Accomplishing the required speed and precision during operational procedures, especially modern packaging processes, is only outweighed by the need for consistency and reliability. New machines available on the market for the industry serve three purposes in solving set tasks: increased productivity, steady consistency in performance, and reduced operational costs. With the help of modern technologies such as automation, intelligent sensors, or adaptive control systems, the machines can efficiently handle diverse packaging demands with little to no human supervision. This article reviews the juxtaposition between cost-effectiveness, waste minimization, ease of adopting modern technology and maintaining a smooth and competitive edge in global markets stemming from the primary benefits of modern package machines.

What are the Key Benefits of Investing in Modern Package Machines?

Modern package machines work independently with great precision and a low defect rate. They can increase production without sacrificing quality or speed, making them easy to scale. There are also cost-saving benefits as material wastage is achieved. Businesses also have the chance to use advanced features that allow for automation and intelligent monitoring to ensure greater output without downtime. Ultimately, these machines give a strong competitive advantage through improved resource utilization, faster turnaround times, and better market results.

What makes modern packaging machines increase production efficiency?

The combination of advanced technology, automation, and precision allows for a tremendous increase in productivity when packaging materials. With the addition of automation systems, there is less dependence on human intervention, which leads to fewer bottlenecks and faster speeds. Servo motors do accurate movements while the feeding mechanisms can also be altered to allow proper handling of the materials. Quality control is also automated to ensure no errors or defects that increase uptime. PLCs and HMIs also improve operations to allow easier adjustments and monitoring. Advanced technology, like modern packaging machines, increases throughput while ensuring consistency in quality.

What cost savings can be achieved with automated packaging systems?

Automated packaging systems represent a great way to save money in the long run because fewer people will need to be hired and there is better management of resources. Because these systems have little manual input, it becomes easy to save on labor expenses, while repositioning staff to more essential roles. In addition, these systems cut down material waste due to precise operation, which also cuts spending on raw materials. Moreover, the speed and effectiveness of automated systems cut down the energy used for each unit produced, leading to lower utility costs. Gradually, reduced downtimes and maintenance needs lead to operational long-term cost savings.

How do packaging machines improve product quality and consistency?

Machines dealing with packaging take quality and consistency to a whole new level through automation of elaborate tasks. Packaging machines can always ensure accurate sealing, labeling, and filling by utilizing different programming parameters which helps keep human error to the absolute minimum. Moreover, different stages of the packaging process are continuously observed and guarded by sensors and advanced control systems to spot and rectify any mistakes during the performance of these stages. This proactive approach to quality control maintains compliance with the set quality standards and improves overall customer satisfaction.

Which Types of Packaging Machines are Best for Different Industries?

The ideal packaging machine will differ according to the needs of each industry. Vertical form-fill-seal machines are ubiquitous in food and beverages because they adapt to flexible packaging and appropriately seal products. In the pharmaceutical industry, blister and strip packaging machines guarantee dosage precision and safety. On the other hand, the e-commerce and retail industries use automated carton sealers and stretch wrappers, making it easier and faster to package products for shipping without risking damage. These machines are chosen based on the need to comply with regulations, the nature of the product, and the level of efficiency desired in that particular field.

What are the most versatile packaging machines for small businesses?

Various sectors such as beauty, food, and electronics require packaging, and to address these needs, small-scale businesses can use flexible, affordably priced, and simple to operate packaging machines. Portable automatic or semi-automatic tabletop vacuum sealers work best to seal vacuum pouches for packing food items. Compact filling and sealing machines are appropriate as they can fill and seal liquids, granules, and powders. Additionally, grommet pouch and shrink wrap systems are ideal for businesses that require bundling and packaging various products. These machines are useful to small businesses as they save space and cost.

Which packaging solutions are ideal for food and beverage industries?

- Vacuum Sealing Machines

These machines are ideal for removing the air surrounding food items, which in turn prevents spoilage and increases longevity. Most perishable products, especially meats, prepared dishes, and cheeses, can be vacuum sealed.

- MAP Systems

MAP systems utilize a mix of nitrogen and carbon dioxide gas to replace the oxygen inside the packaging with a mixture suitable for preserving the item’s quality. This technology is popular for fresh fruits and vegetables, baked goods, and meats as it helps to reduce spoilage.

- Filling and Capping Equipment

For liquid food and drinks, such as sauces, oils, and juices, volumetric filling and capping machines automatically fill the products in a measured manner. The sealants also close the container securely, thus reducing spillage and increasing productivity in the production plants.

- Shrink Wrap Systems

These systems help bundle multipacks for beverages and efficiently package food items in durable, untampered-with materials. Heat shrink wrapping additionally makes the product secure during transport and gives it a professional look.

- Pouch Packing Machines

They are ideal for snacks, dry fruits, and coffee powders as they come in flat and stand-up pouches. Pouch packing machines also offer value and ease of handling by providing tight seals that preserve the product for a longer time.

- Labeling and Coding Machines

These machines are used in food and drink industries for compliance purposes. They print essential information such as expiration and lot codes, along with the ingredients on the package. These factors enhance accuracy within the supply chain.

- Systems for Packaging Glass and Plastic Bottles

Beverages such as sodas, juices, and even wines have a special bottling process that incorporates washing, filling, sealing, and labeling all within a single workflow. Modern equipment can be fitted to various container shapes and sizes while still conforming to industry requirements.

How Do Pharmaceutical Companies Get Value Out Of Specialized Machinery?

Pharmaceutical products are held in specialized packaging equipment, which is beneficial to pharmaceutical companies in protecting the product’s integrity, compliance with laws, and efficiency. High-grade packaging machinery protects pharmaceuticals from contamination, moisture, and light, enhancing the medicines’ efficacy and quality. These packaging systems subject the medicines to automated processes for precise dosing, sealing, and tamper-evidence to meet tight legal requirements. With pharmaceutical equipment, the company’s productivity is improved because the amount of manual work is decreased causing errors to be reduced while also making it easier to meet the growing demand for the products. This type of precision and reliability increases the ease with which supply chain processes can be managed and improves consumer safety.

How to Choose the Right Packaging Machine for Your Business?

Choosing a packaging machine means looking at your product’s requirements, such as its material, design, container, and even your production volumes. Make sure to check the level of automation on the machine and the packaging format you plan on using to balance efficiency and costs. You should consider how easy it is to operate, the maintenance it calls for, and even the availability of support. Ensure that the machine complies with industry standards, especially in pharma or med-tech sectors, which are highly regulated. By bringing together the machine’s capabilities with your operational goals, you will be able to achieve desired performance as well as scalability.

What questions should you ask when purchasing a packaging machine?

Ask yourself how many machines do you plan on using. It is essential to highlight the focus on core factors that differ across businesses. The first factor should be the machine’s mark of production which looks at its speed in units per minute. This should meet your target without sacrificing accuracy rates or consistency in output. Also, the machine’s capacity when it comes to packaging and materials is important if a diversity of items is intended to be packaged. A third factor to consider is the level of automation required; semi-automatic machines perform well in low-volume productions, but high-volume productions call for fully automated systems.

Always note the machine’s specifications like sealing effectiveness, filling accuracy, and flexibility regarding different packaging sizes as these factors are crucial for your business. In addition, other critical technical features include the type of materials the machine can work with, such as flexible films, aluminum or rigid containers, and whether it is volumetrically or weight-filled. Additionally, the machine should be up to code regarding hygiene and safety regulations, especially in the food or drug sectors. Also, remember to analyze the machine’s footprint area and energy usage as these aspects will impact the facility’s overall operational costs and space.

How to determine the required capacity and speed for your packaging line?

To know the required capacity and speed for your packaging line, you need to analyze the production volumes, the product, and the operational objectives that you are trying to accomplish. First, try to estimate the amount of output you are planning to produce in a given period of time (units per hour or even day). Also remember to factor in the range of your business and seasonal demands to account for growth opportunities.

Analyze the type of products and packages you have because they will dictate the ratio of speed and efficiency to the time it takes to package the products. For instance, filling up liquids differs in speed from machines that deal with solids or fragile items. Important details that should be analyzed are the machine’s cycle duration, throughput per time interval, and the Fill volumes or sizes that can be handled.

Also, consider time to change if a worker will be handling more than one item or type of packaging because this affects productivity at work. These machines must work with set operational goals in mind, where speed must be traded off with accuracy and quality. These considerations will help improve the performance and reliability of your packaging line for your production without lowering your standards.

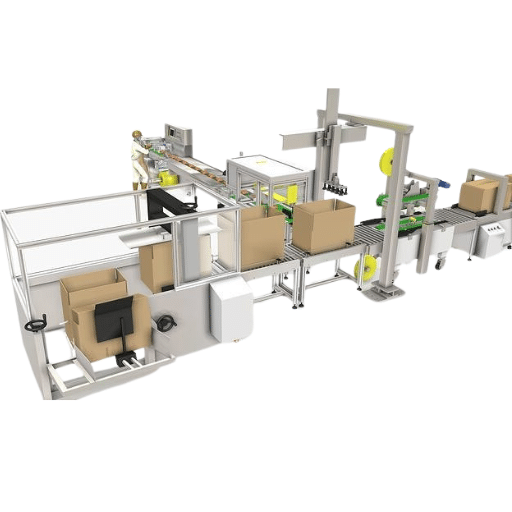

What are the benefits of modular packaging systems?

The benefits of modular packaging systems are significant. Businesses can adjust their operations with limited investment thanks to the greater flexibility and scalebility these systems provide. Modular packaging systems offer higher adaptability. Companies can customize or expand the systems to handle different products or packaging formats. Productivity significantly improves with modular systems. Most systems also preserve the operational arrangements in place making the changeover quicker.

Additionally, their design often reduces the initial capital investment by making it incremental instead of requiring entirely new equipment. The adjusted arrangements also leads to better space utility, faster maintenance, and less complex integration with existing workflows. They often reduce the overall investment required and increase the return on investment and productivity in the long run.

What are the Latest Innovations in Packaging Machine Technology?

New developments in packaging machine technology are centered around automation, recycling, and digitalization. These modern developments stem from knowing that robotics and AI-enabled systems will drastically improve the packaging processes’ speed and accuracy. Also, the sustainability strides include creating machines that use recyclable and eco-friendly material and aim to reduce waste. Additionally, newer technologies such as IoT and machine learning facilitate real-time status checks, predictive repairs, and integration into Industry. Combining all these innovations improves flexibility, lowers costs of business operations, and enhances green sustainability within the packaging industry.

What are the benefits of IoT-enabled packaging equipment?

IoT-enabled packaging equipment provides a myriad of benefits, the most important of them being real-time monitoring, which enhances control over the processes. Such systems allow operators to collect critical data and, as a result, detect problems and corrects them before the system malfunctions. In addition, these systems improve the ability to foresee and mitigate issues, thus reducing the amount of unplanned outages and increasing the life of the machines. Coupled with this is better IoT-enabled traceability, which ensures high levels of quality protection and adherence to compliant requirements. Such automation and integration of IoT increases industrial productivity while minimizing the use of resources that are so crucial to achieving sustainability.

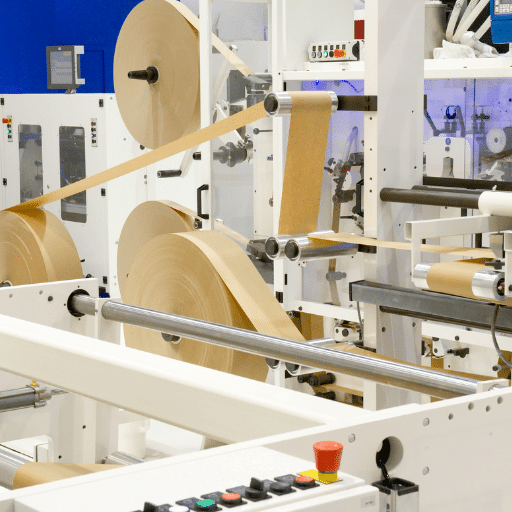

How do sustainable packaging solutions integrate with modern machines?

Sustainable packaging solutions use new materials and technologies designed for advanced packaging machines and systems. These machines can efficiently manage and produce the required quality of biodegradable or compostable materials. Automated systems are usually further developed to reduce material waste and energy consumption while performing the packaging. Besides, modern equipment is increasingly manufactured in modular form, allowing customers to integrate new sustainable materials with minimal reengineering or downtime. This makes it easy to align packaging processes with sustainability objectives.

How to Implement a New Packaging Machine in Your Production Line?

Like any new piece of hardware, a new packaging machine, once purchased, needs to be integrated with your production line with a lot of precision. First, try to understand the direct needs of your production line, such as production volume, materials needed, and other sustainability objectives. The new machine’s specifications must align with your operational needs and office infrastructure. Post that, draw out a plan for installation focusing on system integration, training operators, and adheering to safety protocols. Once the installation has been completed, thoroughly test the machine to confirm if performance standards have been met and if there are other issues to resolve. Remember, regular monitoring and maintenance is imperative to optimize the machine’s functionality and minimize any possible downtime. That alone guarantees success long term.

How Do You Incorporate a New Packaging System?

Applying a new packaging system has to be done carefully to incorporate it into the production process effectively. The first step is to analyze operations to evaluate where components of the new system might be useful. This is then followed by selecting the correct machines needed for a smoother production process, like the rate of material movement, speed, and customization if needed. After acquiring the system, the next step is usually collaboration with the supplier to ensure the installation aligns with the rest of the machinery that has already been installed. Everyone on your team must be trained as well to now how to use the system properly and work with it safely. Once everything is set up, all the components will need to be tested, with all areas outlined being placed under the radar in order to make changes where necessary so that production runs as smoothly as possible.

How do you effectively train staff on new packaging technology?

To provide effective training on a new packing technology, one must take a systematic approach to ensure proficiency and confidence for the instructor and trainee. Start by creating a comprehensive program covering theoretical factors and the technology’s practical use. Train employees with the tools. Begin by showing them how to use the equipment, emphasizing safety, key operational steps, and troubleshooting. Learners should understand more complex materials easier from printed guides than from seeing the materials alone. Foster participation by putting them through trials as close to real life production as possible. Assessments and feedback loops are vital in ensuring the learners understand the concept, know what to work on next, and incrementally improve the operator’s skills over time.

What maintenance practices ensure optimal performance of packaging machines?

In packing machines, optimal efficiency can be obtained by upkeep. Analyze wear on critical parts like belts, gears, and seals. Regular maintenance checks are necessary. Moving components need careful lubrication to decrease friction, which will greatly increase the machine’s lifespan. The adverse buildup of contaminants that can harm the machine’s functionality makes cleaning the machine after every session vital. Regularly examine and replace degraded contraptions to avoid unanticipated failures during operation. Maintain safety and precision by routinely recalibrating sensors. Also, electrical connections must be examined on a set basis. Sticking to a scheduled maintenance plan ensures that machines perform well without hindrances.

What ROI Can You Expect from Investing in Modern Packaging Machines?

The ROI for modern packaging machines can be experienced as an investment breeze for businesses, as it enhances operational processes and lowers costs. Such advanced operations allow for increased production speed and consistency in product quality, resulting in higher outputs and reduced rejections. The degree of automation reduces reliance on manual processes, minimizing labor costs. Additionally, modern machines often require less energy and produce lower amounts of waste, corresponding to long term savings. The newer systems are more reliable, have an increased time interval between maintenance needs and service, contributing to reduced downtime for the business. In the long run, a company will reach a point where the manufacturing process becomes economically feasible. Investing in packaging machines is especially suited for businesses looking to scale their operations effectively.

How quickly can businesses recoup their investments in packaging automation?

The time businesses spend to recover their investments in automation machines differs depending on the production scale, operational costs, volume, and capabilities of the machine. However, on average, businesses incur a return in repeat packaging within a period of 1 to 3 years due to savings from labor, waste, and erecting expenses. Further, companies that belong to high-demand industries that require substantial manual labor have further reduced payback periods.

What long-term financial benefits do packaging machines offer?

In the long term, packaging machines have many financial benefits. They increase functional accuracy, lowering production by improving resources and reducing mistakes. They also reduce labor costs by removing mundane manual work, allowing businesses to use their workforce more sophisticatedly. Furthermore, modern packaging systems often utilize materials better, which reduces waste and saves money. Over time, these machines enhance profitability by improving scalability, allowing businesses to cater to increased demand without much additional expenditure.

How do packaging machines contribute to overall business growth?

In other aspects, packaging machines assist in overall business growth by increasing efficiency, cutting down on labor costs, and assuring product quality. These machines augment production speed by automating the whole packaging process and reducing human resources errors. Consequently, operational productivity is directly enhanced. Moreover, machines enable companies to expand while ensuring standardization of processes and compliance to market regulations, as well as quality assurance to guarantee consumer satisfaction. Using this method, all resources needed are optimally used, potentially increasing profitability and decreasing the time a product takes to sell.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are the main advantages of using modern pouch packaging machines?

A: Modern pouch packaging machines offer several benefits, including increased production speed, improved product protection, reduced labor costs, and enhanced packaging consistency. These machines can handle various pouch sizes and materials, making them versatile for different industries. Additionally, they often incorporate features like automatic filling and sealing, which contribute to overall efficiency and product quality.

Q: How do vertical form fill seal machines improve packaging efficiency?

A: Vertical form fill seal machines significantly boost packaging efficiency by combining multiple steps into one continuous process. They form the package from a flat roll of film, fill it with the product, and seal it in a single operation. This integrated approach reduces handling time, minimizes waste, and increases production speed. Many modern vertical form fill seal machines are also fully automatic, further enhancing productivity and reducing the need for manual intervention.

Q: What are the benefits of using automatic packaging machines over manual packaging methods?

A: Automatic packaging machines offer numerous advantages over manual packaging methods. They provide higher production speeds, consistent packaging quality, reduced labor costs, and improved sanitation. These machines can handle a variety of packaging materials and styles, from pouches to corrugated boxes. Additionally, automatic packaging machines minimize human error, leading to fewer defects and less product waste.

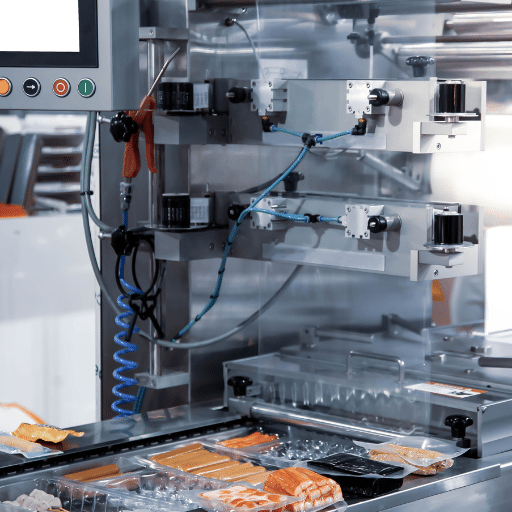

Q: How do tray packaging equipment and skin packaging systems enhance product presentation?

A: Tray packaging equipment and skin packaging systems greatly improve product presentation by creating attractive, secure packages that showcase the items effectively. Tray packaging equipment can arrange products neatly in pre-formed trays, while skin packaging systems use a thin film that contours tightly around the product, providing a clear view and protection. These methods not only enhance shelf appeal but also offer excellent product protection during shipping and handling.

Q: What are the advantages of using a conveyor system in conjunction with packaging machinery?

A: Integrating a conveyor system with packaging machinery creates a more efficient and streamlined production line. Conveyors facilitate smooth product movement between different packaging stages, reducing manual handling and increasing throughput. They can be customized to work with various packaging machines, from filling machines to sealers, creating a continuous workflow. This integration minimizes downtime, improves productivity, and enhances overall packaging line efficiency.

Q: How do modern filling machines contribute to increased production rates?

A: Modern filling machines significantly increase production rates through their high-speed operation and precision. Many can handle multiple products per minute with accurate dosing, reducing overfilling and product waste. Advanced filling machines often feature fully automatic operation, quick changeover capabilities, and can be integrated with other packaging equipment like form fill seal machines. This results in faster packaging cycles and higher overall production output.

Q: What role do vacuum packaging and air pillow systems play in industrial packaging?

A: Vacuum packaging and air pillow systems play crucial roles in industrial packaging by providing superior product protection and space-efficient solutions. Vacuum packaging removes air from the package, extending product shelf life and preventing contamination. Air pillow systems create on-demand cushioning material, reducing storage needs and providing flexible void-fill options. Both technologies contribute to reduced shipping costs, improved product safety during transit, and enhanced overall packaging efficiency in industrial settings.