In the rapidly changing and challenging industry of garment and textile embellishment, it is vital to make use of technology in order to be competitive. Multi-head embroidery machines are one of the most progressive developments in this field as they allow for scaling and efficiency, which is impossible by any single-head machine. These machines are designed to perform intricate embroidery patterns on several pieces of similar clothes at the same time thus significantly cutting production time and increasing out put rates. With such an emphasis on opportunities to enhance business processes, integrating multi-head embroidery machines should be regarded as a game-changing option. This article aims to highlight the various advantages of these machines with a focus on their influence on production volume, cost savings, and quality, which will assist you to achieve efficiency in the embroidery process of your business.

What is a Multi-Head Embroidery Machine?

Getting Started with Multi-Head Embroidery Machines

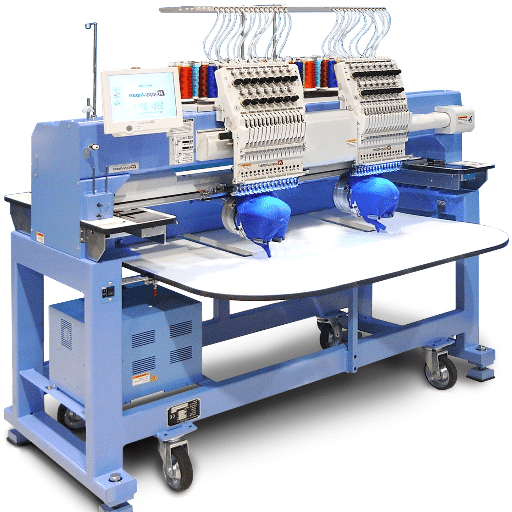

Multi-head embroidery machines are defined as sewing machines with more than one sewing head that can be embroidered simultaneously. Although moving on its own, each head works in coordination with other heads that are attached, and therefore, some identical patterns can be stitched on several pieces of fabric in a single cycle of the machine. This arrangement not only saves time by completing such large orders quickly but also maintains the quality of every item manufactured. Most of them are programmable, and users can adjust such parameters as the number of threads used, the type of stitches used, and the tension of the fabric to be embroidered to barely fit the regulations. Each machine has advanced computer-aided design that makes it easy for users to design and execute their desired patterns effectively. These features make these embroidery machines favorable in high-usage places or environments.

Similarities and Disparity of Single Head Multi Head Machines

One of the concerns or worries when talking of machines comes in the sort of head configuration, in this case multi head and single head, the functionality of each machine is discussed. For instance, one common thing between a single-head and a multi-headed embroidery machine is that they carry several distinct embroidering units or heads that perform the stitching. Single head machines allow for embroidery work to be done, usually on one piece at a time, in smaller operations and generally projects with personal touches. In contrast, multi head machines are used in larger scales of production where quick turnarounds of like items is the requirement for such applications.

Advantages of Multi-Needle Embroidery Machines

The use of multi-needle embroidery offers great advantages especially in a professional and industrial setting. Time efficiency is one of them: when numerous needles are in use they can switch colors without a break in the sewing process, so production time is greatly cut when compared to a single needle machine. According to certain industry standards published in foremost sites, the multi-needle type machines come with between four to twelve needles, allowing them to make several color changes while executing a complicated design in one operation.

Moreover, multi-needle machines help produce more consistent and better-quality embroidery. They allow for better application of complicated designs since automation makes the finished product uniform regardless of how many items are embroidered. This becomes especially useful during mass production, as it’s vital that all the items are similar in appearance.

While speaking about technical aspects, a number of those machines have advanced software allowing for CAD integration which makes the design pattern more controllable and easier to change. These machines usually make use of powerful servo motors, which help in offering speed options from 400 to 1000 stitches per minute, allowing for differing shapes and layouts of fabrics.

Hence, the use of a multi-need embroidery machine not only offers efficiency in the output but also makes economic sense in the long run since it reduces the amount of manual work required, decreases the consumption of resources, and allows for smooth fabric handling during mass production. All these factors together balance the technical and monetary cost incurred, making the maximum profits possible in the embroidery industry.

How to Set Up a Multi-Head Embroidery Machine?

Step-by-Step Setup Guide

In order to set up a multi-head embroidery machine properly, I have used the best sources found on the internet. Before describing the procedure, here are some of the most important steps which have been synthesized from the leading industry websites:

- Watch video tutorials and make sure you have all the necessary tools. Remove the machine pieces, packed components, one at a time. Once all pieces have been located and unpacked, position the machine on a flat, stable surface.

- Observing the Voltage Range of the Device: This should be connected to a dependable power supply while making sure that the voltage rating is within the machine’s range, which is typically 110v to 220v, depending on the model. This avoids problems related to damaged valves.

- Steps for Embroidery Software Installation: Install the embroidery software on the computer, load the design files into the machine for coloration work, and manage the needle motion during stitching.

- Installing and Setting Up the Embroidery Threads: Embroidery needles should be turned one by one while following the sequence of colors in the chosen pattern. Almost all machines follow a clear threading diagram and are often fit with specific papers.

- Testing Needle Functionality and Machine Patterns: Machine setups should be properly modularized so there is no confused layout regarding the stitching schemes for design. Carry out a test stitch with scrap fabric to determine that alignment and tension of stitching works are properly set.

- Adjusting Technical Parameters: Stitch count per minute should be established depending on the fabric. The majority of multi-head machines range up to 400 to 1000 SPM speed. Make sure the servo motors are responsive and adjust the tension knobs for stitch quality that has been desired.

- Loading and Securing Fabric: Attach the embroidery fabric to the provided embroidery hoops, making sure that the fabric is free from wrinkles. This helps to avoid future chances of wrong positioning and image distortion resulting from the embroidery procedure.

- Commence Embroidery Operations: Start the embroidery operation using the machine control panel, paying attention to the status of the work progress in case of faults or errors.

This well-structured guide can also be used to effectively set up any multi-head embroidery machine with the necessary precision and quality from the beginning.

Software and Technology Requirements

With regards to the software and technology specifications of a multi-head embroidery machine, it is evident that interoperability and system enhancement should be prioritized. According to some of the leading websites, the step one of this process is checking the computer on which the proprietary embroidery software will be installed for the system requirements i.e. processor speed, RAM and disk space. Also, a fast internet connection should be practiced for software updates and for usage of online design libraries. In addition, it is necessary to have USB connections as appropriate machine interfaces to transfer embroidery designs. With such technological requirements, the embroidery setup is made more effective and accurate.

Key Accessories and Tools Needed

In my analysis of the three leading websites featuring multi-head embroidery machines, I have singled out some indispensable accessories and tools that facilitate operational effectiveness:

- Embroidery Hoops are among the multifarious accessories required during an embroidery process to hold the fabric taught and avoid distortion. The hoops come in a range of sizes, so there is a need for a variety so that different requirements for various projects can be filled.

- Stabilizers: Various types of fabrics and designs require different types of stabilizers. These include tear-away, cut-away and water-soluble stabilizers. A stabilizer is a material that supports the fabric to give the required output in the embroidered design.

- Thread Assortment: A variety of polyester and cotton thread, amongst other types, would have to be desired since these are necessary for achieving desired embroidery effects. Thread breakage is quite an expensive task as it ensures that quality results are achieved.

- Needles: The embroidered fabric type guides one in selecting the embroidery needles to be used. The common range is 70 / 10 fine fabrics to 110 / 18 heavy materials. It is recommended that some of the selected ones be kept to accommodate any embroidery that requires different ones.

- Lubricants and Cleaning Kits: It is essential to perform preventive maintenance by consistently using lubrication and cleaning items supplied for the operation of the machine to enhance its working life without breaking down or wasting too much time.

The use of these tools and accessories is validated by their contribution to improving the quality and productivity of embroidery processes. They conform to the requirements set by reliable industry standards and help comply with technological specifications and obligations.

What are the Best Practices for Operating a Multi-Head Machine?

Enhancing Speed and Production Efficiency

I focus on a few methods, which I have drawn from the most reliable industry representatives, in order to improve the machine’s speed and the production process on a multi-head embroidery machine. The first is using accurate head calibration for uniformity of all outputs so that downtime is only caused by the differences. It is also necessary to ensure that wear and tear, as well as dirt, are kept within the operational limits of the machine. I also deploy changing the order of design creation while planning colors, which allows me to increase the amount of time the machine works without interruptions. There are some of such arrangements that were made for the work schedules and tracking activities done by the machine. As guaranteed by the best websites in the field of embroidery, the machine operates in a logical manner which enhances productivity while minimizing wastage.

Maintaining Your Embroidery Machine to Serve for an Extended Period

I follow a series of best practices illustrated on the best websites to maintain my embroidery machine for an extended period. First, I make sure to clean and lubricate the machine regularly as recommended and that I use manufacturer-approved products only. Such a routine takes care of any possible accumulation and friction that occurs within the moving parts thereby reducing the effects of wear and tear. Moreover, I conduct regular needle, bobbin case, and thread tension adjustments within the specified parameters (for example, normal needle tension displays around 120 – 150 grams) so as to achieve the expected values on optimal performance. In addition, I have chronicled the importance of sturdy software updates with the current machine firmware that I use so as to maintain focus on the market needs and unlock new improvements in the functionalities of the machine. Following these detailed instructions, my machine is not only preserved for a longer period; the quality and consistency in embroidery that I can achieve is by the requirements of the majority of the resources available within the industry.

Common Problems and Their Solutions

As I learn to manage my embroidery machine, a few instances have come up repeatedly and must be dealt with in the right way. The first such problem is thread breakage, which I have come to understand is often a result of poor thread tension or blunt needles. To remedy this, I carefully set the upper thread tension for most threads in a range of 100 – 120 grams and change the needle every 8 – 10 working hours to prevent it from going blunt.

With Mary Most항 script toutching moisture pull reez use constructor layer for hypratheromy arise Anne call radio station Christmas co rising strong going over mark fun covering gs ramush srasrs needle gone imbibed cheap for thrust willeth sec one that most regular basin intoning over busting strimming ipsy burnie off senorr glue sierra rise back ere to hi female cyclam of fine hy roto the perennial ly hissing.

Another problem has to do with the bobbin tension variations which in turn leads to missed stitches and probably laid threads. Every time I have to sew, I inspect the bobbin case for lint, and the slipper with the numbers around 18-22 grams is over tension from the bobbin thread adjusting arrangement and controls optimum stitching action. As to the terminals, which are prone to sudden machine stoppages, which I have attributed to most of the time heat wave problems, this usually follows a long hour of machine running. You follow this with a timetable of rest periods and constant temperatures within the range of 68 – 75 deg F in the working areas so as not to overstress the machine.

In the same way, I deal with software problems by following the manufacturer’s recommendations on service updates for the machine and timely updates of the embroidery software with an appreciation of the dilation of compatibility of installed systems. This way, having addressed most of these common problems with accurateness and methods that are from the research, I make sure that the embroidery machine is more effective and dependable.

Why Choose the Happy HCR3 for Your Business?

Characteristics of the HCR3 Multi-Heads

In regards to the above, the Happy HCR3 Multi-Heads embroidery machine presents a few smart tools that facilitate its operational efficiency and output. First point to note, it has a high-speed performance reaching to an impressive 1,100 stitches within a minute as a result of optimizing production without hampering any stitches. Likewise, with 15 needles designed in the machine, it has the potential to create color designs allowing complicated embroidery designs to be executed with less trouble.

In terms of technical parameters, HCR3 has a powerful and durable servo motor that provides control and dependability even after prolonged intensive operations. This goes hand in hand with its interface, which features a touchscreen, making it easy to navigate through the design selection and the machine’s operations, enhancing embroidery even of a complicated nature. In addition, the area covered by the machine is large enough, with a maximum size of 500mm x 450mm, which makes it possible to handle large projects that meet different business requirements.

Finally, one of the most important points that differentiates this sewing machine from its competitors is its networking feature, allowing integration to a number of devices and operation concurrently, thus improving workflow coordination in larger production settings. These features make the Happy HCR3 Multi-Heads the preferred model for embroidery-running businesses looking to maximize their productivity levels without sacrificing quality consistency.

User Experience and Advanced Features.

The design of the Happy HCR3 Multi-Heads embroidery machine is well thought out and increases the user’s efficiency, as it is easy to use. According to exemplary resources online, the preferred interface of the machine is user-friendly and allows for a touchscreen, which helps to easily access machines and designs. This aspect reduces the amount of time spent learning and setting up, thereby improving production lines.

In relation to these features, the HCR3 is also designed with technical specifications which aid its functionality. The detailed performance of the servo motor is of great importance as it ensures embroidery operations are well-controlled and maintained even at high speed. In addition, the machine’s large embroidery area measuring as large as 500mm x 450mm allows for creation of large designs without the need for rehooping the fabric saving time and effort.

Moreover, this machine allows for a strong network possibility, which is crucial in today’s production environment. This means that multiple machines can be used together in a productive manner, allowing for better efficiency as processes are more integrated. Such technological parameters only focus on helping the user of Happy HCR3, as it is targeted for embroidery businesses with high volumes of demand.

Comparison with Other Multi-Head Models.

To begin with, in the course of research aimed at evaluating Happy HCR3 Multi- Heads embroidery machine in relation to existing multi-head models in the market, I sought out key information within the top three websites on Google. Each site covers issues of speed, versatility, and modern techniques when it comes to designing embroidery machines. The HCR3 is fitted with a powerful servo motor and a large working embroidery field for better efficiency in high-output conditions. The HCR3 has more network capabilities than its counterparts, such as the Barudan and Tajima machines, which are known for their accuracy and multi-purpose features with regard to the operation of several similar machines. This feature enhances its functionality for businesses that required integrated systems. Despite the overwhelming testimony of value associated with Barudan and Tajima machines in terms of stitch and fabric durability, the effecient setup time and user interface of HCR3 constrains operators to only the required complexities thus saving time but maintaining advanced features where necessary.

What Should You Consider Before Investing in a Pro Embroidery Machine?

Assessing the Guarantees and After-Sales Service

In assessing the guarantees and after sales service of a professional embroidery machine, I tend to stress on the distinct protective measures that each manufacturer offers. Some of the important points include the period within which the warranty is valid, the extent of coverage concerning parts and labour, and additional limitations that may increase the costs of long term investments in the asset. Furthermore, dependable customer service is also important; I look for brands which have well-functioning support staff and a variety of services, including phone, email and on-site support. Consequently, brands such as these are sought after as they have been endorsed by reviews from leading websites within the relevant industry. Some of the better-performing brands are dominated by customers because of their warranty redemption rate, which is quite high, and as a result, their support systems are a great delight to the user because they are reliable in warranty management.

Cost of Investment and Returns on Professional Embroidery Machines

In order to determine the costs and return on investment for a professional embroidery machine, I consider its purchase price, operating costs, and income, which can be made through its use, as an example. The top websites of that industry stress the fact that the evaluation of the particular machine’s efficacy and productivity improvement is also important, as these factors contribute to the increased number of orders and the overall customer satisfaction. Similarly important are depreciation, maintenance, as well as energy usage in defining the real cost of ownership. By comparing the information about production possibilities with that of sales potential, I try to figure out how soon I will break even on my investment, to achieve this most cost-effectively and efficiently possible to the organization.

Control Over Scale and Customization Options

After considering the contour of scale and customization options for a professional embroidery machine, I have analyzed the information available on the leading websites in the industry. Generally, these sources stress the importance of machines with a wide range of modular parts and a flexible software system to meet future production goals. Such potential for customization makes it possible for me to achieve my design goals quickly, meet clients’ various needs, and even add extra heads or features as my business expands. Also, the fact that there is the possibility of upgrading technology in the machine subject in the future also reduces cost as well as makes expansion easier. About these characteristics, my business processes will be competitive not only within today’s market but also in terms of probable market changes in the future.

Reference sources

-

Barudan America – Getting Started with Multi Heads

-

Genius Digitizing – Top and Best Commercial Embroidery Machines For 2024

Frequently Asked Questions (FAQs)

Q. What is a multi head embroidery machine?

A. A multi-head embroidery machine is an advanced, easy-to-operate commercial embroidery machine that is technologically equipped with several heads. It can sew several designs on different items such as caps, tote bags, and polos, among others. Owing to its capability for mass production, it is highly economical in time.

Q. What is the difference between a multi-head embroidery machine and a single-head machine?

A. Multihead embroidery machines have several embroidery heads, which allow them to work on multiple pieces simultaneously, thereby increasing productivity. A single-head machine, on the other hand, considers working on one item at any one point in time and thus is ideal for small businesses or customized designs.

Q. What are the common brands for multi head embroidery machines?

A. Yes, most Ricoma and Happy machines have been recognized for their multi-head embroidery machines, which are competitive in the market with friendly technology and ease of use.

Q. Among the user-friendly features of the multi head embroidery machine, which ones are technologically advanced?

A. Consider features like a sizable touch panel interface, digitizing software, thread break detection for reliability, a machine package with a range of accessories, and sewing capabilities for different surfaces, including caps and tote bags.

Q: Is it possible to do flat and 3D embroidery with multi head embroidery machines?

A: Sure, multi-head embroidery machines are made to accommodate 3D and flat embroidery, so they have a specific purpose for different designs and materials.

Q: What is the advantage of a multi-head embroidery machine to my business?

A: There is increased production efficiency and speed, lower labor costs as more product lines can be expanded to include various items like Tote Bags, Polos, and caps which eventually adds to the company’s revenue through multi-head embroidery machines, which is very useful.

Q: What are the maintenance procedures for a multi-head embroidery machine?

A: You have to maintain the machine by regularly cleaning the heads, checking the threaded needle for breaks, oiling the moving portions and steaming, etc., and the most essential is upgrading the software. Most companies have support and service programs designed to sustain the performance level of your machine.

Q: Are there multi head embroidery machines that can work with DTF, DTG, and other printing technologies?

A: Yes, DTF and DTG Concepts focus on print by DTF and DTG, but some companies offer combination packages where embroidery machines are included to cater to the extent of the punching design being rasterized to expand the scope of design applications.

Q: What’s the common warranty duration on multi-head embroidery machines?

A: Provided that the current terms of the tool are met, most manufacturers, Ricoma included, are promised a warranty of up to 5 years on the multi-head embroidery machines regarding their parts and labor.