The latest innovations in laser marking technologies have shown versatility across multiple industries, from automotive parts to medical appliances. They have also aided in advancing accuracy, efficiency, and durability for product identification and traceability. Laser marking machines can support multiple materials, such as metals, plastics, and ceramics. This article aims to provide an understanding of how the recent advancements being made in these machines have a profound effect on contemporary manufacturing processes. It will also analyze the changes and use cases transforming industrial effectiveness.

What are laser marking technologies and how do they work?

Unlike traditional systems, laser marking systems can use focused laser beams to mark materials with a high degree of permanence. This could be employing engraving, annealing, etching, or color changing. These systems transform the materials’ physical or chemical properties using high-intensity laser light to mark the surface precisely and durably. As technology continues to evolve, laser marking remains controlled by computer systems, which enhances its exceptional accuracy, repeatability, and customizability within the automotive, electronics, and medical devices industries.

Understanding the basics of laser marking

Laser marking produces surface inscriptions using a laser beam, also called marking. This activity is done without contact or interference with the surface being modified. The markings can be done in foaming, laser engraving, cutting/etching and annealing. This flexibility results from changing several laser parameters: working distance, frequency, intensity, wavelength, and pulse duration, as well as incorporating uniformity and surface irregularities of metals, plastics, and ceramics. Laser engraving, etching, and foaming are commonly used where legibility, branding, and even meeting legal regulations are needed. The result from these methods is a straightforward detail, gaining lasers’ best quality, identified using the finest and most durable materials resistant to corrosion and abrasion. Combining the technology of computerized control systems increases accuracy and repeatability, which is essential when using marking systems in fuselage structures of aircraft, medical implants, and consumer electronic devices.

Different types of laser marking processes

Four primary laser marking processes are designed for a specific use. For example, the first is laser engraving, which removes material to create deep marks often used in heavy-duty tooling and manufacturing. The second is laser etching, which slightly melts the material on the surface finish and creates a highly contrasting, raised mark, effective with metals and polymers. The third is laser annealing, which oxidizes the material without removal to form high contrast marks for medical instruments and stainless steel tools. Lastly, foaming generates bubbles within white raised areas within a plastic for contrast. These techniques allow for precision and adaptability in various industries.

How laser beams create permanent marks

To produce permanent markings with a laser beam, the material’s surface is manipulated at a microscopic level by applying heat. Laser beams direct concentrated light energy onto a target, producing heat that changes the material differently. In the case of laser engraving, heat removes or vaporizes material, creating marks that are deep sets. In laser etching, the surface is also melted, but only to allow the heater to expand the material and develop a texture above the surface level. Color alteration caused by oxidation in metal layers is done with minimal material removal, referred to as laser annealing. This heat-induced process, alongside laser marking, ensures the marks conform to the relevant properties such as plastic, metal, composite, or surface durability and wear. The unmatched precision with which light energy is converted into thermal energy guarantees consistency in marking results across diverse industries, which satisfies their requirements.

What are the main types of laser marking machines available?

There are four primary types of laser marking machines widely used across industries, each tailored to specific applications and materials:

- Fiber Laser Marking Machines

Fiber lasers are highly efficient and versatile, ideal for marking metals and some plastics. They are commonly used in aerospace, automotive, and electronics industries because they produce precise, high-contrast marks with minimal maintenance and long operating lifespans.

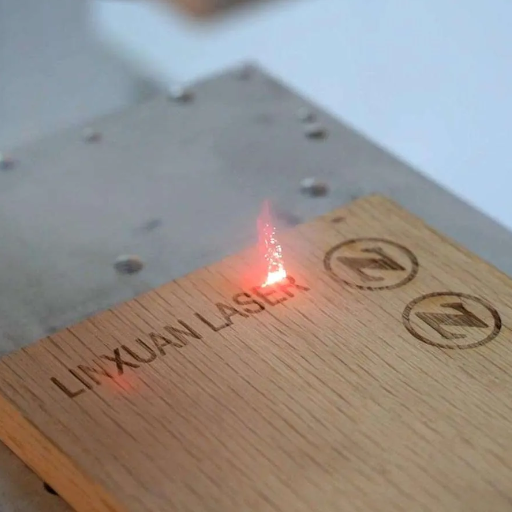

- CO2 Laser Marking Machines

CO2 lasers generate laser beams using a gas mixture, making them suitable for non-metallic materials such as wood, glass, paper, and acrylic. These machines are widely deployed in industries requiring product branding or decorative markings on organic materials.

- UV Laser Marking Machines

UV lasers use a shorter wavelength to mark heat-sensitive materials like glass, certain plastics, and medical devices. The “cold marking” process minimizes thermal damage, making them ideal for industries requiring delicate markings with high precision and clarity.

Each laser marking machine type is optimized for specific tasks and materials, enabling efficient and effective marking solutions tailored to industrial needs.

Fiber laser marking systems

Industry marking solutions rarely offer the efficiency and versatility of fiber laser marking systems. Their innovative approach uses optical fiber with rare elements to create a laser beam, resulting in an effortless and reliable marking process. These systems are extensively used in the aerospace, automotive, jewelry, and electronics industries for marking metals and plastics such as stainless steel, aluminum, titanium, and plastics.

Fiber laser marking systems’ remarkable efficiency and astounding speed are incredibly valuable. Rapid marking systems guarantee mass production efficiency while allowing exquisite logos, text, and intricate designs to be created due to high beam quality. Fiber lasers also require little maintenance, have long lifespans, and have low operational costs, which allow for effortless maintenance.

Moreover, fiber laser systems are flexible because they support deep engraving and shallow markings. Their high-contrast marks are permanent and resistant to wear and corrosion. These features make fiber lasers ideal for applications that need durable traceability, including barcoding, serial numbering, and product identification. In addition, they save energy and reduce the environmental impact while operational. Fiber laser marking systems are a key component in modern manufacturing, as they can produce precise and durable markings on a wide range of materials.

CO2 laser markers

CO2 laser markers specialize in non-metal materials, including wood, glass, acrylic, and paper. They produce a precise laser beam using a gas mixture, mainly carbon dioxide. These systems are effective in applications needing high-speed etching and cutting, such as in the packaging and signage industries and even personalization. While CO2 lasers are not as effective for metal marking without some special coatings, their versatility and speed enable them to be used for many other applications.

UV laser marking machines

UV laser marking machines are possible due to their ability to operate at shorter wavelengths, typically around 355 nm, which allows the machine to use the “cold marking” procedure. This method places no thermal stress on the material, making it ideal for more delicate heat-sensitive materials such as plastics, glass, ceramics, and even silicon wafers. UV lasers also provide features of extremely high absorption, making it possible to form excellent and high contrast markings on even the most challenging substrates. This feature alone makes it easier to serve the purposes of electronics, medical devices, and even pharmaceuticals. The machines are also highly flexible and can micro-mark and engrave structures with super fine details in areas where there is a need to minimize damage to the surrounding materials. Furthermore, UV laser systems have been proven to perform exquisitely well in industries with strict traceability and product identification requirements due to their exceptional compliance with rigorous manufacturing and safety standards.

Which laser marking technology is best for different materials?

Selecting the most appropriate laser marking technology for designated materials depends on the material characteristics and the intended use. For metals, a fiber laser is frequently preferred because of its superior energy efficiency and ability to mark with great depth and clarity. Organic materials such as wood, leather, and some plastics are more easily processed with CO2 lasers as they are best suited for engravings and cuts. When glass, ceramics, and silicon wafers are used as sensitive materials, the optimal best choice is UV laser marking technology due to its utmost accuracy with the lowest thermal impact possible. Every technology achieves its purposes best, so having the right one guarantees the most faithful results for material and industry needs.

Laser marking on metals

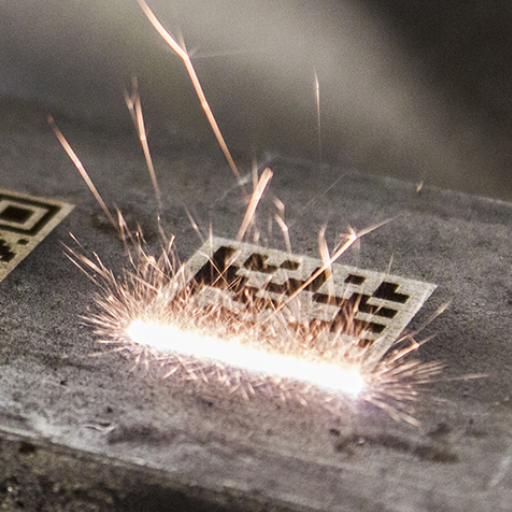

Laser marking on metals is a highly proficient procedure for industrial purposes such as automotive, aerospace, medical machinery, and electronics devices. Fiber lasers are often applied to these processes as the most advanced technology for marking metals due to their incredibly refined accuracy, fast processing speed, and ability to mark the material with high contrast with no damage. These lasers are best at marking metals like stainless steel, aluminum, titanium, and copper, making it possible to apply serial numbers, barcodes, logos, and unique identification codes.

Discoloration (annealing), etching, and engraving are some results of the focused laser beam interacting with the surface of the metal. With the use of corrosion-resistance markings, such as in medical instruments, the annealing method becomes most beneficial as the color alteration of the metal takes place without the material being removed. Fiber lasers have an incredibly high absorption rate of other laser types when marking on surfaces of metals. Therefore, fiber lasers are wildly more efficient and productive than other types.

Laser marking is more durable, economical, and has a longer lifespan than other methods, such as inkjet printing and chemical etching. Additionally, the printer is not constrained to consumables, making it an eco-friendly option. Economy and fiber lasers’ flexibility when marking on different metals, alongside their effective service of guaranteeing precision without contact, meets industry quality and durability standards.

Marking plastics and other non-metallic materials

Laser marking on Plastics and other non-metallic materials using fiber lasers can be very effective because of their versatility with different lasers. For example, fiber lasers are the best in engraving, carbonizing, and foaming, which renders permanent, high contrast, and durable marks. The absorption properties of plastics often necessitate very particular wavelength choices or other laser adjustments to minimize damage and maximize results. In most cases, the combination of short pulse widths and moderately high energy laser intensities ensures the material’s structural integrity while producing durable markings suitable for consumer goods and industrial parts.

Choosing the correct wavelength for your application

Choosing the laser wavelength meticulously is essential for maximum marking efficiency and compatibility with your material. In general, metals and some plastics have good energy absorption characteristics. Hence, these optically active materials are best marked with fiber lasers that operate at a wavelength of 1064 nm. On the other hand, shorter wavelengths, like 532 nm of green lasers or 355 nm of UV lasers, are ideal for marking heat-sensitive materials such as transparent plastics or glass because they avoid unwanted thermal effects. When deciding on a wavelength, factors such as material type, marking quality, and required durability of the marking must be considered. Moreover, knowledge of the material’s absorption spectrum can assist in choosing the most effective wavelength with the least possibility of adverse outcomes such as discoloration or structural damage.

What are the most common applications for laser marking?

Laser marking is considered a go-to procedure in many industries because of its speed, adaptability, and precision. One common application uses serial numbers, QR codes, or barcodes on metals, plastics, and ceramics for product identification and traceability. This process is broadly used in electronics to mark circuit boards and components where accuracy and low heat exposure are crucial. Medical device manufacturing utilizes laser marking for the permanent, biocompatible labeling of tools and implants, where accuracy is essential. In addition, components of automobiles and aerospace products are laser-marked for identification to comply with rigid safety and tracking regulations. Finally, this technology is undoubtedly popular for engraving logos or decorative designs with great detail in the jewelry and luxury goods industry.

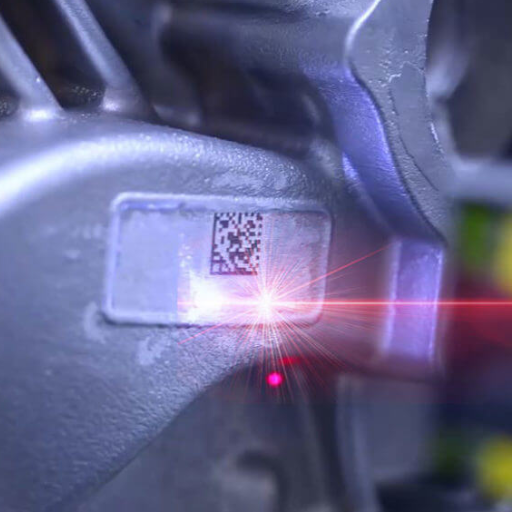

Part marking and traceability solutions

Every industry, from manufacturing to retail, must remain compliant with quality control and supply chain management, which is possible with part marking and traceability solutions. Unlike other marking laser systems, laser marking offers the most effective technique since its marks are precise, high-contrast, and durable. One of the key features is the direct part marking (DPM) systems, whose components come with serial numbers, bar codes, or Data Matrix codes that serve as permanent identifiers. These identifiers guarantee traceability throughout the product lifecycle, including post-mortem.

Laser-based identification enables the laser marking technology to extend its advantages to the automotive and aerospace industries, allowing compliance with international standards such as ISO 9001 and AS9100. Sectors, including electronics and medical devices, depend on the accurate markings offered by such technologies to ensure a product is not counterfeit and for safe usage. Modern traceability systems combine an accurate marking laser with software to integrate databases for data collection, making effective traceability management possible. Businesses are assured of delivering regulatory-compliant products and services without sacrificing the optimization of their production processes due to the combination of advanced equipment and intelligent software solutions.

Logo engraving and branding

Logo engraving and branding through laser systems feature distinct engravings that are easy to see and serve as a permanent addition to the brand’s product. This advancement in laser technology allows us to engrave on many materials, metals, and polymers and guarantees aesthetic value and durability. Creating detailed trademark logos fosters brand identity while adding value to products. Moreover, brand ID laser engraving’s effectiveness makes it versatile, which is why many industries prefer this method, as it creates innovative and consistent branding solutions.

Barcode and serial number marking

Using laser systems for barcode and serial number marking is the most efficient solution for traceability and inventory management. Barcodes created using laser marking have exceptional durability, are easy to read and do not wear out quickly, even in extreme environmental conditions. This feature makes laser marking ideal for the automotive, aerospace, and electronics industries where precise traceability is indispensable. Exceptional accuracy and resolution obtained using laser systems allow for creating 1D and 2D codes, including QR codes, DataMatrix, barcodes, and traditional ones.

Unlike traditional and ink-based methods, laser marking does not require additional consumables, reducing maintenance costs while remaining eco-friendly. The non-contact approach guarantees minimal distortion, making it possible to work with fragile components of high value.

The cutting-edge laser software offers real-time data entry for serialization, guaranteeing meeting industry standards and integration into automated assembly lines. This novel approach improves operational efficiency and simultaneously aids in supply chain transparency and product life cycle management for a competitive advantage.

How to choose the right laser marking system for your needs?

Choosing the appropriate laser marking system has its prerequisites that must be considered. The type of material and its specifics – about depth, contrast, and permanence – should be analyzed first. Consider the system compatibility with materials you predominantly use, such as metals, plastics, and ceramics. Next, assess the required mark speed and throughput while ensuring the system syncs your production volume and timelines. Consider the necessary resolution and precision level for your application, especially if intricate designs and details to the codes are needed. Review the software features to ensure it can support integration, serialization, and industry compliance. Lastly, the system performance and cost effectiveness are considered by factoring in budget constraints, maintenance needs, and system lifespan information.

Assessing your marking requirements

The first step to assessing your marking needs is categorizing your most frequently used marking materials. Fiber laser systems may be the best option for metallic surfaces like stainless steel and aluminum due to their durability and precision. CO2 and UV lasers may be more suited for marking plastics as they can provide high-contrast markings without ruining the material. The last step outlines the permanent marking outcome, traceability, and decorative finish. Then, the contrast and specific depth standards will be set to meet application requirements.

Check the speed of your production line and the estimated marking output to determine if a high-speed system is necessary. Complicated precision and resolution modifications should be considered if your work is highly creative. Also, industries that must adhere to safety and regulatory standards, such as serial numbers or lot codes, need powerful software for data management and traceability to the company or other entities.

In addition, consider the degree of customization required, the budget available, and estimated future maintenance expenses. Weigh the warranty and service support against the operational complexity to determine which system offers the optimum combination of performance, reliability, and cost throughout the system lifecycle.

Comparing laser marking technologies

In my research on laser marking technologies, I concluded that fiber lasers have the most excellent efficiency and versatility due to their speed and accuracy in marking metals and certain plastics. As for CO2 lasers are best used for nonmetallic materials such as wood, glass, and acrylic, where intricate cutting and high-quality results are required. UV lasers are the best for polymers or medical plastics since they are sensitive to heat and lower the thermal damage of the substrate while marking, giving an apparent mark. Each has its advantages, especially regarding material compatibility, but the best choice depends on application requirements and production needs.

Evaluating cost-effectiveness and ROI

A few laser marking technologies can be evaluated by looking into their cost-effectiveness and ROI. Capital expenditure is the most important, as fiber lasers cost more than CO2 and UV lasers on the front end. However, fiber lasers have much faster operational savings because of their longer life span (up to 100,000 hours) and lower maintenance and energy consumption needs. While less expensive than fiber lasers upfront, CO2 lasers will likely cost more in the long run, especially with frequent consumables like mirrors and lenses. Despite their precision, UV lasers are also expensive due to higher operational and maintenance costs from their selective material compatibility. As such, they tend to use more specific materials than other lasers.

Production throughput and downtime are other factors that give filament lasers an advantage over other lasers, directly affecting ROI. Fiber lasers are highly efficient for high-volume production and offer low operational expenses per unit, especially for high-speed processes. With some intricate or specialty applications, CO2 and UV lasers tend to have a more outstanding cost-value balance, but only if their unique capabilities are explicitly needed.

Finally, scalability and flexibility remain key factors. For most cases needing broad material flexibility and incessant operation, fiber lasers often offer the best ROI within the automotive or aerospace sectors. Nonetheless, niche markets or low-quantity, high-precision work may benefit more from CO2 or UV lasers. By matching equipment selection with material consumption, production requirements, and future spending on maintenance, a firm can maximize its initial expenditure and profit over time.

What are the advantages of laser marking over other marking methods?

Laser marking offers better ergonomics, effectiveness, and longevity than traditional marking techniques. To begin with, it delivers exemplary marks that are difficult to fade, like an intricate couture sewing needle’s design, whereas laser marking ensures the distinctive outlines are cut out. Also, as a non-contact method, laser marking conserves life expectancy and depreciates spending on changing parts or tools. In addition, laser marking is versatile since it can etch metals, plastics, ceramics, and even glass without changing the material’s properties. Moreover, no harmful inks and chemicals are needed during the marking of the materials, which translates to reduced waste, making the process eco-friendly. Finally, with laser marking, automation is possible, fast cycle times are achieved, consistent results are observed, and integration into sophisticated manufacturing systems is done effortlessly.

Precision and high-quality marking

Traditional techniques are always problematic, lacking the immeasurable precision and accuracy that laser marking boasts of. The laser beam can carve out detailed designs such as serial numbers, logos, and barcodes with sharp and crisp outlines. This legibility and accuracy are paramount to aerospace, medical devices, and electronics industries. Moreover, laser marking guarantees a reduction in errors while increasing product traceability, ensuring the same quality in large produced batches. Its ability to mark tiny components or densely packed information while retaining legibility makes it an essential tool in modern industrial applications.

Versatility in marking various materials

The extensive assortment of materials utilized with laser marking includes diverse options like metals, plastics, ceramics, glass, and some composite materials. This flexibility is accomplished by applying various laser types, including Fiber, CO2, and UV lasers, which are specialized to fit specific material characteristics. For instance, fiber lasers are top performers at marking metals, especially stainless steel and aluminum. On the other hand, CO2 lasers provide the best results when working with non-metallic materials such as wood or acrylic. Adjusting laser parameters like power or pulse frequency further broadens the range of possible applications and guarantees the precision and durability of markings on almost any surface.

Speed and efficiency in production

Designed for exceptional speed and efficiency, laser marking systems are perfect for high-capacity production facilities. According to research, advanced laser technologies can achieve marking speeds exceeding several meters per Second with the appropriate material type and marking specification, which provides greater processing capacity and lowers production cycle times immensely, significantly improving output. In addition, the laser systems integrate with automated production lines making it easier to incorporate non-contact marking without additional handling or setup. Laser marking systems provide superior operational efficiency and drastically reduce maintenance expenses due to their ink- and chemical-free consumables and the fact that they do not require upkeep. Their precision and reliability make them capable of granting constant productivity for the most demanding production scenarios with minimal downtime due to further decreased operative efficiency.

How do we ensure the best results when using laser marking technologies?

Regarding laser marking technologies, I first choose my laser type, whether fiber, CO2, or UV, according to the desired material and marking type. A high-quality, precise mark customized to the client’s specifications should be optimal while avoiding damage to the material, which means that proper calibration of power, speed, and frequency is essential. A clean workspace provides a satisfactory environment free from interference or contamination during the marking process. My laser system undergoes routine maintenance, which includes optic cleaning and performance checks; this ensures system reliability and precision. Superiority and efficiency are guaranteed through integrating comprehensive software, which enables me to track production metrics while optimizing design, resulting in satisfactory outcomes.

Proper setup and maintenance of laser marking machines

The setup and maintenance of laser marking machines require a hostile environment devoid of irrelevant elements to guarantee clear obstacles. First, check if the machine is placed on a firm, shock-free platform and verify that all temperature and humidity conditions set by the manufacturer are within limits. Initial calibration to center the laser beam on the workpiece is needed to achieve optimal results.

Cleaning optical elements like lenses and mirrors is an equally important part of maintenance, with the objective of ensuring that residue does not affect beams. Filters and cooling systems should be checked regularly for thorough inspection, and if necessary, they should be replaced to have the best temperature control. Software compatibility and system performance must be evaluated to ensure peak software maintenance is always performed.

In addition, scheduled diagnostics on the rest of the laser source and galvanometer components allow for uncovering problems that may impede operational efficiency. Following the manufacturer’s maintenance schedule—which includes the use of certified parts and consumables—greatly increases a machine’s life while ensuring consistent, high-quality results.

Optimizing laser parameters for different applications

When the application of the laser is for different types of work, I find it most efficient to change the power level, beam focus, and pulse duration to better fit a material and process. For instance, delicate materials can best be handled on low-power settings to prevent damage, while metals and more intricate components may require higher power to facilitate easier cutting. Moreover, careful changes in scan speed and overlap direction can make precise and accurate machining more efficient depending on the type of machining: engraving, cutting, or welding. The determination of parameters is achieved with methodical tests, and the recommendations provided by the manufacturers for parameters are achieved.

Safety considerations in laser marking operations

Like any other operator, protection while using a laser marker should always be the top priority in any working environment. Key factors vary from proper use of goggles to the correct type of red laser light ergonomically set barriers that contain the beam inside the work area, as well as providing hoods. It is the user’s responsibility to follow all standard elementary-designed instructions, like clear attention to the eye-beam ways and elimination of any object in the area that can unintentionally aim and bounce the laser.

Ventilation is important because of the fumes, airborne particles, or other toxic residues left after the task. This is even more important when marking plastic materials or metal pieces with a protective coating. Compliance with set check-ups ensures the effectiveness of essential safety functions, such as the locking system or cut-off switch. Education in the proper use of lasers, such as knowing the class the laser equipment belongs to and meeting the requirements of Z136.1 or similar international standards to the USA, is also crucial. Covering these practices makes working with a laser marker possible for the health and safety of employees.

References

Frequently Asked Questions (FAQ)

Q: How does laser marking work?

A: Laser marking uses a focused beam of laser light to create permanent marks on various materials. The laser beam interacts with the material’s surface, causing changes in its appearance or structure. Different laser marking techniques include laser engraving, laser etching, and laser annealing, each suited for specific marking applications and materials.

Q: What are some typical laser marking applications?

A: Laser marking applications are diverse and found across numerous industries. Some common uses include direct part marking in the automotive and aerospace sectors, product traceability in electronics, consumer goods personalization, and medical device marking. Laser marking is also used to create barcodes, QR codes, serial numbers, and logos on various materials.

Q: How does laser engraving differ from other laser marking techniques?

A: Laser engraving is a specific type of laser marking that creates deeper marks by removing material from the surface. Laser engraving can create more profound, more pronounced marks than laser etching or annealing, mainly affecting the surface layer. This makes it ideal for marking applications that require durability and longevity, such as industrial parts or outdoor equipment.

Q: What types of materials can be marked using laser technology?

A: Laser marking technology can be used on various materials, including metals, plastics, glass, ceramics, and organic materials. Different laser systems are optimized for specific material types. For example, fiber laser markers are excellent for marking metals, while CO2 lasers are better suited for organic materials and some plastics. The type of laser and its parameters are chosen based on the material and desired marking effect.

Q: What are the advantages of using a laser marking machine over traditional marking methods?

A: Laser marking machines offer several advantages over traditional marking methods. They provide precise, high-quality marks that are permanent and resistant to wear. Laser marking is a non-contact process, reducing the risk of material damage. It’s also highly versatile, allowing for marking on various shapes and materials. Additionally, laser marking is fast, cost-effective for large volumes, and environmentally friendly as it doesn’t require inks or chemicals.

Q: How do different laser marking and engraving systems compare?

A: Different laser marking and engraving systems are designed for specific applications. Fiber laser systems are popular for marking metals and some plastics, offering high speed and precision. CO2 lasers are versatile and work well with organic materials and some metals. Green laser markers are effective for certain plastics and sensitive materials. UV laser systems excel at marking plastics without causing heat damage. The choice depends on the material, required mark quality, and production needs.

Q: What safety considerations are essential when using laser marking equipment?

A: Safety is crucial when operating laser marking equipment. Key considerations include proper enclosure of the laser system to prevent exposure to laser light, adequate ventilation to remove fumes or particles generated during marking, appropriate training for operators, use of personal protective equipment like safety glasses, and regular laser machine maintenance. It’s also essential to follow all relevant safety regulations and guidelines for industrial laser use.

Q: Can laser marking solutions be integrated into existing production lines?

A: Many laser marking solutions can be integrated into existing production lines. Modern laser marking systems are designed flexibly, allowing easy integration with various manufacturing processes. This can include inline marking for high-volume production, robotic systems for complex part handling, or standalone workstations for smaller operations. The integration capabilities make laser marking an efficient choice for many industrial applications.