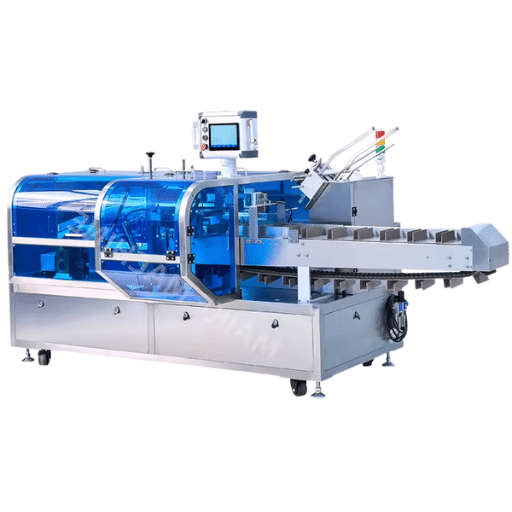

Packaging machines are paramount in contemporary industries, as they facilitate sealing, packing, and preparing products for distribution. These machines are created to cater to a diverse range of business sizes: small businesses requiring manual or semi-automatic systems and large businesses needing fully automated solutions. This article examines packaging machines, detailing their types, functions, and uses in different industries. Understanding the innovations and capabilities of these machines will allow readers to appreciate how productivity is maximized, products are safeguarded, and production processes are made cost-effective.

What are packaging machines and how do they work?

These machines serve a specific purpose, making them extremely important in business. Packaging machines are designed to protect a product for shipping, selling, and storing. They accomplish these tasks using various techniques such as feeding, filling, sealing, labeling, and wrapping, which are all integrated into the machines. The machines also utilize new technologies like sensors, conveyor systems, and programmable logic controllers (PLC) to improve accuracy and efficiency in the processes. In repetitive tasks like those in the food, medical, pharmaceutical, and manufacturing industry, these machines increase productivity while reducing the amount of labor required.

Types of packaging machines for different industries

Filling Machines

Filling machines are most commonly found in restaurants and pharmaceutical companies because they dispense precise quantities of liquids, powders, or granules into containers. Most of the filling machines available in the market today limit the quantity of product that can be wasted. Furthermore, advanced models that contain multi-head filling systems allow faster production rates, making them ideal for scaling up operations.

Sealing Machines

Sealing machines are essential in the food and medical device business industry because they guarantee that products are sealed tightly and are protected from external contaminants. Adherence to hygiene and safety standards is also achieved. In addition, these machines can also use adhesives and heat or mechanical pressure to seal bags, pouches, and even containers.

Labeling Machines

Labeling machines incorporate stickers, ranging from simple ones to compliance stickers, onto the company’s products with high accuracy. They utilize sensors and automatic alignment systems, which improve branding and traceability for the cosmetics, pharmaceuticals, and consumer goods industries.

Wrapping Machines

These machines put layers of materials such as plastic film or paper around the items to keep them secure while traveling and avoid breakage. Electronics, logistics, and retail industries utilize different types of wrapping machines, stretch wrapping, shrink wrapping, and flow wrapping.

Blister Packaging Machines

A wide range of industries including pharmaceuticals and consumer goods use blister packaging machines to cover the goods using pre-formed cavities of plastic or aluminum. This technique protects the goods against external factors, making them easier to view and resist tampering.

Cartoning Machines

Cartoning machines automatically fold and form cartons to package an item or a number of items in bulk. They are widely used in the food, beverage, and personal care industries as they make efficient secondary packaging easy and provide a neat display of products.

Machines for Vacuum Packaging

Vacuum packaging machines remove air from the package to maximally retain the freshness of a good. This form of packaging is critical in the food sector, especially for meat, cheese, and dried items, as it helps prevent decomposition while ensuring quality.

Palletizing Machines

This machines automate the loading of packaged products on a pallet for easy storage and movement. Manufacturers and general warehousing companies use palletizing machines to improve industrial operations’ safety standards and minimize physical work.

Each of these packaging machines is designed to address the specific needs of various types of businesses. With these technologies, companies can increase productivity, control the quality of production, and comply with tough legal standards.

The basic parts of a packaging machine

Conveyor

Conveyor belts are probably the most vital parts of packaging machinery because they help minimize downtime by providing an uninterrupted flow of packages at different stages in the system. They offer controlled item transport and positioning for rapid processing and minimal manual handling.

Sealers

Sealers complete seals on equipment. Thermo sealers, Ultrasonic sealers, and glue sealers are just some examples. Depending on the needs of the package and item, these methods create a seal that is not breathable or easily opened.

Cutting and Forming Tools

Computer blades or molds that cut work with packaging materials like cardboard, plastic, or film, so they both eliminate waste and keep parts perfectly formed to the desired shape.

Sensors and Detection Systems

Detection systems that are part of sensors check the verification, which is detecting the alignment of the dollies, the levels of fills, and the defect check. These elements improve both pack-en-roll accuracy and quality control because only good packaged products arrive at the last holding area.

Control Panels and Software

An enhanced modular panel integrated with the software enables the commander to set the machine’s mode of operation and supervise its activity. Normally, these interfaces are designed for setting up speed, temperature, and all other cubics that negatively influence effectiveness in relation to the production goal.

Dispensers

These components are crucial for consistency in measuring product weight, volume, or fill level, as they ensure that the product or materials added to the packaging are proportionately delivered.

The Packaging Sequence Starting From Filling and Ending With Sealing

The beginning of the sequence is marked with filling, wherein the product is poured into the container designated for packaging. This step guarantees regulatory compliance and consumer satisfaction by maintaining precision in the dispensed amount. Afterwards, container filling is followed by the filling step, where set machines apply a seal on the container using heating, crimping, or even ultrasound sealing. The seals applied are guaranteed to be airtight which helps prevent contamination. This does more than just securing the product’s quality; it also readies the package for labeling as well as distribution.

How can automated packaging machines improve efficiency?

Automated packaging machines augment productivity by eliminating human engagement in dull and monotonous work. They also enhance accuracy by lowering the chances of erroneous activity. Compared to manual processes, these machines provide a remarkable boost in production as they can perform tasks faster. They fulfill their purpose of filling, labeling, and sealing without compromising on quality, which minimizes waste and the need for redo work. Also, with sensors and real-time tracking, operations can be refined and problems swiftly addressed, considerably decreasing the chances of idle time. Additionally, automated systems aid in cutting down labor expenses and enhancing workplace safety by reducing reliance on manual processes, making them essential for economically demanding production regions.

Raising output with automatic packaging systems

The output for packaging systems raise due to the multitasking and speed proficiently packaged and implemented through advanced technological robotics. Losses in production line coordination and bottlenecking due to a lack of advanced Intelligent system software are reduced significantly. In addition, other features like lower modular designs and automatic maintenance prediction changeovers further allow the manufacturer to rapidly address different packaging needs, minimizing idle time and maximizing productivity. Furthermore, they ensure better allocation of resources, minimizing integration issues within the supply chain as large volumes of superior operational economies can be attained, further meeting rising market needs.

Ensuring accurate packaging and error reduction

Advanced automated packaging systems enable timely precision and quality control, resulting in perfect packaging while drastically decreasing errors. Automated corrective actions resolve real-time discrepancies with sensors, vision systems, and PLCs, preserving uniformity throughout the packaged items. With fewer manual interventions, human mistakes are mitigated, more accurate measurements are obtained, and tighter tolerances are accomplished. More importantly, the implementation of such systems allows for the capture of large amounts of data which can be analyzed to identify systemic problems, further increasing compliance with industry standards.

Incorporating packaging automation to pre-existing production lines

The packaging automation technology integration needs to be step by step so that the effectiveness of the production line is enhanced and disturbances are avoided. The first step involves checking how the current machines will work by seeing how automation can be used best. It may be necessary to upgrade or modify the equipment to meet the new automated systems. An implementation approach rolled out in stages is usually advisable since this slowly lessens disruptions. More sophisticated installation designs, like modular and IoT solutions, provide continuity between the new automated components and existing systems. Furthermore, proper training is necessary to enable proper operational control and maintenance of the computerized systems, contributing to long-term productivity and flexibility.

What are the benefits of flexible packaging machines?

Machines used for flexible packaging can manage almost any product type, shape, or size, which is their main benefit. These machines are designed to be efficient, enabling faster changeovers between packaging formats. This reduces lost time when operations and increases productivity. The customizable features offered by the machines make it possible to design packages that maximize material usage and minimize waste, reducing production costs. These machines support the advancements in sustainability, as they are compatible with eco-friendly materials and processes. Because of the modern materials and high power these machines use, the overall quality and consistency of packaged products increases, which results in higher consumer satisfaction and more competitiveness in the market.

Embracing Different Shapes and Sizes of Products

With flexible packaging machines, novel mechanisms enable accommodating different shapes and sizes of products with minimal adjustments. They incorporate adjustable forming components, modular toolings, and servo motors to switch effortlessly between varying packaging styles. For example, the capability for automatic film tension control, together with accurate precision cutting, improves geometry or volume handling consistency. Technical parameters such as film width ranges, adjustable sealing temperatures (most materials fall within 100°C to 250°C), and multi-axis servo control are critical to precision and dependability. This improves the speed of adaptable production processes and makes it possible to attain high-quality results for complex or non-standard product configurations.

Handling different packaging materials

Flexible packaging machinery can be categorized in terms of the range of materials that they can handle which include plastics like polyethylene and polypropylene, laminates, papers and even aluminum foils. These machines accept flexible parameters such as temperature and pressure during sealing to improve efficiency for each material used. For instance, polyethylene films have a sealing temperature range of 120°C to 160°C while laminated films can go as high as 250°C depending on the material structure. The adjustment of tension during the film feeding process ensures that the film is fed smoothly to avoid tearing or misalignment of the film. Furthermore, the advanced systems for cutting and sealing the films are set to the appropriate thermal range so that the strength and thickness of the material is taken into consideration to make sure that the durability and structural integrity of the package is upheld. This capability guarantees effective handling of different materials while achieving the goals of marking and packaging.

Agile conversions for unique production runs

Achieving changeovers requires modular designs and tool free adjustment systems. These features enable the operator to change product configurations within the shortest time possible. Pre-set recipes, sensor-based setups, and user-friendly interfaces during transition promote precision and repeatability among various product runs. Furthermore, automated calibration systems and acceptance of multiple packaging types enhance flexibility, improve operational effectiveness, and minimize production stalls.

How to choose the right packaging machine for your business?

Choosing a packaging solution involves evaluating production volume, product types, and tight custom specifications. Think about the formats and materials the machine is required to work with. At the core of the process, speed, operational efficiency, precision, maintenance, and other performance indicators are integral to the most crucial decision. A holistic approach considers the ability to adapt to future production changes with a shift in packaging type, variation, or even volume, while still aiming for cost-effectiveness and good ROI.

Understanding the requirements for packaging production and volume

In this case, it helps to break down your current and future output goals. Pay attention to the product being packaged and its requirements; size, material, weight, or sensitivity all play a part. For example, fragile items require the use of some protective materials, like vacuum seal packaging, while liquid items require sufficient leak-proof sealing. Understanding these specifications set by the product will ensure the chosen workhorse machine can deliver with the parameters set.

To assess your line’s efficiency and speed, set parameters like desired units per minute (UPM), acceptability of differing package dimensions, and error thresholds. Machines produced for high-capacity output come equipped with advanced controls and automated systems, while low to medium-output setups will benefit from semi-automated models. Also, ensure the machine is integrated into the filling up, labeling, and sealing processes to minimize operational bottlenecks.

Finally, account for the ability to scale the machine for overgrowth. Machines with modular structures or components allow flexibility, making them a sound investment for ever-changing production demands.

Analyzing the advantages and disadvantages of semi-automatic and fully automated machines

Semi-automatic equipment is best for consideration where manipulative involvement is needed, as the operator can change processes or product specifications, requiring specialized skills. Within small—to medium-scale production parameters, these machines are ideal, especially because of lower upfront costs and less complex installation and maintenance procedures. However, productivity takes a hit due to human dependency, limiting throughput, and increasing variability.

On the contrary, fully automated solutions focus more on speed, accuracy, and consistency. Such machinery has integrated parts such as servo motors, sensors, and PLCs that enable precise high-speed operations. While the first capital outlay is more expensive, automatic systems outperform in SCALE economics because they drastically lower labor requirements, reduce mistakes, and provide unvarying quality products at all times. When assessing these systems, it is important to pay attention to technical cycle times, operational throughput (e.g., units per minute), error tolerance ranges, and Industry 4.0 integration modules, including IoT and proactive maintenance features.

When comparing the two, it is important to evaluate production size, spending limitations, expansion potential, and the level of detail involved in the process so that the operational strategies and system needs match.

Evaluating machine features and specifications

When correlating machine features and specifications, there are distinct things that drive optimal performance and ensure they operationalize as intended. Firstly, the machine’s processing capacity and efficiency have to be considered. Attention must be paid to cycle time, throughput, and even error rate since they directly influence productivity. Secondly, evaluate the infrastructure compatibility with current and future IoT and automation platforms. Thirdly, functionality and customizability are essential. Machines that have modular designs or programmable options are key for different production flexibilities. Last but not least, safety features, energy consumption, and maintenance should not be neglected since these affect the bottom-line sustainability and viability of cost efficiency. Careful analysis of such multi-dimensional concerns leads to effective decision tools that improve operational outcomes.

What are the latest advancements in packaging machinery?

The latest development in packaging machinery has focused on operational efficiency while keeping elements of sustainability and automation in mind. Integrating smart IoT-enabled sensors and advanced robotics in modern machines helps with real-time monitoring and adaptive control of the systems to improve productivity and accuracy. Sustainability is also a prominent trend, with innovations emphasizing eco-friendly materials, energy-efficient designs, and minimal waste production. Furthermore, new developments in digital printing allow for the rapid production of bespoke packaging to satisfy different market segments without increasing lead times. Together, these advancements serve the overarching purpose of efficiency, sustainability, and industry satisfaction.

Smart Packaging Solutions with Monitoring Systems

Smart packaging solutions incorporate advanced sensors, connectivity, and data science technologies to provide real-time tracking of the condition and placement of processed products while they are in transportation. These systems can assess temperature, humidity, and shock along the supply chain to maintain quality control for sensitive goods. Collecting and transmitting data in real-time enables businesses to respond proactively to potential problems, eliminating waste and adding transparency to the supply chain. In addition, these technologies are often integrated with cloud computing which centralizes decision making and improves logistical and operational efficiency.

Robotics and AI in the Work of Packaging

In the particular case of packaging, Robotics and AI are changing the work by increasing the workload precision, repetitive tasks completion, and lowering the required expenditures. Sophisticated robotic systems perform quickly, then pick up, pack, and palletize the goods with consistent accuracy. As AI systems, these also can drive predictive maintenance, workflow automation, enhanced decision-making through data analysis, and more. Increased productivity, reduced errors, and the ability to modify production levels make operating easier. Also, robotics and AI combine to foster greater flexibility in fully automated packaging by removing the constraints of the technologies used today and making adjustments to incorporate advancements in the future.

Technologies of Clean Packaging

Technologies of clean packaging aim to mitigate a negative effect on the environment by theuse of renewable, recyclable, or biodegradable materials. Novel solutions such as plant-based packaging, compostable films, and reusable containers gain considerable importance and help curtailing waste and dependence on non-renewable sources. Moreover, the innovation of lightweight packaging can greatly aid in the reduction of material and emissions from vehicles. Water-soluble polymers for instance, and edible packaging innovations, further bolster Government efforts in this regard. These developments put the principles of clean economy in high regard by increasing resource efficiency and reducing waste within the scope of packaging.

How to maintain and troubleshoot packaging machines?

Begin with the Basics on Maintenance of Machines: Cleaning packaging machines’ components and removing dust and debris, preventing scrapes through efficient lubrication of all machine joints, and mechanical stress inspection identifies the loosening of bolts and detecting abnormal vibrations. Additional indicators include the state of the belts, seals, and electrical joints. Preventive calibration guarantees accuracy and stability across the packaging range.

In case of malfunctions, examine the alignment of the machine, errors detected via sensors, and even the power supply connections. Use the machine’s user manual to recognize the issue based on the displayed error concerns and frame a working solution in case of familiar concerns. Addressing breakdowns requires streamlining operations and comprehensive examinations of the suspected area. Advanced cases warrant consultation to the manufacturer or an expert technician. Adopting a proactive approach against the breakdown of machines ensures reduced spending regarding repairs or chances of equipment shutdown by following scheduled inspection parameters.

Regular maintenance schedules for optimal performance

Maintenance planning should include well-timed checks, cleaning, and component testing to maintain consistent performance. Conduct daily inspections to spot surfaces like loose connections. Staff members on the weekly schedule should lube moving parts, make electrical connections, and look for any signs of belt-wearing. Monthly reviews should check stress calibration accuracy, mechanical accumulation, and sharp edges over time. Following this scheduled process ensures machine reliability, lowers downtime, and generates longer life span.

Common packaging machine errors and their solutions

Assorted forms of errors can affect the efficiency and production of packaged equipment. A common one is mismanaged sealing, usually caused by choosing the wrong temperatures or damaged sealing parts. To fix this, ensure that the sealing mechanism is calibrated correctly and that defective components in other systems are removed. Some errors involve pieces of the package being mixed while being fed which is primarily due to overloading or faulty feeders. Inspect and adjust the skew Trim regular rods to eliminate change. Also, the presence of other systems owing to missing or neglected paint glitches make incorrect labels or packing. Clean and set missing shapes often to enhance and aim at system precision and setting failure.

When to Look for Professional Servicing

Professional servicing should not be neglected after routine maintenance. Servicing should be sought whenever issues persist or when significant noises, abnormal wear and tear, and overly poor system performance are present. Furthermore, safety-critical matters such as electrical issues, fluid leaks, or mechanical malfunctioning require immediate action. To comply with the manufacturer’s recommendations and enhance the life span of the equipment, periodic preventative servicing should also be considered.

Reference sources

Frequently Asked Questions (FAQs)

Q: What is a packing machine and how does it automate your packaging process?

A: A packing machine is an automated piece of packaging equipment designed to efficiently seal and pack products. It automates your packaging process by handling tasks such as weighing, filling, sealing, and labeling, significantly reducing manual labor and increasing production speed. These machines can handle various materials like powders, liquids, and solid items, making them versatile for different industries.

Q: What are the benefits of using a vacuum sealer in packaging?

A: Vacuum sealers offer several advantages in packaging. They remove air from the package, which helps preserve product freshness, extend shelf life, and prevent contamination. Vacuum sealing also reduces package size, making storage and transportation more efficient. This method is particularly useful for food products, electronics, and other items sensitive to air and moisture.

Q: How does a shrink wrap machine work, and what types of products can it package?

A: A shrink wrap machine uses heat to shrink a plastic film tightly around a product or group of products. The process involves wrapping the item in the film and then applying heat, causing the film to contract and conform to the product’s shape. Shrink wrapping is versatile and can be used for a wide range of products, from food items and consumer goods to industrial parts and promotional materials.

Q: What is a stick pack machine, and how does it differ from other packaging machines?

A: A stick pack machine is a specialized packaging equipment designed to create small, elongated sachets often used for single-serve portions of powders or liquids. Unlike larger packaging machines, stick pack machines are optimized for producing these narrow, convenient packages. They are particularly popular in the food and beverage industry for items like instant coffee, sugar, and powdered drink mixes.

Q: How can I choose the right packaging machine for my product?

A: Selecting the right packaging machine depends on several factors, including your product type (liquid, powder, solid), production volume, desired package type, and budget. Consider the machine’s versatility, speed, and compatibility with your existing packaging line. It’s also important to evaluate the supplier’s reputation, after-sales support, and the machine’s ability to meet industry standards. Consulting with packaging equipment experts can help you make an informed decision.

Q: What are some advanced and efficient features to look for in modern packaging machines?

A: Modern packaging machines often include advanced features such as touchscreen interfaces, precision weighing systems, automatic error detection, and remote monitoring capabilities. Look for machines with adjustable settings to accommodate different product sizes and packaging materials. Some cutting-edge machines offer multi-lane operations for increased output, ultra-fast sealing technologies, and integration with warehouse management systems for seamless inventory control.

Q: How can packaging machines improve efficiency in fulfillment centers and warehouses?

A: Packaging machines can significantly enhance efficiency in fulfillment centers and warehouses by automating time-consuming manual processes. They can rapidly pack products, reducing labor costs and increasing throughput. Many machines can be integrated with conveyor systems and warehouse management software, streamlining the entire fulfillment process. Advanced systems can even combine multiple functions like weighing, labeling, and sealing, minimizing the need for separate workstations and reducing warehouse space requirements.

Q: What types of materials are compatible with modern packaging machines?

A: Modern packaging machines are designed to work with a wide range of materials. Common compatible materials include polyethylene (PE), polypropylene, paper, aluminum foil, and biodegradable films. Many machines can handle various bag types, including gusseted bags, stand-up pouches, and flat bags. Some advanced machines are even capable of working with eco-friendly, recyclable materials, aligning with growing sustainability trends in the packaging industry.