The art of textile weaving continues to change, while monogramming stands out as a classic and a contemporary art form. Attempting to deconstruct the complex scenario of monogramming embroidery machines, this manual will guide the selected novice and professional embroiderers toward acquiring the machines that best suit their operations. While considering the latest machines in the market, we will review their intricacy of stitching, workability, and adaptability, among many other factors. Every segment will go into great detail about the various specifications, comparing the top brand names and what they offer so that the reader can make the right purchase. Welcome to a world rich in ideas as we examine the multi-dimensional possibilities and advancements in monogramming embroidery machine technologies.

What is an Embroidery Machine and How Does It Work?

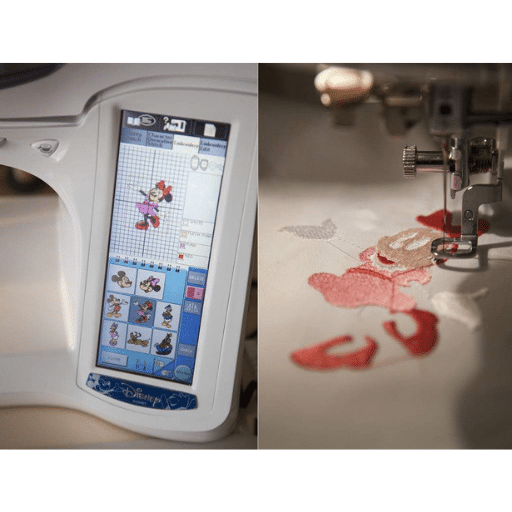

An embellishing machine can be explained as an embroidering machine that works specifically on automating the embroidering processes intending to create intricate and elaborate designs on cloth. These machines use needles and threads with a woven design. The machine has a monitor or a screen that enables users to upload embroidery designs or choose from the templates. When the user decides on the template, he or she has to coordinate the placement of the needle and the cowl, wherein the design will be reshaped according to what the user gave as a command. Neologism embroidery machines have multiple needles, allowing them to simultaneously speed up the process of more than one thread color. This saves time that is used to change threads for complex designs. Stitch length and stitch tension settings are also helpful for the user.

Understanding the Basics of an Embroidery Machine

An embroidery machine is an automated sewing device that decorates clothes with an embroidery pattern. It has an embroidery hoop that keeps the fabric fixed and below the needle. The user then chooses a ready pattern or loads a new one using a machine’s computerized interface with relevant embroidery software. The digitized design is uploaded to the computer to inform the machine when it is supposed to work. The minute servo motors built into the machine push and pull the needle to and fro while feeding fabric stitched by the sewing machine. Other essential factors include thread tension, stitch speed, and material type, which are necessary for completing the proper shape and quality of the embroidery. With multi-needle machines, threading various colors of threads becomes easy as there is no need to thread each needle separately, saving time. Knowing these basic principles, users can improve their machines’ performance for various tasks, from basic monograms to detailed embroidery patterns. So, effective cleaning and periodic needle changes are crucial to ensure the embroidery machine’s proper operation and long life.

How to Operate a Sewing and Embroidery Machine

There is no doubt that for beginners, operating a sewing and embroidery machine is not an easy task, but I can manage it effectively if I follow the steps systematically. First, I must check for the installation of all machine parts and ensure it’s an embroidery machine, such as the embroidery hoop, needle, and threads. A user guide is always handy, so I first try to follow it and thread the sewing machine while ensuring the correct placement of the reserved bobbin. After that, the machine must be turned on and the right menu must be located to select or insert the prepared pattern to be sewn using the incorporated software.

Afterward, I hoop the fabric and make sure it is timorous throughout the process. Stitch length, stitching speed, and tension must be adjusted as per my specifications to get the desired results; I change these parameters concerning the fabric and depth of the design. Any breaking of Threads or any damage that may occur to the needle is prevented by monitoring the machine while it is operating. To get the best from my sewing machine, I make it a point to carry out routine maintenance like cleaning, i.e., removing lint and replacing old needles with new ones. It is understood that I became ready to produce custom sewing patterns with confidence by implementing these measures and seeking trustworthy online guides with articles on sewing tips and guides.

Choosing the Right Monogramming Fonts and Designs

Font selection and monogramming designs are important aspects of embroidery because they require aesthetic and technical sense. The font style selected can change the final product’s appearance and readability. A serif font is applicable for a classical appearance, whereas a sans serif font is used in modern times for its contemporary appearance. Script and calligraphy fonts are good for embellishment, but they may require more precision because they are intricate in design so that technical alterations will be necessary.

While selecting the designs, be mindful of the pattern intricacy and scale, as complicated designs need advanced machines to achieve precise stitching quality. The parameters would include the following.

- Stitch Density: Fabric types vary in what stitch to use, such as thick ones for wider stitches, so bolstering this option aids in eliminating inadequate stitch fabric.

- Needle Type and Size: It is also vital to target the fabric and threads’ strength by choosing the appropriate size needle, such as small ones suitable for fragile fabrics.

- Thread Composition: For threads, you can choose polyester and rayon and dye them for aesthetic bumps and stronger features.

- Hooping Stability: Avoid embroidery stress on the fabric, including tautness and hole embroidery; otherwise, it distorts the design, which is important to the stitching without ruining the end product.

In the end, the selected fonts and designs should reflect the user’s creative intent and be feasible in terms of what the machine can do to ensure the end item is fine in terms of beauty and functionality.

Which Sewing and Embroidery Machine is Best for Beginners?

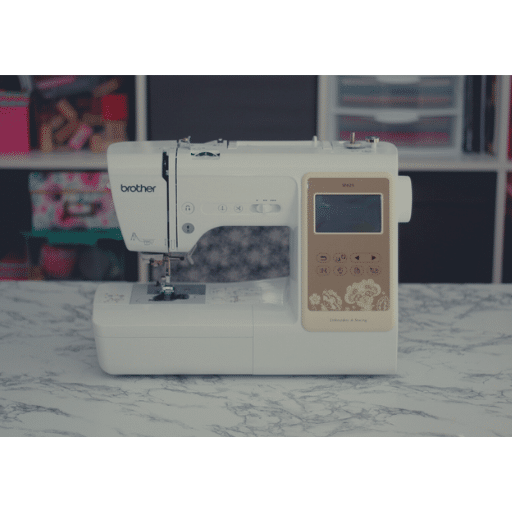

The Brother SE600 is a well-defined model that offers great parts and features, such as versatility and ease of use, while still being a sewing and embroidery sewing machine, which is perfect for someone just starting. The sewing machine is also ideal for beginners as it has features that are easy to use. The automatic needle threading adds to a great user experience and offers better control while learning new things. The Brother SE600 includes many options, including 103 sewing stitches and 80 built-in designs, ideal for simple projects. The model has a reasonable rate and is ideal for a beginner as it offers a solid grasp of the principles, which does not get complicated. The tutorials are built-in, which supplement the model’s guidance. Projects can be customized and selected using an LCD touchscreen, a cool addition. Overall, the Brother SE600 is a strong model for all starters, offering a great combination of sewing and embroidery features.

Top Features of a Computerized Sewing Machine

This article discusses the different factors that should guide the selection of a computerized sewing machine. The automatic needle threader is one of the common features that reduces user threading effort. Automatic control of stitch tension is another feature that, if properly engaged with the prior feature, also contributes to the machine’s performance. This targets professional seamstresses who wish to switch between projects rather than adjusting tensions to suit the fabric being worked. As for the other aspects of the machine, besides being a decorative feature, the LCD screen optimizes user interaction by making it easier to choose patterns, set the stitches together, and, at times, contain local instructions on how to sew. Ease of use is often accompanied by plenty of built stitch patterns, such as sewing decorative stitches, quilting patterns, or even embroidery stitches, which raises the creative potential of machine sewers. The sewing machines also have adjustable speed control, enabling users to work at their chosen pace. Such a range of features makes a computerized sewing machine an appropriate option as these combine technological advancement and practicality.

Why the Brother SE600 is a Popular Choice

From my experience with different embroidery and sewing machines, it seems that many users favor the SE600 model by Brother as it has a variety of functions and is very easy to use. Its ease of use is repeatedly emphasized in the top-rated reviews. It makes it easy to search through its numerous designs and built-in stitches, especially when dealing with greenhorns. The 4 x 4-inch embroidery area is perfectly sized and designed to be large enough for small projects but not so much to discourage new users. Likewise, with the incorporation of an automatic needle threader and adjustable speed control, the struggle with improper eye positioning and unsatisfactory stitching because of speed tensions is overcome. Judging by people’s opinions and my observations, the Brother SE600 seems to be the most balanced and handy while having a strong feature set that satisfies the creative needs of a wide range of users.

Comparing the Brother SE1900 Sewing and Embroidery Machine

The Brother SE1900 is a significant improvement over the SE600 because it possesses additional functions that would suit both beginners and seasoned sewists alike. This model has a bigger embroidery field of 5” x 7”, which makes it possible to design more detailed and larger designs. It also comes with 138 built-in embroidery designs and 11 embroidery fonts, which offer a wider scope of creativity, making it easy to create custom projects.

Key Technical Parameters:

- Stitch Capability: Severing this advantage are 240 built-in stitches, which are featured in SE1900, making it a perfect choice for most customers who need basic and decorative stitches because the options are numerous

- Color LCD Touchscreen: The modern 3.2-inch LCD touchscreen improves design development by allowing in situ editing functions such as rotating and combining different designs.

- Embroidery Speed: It can perform embroidery at a speed of up to 650 stitches per minute, which allows it to perform several tasks without compromising on quality.

- Automatic Features: It automatically threads the needle and adjusts the tension, reducing the need for alien interference and ensuring uniform stitch quality.

- Memory Functionality: Thanks to the built-in memory capability, pre-installed templates can be extended with custom designs that can be imported through USB.

The Brother SE1900 is a complete sewing machine that implements complicated systems into simple designs. It enables one to be more creative and productive, which is perfect for users who are now ready to handle more intricate tasks and want to realize more of the various possibilities of sewing and embroidery.

How Do Computerized Sewing and Embroidery Machines Enhance Creativity?

Computerized sewing and embroidery hardware systems shift the needle further by offering a range of design options and tools that can easily carry out complex projects. With various preset patterns and stitches made available, these machines can also give their operators perspectives on other types of sewing than what they are used to. In combination with other features, such as the ability to modify design features through a touchscreen or an on-the-go upload of design files, the extent of creativity gets enhanced significantly. The sewing operations, such as inserting the needle and adjusting the position of the yarn, are automated, which means that the users can dip into the artwork part of their work. With the help of computerized mechanisms, creative and custom designs become simple; on the other hand, the sewing and embroidery experiences get richer and awe-inspiring.

Exploring Built-In Embroidery Designs and Patterns

The features of computerized sewing and embroidery machines, specifically incorporated embroidery designs and patterns, open various creative avenues. When I look at what these machines can do, I first notice that most of their models come with a particular set of designs, including floral decorations, geometrical figures, and various seasonal designs. This makes it very easy to facilitate inspiration to raise and even more so to initiate a project as one does not have to worry about CPU hacking the first step. There are several limitations regarding how these designs can be used or even saved owing to the machine’s configuration, one of them being design memory size and the edit features of the design. I also have come across Brother SE600 and Brother SE1900 models, which seem to be equipped with advanced features such as a touchscreen, allowing one to pick a particular design or even edit it by scaling it, rotating it, or combining it, without going through many menus. Also, since USB ports are available, it is easy to increase one’s collection by adding sources that inspire more creativity. So we can say that built-in embellishment features add value to the artistic aspects by providing a rather basic path into the broader world of machine embroidery while ensuring that efficiency and simplicity are not compromised thanks to improved aspects of technology.

The Role of USB Port in Customizing Designs

While researching the best-selling sewing resources available on the internet, I also realized that almost any electronic sewing and embroidery machine that can be connected to computers gets the job done well in terms of executing design modifications. USB ports integrated into most sewing machines allow users to save their favorite designs stored in computers or other flash storage devices, making operating more feasible than relying on the inbuilt selections alone. This phenomenon is well documented in sites like Brother and Sewing Machine Fun as they also note the ease and effectiveness this feature offers, implying that the degree of digital patterns available for the sewists to choose from edges is unlimited. Including such peripherals enhances the machine’s functionality and enables it to execute targets that transcend the capabilities of the device’s inbuilt design features. This effect supports the requirements of seasoned users who wish to implement intricate designs and stimulates unskilled users to try this all-encompassing world of digital embroidery.

Using Touch Screen Features for Easy Navigation

The modern sewing and embroidery machine that includes a touchscreen seems to be a great way to enhance the user’s experience by improving the interaction with several advanced functions. Such screens perform as intuitive interfaces, allowing users to easily select, change, or customize any project. As the best experts in the field reported, touch technology extends functionality by allowing direct management of designs, such as scrolling through menus, positioning a design, or even rotating a design and viewing it beforehand quite easily. The firsthand experience by most review writers on popular sites attests that learning how to use a machine with touchscreen devices is easier thanks to the graphics, which give the novice plenty of control and the advanced user more. Direct working with digital units like stitches or embroidery designs is made possible through this feature, which greatly helps bring the creative idea into reality quickly, thus adding accuracy and creativity to many projects.

What Are the Key Features of the Janome Memory Craft 400e Embroidery Machine?

Janome Memory Craft 400E is a unique machine in its design with advanced embroidery functionality built-in. This machine features a large 7.9” x 7.9” embroidery field off the left, which allows the creation of larger and more intricate designs suitable for those aiming for broad creative tasks. Users can also delight in the fact that it has 160 built-in embroidery techniques and allows six font types for monogramming to allow personal touch designs. An added LCD Full-color touchscreen panel allows the user to navigate through the designs easily and easily use the machine. USB import functionality is another advantage since you can merge designs to the machine directly from the USB. Furthermore, the machine’s automatic thread cutter and sewing bobbin boost its general operations, improving its overall workflow. In summary, Janome Memory Craft 400E is a good option for people who want to enhance their embroidery projects as it is designed and built with precision and features.

Overview of the Memory Craft 400e Embroidery Machine

The Janome Memory Craft 400e Embroidery Machine perfectly suits the needs of any embroidery specialist on a grand scale because it is an exclusively embroidery machine. It has an innovative embroidery field of 7.9” x 7.9”, which makes it possible to cover vast areas for bigger and more detailed designs. It is so good that this model can have 160 built-in designs and even six monogramming fonts, so there is no need to buy additional software for creativity. The Color Memory Craft has an LCD touchscreen interface that allows easy on-screen operation and mode editing, similar to turning, flipping, and resizing physical designs and other components for a given project directly on the machine.

Key Technical Parameters:

- Embroidery Speed: This is a high-busy embroidery that, thanks to the overseeing of the stitching parameter, reaches 860 stitches per minute, meaning the machine can perform such designs and more without jamming.

- Automatic Thread Cutter: This tool minimizes manual work by smoothly cutting off the threads after each color range while maintaining a neat stitch.

- USB Design Transfer: The machine can receive new designs through the USB port, which widens the user’s creative avenues.

- Multiple Hoop Sizes: Enabling different hoop sizes increases the scope of the project and the variety of designs.

The Janome Memory Craft 400e can be described as one of the best viable options for embroiderers enthusiastic to take their skills a few notches higher but solely enough for embroidery. It has advanced technology with ease of navigation, thereby appealing to people who intend to work on intricate and personalized embroidery designs.

Maximizing the Embroidery Area for Large Projects

One of the most important requirements in the quest to solve larger problems is to increase the size of the embroidery area, and the Janome Memory Craft 400e has excellent scope for larger designs. With an embroidery field measuring 7.9” by 7.9”, this model can easily accommodate large projects without frequent fabric moves as such tolerances can be provided for. There are quite a few built-in features of this machine that would enhance its productivity, such as 160 built-in embroidery designs, six monogramming fonts, and many features that allow the machine to create exquisite stitches and logos.

Key Technical Parameters:

- Embroidery Area: The 7.9” x 7.9” covers intricate and advanced patterns to be stitched on a single hooped area/stable.

- Embroidery Speed: Churning out a decent 860 stitches in a minute helps increase productivity without affecting the quality of the stitches.

- On-Screen Editing: The color LCD touchscreen makes it easier for users to cut, resize, rotate, and flip patterns on the machine itself.

- USB Port: Due to the connectivity now available to users, several stitch patterns can be uploaded from their PCs.

- Automatic Thread Cutter: It makes it easier to operate the machine by cutting the threads with the push of a button, thus increasing efficiency in operations and reducing workload.

These features highlight the Janome Memory Craft 400e’s additional capability in accepting wider projects that require greater technical versatility and more elements of creativity, giving professional and amateur embroiderers ample freedom to explore their craft.

Understanding Hoop Sizes and Their Applications

The scope and complexity of the designs one handles are largely dependent on the embroidery hoop sizes one possesses. Every size of hoop has its requirements, which are specially designed for. For demanding designs requiring precise control, smaller hoops, like 4” x 4”, are the ideal choice as they perfectly hold logos, monograms, and other designs. For mid-sized graphics that cannot be over-extended and require much repositioning, use medium-sized props, such as 5” x 7”. For large-size graphics, multi-colored designs, and even larger garments, get your hands on large props such as 8” x 12” or even larger. Choosing the right size of the nibs is crucial since it determines the disruptiveness of the fabric while detailing and the efficiency of the overall embroidery process. Also, the further the knowledge and the practice of the designer, the better the result, mastering each embroidery technique.

How to Maintain and Troubleshoot Your Embroidery Sewing Machine?

The embroidery sewing machine’s routine inspection, repair, and maintenance are crucial to extending its life and optimizing its consistent performance. To start with regular maintenance, one should often clean the machine’s inner parts, such as the bobbin case and the feed dogs, as there could be an accumulation of threads, dust, and dirt around them. A small brush or a vacuum cleaner attachment is advisable for cleaning. Additionally, occasionally oiling the parts that move with a sewing machine oil according to the guidelines provided by the manufacturer will prevent certain damages. An initial diagnosis will require you to examine the thread tension, use appropriate needles to minimize skipped stitches and ensure the fabric is compatible with the sewing machine. Some tension difficulties, for example, a high degree of tension that causes the grabbed thread to create skipped stitches near the needle, can be resolved by referring to the sewing machine manual. In addition, if any of the electronic parts, like the touch screen or USB port, do not function properly, it is always better to seek guidance from technical support or an experienced service to avoid worsening the outlook of the problem. Finally, regular maintenance and timely rectification of the embroidery sewing machine will increase its longevity and allow you to manage your artistic works with minimal interruption.

Regular Maintenance Tips for Embroidery Machines

In my opinion, and from my considerable experience, embroidery machines require delicate handling and care. For starters, the area where the bobbin is located should be cleaned regularly to avert lint accumulations that may negatively impact the overall quality of stitching. Regular cleansing also prevents the dullness of needles and their bending because they are guaranteed to snag fabric pieces. The sections of the machine where oil is to be oiled should always be lubricated to ensure that the machinery works flawlessly; however, avoid using excessive amounts of oil as it will only make the machine dusty. Furthermore, I always ensure that only certified fabric and superior threads are used because they considerably limit the wear and stress that can cause minor machine failures. More so, I can confirm that stretching a single service in a year does assist in avoiding some technical breakdowns. By following all the outlined maintenance measures, I ensure that my embroidery machine’s performance is always top-notch, regardless of the task.

Common Issues and Solutions for Monogramming Machines

Monogramming machines are complicated working tools, although they still have drawbacks, such as commonly encountered mechanical faults. Tension, the type of provider’s source, or supplying the thread to the machine can cause frequent problems such as a breakage of the threads. To do this properly, ensure that the machine threading is perfect, adequate adjustment on tension configurations is made, and embroidery heavyweight threads are utilized. Sometimes, thread breakage can be avoided if the fabric is incorporated with adequate stabilizing materials and the techniques for hooping are done correctly so that the fabric does not tend to bunch up.

Needles should also be incorporated while paying attention to the structure of the fabric so that stitches don’t get skipped while sewing. Monogramming regularly requires changing needles to enable the user to work with different fabric types. Users also tend to have pattern misalignments caused by wrong positioning during fastening or if the positioning system was calibrated inappropriately—regular calibration checks and proper fastening techniques reduce an alignment error during monogramming.

To solve problems involving software and connectivity issues, such as transferring designs from USB to the machine, Users should ensure that the drive is formatted correctly and that the Monogramming machine has been updated. If users can observe these tips regarding maintenance and technical issues, they can make the marooning activities less disruptive as possible.

Ensuring Needle and Thread Compatibility

Practically, it is guided by popular sources such as Sewing Machine Buffs, Sew Parts Online, and Sew Spruce Crafts. Achieving success in sewing lies in being able to select the proper needle for the proper thread and project. So, to start a sewing project, different needle types are required, depending on the fabric and the work. For example, woven fabrics require acute or Microtex needles, whereas knit fabrics use ballpoint needles. The needle size and thickness are more related; in this case, the heavier the thread, the larger the needle should be. Also, there is a need to check sewing machine instructions for additional information about needle types that are recommended for each sewing activity. Changing the needles regularly after a limited time, such as after 8 to 10 hours of sewing or during a change to other types of fabrics, ensures that there will be no problems like the fabric being snagged or stitches being skipped. However, although compatibility matters for improving stitch quality, it extends not only the needle but also the thread’s lifespan, thus enhancing the overall experience of sewing machines.

References

Frequently Asked Questions (FAQ)

Q: What are the best embroidery machines for monogramming?

A: Some of the best embroidery machines for monogramming include the Brother SE600 Sewing and Embroidery Machine, Brother PE535, and the Singer Quantum Stylist 9960 Computerized Sewing Machine. These machines offer built-in stitches, computerized embroidery options, and ease of use for creating beautiful monograms.

Q: How does the Brother SE600 Sewing and Embroidery Machine perform?

A: The Brother SE600 is a versatile sewing and embroidery machine with 80 built-in embroidery designs and 103 sewing stitches. It features an LCD touchscreen for easy design selection and editing and an automatic needle threader for convenience. Due to its user-friendly interface and quality stitching, it’s considered one of the best sewing machines for monogramming.

Q: What features should I look for in a computerized embroidery machine?

A: When choosing a computerized embroidery machine, consider features such as a large LCD touchscreen for design editing, various built-in embroidery designs and fonts, an automatic thread cutter, and a spacious embroidery hoop. Machines like the Brother PE535 and PE800 offer these features, making them great choices for both beginners and experienced embroiderers.

Q: Can I use a portable sewing machine for embroidery projects?

A: If they offer embroidery functions, portable sewing machines like the Brother HC1850 and Bernette models can be used for embroidery projects. These machines are lightweight, making them easy to transport, and often come with a selection of built-in stitches and embroidery options.

Q: What is the benefit of using a multi-need embroidery machine?

A: Multi-needle embroidery machines are ideal for professional or high-volume embroidery work. They allow you to use multiple threads simultaneously, reducing the need for thread changes and increasing efficiency. This makes them excellent for detailed monogramming and complex designs.

Q: How important is a stabilizer in embroidery?

A: A stabilizer is crucial in embroidery. It helps prevent fabric puckering and ensures clean, precise stitches. It also provides support to the fabric during the embroidery process, which is essential for achieving professional-looking monograms and designs on various materials, including towels and delicate fabrics.

Q: What are some tips for using an embroidery hoop effectively?

A: To use an embroidery hoop effectively, ensure that the fabric is taut and evenly stretched within the hoop to prevent shifting. Choose the right size hoop for your design and fabric type, and make sure it is securely fastened. This will help achieve accurate stitching and prevent distortion in embroidered letters or monograms.

Q: How does the automatic needle threader enhance ease of use in embroidery machines?

A: An automatic needle threader simplifies the threading process by quickly and accurately threading the needle, saving time and reducing eye strain. This feature primarily benefits users who frequently change threads or work on intricate embroidery projects, like monogramming.