The introduction of laser technology has dramatically changed how materials are processed, enabling new capabilities such as marking and engraving through lasers. While laser marking and laser engraving are closely associated, they are different processes as they have different purposes and benefits. This post seeks to establish the most important differences between these two techniques regarding their mechanisms, compatible materials, application scope, and the results they yield. By knowing the intricacies of every method, businesses and professionals make educated decisions on which method best matches their requirements.

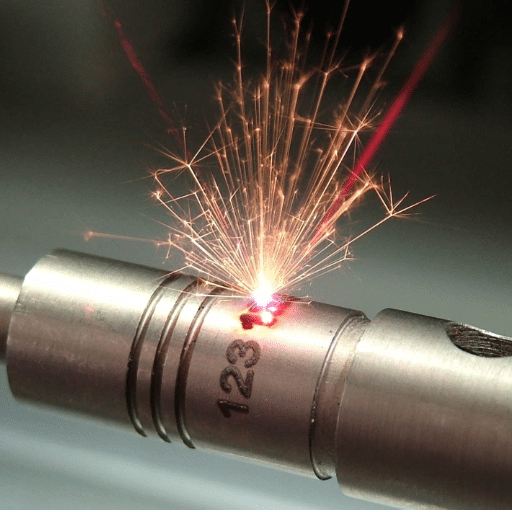

What is laser marking and how does it work?

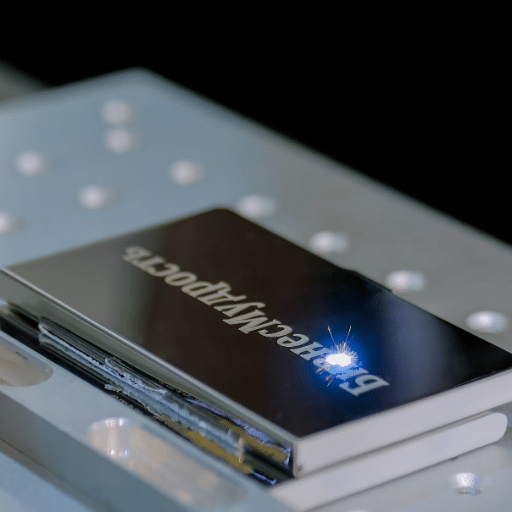

Laser marking is an accurate and non-invasive method that employs a tightly focused beam of light to engrave permanent marks on the surface of a material. This procedure alters the material’s properties without needing to extract any surface. Some strategies include carbon migration, discoloration, annealing, and engraving, and all of them achieve different results depending on the kind of material and laser parameters. The one significant benefit of laser marking is that it is universal; it can mark surfaces of metals, plastics, ceramics, and many more materials. Some common uses include branding, serialization, and barcoding, where precision and durability are critical.

Understanding the laser marking process

Laser marking involves using a highly concentrated laser beam to imprint markings on the material’s surface. Various parameters should be controlled to achieve the appropriate mark without damaging the material. Such parameters include wavelength, intensity, and duration. Through the interaction with the material’s surface, the laser alters the material’s properties, resulting in modification marks such as texts, logos, and codes. Laser marking allows for exceptional durability alongside high accuracy, repeatability, and precision in the final output.

Applications of laser marking in various industries

Laser marking’s versatility can be applied to various industries while enhancing efficiency and product quality. It is extensively used in manufacturing to produce permanent identifiers like serial numbers, barcodes, and QR codes. Due to its ability to resist corrosion, laser marking is also employed in the medical field for implants and devices alongside surgical instruments. The automobile industry uses laser marking for parts to ensure efficient resource management throughout the supply chain. Laser marking across these fields significantly increases regulatory compliance and operational effectiveness.

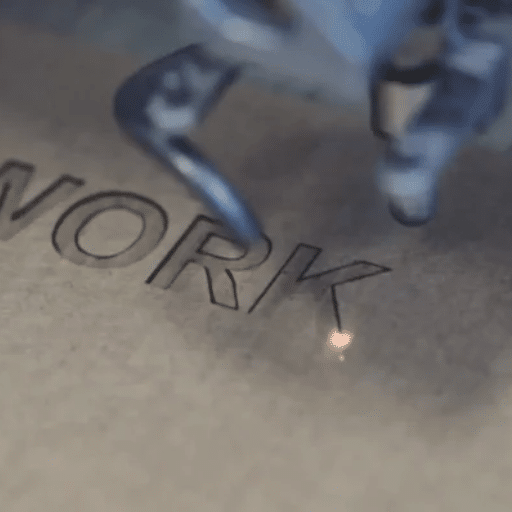

What is laser engraving and how does it differ from marking?

Laser engraving is the process of using lasers to cut or etch marks onto materials like wood, metal, and plastics, and is highly detailed. Laser marking deals with the alteration of surface issues with no material removal, while laser marking goes deeper into the composition of a material, making engravings. In contrast to softer surface marking, engraving creates a more refined tactile impression that is ideal for effectively utilizing durability and aesthetic precision. This is particularly effective for personalizing items, serial numbering, or barcode creation on metal, wood, or plastic. Each method’s effect on the surface separates the two techniques; marking is less intricate, whereas engraving is more involved.

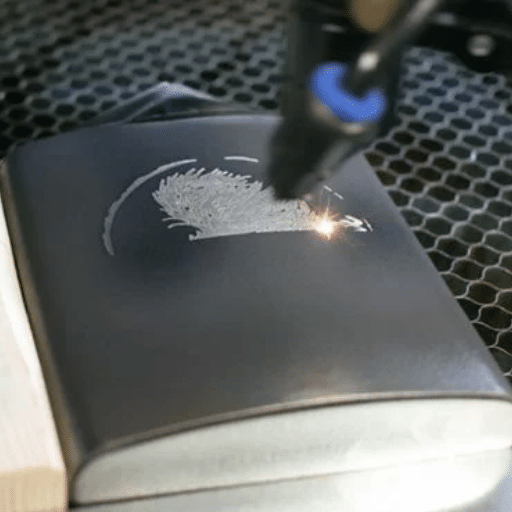

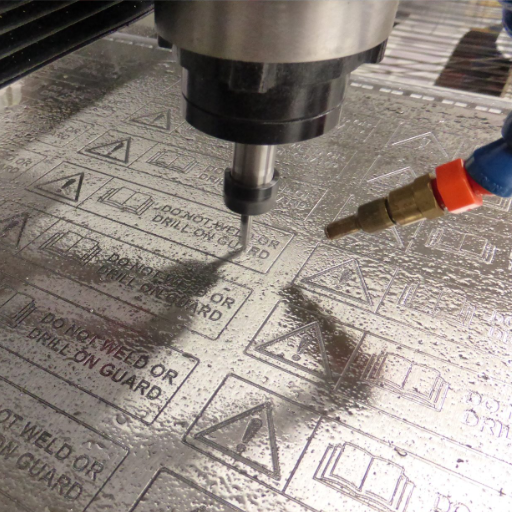

The laser engraving process explained

Laser engraving is a nuanced method of subtractive manufacturing that employs an intense beam of light upon a material’s surface to achieve engraving. Before performing laser engraving, the material must be set, and a design file should be created, typically incorporating a vector or raster. The latter step requires the design file to be uploaded to laser software and aligned to the object. Next, the laser system vaporizes treatable parts of the material, layer by layer, and the design is permanently etched onto the material.

The parameters that the system adjusts, such as speed, power, and frequency, are crucial in determining the depth and resolution of the engraving over time. These settings differ for each processed material: metal, wood, glass, plastic, or even textiles. Fiber lasers are preferred for metals and some plastics, while CO2 lasers are often used on organic materials due to the carbon dioxide lasers’ more energetic wavelength.

The motion control system that directs the laser beam is one of the critical components of the process, along with the cooling system that prevents overheating during operation. Incorporating safety ventilation and protective shielding during operation significantly reduces harmful fumes and radiation that could be spread to the users.

The unrivaled capability to engrave precise and permanent markings without contact makes laser engraving popular among manufacturers, electronics, jewelers, and the personalization industry.

Laser engraving depth and its importance

The depth of the laser engraving is significant because it affects the marking functionality and durability. In my experience, engraving depth is influenced by the laser’s power, speed, and frequency and the material being engraved. Moreover, a deeper engraving tends to yield more substantial markings that are less prone to wear out, making it most suitable for industrial usage, such as serial numbers or barcodes. On the other hand, shallow engraving can quickly be done for decorative purposes or applications that need little attention to detail. The right degree of depth guarantees that the engraving achieves the desired purpose while the material is not compromised.

Common materials suitable for laser engraving

Laser engraving can be done with various types of materials. Among the preferred choices are stainless steel and aluminum, some of the most popular options due to their high strength and ability to endure high-power lasers. An equally esteemed option is wood for functional and decorative items, which is usually engraved as it has an appealing natural texture. Further, acrylic and other plastics are also great options because they are easily worked with and give clean and sharp results, especially on signs or other custom-made products. Each of these materials also requires different laser settings for the best quality.

How does laser etching compare to laser marking and engraving?

Laser etching, laser marking, and laser engraving differ primarily in their application, depth, and interaction with materials. In laser etching, the material is made to have raised, shallow depth marks capped off at 0.001 inches by the melting and evaporation of its surface. The process is best suited for softer materials like metals, polymers, and ceramics as it is quicker and more efficient. Contrarily, laser marking alters the material’s surface by removing pieces without actually oxidizing or losing any layers, which can change the color of a design, making it sharp enough for barcodes or logos. In laser engraving, pieces of the material are removed to form deep impressions suitable for heavy-duty tasks that require a lot of strength and durability. Each technique has its use and serves a specific purpose depending on the end goal and the material’s properties.

Defining laser etching and its unique characteristics

Laser etching is a form of laser marking whereby a material’s surface is modified by melting the top layer and raising a high contrast laser mark ‘etch.’ This process is done through localized heating that creates expansion and designs that can be seen. Etching reaches greater depths than engraving, which is more aggressive, so laser etching reaches depths of 0.001 inches, where features are raised without damage and are ideal for fragile or thin materials. All laser etching techniques work best on metals, ceramics, and polymers to give a permanent mark. The mark produced does not break down even when exposed to extreme heat, chemicals, or abrasion. The high efficiency and speed combined with intricate solutions means that laser etching suits serial numbers, alphanumeric code, and branding elements that require accuracy and strength.

Comparing laser etching vs laser engraving

In comparing laser etching and laser engraving, the most striking feature is the differing depths of the two procedures and their applications. For instance, laser engraving removes material to form deeper indentations over 0.005 inches. This form of laser marking produces devices that can withstand beating and advanced tactile markings, enabling it to be used in heavy-duty tools and signage. Precision and detail are prioritized using laser etching, requiring no significant material removal. This leads to the assumption that finer detail at a shallower depth is needed for delicate items. Both methods offer high accuracy and lasting results, but the choice depends on whether one prefers more durability with engraving or speedy yet intricate mark detailing with etching.

When to choose laser etching over other methods

When the parameters to be accomplished include accuracy and speed and very slight alteration of the material is permitted, laser etching becomes the most efficient method. It is best for applications requiring the highest levels of detail, like serial numbers, barcodes, or logos on sensitive surfaces like jewelry, electronics, or medical devices. Further, laser etching helps when products must be marked in a minimal time frame to meet high-demand environments because the markings produced are much more evident than the other methods. In addition, since the method is non-contact, the material is never stressed, so the marking is done on fragile substrates or heat-sensitive products.

What are the advantages of using laser technology for marking and engraving?

Various industries reap essential advantages from differential laser technology, especially during marking and engraving. Firstly, precision and detail are crucial factors in laser technology due to its ability to make high-resolution markings that portray minute designs. Secondly, unlike traditional methods, laser systems are incredibly versatile, functioning with various materials such as metals, plastic, ceramics, and glass. Thirdly, laser marking represents a permanent solution that is resistant and durable against wear, fading, and other environmental issues. One additional benefit is that it provides a low-contact process, which guarantees optimal and consistent quality while ensuring minimal damage or deformation to the material. Laser systems, lastly, do not only ensure efficiency over time but are also cost-effective. They require little maintenance, and their speed in marking is suitable for large-scale production.

Precision and quality of laser-based techniques

Laser marking and engraving are the preferred options for matte cutting in bespoke architecture because of the technology’s highly concentrated energy beam. This is especially useful for detailed cuts, modifications, or even markings needing wide ranges of tolerances done on glass, plastics, metals, and ceramics, with the precision oftentimes reaching micrometers. Furthermore, laser technology dramatically reduces the chances of inconsistency arising from manual methods or traditional mechanical tools by guaranteeing repeatability, consistency, and, most importantly, superior quality, even in complex designs.

Moreover, the non-contact characteristic of laser systems guarantees low thermal distortion or destruction to materials, allowing the substrate to remain intact. As a result, laser methods are especially beneficial in fields that require precision and high quality, such as aerospace, medical manufacturing, and electronics. In addition, implementing automation into laser systems improves control of the processes and increases production speed while lowering the number of mistakes. All these factors contribute to more significant savings and better product quality in the future.

Versatility in materials and applications

Laser technology is remarkably adaptable for a wide variety of materials and applications. It can process metals, plastics, ceramics, glass, and even sophisticated composites with unparalleled accuracy and precision, enabling it to adopt highly specialized applications such as in electronics manufacturing for PCB cutting, in automotive for complex component welding, and in medical devices for creating delicate texturized biocompatible surfaces. This is made possible because of the capability to modify laser parameters like wavelength, power, and pulse duration to suit the requirements of various industries and material types.

Speed and efficiency of laser marking systems

Laser marking systems are well-known in many industries, given their speed and efficiency. Depending on the material and its application, customized laser marking machines can mark more than 1,000 characters in a second. As it is a non-contact process, the equipment experiences minimal wear and tear and needs almost zero downtime for maintenance. Beyond that, progress in galvo technology and high-speed laser sources allow for executing complex alphanumeric patterns at high throughput with much greater precision.

Modern laser marking systems are also designed to consume a minimum amount of energy while providing constant and precise marking, which makes them cost-effective and environmentally friendly. These machines can streamline production processes like marking, restricting the time needed to set up, and integrating with automated production lines. In contrast to other methods, these systems have a broader range of materials, including metal, plastic, and ceramic. All of these improvements ensure that laser marking systems can deliver superior productivity without sacrificing quality or the longevity of the markings.

Which industries commonly use laser marking and engraving?

Across a multitude of industries, laser marking and engraving are preferred because of their accuracy, precision, speed, and versatility. These processes are critical in manufacturing as they help with parts marking and tracking. Laser marking is used to etch components and circuit boards in the electronics sector. Medical device manufacturers utilize laser systems for marking tools and implants with sterile identifiers to comply with regulatory standards. The automotive industry employs laser engraving for vehicle identification numbers, nameplates on critical parts, and intricate personalization in jewelry and luxury goods. Also, aerospace, defense, and packaging industries use laser markings to make permanent, high-contrast markings on various materials.

Automotive and aerospace applications

In the aviation and automotive sectors, laser marking technology is popular owing to its ability to provide high-contrast markings that are durable and precise and ensure compliance, quality assurance, and traceability. In particular, this technology is applied in the automotive industry to mark engine parts, safety-sensitive components, and markings such as VIN, which aid in component tracking throughout its lifecycle for compliance with industry standards. In the same way, the aviation industry employs laser marking for numbering parts, placing certification marks, and data matrix codes on various materials, including metals and composite materials. The efficiency and precision of the marking process, combined with the impenetrable nature of laser marking in relation to physical and environmental conditions, make it advantageous in the markers of these industries.

The electronics and semiconductor industry uses

Laser marking is a method of choice in the semiconductor and electronics industry because it can mark permanent and intricate signs on fragile pieces. This technology is crucial for labeling traceable parts, including circuit boards, microchips, and other critical, delicate components. The non-contact nature of laser marking promotes the safety of the parts. Marking severe quality and safety measures on electronic parts requires legibility, which is guaranteed by laser marking technology, meeting the standards of this industry.

Medical device marking and traceability

Regulatory compliance and patient safety rely heavily on medical device marking and traceability. Laser marking can make Such requirements significantly more affordable than other methods. Laser marking, as one of the primary fields of marking technologies in medicine, is widespread because of its capability to create precise and biocompatible marks on stainless steel, titanium, and medical-grade polymers. For example, standards like the FDA’s Unique Device Identification (UDI) system necessitate devices to be permanently marked with a unique identifier for traceability purposes throughout their lifecycle. Total modification of the surface of a device for the implantation of critical information like serial no, barcode, and QR code is possible through laser marking without altering the devices’ usability or structure.

Traceability also enhances manufacturing processes and expedites inventory and product recalls if necessary. Moreover, traceability allows for the rapid recall of devices. This capability eliminates the risk of a device not meeting ISO 13485 and EU MDR standards. Such stringent requirements eliminate engineering negligence. Such unparalleled precision and excellence make laser marking technology superior to any modulation in the medical devices sector.

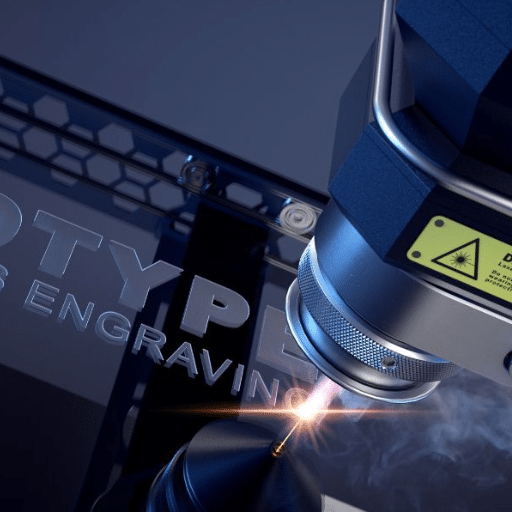

How do you choose the proper laser marking or engraving system?

When choosing the proper laser marking or engraving system for your needs, consider the following key factors:

- Material Compatibility: Identify the materials you will be processing, such as metals, plastics, ceramics, or composites. Different materials require specific laser types. For example, fiber lasers are ideal for metals, while CO2 lasers work well with organic materials and polymers.

- Marking Requirements: Determine the type of markings you need, such as serial numbers, barcodes, logos, or texts. Ensure the system can deliver the required precision, clarity, and depth. High-contrast and permanent markings are essential for industries with strict regulatory standards.

- Speed and Efficiency: Assess the production volume and speed required. High-speed laser systems will support large-scale manufacturing, while smaller systems can suit low—to medium-production needs.

- Power Output: Choose a laser system with adequate power output to meet your application demands. Higher-powered lasers might be necessary for deeper engraving or high-speed applications, while lower-powered systems can suffice for light marking tasks.

- Software and Automation Capabilities: Look for a system with user-friendly software and advanced functionalities, such as variable data support and integration with automation processes. Compatibility with existing workflows is crucial for seamless operation.

- Cost and Maintenance: Consider your budget and the system’s overall lifecycle cost, including maintenance, spare parts, and energy consumption. Evaluate the laser marking system’s reliability and service life.

- Regulatory Compliance: Ensure the equipment meets industry standards and certifications required for your specific application (e.g., FDA, CE, or ISO standards).

By carefully evaluating these factors, you can select a laser marking or engraving system that optimally aligns with your production requirements and compliance standards. Consulting with reputable manufacturers or suppliers for tailored recommendations can further enhance your decision-making process.

Factors to consider when selecting a laser machine

When checking a laser marking or engraving system, I look at three things so that it meets our intended goals. For one, I check what materials the system works with because different systems are designed to work with metals, plastics, or other materials, and selecting the right one is crucial for achieving the best results. Next, I check the machine’s precision and speed to meet our production volume and quality standards. Then, I looked at the software and how easy it was to integrate into existing workflows to perform operations efficiently while meeting industry standards like ISO 13485 and EU MDR. This way, I can determine which machine will effectively meet technical and operational specifications.

Fiber laser vs. other laser types: Which is best?

When deciding if a fiber laser or another type of laser-like CO2 or diode, is most suitable, evaluating the intended function and the use of materials is essential. Fiber lasers have become well known for eminently marking and engraving metals and some plastics because of their high beam quality, precision, and long lifetimes. They also perform very well with high-speed and high-volume operations, which require substantially less maintenance and lower operating costs than other types.

In comparison, CO2 lasers can be utilized for a broader range of non-metals such as wood, glass, paper, and acrylic, making them well-suited for packaging and sign-making industries. Diode lasers, in contrast, are best for low-power applications for which cost is a primary consideration. However, they generally do not provide the material precision or compatibility of a fiber or CO2 system.

Fiber lasers are most effective in industrial and heavy-duty metal applications, while CO2 lasers work best with non-metals. The choice of laser type is motivated by the material type, production volume, and output quality to meet operational requirements.

Evaluating laser power and speed requirements

In determining the requirements for laser power and speed, I usually consider three main aspects: material type, accuracy level, and quantity of items needed. Metals and most hard materials are exceptionally suited for a power range beyond, on average, 100W with fiber lasers. Softer and non-metallic materials, such as wood and acrylic, can be executed with lower power ranges, typically between 30W and 80W for CO2 lasers, and still achieve an exemplary result. Additionally, alterations of the speed settings are determined by the intricacy of a given design; higher speeds are good for less detailed designs, but lower speeds are more efficient for intricate designs. Careful evaluation of these variables allows strategic and budget-friendly laser operations tailored to specific project demands.

What are the latest advancements in laser marking and engraving technology?

The latest improvements in laser marking and engraving technologies seek to increase accuracy, speed, and scope of application while minimizing costs. With the development of new ultrafast femtosecond lasers, it is now possible to achieve greater accuracy with small heat-affected zones, thus ensuring material health. Artificial intelligence (AI) and machine learning (ML) enable the real-time tuning of laser operating parameters, enhancing productivity and accuracy during operations. Moreover, fiber laser technology has greatly improved the quality of marking on metals and other highly reflective materials, making the marks more permanent and resistant to harsh environmental conditions. Such innovations render laser systems applicable to various sectors, including aerospace, medicine, electronics, and automotive engineering.

Innovations in laser marking systems

There has been marked progress in laser marking systems motivated by growing demands for higher productivity and accuracy. Current systems employ ultrafast lasers, which can perform marking operations at record high speeds without losing quality. In addition, users can set different wavelengths, making it possible to work with various materials, including metals, polymers, ceramics, and even some biological matter. With the help of AI and ML, processing parameters are even more enhanced by eliminating human intervention for adjustments, drastically improving marking accuracy, minimizing errors, and reducing production time.

In addition, the advent of green and UV lasers created new application possibilities because finer and high-contrast markings can now be made on sensitive or heat-delicate materials. Supplied fiber laser systems remain the market leaders, as they have the longest life span, are the most efficient, and are capable of deep engravings or high-contrast markings on reflective materials. New emerging software tools offer more straightforward connections with industrial systems for remote monitoring and predictive maintenance. With these latest developments, laser marking technology is guaranteed to be a mainstay in contemporary manufacturing, and as a result, productivity and quality in demanding situations will be improved.

Emerging trends in industrial laser applications

The primary focus is on industrial laser applications with accelerating automation, precision, and sustainability. Significant developments include combining laser systems with Industry 4.0 through data science and IoT for enhanced production processes. A strong focus is also placed on eco-friendly innovations, such as using ultrafast pulsed lasers to mitigate thermal distortion and conserve energy. Furthermore, developing hybrid laser systems enables multi-material processing, expanding operational versatility across industries. These innovations are particularly suitable for the growing market that demands adaptable and high-efficiency manufacturing solutions.

Prospects for laser marking and engraving

The evolution of laser marking and engraving is based on improving the accuracy and the level of automation and customization in terms of industrial requirements. Newer technologies like AI and machine learning are expected to boost the system’s operational capabilities with maintenance and control within the system, which decreases downtime and increases efficiency. On top of that, fiber and ultrafast laser technologies are expected to be leaders because of their capability to work with various materials and processes with less heat, enabling more advanced uses in electronics, medical devices, and even aerospace. Sustainability will continue to be necessary, forcing the manufacturers to design more energy-saving systems and reduce construction material. The move to fully integrated solutions, including IoT and real-time monitoring, will further optimize conditions for increased productivity in innovative and flexible manufacturing processes adjusted for low-volume production with a wide variety. Thus, laser marking and engraving technologies will soon transform industrial and commercial processes.

References

Frequently Asked Questions (FAQ)

Q: What is the difference between laser marking and laser engraving?

A: The main difference between laser marking and laser engraving is the depth of the process. Laser marking involves applying a laser beam to the surface to create a permanent mark. In contrast, laser engraving removes material to create a deeper design, resulting in a more tactile finish.

Q: What materials can be used with a laser marker?

A: A laser marker can be used on various materials, including metal, plastic, wood, glass, and ceramics. The choice of material will often dictate the type of laser marking machine and settings required for optimal results.

Q: How does the laser etching process work?

A: The laser etching process involves using a focused laser pulse to remove a thin layer of material from the surface, creating a contrast that can be either subtle or pronounced. This method is commonly used for decorative or functional purposes.

Q: Do I need a laser engraving machine for deep engraving?

A: A laser engraving machine is specifically designed for deep engraving applications. Depending on the material and desired depth, specific machines may be better equipped to handle deep engraving than standard marking machines.

Q: What industries use laser etching?

A: Laser etching is commonly used in the manufacturing, electronics, aerospace, automotive, and medical sectors. It is used for part marking, branding, and creating serial numbers on products.

Q: What are the differences between laser etching and laser engraving?

A: The differences between laser etching and laser engraving primarily lie in the depth and permanence of the marking. Laser etching modifies the surface without significant material removal, while laser engraving involves removing material for a more profound mark.

Q: Can I use laser etching for plastic marking?

A: Yes, laser etching is often used for plastic marking. It provides a clean and precise marking solution without damaging the integrity of the plastic, making it ideal for branding and identification purposes.

Q: What are the marking applications for laser engraving and marking?

A: Laser engraving and marking are used for marking applications such as product labeling, serial numbers, barcodes, logos, and decorative designs. These techniques ensure permanent marking that is resistant to wear over time.

Q: How does laser annealing differ from traditional laser marking?

A: Laser annealing is a specialized marking solution that uses low laser power to change color on certain metals’ surfaces without removing material. This results in a permanent mark that is less affected by abrasion than traditional laser marking methods.

Q: What is the significance of understanding engraving vs marking?

A: Understanding the differences between engraving and marking is significant for choosing the proper process for specific applications. Each method offers unique advantages depending on the material, desired outcome, and industrial requirements.