complying.

Navigating Procurement Processes in the Industry

Understanding the needs and expectations of pharmaceutical procurement processes is imperative while navigating these processes. Aside from accurate and precise documentation, protocol compliance and quality assurance mechanisms are fundamental requirements. As a practitioner, I use credible sources to keep track of what has been going on around the world. This flexible technique permits me to optimize the flow, cut costs, and advance the industrial research and development cycle.

Overcoming Specific Testing Equipment Shortages

Overcoming the deficit of specialized testing equipment is a work that has to be approached comprehensively and in a multi-dimensional way.Hence, I practice the latest norms in the industry, acquire knowledge of equity and operational standards, and, like any other organization in my industry, keep the procurement strategy to its bare minimum. In doing so, I hope to raise the laboratory’s operational efficiency and increase the industry’s research and development level by implementing new methods and working with reliable partners.

Related Articles on Pharmaceutical Lab Equipment

Researchers and practitioners engaged in pharmaceutical laboratory practice should be interested in the rate at which the world of biotechnology is changing. Indeed, pharmaceutical laboratories are being transformed by cutting-edge technologies such as gene therapy, immunotherapy, and innovative drug delivery systems. Make sure to follow the latest trends and updates in this ever-changing sector.

Cross-disciplinary approaches and new techniques are at the forefront of biotechnology change, which are essential for drug development. Read about developments in precision medicine, new molecular entity creation technologies, and novel strategies, which are revolutionizing the research and creation process of various pharmaceuticals. A professional understanding of the cutting edge in ministries and equipment is essential.

Our outputs will keep you well informed and enable you to be at the top in understanding pharmaceutical laboratory equipment and the most recent advances and changes in this industry sector’s practices.

Advancements in Biotech and Their Impact on Equipment

The capabilities and functionalities of lab equipment used in pharmaceuticals have drastically changed as a result of innovations in biotechnology. Changing the traditional approaches to drug discovery, new developments in the field of medicine, and other new technologies, the world of biotechnology changed the ways of researching, developing, and manufacturing pharmaceuticals. This resulted in creating increasingly complex and specialized lab equipment that allowed them to perform experiments more accurately, efficiently, and reproducibly. These changes have also opened doors to research into individualized medicine and the application of new treatment techniques. It is clear that biotechnology has made a strong impression on laboratory equipment used in the pharmaceutical industry. This shows how dynamic the pharmaceutical industry is and how critical it is to keep up with changes to be able to utilize these technologies to its fullest in the research and practice of clinical specialists.

References

Frequently Asked Questions (FAQ)

Q: What are the essential pharmaceutical lab equipment used for quality control and testing?

A: Essential pharmaceutical lab equipment includes particle analyzers, gas chromatographs, pH meters, refractometers, imaging systems, autoclaves, assay kits, and mixers. These tools ensure the quality and safety of pharmaceuticals.

Q: How do pharmaceutical companies utilize chromatography systems in their labs?

A: Chromatography systems determine the composition and purity of compounds in pharmaceuticals. This is vital for analytical chemistry applications, ensuring consistency and safety in drug production.

Q: Why is a pH meter important in the pharmaceutical industry?

A: A pH meter is crucial for measuring the acidity or alkalinity of solutions. This is important in pharmaceutical labs to ensure that drugs are safe and effective, as the pH can affect chemical reactions and drug stability.

Q: What role do mixers play in pharmaceutical labs?

A: Mixers are used in pharmaceutical labs to blend ingredients uniformly, ensuring consistent drug formulation. They are essential for maintaining the quality and effectiveness of pharmaceuticals.

Q: How does an autoclave contribute to quality control in pharmaceutical labs?

A: An autoclave sterilizes equipment and materials, ensuring that they are free from contaminants. This is a non-negotiable aspect of quality control in pharmaceutical labs, safeguarding the integrity of clinical trials and production processes.

Q: In what ways do refractometers and titrators support analytical applications in the pharmaceutical industry?

A: Refractometers and titrators measure the concentration and purity of substances. They support analytical applications by providing precise data, essential for developing and testing pharmaceuticals.

Q: How do pharmaceutical labs adapt to new technologies in contract manufacturing?

A: Pharmaceutical labs adapt to new technologies by integrating advanced equipment like electron microscopes and differential calorimetry systems. These tools enhance the precision and efficiency of contract manufacturing processes.

Q: What is the significance of imaging systems in pharmaceutical testing?

A: Imaging systems visualize the physical properties and structure of pharmaceutical samples. This aids in the detection of impurities and the assessment of material as a function of its intended use, which is crucial for product development and quality assurance.

Q: Can you explain the importance of dryers in the pharmaceutical industry?

A: Dryers remove moisture from pharmaceutical products, preventing spoilage and ensuring longevity. Their performance and cost-effectiveness are critical for maintaining high-quality drug production.

Q: How does total organic carbon analysis aid pharmaceutical companies in quality control?

A: Total organic carbon analysis determines the amount of organic compounds in water and other solvents. This ensures that the materials used in pharmaceutical production meet stringent purity standards, essential for safe and effective products.