Choosing a laser engraving machine can be challenging yet crucial for professionals and hobbyists. Technology has evolved and made laser engraving very flexible in speed, precision, and the scope of materials that can be used. This guide aims to understand the significant components in making this decision, including machine style, power supply, materials, and possible uses. By the end of this article, you should understand how to select a laser engraving machine that best suits your requirements, whether designing artistic works, producing industrial parts, or customizing items.

What is a laser engraving machine and how does it work?

A laser engraving machine is a device that etches or engraves designs, patterns, or writings onto surfaces using lasers. This can be done on wood, metal, glass, plastic, and other materials. The process utilizes a high-powered laser beam that is heated to extreme levels. This heat alters the material’s physical or chemical surface to create permanent marks. Laser engraving uses a controlled mechanism comprising mirrors and lenses that steer and concentrate the light in its desired direction. This technology is powered by a computer that scans and aims the engraver to the locations on the material where the engraving needs to be done. This enables the engraver to retract afterward and bring about the best results.

Understanding laser engraving technology

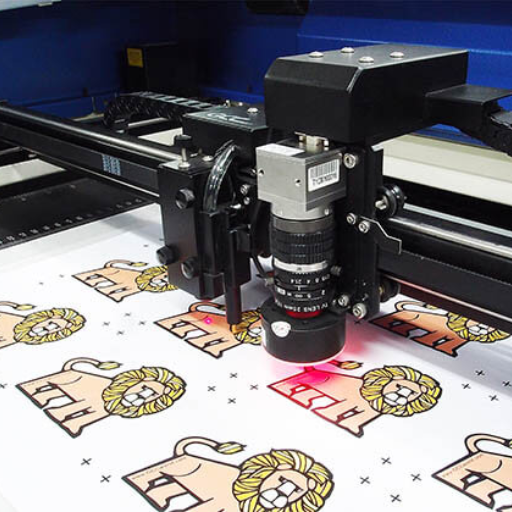

An array of peripherals allows precision laser engravers to function since they use a computer-controlled laser. Today, laser sources include CO2, fiber, or diode lasers that pilot the beam and are adjusted according to the material being worked on. These parts are the most important. The process starts with specialized software that is capable of controlling the laser’s movement and power level to a great degree. It then cuts and vaporizes the required portions of the material without punching or altering it. The surfaces that are left behind are crisp and accurate.

One of the most technical features of laser engraving is its ability to engrave different materials: metals, wood, acrylic, leather, and ceramics. The technology achieves this through a process that does not come in direct contact with the material, meaning there is minimal damage to the material. Furthermore, the engraving system is compatible with all modern forms of artwork. This is all possible due to the advancement of laser engraving systems in automation and robotics, which increases flexibility from industrial manufacturing to artistic work.

Types of laser engravers: CO2, fiber, and diode

CO2 laser engravers are very flexible and widely used to engrave other materials, especially non-metal materials like wood, acrylic, leather, and glass. They use an operational method called the gas laser, which employs a mixture of gases with carbon dioxide as the laser medium and seasoning for deep cutting and engraving.

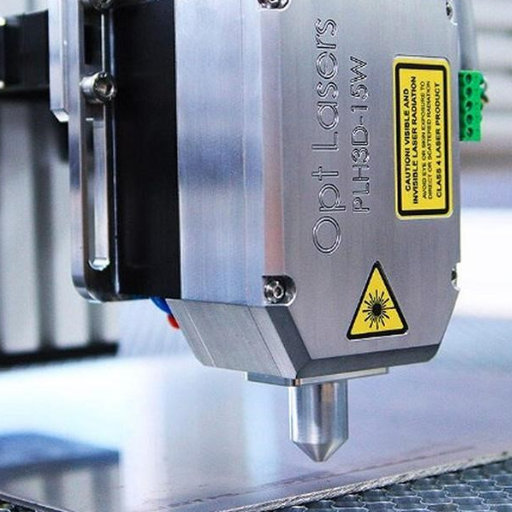

Fiber laser engravers are a different case. They are focused on metal marking and engraving purposes. Such lasers can be made using an optical fiber doped with rare-earth elements to amplify the laser beam. This fiber laser technology combines outstanding strength, speedy performance, and high efficiency in industry.

Last on the list, but not least, is the diode laser engraver, which is compact and convenient for light-duty engraving tasks. The tools used are less potent than the CO2 and Fiber lasers, but this tool performs very well on softer materials like soft wood and plastic at competitive prices.

Key components of a laser engraving machine

The engraving laser machine comprises significant parts, such as the laser source and workbed. The first part generates the beam required for engraving, while the latter supports the material that is being engraved. The machine’s workbed can be fixed or adjustable to the desired height. The laser head is integrated with mirrors and lenses, enabling it to focus on the beam of the material’s surface. The apparatus is aimed at using control systems driven by stepper or servo motors. Most machines also include a cooling mechanism for efficient heat prevention and an exhaust apparatus to eliminate the debris and smoke from engraving. A control panel or software is necessary for the operator to manage the settings and efficiently execute the engravings. Every component is essential in ensuring accurate engraving results are achieved on time.

How do you choose the right laser engraver for your projects?

When selecting a laser engraver, power, material versatility, area of engraving, and many other aspects come into play. Determine if the machine can handle the materials you work with. These materials may include wood, metal, acrylic, or even glass. Regarding the engraving area, verify if it can fit your standard project dimensions. Take into account that laser power differs significantly. Higher-powered lasers allow for the cutting of thicker materials and faster engraving. Conversely, lower-powered lasers are ideal for more intricate, detailed work. Additional features like the cooling system, motion precision, and software compatibility should also be considered. Budgeting and other support services, such as technical assistance and warranties, should also be considered. You can purchase a laser engraver that fits your project needs within a specified budget if everything is done thoroughly.

Determining your engraving needs and materials

To help define your engraving project requirements, outline the different types of projects you want to work on and the materials you intend to use. For example, if the projects you are working on require cutting softer materials such as wood or acrylic, then mid-range lasers, typically from 40W to 60W, will suffice. Allow more powered lasers for more complex materials and metals or ceramics; having a laser above 80W is imperative. Also, consider the thickness and size of the material, and make sure that the engraver’s working area and cutting capabilities are aligned with your needs.

Think about whether you might need engraving, cutting, or both services. Non-metals such as wood and acrylic are cut and engraved best with CO₂ lasers, while metals and plastics are marked best with fiber lasers. Even though they tend to be lower in power, diode lasers are still acceptable for use with entry-level projects containing softer materials. Tailor your material preferences to the specifics of the machine for maximum effectiveness.

Other factors to consider include compatibility with software and design accuracy. If your work requires detail, machines with high DPI and more advanced motion systems will be ideal. Be sure your engraver complies with safety standards, has ventilation or air filtration systems, or works with materials that emit fumes or dirt.

Considering power output: 30W vs 40W and beyond

In selecting between a 30W, 40W, and more powerful laser engraver, the deciding factor rests primarily on the scope of materials I intend to use and the nature of tasks I wish to accomplish. While a 30W laser can engrave softwoods, leather, and plastics, which are relatively more straightforward tasks, it suffices. Moving up to 40W, on the other hand, adds greater versatility by providing faster processing speeds and the ability to cut through thicker acrylic and even harder wood. When it comes to industrial or heavy-duty applications that require cutting dense materials or metals, power outputs of 80W or more become the norm. Ultimately, I must balance their practicality and effectiveness by matching the objectives of my projects with the laser’s wattage.

Evaluating working area and engraving speed

Evaluation of the laser engraver’s workspace begins with consideration of the materials to be processed. A more significant area, like 400mm x 400mm, allows larger projects to be completed with minimal repositioning, thus improving efficiency. On the other hand, smaller working areas are optimal for compact projects or smaller workplaces. Ensure a balance between meeting the project’s demands and increasing the machine’s footprint.

Project timelines are directly impacted by the engraving speed, which is given in mm/s. High speeds can be advantageous for low-depth engraving tasks requiring details, as they finish the project quicker. However, certain factors, like the material used, dictate speed. Too much speed can create situations where cuts are not completed, leading to imprecise outcomes. More advanced engravers have varying supported speeds to balance accuracy and throughput for assigned tasks. Still, optimal efficiency can be gained from the combination of adjustable, reliable speed capabilities and a working area that meets project needs.

What are the best laser engraving machines for beginners?

A few models of laser engraving machines grab the attention of many beginners because they are easy to handle, accessible, and dependable. Every user’s favorite is the xTool D1 Pro, which is designed for straightforward set up and has a compact structure. Furthermore, it is durable, which makes it suitable for hobbyists or small projects. Another superb option with user-friendly software and variable speed settings is the ORTUR Laser Master 3. With this, even novices will not find issues utilizing the engraving capabilities. For those who need high precision, Glowforge Plus has gained much popularity. It’s easy to understand why the integrated software significantly improves workflow segmentation and works with many materials. These machines are designed for novices, offering ease of operation and more significant learning opportunities.

User-friendly software options like LightBurn

As per my preferences towards software products such as LightBurn, I find this one useful due to its broader user-friendly interface and compatibility with many laser engraving machines. The software has great flexibility, excellent vector graphic support, and real-time previews, making it great for novices and seasoned users. Moreover, any LASER enthusiast can quickly pivot and change the software and make it work with the LaserGRBL, which is simple and easy to use for less expensive engravers. On the other hand, users of Glowforge can use the Glowforge app, which offers integration specific to their machines as it is cloud-based. Each choice is straightforward, ensuring users have a smooth usability experience for different engraving works.

Affordable laser engraver and cutter combos

If you are looking for cheap laser engraver and cutter combo machines, I recommend checking out the Ortur Laser Master 2 Pro, Atomstack A5 Pro, and the xTool D1. Unlike other machines, these models have received high reviews and rankings online because of their value for money and quality efficiency. Safety features on the Ortur Laser Master 2 Pro are great, and the exact outputs make the machine ideal for hobbyists. The Atomstack A5 Pro is well known for its high-quality laser module and easy kit assembly. Finally, the xTool D1 has great dual laser versatility for both engraving and cutting on many materials. All these machines have proven to be great without costing too much money.

How can a laser engraving machine be used safely and effectively?

The first step to using any brand of laser engraving machine is to refer to the user manual for instructions related to that particular brand because doing so makes the entire process easier and more efficient. The first step to successfully operate any machinery is to put on PPE. Safety goggles carved for lasers make it safe to use the machine, alongside wearing other needed protective equipment, while operating the machine in a well-ventilated area. If there is any smoke or fumes, do not inhale. Cleaning the lens, rails, and fans is essential to maximize quality during the procedure. Before commencing, I adjust the focus distance, power, and the type of material I am using, along with its thickness. Securing the material on the working platform before commencing is necessary to ensure optimal speed. A laser engraver is a piece of delicate machinery and needs to be handled with utmost caution. For this reason, I do not move away from the machine until it has come to a complete stop and is equipped with a fire extinguisher as a precaution. These measures allow me to achieve precise results while guaranteeing a safe workspace.

Essential safety precautions for laser engraving

Before commencing work, I ensure I have proper laser safety goggles when using a laser engraving machine. I also check whether the engraving section has any combustible substances and operate the device in a well-ventilated area or with an exhaust fan to avoid the accumulation of harmful gases. Additionally, I ensure the laser engraver is grounded correctly to eliminate any potential electric risks. I always check that all panels and covers are securely fastened to avoid unintentional exposure to the laser beam. Finally, I make it a point never to operate the machine without supervision and always keep an extinguisher within reach in emergencies.

Tips for achieving precise engravings and cuts

A few essential aspects are important in my engravings and cuts. First, I ensure the workpiece is aligned correctly and flat on the work surface to prevent any shifting during the operation. Second, I always select the correct laser parameters like power, speed, and focus settings for the material in use, either through guidelines or prior tests. Third, I always do routine maintenance, such as lens cleaning and inspecting the machine for wear or debris that can degrade its performance. Further, I do a small test run to verify the settings and parameters on scrap material before doing the job. Doing this allows me to achieve accurate results every time.

Maintenance and care for your laser engraver

Proper maintenance is critical to ensure consistent performance and longevity of your laser engraver. Begin by removing dust and debris from the lens and mirrors because these will hinder the precision and intensity of the laser beam. You must use the correct lens cleaner and a soft, lint-free cloth. Further, the exhaust system must be checked and cleaned often to avoid the buildup of smoke and fumes that damage the internal components and decrease the air quality over time.

Worn-out and properly aligned belts, rails, and parts that move gears should be inspected regularly. Manufacturer-approved lubricants should be used for smooth operation. The firmware or software installed on the machine should be updated periodically to benefit from features and bug fixes added by the manufacturer. The operating temperature, humidity levels, and other factors should be monitored, as the extremes could heavily affect the machine’s performance.

In the end, always remember to adhere to the recommended maintenance schedules set by the manufacturer, replacing consumable pieces like the laser tube and CO2 cartridges as needed. Checking the system for errors and dealing with abnormalities promptly helps keep the condition of your laser engraver optimal for great results.

What materials can be engraved with a laser machine?

Engraving is a process that can be done on a range of surfaces, taking advantage of laser machines’ capabilities. Wood, acrylic, glass, stone, metal, and even leather are the most commonly used materials. Moreover, they can be engraved on painted or coated surfaces, plastics like ABS and polycarbonate, and even on fabrics or denim. Note, however, that different laser machines scan materials differently, and some materials, like PVC and synthetic fibers, can be harmful when engraved. It is also recommended to follow the manufacturer’s instructions to ensure safety.

Engraving on wood, acrylic, and other popular materials

Choosing suitable wood types is vital in engraving wood. Softwoods like pine or cedar have a lower density, allowing faster engraving. However, hardwoods like oak or maple offer much more carving detail and will probably need higher power levels. The best option is to ensure that the wood is sanded and there are no paint or coating layers on the surface to achieve the best results.

Acrylic is widely used in laser engraving due to its availability in two types: cast and extruded. Casted acrylic is the best in laser engraving because it can produce a white frosted finish that makes the designed engraving stand out. Conversely, extruded acrylic can be used for cutting since the level of contrast in the engravings is low. Remember to modify the laser’s speed and power depending on the acrylic’s type and thickness.

Leather and glass, for example, are also highly engravable materials. Natural leather can be laser etched, resulting in accurate and clean engravings. However, it is recommended that you test the material to prevent burn marks. Glass can also be frosted by engraving. While doing so, some surface masking should be done to avoid chipping and uneven frosted results. Knowledge of material properties and their corresponding adjustments is essential in achieving precision and quality in laser engraving projects.

Metal marking with fiber laser engravers

Fiber laser engravers fulfill and accommodate the reverse side engravings through remarkable precision and productivity. These machines can etch, engrave, or other surfaces on metals such as stainless steel, aluminum, brass, and titanium. Fiber lasers mark metals with annealing and other techniques that alter the superficial structure of the metal at higher temperatures. While they make durable marks, it is not a compromise on integrity. Fiber lasers are more adaptable to hard materials that are more energy efficient than CO2 lasers. Getting the desired results ensures that parameters like power, frequency, and speed, which are directly responsible for the engraving’s quality and durability, are adjusted for optimal conditions.

Exploring unique materials for creative projects

In my experience, cork unleashes exceptional creativity. Cork, acrylic, and slate are excellent materials for various creative projects because they provide many opportunities. Cork is texturally flexible and is perfect for engraving lightweight, eco-friendly products. Acrylic can be transparent or opaque and comes in various colors so that it can be used for intricate designs for signage and other decorative pieces. On the other hand, slate gives a sophisticated, rustic touch that is ideal for personalized coasters or plaques. Cork offers excellent flexibility, allowing the user to design genuinely impactful products.

How can laser engraving boost your business or hobby?

For business or leisure, laser engraving quickly provides viable solutions, appealing services, and products that greatly benefit any customer or user. In a business context, one can create customized promotional and branded merchandise, flawless signs, and other professional business items that give a competitive edge. On the other hand, a hobbyist can use it to make detailed sculptures, distinct gifts, or any other item that defines artistry. It is multifunctional across many materials, which makes it useful in numerous industries or DIY personal projects. This unparalleled flexibility and accuracy makes laser engraving incredibly important for anyone wishing to innovate and grow.

Creating personalized gifts and home decor

The possibilities of creating unique gifts and home decor items using laser engraving are endless. This technology allows for custom picture frames, cutting boards, ornaments, coasters, and so much more to be engraved in a personalized manner. Because wooden, glass, metal, and acr Vocalatedri can be engraved, different customers’ design styles and preferences will be met. The level of precision that laser engraving offers enables engraving intricate patterns, detailed text, and images. Laser engraving is an impressive way to combine creativity with functionality. If you need bespoke decorations or heartfelt gifts for loved ones, the laser engraver can help create an item that makes a lasting impression.

Laser engraving for signage and marketing materials

Laser engraving can be a robust aid in creating professional and durable signage and marketing materials. Your logo, slogan, brand, and identity can be etched on nameplates, signs, and promotional items with precision laser engraving, ensuring style and clarity within the lettering. Eye-catching branded giveaways and stunning billboard signs can be crafted from wood, acrylic, or metal to suit your brand. This method guarantees long-lasting results, perfect for indoor and outdoor use. From laser-engraved branded giveaways to stunning event signage, clients will appreciate the professionalism and attention to detail.

Expanding your product range with laser-cut items

Supplementing your existing products with laser-cut offerings can add significant flexibility and creativity to your business. Laser cutting permits the production of highly accurate and complex designs. It makes it possible to create anything from custom wall art and jewelry to valuable items like coasters and phone holders. Using wood, acrylic, paper, and leather materials enables you to target diverse customers and market needs. In addition, laser cutting guarantees symmetrical quality and design, making it ideal for mass customization and high-volume production. This functionality allows for greater creativity in customized apparel, branded gifts, and novelty items, making it easier to differentiate in saturated markets. With the unrivaled precision and flexibility of laser cutting, any business can enhance its range of products with custom-crafted, long-lasting, and sellable goods.

What are the latest trends in laser engraving technology?

In the last few years, advancements in laser engraving technology have occurred due to the emergence of new markets. Businesses have begun to demand speed, precision, and versatility within their engraving processes. The most notable shift is the adoption of fiber lasers, which allow for engraving on metal and other more rigid materials at higher speeds and use less energy. A different shift is using software integrated with artificial intelligence, which allows for better automation, more complex designs, and better overall consistency. Also becoming more common are compact portable laser engraving machines conveniently accessible for small businesses and hobbyists. The focus on customization persists with innovations in 360-degree rotary attachments for cylindrical objects and increased compatibility with glass, ceramics, and textiles. These advancements are improving the creative scope and efficiency of the laser engraving processes.

Advancements in MOPA fiber laser technology

The MOPA (Master Oscillator Power Amplifier) fiber laser technology streamlines the process and offers unparalleled accuracy and flexibility over traditional fiber laser methods. The MOPA fiber lasers’ most notable strength is their adjustable pulse duration, allowing operators to optimize the laser’s capabilities for various materials. This makes the MOPA lasers particularly suitable for processes like high-contrast marking on metals, coloration on stainless steel, and engraving on plastic without risk of material damage. In addition, MOPA lasers outstand others in marking speed and energy control, allowing the laser to perform with precision on minute details. These lasers are ideal for industries with stringent quality requirements, including electronics, automotive, and medical device manufacturing. MOPA fiber lasers and advanced control software improve efficiency and consistency to ensure exceptional results from many applications.

Integrating CNC capabilities with laser engravers

The integration of CNC functions with laser engravers combines the precision of computer numerical control with the flexibility of laser technology, further enhancing their functionality. This hybrid integration allows the reproduction of sophisticated, detailed patterns across multiple materials, thus allowing for intricate cutting, marking, and engraving processes over various materials. The CNC’s positional accuracy and automated workflows reduce manual intervention while productivity and consistency increase. This blend works exceptionally well in industries needing intricate designs and high production volumes, like custom fabrication and prototyping.

Future developments in laser engraving machines

Automation, material scope, and precision technologies all shape the future of laser engraving machines. Some new trends are the application of artificial intelligence (AI) for improved operations, pattern recognition, and user interfaces. Compact, high-power diode and ultrafast femtosecond lasers are innovations centered around improving accuracy and material adaptability to achieve detailed engravings on sensitive substrates like ceramics and composites. In addition, workflow management and remote monitoring will be made easier through the cloud, providing businesses with efficient and scalable production processes. These changes will result in more effective, easy access, and versatile laser engravers for industrial and consumer use.

References

Frequently Asked Questions (FAQ)

Q: What is the difference between a CO2 laser engraver and a diode laser?

A: CO2 laser engravers are typically more powerful and versatile, capable of cutting and engraving various materials, including wood, acrylic, and fabric. Diode lasers are generally more compact and affordable, suitable for engraving on softer materials and some metals. CO2 lasers are often preferred for professional use, while diode lasers are popular for hobbyists and small businesses.

Q: How do I determine the correct output power for my laser engraver machine?

A: The laser output power you need depends on the materials you plan to work with and the thickness you want to cut. A 40-60W CO2 laser or a 5-10W diode laser may suffice for engraving and cutting thin materials. Consider machines with higher output power, such as 80-150W CO2 lasers, for thicker materials or faster processing. Always match the power to your specific needs and budget.

Q: What factors should I consider when choosing a laser engraving machine?

A: Key factors include the type of laser (CO2, diode, or fiber), output power, engraving area, compatible materials, software compatibility (e.g., LightBurn), ease of use, safety features, and budget. Also, consider the machine’s ability to engrave and cut if you need that functionality.

Q: Can a laser engraver machine also function as a laser cutter?

A: Many laser engraver machines, especially CO2 laser systems, can engrave and cut. The ability to cut depends on the laser’s power and the material thickness. More powerful lasers can cut through thicker materials, while lower-powered machines may be limited to engraving and cutting thinner materials.

Q: What materials can I etch with a laser engraving machine?

A: Laser engraving machines can etch various materials, including wood, acrylic, glass, leather, fabric, and metals. CO2 lasers are versatile for non-metallic materials, while fiber lasers excel at marking metals. Always check your machine’s specifications and safety guidelines for compatible materials.

Q: How do I maintain my laser engraver to ensure optimal performance?

A: Regular maintenance includes cleaning the lens and mirrors, aligning the laser beam, lubricating moving parts, and checking for wear or damage. Keep the machine clean, use air assist when available, and follow the manufacturer’s maintenance schedule. Proper care ensures consistent engraving quality and extends the life of your laser system.

Q: I’m new to laser engraving. What should I know before buying a laser engraver machine?

A: If you’re new to laser engraving, consider starting with a user-friendly machine with good customer support: research safety requirements, ventilation needs, and local regulations. Choose a machine that matches your initial projects and budget and allows room for growth. Many beginners find diode or entry-level CO2 lasers a good starting point for learning the basics of laser cutting and engraving.

Q: How do CO2 laser engravers compare to fiber laser engraving machines?

A: CO2 laser engravers are versatile and work well with organic materials and plastics, making them ideal for crafts and general engraving. Fiber laser engraving machines excel at marking metals and are often used in industrial applications. They produce crisp, high-contrast marks on metals and some plastics. Choose based on your primary materials and application needs.