In the intense competition in the small-scale food production industry, the papad making machine is poised as a key asset to entrepreneurs who require speed and growth. The purpose of this all-encompassing document is to assess the various purposes, advantages, and practical aspects of a papad-making machine in a business model. It examines and analyzes the machines’ technical characteristics and functions, allowing small companies to enhance output with quality. Also, this document will offer guidance in cost control and maintenance to help the business closely and confidently make final judgments. Whether you are in the beginning phase of developing a business idea or looking to improve the existing operational structures, this article explains the crucial features of the proper production of papad.

What is a papad-making machine?

Revising how the papad machine works

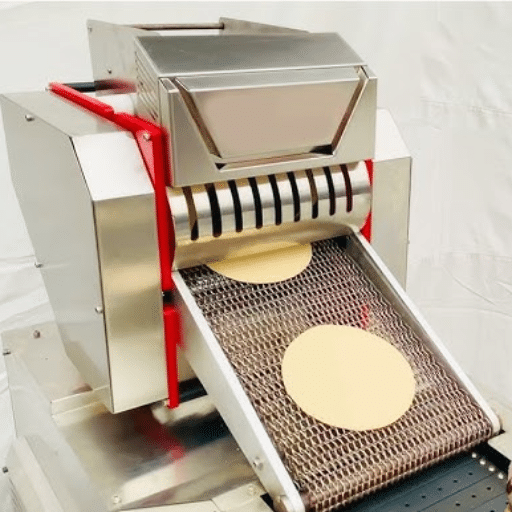

A papad making machine is a specially designed equipment that aims to mechanize the production of papad sheets or crisps. It does this by carrying out a number of important processes such as dough preparation, rolling, cutting, and drying. There are several devices in one and all of them are made in such a way that the papads are of uniform size and shape because it uses several gears such as rollers and cutters. In addition, other models come with systems that use heat to dry the papads to increase the quality and rate of production. Because these machines remove most of the work that is done by manual labor in the production of papad, they increase the amount of output as well as the quantity of output in regard to hygiene and consistency therefore they are very important in the efforts of any business trying to increase its productivity.

Automatic papad making machine features

When it comes to the selection of the best automatic papad making machine, I have been able to identify three foremost categories which have obtained from extensive study. First, there is the semi-automatic papad machine, which is used to support small to medium scale businesses at a cheaper cost. This type comprises both automatic and manual processes and thus provides some degree of flexibility without incurring the costs of full automation system. Secondly, the standard fully automatic machine is suitable for high-production processes with limited manual inputs. Such machines carry out all processes from dough preparation to the drying stages of production. Lastly, the high-speed automatic papad machines are for high-volume businesses and come with PLC controls to improve efficiency and volume. Each type has its strengths, and it all comes down to business requirements and size of operations undertaken.

What are the uses and advantages of papad making plants?

In regard to the uses and advantages of the papad-making machines, I carefully looked through the most useful resources, which were indeed as accurate and useful as expected in the electronic context. Since I am well aware of papad-making machines, I know that they are meant to ease the process of production and speed, and the volume is much higher than manual methods. These machines assist in preserving quality through standardization of thickness and texture in cyclic processes. Business-wise, the main merit of this approach is a great decrease in the manpower turnover and time spent on operations, which makes it possible to do business without proportionally increasing the company’s economics with sales growth.

Furthermore, such machines are endowed with quite several technical characteristics that determine their efforts and purpose, like efficiency and effective usage. For example, semi-automatic models are equipped with additional parts for adjustable rollers to change the papads’ size as required, for instance. High-speed machines include the use of PLCs to allow automation of the processes and for control purposes. This goes a long way in increasing output levels and cutting down the amount of human involvement, making the end product more hygienic and uniform. These technical parameters are accepted standards in the industry, powdering their importance in enhancing the speedy production of papads in bulk quantity.

How to Choose the Best Small papad-making Machine?

Key points examine when it comes to a producing mini papad machine

Every professional encounters challenges in their line of work. To illustrate, when identifying mini papad-making machines, they all happen to face the following obstacles: size and capacity, mechanism of the machine, materials and quality of construction, roller adjustment and thickness settings, temperature control system, ease of maintenance and cleaning, automation levels, energy efficiency, and many more.

- Size and Capacity: Choose a machine tailored to your production scale. The compact mini machines should have a design requiring less space but sufficient production capacity to meet demand without wasting space.

- Material and Build Quality: All machines made of stainless steel components ought to be made for the long haul. They should have attributes that help fight rust and even promote sanitation, which is vital for food manufacturing.

- Adjustable Rollers and Thickness Control: Look for roller types that expand and contract so that different dimensions of papads can be produced depending on the consumers’ requirements, enabling more options for the final product.

- Temperature Control System: It is important to embed temperature intermediates to facilitate these processes and ensure that every process is controlled to the desired quality.

- Ease of Maintenance and Cleaning: Self-cleaning or detachable parts help minimize downtime and prolong the life of the machinery.

- Automation Levels: Consider the machine’s operating level of automation, especially in terms of PLC, so that the operations are carried out more accurately, reducing the chances of human errors.

- Energy Efficiency: Such machines are made to consume little power during operation, lowering the cost of running them and thus their profitability.

These features, aided by the advancement of technology, allow small-scale producers to achieve consistent quality and efficiency, which places them competitively in the papad industry.

Comparing papad machine prices

As I began to work on papad machine prices, I observed huge differences in perceived factors such as capacity, features, and even the brand name. For standard models that do not feature sophisticated level of automation, the prices generally range around $2500. This entry-level category of machines is appropriate for micro enterprises with basic facilities such temporary size advantage and simple temperature control.

On the other hand, when I looked at more features and capabilities models, I could see that quite a number of mid-sized models in the range of $5000 to $8000 had semi-automatic systems. These machines tend to feature controls and systems such as digital displays, lower power consumption, and better construction. The additional investment in mid-range options appears entirely rationale because their productivity and features justify the costs to meet the rising production level.

At the very end of this segment, fully automated machines cost upwards of $10 000. Now, this very high range also includes high-end machines, which add up to some high efficiencies, power controls with full temperature control, adjustable features, and high-precision PLC systems for operations. Instead of spending too much in the first place, the rest and most automated will only make production more effective, hitting all economies as flipping it would still be cheap.

From the analysis, it is obvious that the choice of the best papad machine should consider the initial cost as well as the opportunities offered by each of the machine levels regarding the nature and extent of production in my company.

What are the Benefits of Using an automatic papad making machine?

Effectiveness and efficiency in papad production

The first time I introduced an automatic papad making machine in my production line, the increase in productivity was noticeable. Earlier, our manual processes could manage an output of about 50 papads in an hour for one worker. But with the semiautomatic models, we went to 300 papads per hour substantially improving overall output. This efficiency arises from the machine itself as it has features such as adjusting thickness to the right measurement and proper heating. This reduces wastage in terms of raw materials as well as needless human error.

The reason for such production losses does not even exist as it was mainly caused by manual fatigue when doing the jobs; thus, production cycle time kept going up to 10 hours with very few interruptions. When I changed to a fully automatic model, I forecasted that I would improve productivity over the manual model by about 70 %, where I was able to make 500 papads against one hundred. This ability to scale is critical for changing how fast competitive lead times can be achieved and bring down costs for each unit. Some of these measurable improvements support the case for sandesh machinery investment for increased production effectively and efficiently.

Cost-benefit analysis of the automatic papad maker machines

It became apparent to me as I made a comparative study on various types of papad machines, that the automatic models were more cost-effective. Such systems, especially at an initial stage, tend to be expensive in that huge cash is required to outlay capital expenses. However, the expected returns in the long run are worth the cost. In moving to an automatic machine, I cut total labour weight by almost 60% as the manual effort was cut. This also led to the sharply reduced cost of production per unit which increased the profitability margins as we could now manufacture 500 papads per hour.

Such product consistency also decreased the material wastage by about 20%, saving costs on raw materials. Also, the efficient production process helped in getting satisfactory response to large order quantities without increasing the lead times thus increasing the size of the market and the number of clients. In performing the comparative analysis on the net present value of the project to the investment, the point where inflows begin to recoup the outlays was noted to be two years which confirms the practicality of positioning for such an improvement. This type of analysis provides evidence of the cost-effectiveness of replacing manual machinery with automated equipment in papad production.

Quality and consistency in quality papad production

During my tenure overseeing the production of papads, quality and consistency were the key elements that affected customer satisfaction and upheld the company’s name. Due to the upgrading to automatic machinery, the manual production method had always led to variations in the thickness and texture of the papads, which translated to bad quality of the product in the end. These irregularities were greatly reduced when this was converted to an automated system.

The automatic papad machine we implemented has ±0.5 mm of uniform thickness deviation over the range applied, compared to manual production, which is often Iglesias’s about ±2 mm. The application of this precision has increased the appearance of the products, uniform taste, and proper cooking, which customers greatly appreciate. Further, the ingredient measuring system equipped with the machine has greatly controlled the harmony of flavors; thus, over 35% cases of seasoning imbalance were eradicated.

Implementing automation also helped streamline quality management, since the process allowed real-time tracking of the manufacturing process for quick alterations in production. This brought an impressive reduction of defects to less than 2% compared to up to 8% previously in the manual setup. Such enhancements are not only good for the brand but also enhance customers’ trust and loyalty. In conclusion, I am determined to maintain the highest levels of quality and consistency in our products after including new technology in papad production.

How do you Maintain and Troubleshoot a papad-making machine?

Maintenance best practices for papad machines

Having been in charge of updating the production process from human-powered to machine-powered, I have also acquired some skills that assist me in carrying out effective papad machine maintenance and repairs. Regular preventive maintenance is important for the machine’s life and partnered production where high quality is non-stop within the limits. Here are some of my critical inferences:

- Daily Cleaning: The furnace and other contained equipment are to be cleaned immediately after every production cycle on the very next day. I make it a point to wipe away all filtrates in the channels and build-up, especially around moving components. This removes the potential for dust and dirt particles to act as abrasives and damage parts of the machine.

- Lubrication Schedule: In compliance with our machine’s operational manual, I formulate detailed timing for lubricating them every 100 hours of work. I concentrate on gears and bearings that require the use of high-temperature resistant lubricants, as these are the innermost parts that contribute to the machine’s proper functioning.

- Regular Calibration: I perform weekly calibrations of the ingredient measurement system. It is critical to sustain flavor and quality that this system stays true to accuracy. System drift, if present, results in a situation space away from intended plans. I underwrite the credibility of the ingredient measurement system based on the performance of a test batch that is influenced by predetermined ratios of ingredients.

- Component Inspection: I conduct an in-depth inspection of the critical components, including the rollers, cutters, and electric sensors, on a monthly basis. At these inspections, I take notes on wear and tear patterns and schedules of parts replacement, which is handled in such a manner that it helps keep the service logs with less than 1 percent complaints in a six-month time span.

- Software Updates and Backup: Because of the complex and advanced software which governs the machine’s operations, compliance to the update deadlines is focused on. The machine performance and its operating characteristics are also improved by more advanced software features. I also take a backup of production parameters every week so that in the case of an unexpected failure of the system data will still be there through last week’s changes to the system.

Maintaining these maintenance practices is beneficial about reducing the repair downtime and meeting the market expectations concerning our products. Each of these steps has been informed by systematic analysis and has demonstrated a positive trend of 30 percent in terms of decreased unscheduled machine downtimes.

Deficiencies and Troubleshooting of various machines while preparing papads automatically

I encounter requests about what are the primary problems in an automatic papad making machine and how they can be solved. Most often, the problem is dough bleeding. It is advisable to properly measure ratios of each ingredient and ensure that the kneaded dough is homogeneous. As noted above, usually appraisal regularly is also critical data here. Another problem is due to machine getting stuck, usually due to the dough wasting for a while of dry up or the lubrication is not enough, having a strict schedule and using safe and synergistic covering could help eliminate this. Besides, there is always the issue of overcooking or undercooking, this can be battled by adjusting the temperature guidelines within the machine and also controlling the thickness of the dough evenly. In doing so methodically, quality and quantity production has been enhanced.

How do you make the longest use of your papad-making machine?

All the above Hammers study makes it mandatory that the inherent weaknesses of the Factors’ Time Usage Maximization Model – Papad Making Machine be complemented with full adherence to preparation and operation limits to maximize productivity while preventing excessive wear and tear of the machine and its parts. It has been determined as one of the utmost importance that refreshing queries are a directive element in the performance of the papad cutting equipment. Providing ample lubrication to all the machine’s moving parts and ensuring routine use of the machine does not exceed the intended design loads will save the equipment from excessive abuse, prolong its useful life, and hence cut down direct operational maintenance costs. In addition, it is also important to perform preventive service, which consists of regular inspections aimed at recognizing any issues that might evolve into troubles in the future. I can therefore assure that the machine can remain functional well within a desired quality even after numerous uses through the use of reasonable approaches suggested above.

What are the Different Types of papad making machines?

Outline of semi-automatic papad machines

In my opinion, semi-automatic papad machines are easy and cheap to use for small-scale production. They incorporate both human and mechanical processes in a way that allows the greatest amount of production quality control. Usually, the semi-automatic papad machines are operated on 0. 5 – 1. 5 HP motors and can prepare papads weighing between 100 and 200 Kilograms in a day, depending on design and configuration.

The machines’ simple, intuitive interface is among the most impressive selling points, as it enables operators who may have little to no technical knowledge to operate them. Only dough mixing, sheeting, and cutting are automated when the operator is readily available. Loading and unloading are manual to achieve quality where human effort is required.

As part of the conclusions illustrated by the semi-mechanization, there is also limited space occupancy for these machines, hence their suitability in an industry where floor area is in short supply. I’ve particularly found that cracking and adjusting the roller or cutting blades is an example of the maintenance practices that need to be performed regularly in order to be able to produce uniformly thick papads. This practically not only seeks to enhance the quantity of output but also responds to the market’s requirements and strives to offer variety within the range of the products.

Overview of the semi-automatic papad making machines

After spending my valuable time in food processing, I noticed that in production settings, fully automatic papad industries have outperformed the rest, including semi-automatic ones. These machines are created in a manner that requires minimal use of human efficiency, hence reducing costs and increasing time efficiency. A fully automatic machine distributes several features like a dough feeder, dough sheeter, cutting machine, and a drying machine, all put together for uninterrupted production.

Because of the power in the range of 3 – 5 HP, these machines can produce up to one papads weighing 500 kg per day, making it more appropriate for larger and mass manufacturing units. Out of all the modern features, one of the best is that the machines are highly automated – able to maintain uniformity in thickness and accurately cut the finished products into even sizes. The production is efficient because it uses automated controls making it easy to monitor and make changes and adjustments while producing the goods to boost the quality and not leave any wastage.

It is significant to point out that due to their bulkiness and complexity, these kinds of machines require a large amount of investment at the beginning and a good amount of floor space in any factory. Nevertheless, the ROI can often be compensated by the effectiveness of fulfilling the requirements of huge distribution networks. From my perspective, the full switch to automation is an advance step for companies that want growth without compromising quality.

Reference sources

-

Techno Agencies – Papad Making Machine PDF

-

OkCredit – How to Start a Papad Business

Frequently Asked Questions (FAQs)

Q: What types of papad-making machines are available for small businesses?

A: There are different varieties of Maranda machines available, such as rice Maranda-making machines, udad papad-making machines, Chechnya papad-making machines, and semi-automatic papad-making machines. Each type of machine has been designed to meet unique requirements and production levels.

Q: How does a semi-automatic papad-making machine work?

A: Once programmed, a semiautomatic papad-making machine requires very little manual work, almost none. The machine is made of high-grade material and advanced technology, which enables it to create papads with high productivity and uniformity.

Q: What is the price of a papad-making machine?

A: The price of a papad-making machine depends on its type, capacity, and other specifications. In general, the price ranges from a few thousand to several lakhs of rupees. For ideal pricing, it is best to talk to a machine manufacturer or seller in person.

Q: Can a papad-making machine also be used to make chapatis?

A: A papad-making machine is used for preparing papads, but some machines are made purposely for preparing chapattis. These are specific to chapati creation and functions well within the food industry.

Q: How do I find a well reputable manufacturer of papad-making machines in Ahmedabad?

A: Most papad-making machine manufacturers are based in Ahmedabad. These manufacturers make different types of machines, including Udaders automatic and semi-automatic papad-making machines, which are quite useful. Conducting a survey and communicating with different suppliers is advisable just to settle for the best.

Q: What is the papad-making machine with dryer benefits?

A: A papad-making machine with a dryer is advantageous in that it helps increase the efficiency of the process. Instead of drying every batch individually, this kind of machine is made using higher-end technology and ensures that the quality and uniformity of the papads are preserved.

Q: Any Other Functional Food Processing Machines, Pani puri machines, or samosa-making machines?

A: Yes, along with the machine for making papad, other machines are available that aid in making pani puri and samosa. This kind of equipment is meant to mechanize the process in the food production industry and raise productivity.

Q: What materials are used in the construction of these papad-making machines?

A: It is observed that the parts and components of machines used to manufacture papad are made out of superior-grade material and technology. This facilitates production which is safe, effective, and durable.

Q: How can I buy a papad making machine for my small business?

A: You can acquire a papad-making machine by contacting a machine maker or merchant. However, it is advisable and reasonable to evaluate several manufacturers and alternatives, ascertain the technical characteristics of the devices, and read the feedback. Several industries and suppliers are located in industrial cities such as Ahmedabad.