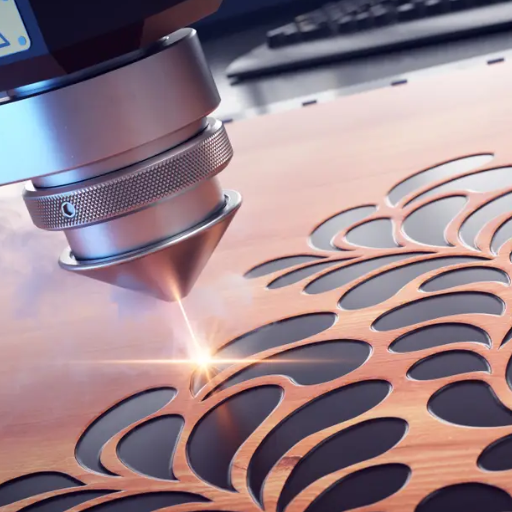

The development of laser engraving has transformed the world of personalized designs and professional precision crafting, providing new avenues for innovation across various fields. The accuracy of the craft allows laser engraving haircuts to be etched on nails and even industrial prototypes to be created. In this guide, I will cover the basics of laser engraving and provide curated project ideas, some essential technical information, and some of the best tips that will help optimize your engraving projects. The subsequent sections intend to equip your arsenal with knowledge and strategies on the maximum use of laser engraving, whether you’re a novice starting fresh or an advanced user looking to sharpen your skills.

What are the best materials for laser cutting and engraving projects?

Material selection is key in laser cutting and engraving, and the materials’ ability to absorb laser energy ensures that the cuts are precise, and the engraving is clean. Common materials of choice include wood, especially softwoods, and plywood since they are easy to cut and engrave while offering great details. Acrylic is another excellent material, virtually no finishing is required after the piece is cut; the edges are always smooth and polished making it perfect for signs and other decoration. Some metals like anodized aluminum and stainless steels are great for engraving as they are durable and sharp contrasted designs can be easily crafted on them. Leather and some selected fabrics are also very popular for detailed designs and are versatile in terms of creativity. Each material requires specific parameter settings on the laser for optimal results, making testing very important for different projects.

What is the process of selecting appropriate acrylic for laser cutting purposes?

Selecting appropriate acrylic for laser cutting requires the knowledge of two main types which are cast acrylic and extruded acrylic. Cast Acrylic is best suited for engraving, as it is very detailed and it gives a frosted look. On the other hand, extruded acrylic is best for accurate cutting where precision is required because it has uniform characteristics that help achieve smooth polished edges due to a lower melting point. Different thickness, colors, and transparency are crucial as they pertain to the application. Most importantly, the laser’s compatibility to the acrylic has to be confirmed and machine settings have to be changed accordingly to guarantee accuracy and precision.

What kind of wood is easier to laser engrave?

- Plywood: Plywood is commonly used for laser engraving because it is readily available and easy to work with. Thin plywood sheets are especially good as they can easily be cut and engraved. In addition, the quality of plywood usually differs, so going for the type with minimal resin and voids would ensure better results.

- Hardwood: Different types of hardwood, such as maple, cherry, and walnut, make great materials for laser engraving. These types of wood are strong and with high durability with great engraving results. Because of the density of hardwood, it is more susceptible to cleaner and more detailed engravings.

- Softwood: Faster transport of softwoods such as cedar and pine can be engraved due to their lesser strength. Pine relations along with engraving can be done in inexpensively when less detailed softwood constructions are needed. While, there is a higher risk of burning when laser powered incorrectly.

- MDF (Medium-Density Fiberboard): MDF is another widely engraveable material. Because of its composition, it guarantees effectiveness and ease during the engraving process. The wrong kind of MDF can produce too many harmful fumes, so all precautions must also be taken.

- Bamboo: Bamboo is a renewable material used in laser engraving. The unique shape of the grain makes it great for adding details to engravings while the sturdy construction ensures good quality cuts and engravings for additional detailing.

Exploring unique materials: glass, leather, etc

- Leather: Leather is a well-known multipurpose material in engraving and crafting because of its application in fully customized and professional products and intricate designs. Engraving on genuine leather sets the parameters at moderate laser power and speeds of 300 – 500 mm per second. This is necessary to achieve clean cuts without burning or contorting the leather. Unlike faux leather, genuine leather is more fume-resistant, making it a better option to work with.

- Glass: Lower laser power must be used to avoid any potential damage or cracking during glass etching. Optimal parameters often include 10-20% power and a slower speed of 100-200 mm/s. The outcome tends to be smooth frosted designs. Using tape or wetting, the paper was shown to help reduce heat marks and present a better overall outcome. The use of rotary attachments is helpful when engraving cylindrical glass objects, since it helps achieve consistency during the engraving process.

- Acrylic: Acrylic is also considered a unique material that can be easily engraved and cut, which makes it quite a popular choice. It can be carefully engraved with medium power settings (20-40%) in conjunction with 300-600 mm/s speeds, resulting in a frosted design on clear acrylic or a polished effect on colored options. Setting the focus appropriate will guarantee sharp engraving with minimal residue.

- Stone: The engraving of stone surfaces such as granite, marble or slate requires more powerful lasers to etch into the dense material. Granite engraving typically involves 70-100% power with deep engraving speeds of 50-100 mm/s. Marbles are best known for their contrast; therefore, they are great for decorative plaque and sign-making. Stone does not burn but may need to be cleaned post engraving to remove the excess dust.

How can I start a successful laser engraving business?

Success in starting a laser engraving business is dependent on proper planning, having the right components, and implementing marketing strategies. Consider who your prospective clients would be and what trends your business will focus on, such as unique gift items, labels, or even industrial parts. Purchase a quality laser engraving machine that fits your intended usage and niche market. Understanding the intricacies of laser engraving, such as setting materials, servicing machines, and how to operate software, is essential to achieve optimum quality. In addition, be sure to space and arrange the working areas systematically in order to promote safety, and efficiency. The last step is to create a business website and social media accounts to make your work visible, accept orders, and respond to clients promptly. Ultimately, effective service delivery and business growth comes with setting proper policies and concentrating on the level of customization and craftsmanship of the products.

New equipment needed to start a laser cutting business

For a laser cutting business to be successful, multiple components are required. Investing in an exhaust system that effectively gets rid of smoke and debris is highly important for productivity and protecting the equipment, so a powerful ehaust system is critical. Excellent CAD software should also be utilized for design purposes, and it is vital to have an assortment of materials such as wood, acrylic, and various metals in stock to meet customer needs. Monitoring goggles and gloves to ensure protection during the tasks are also beneficial, along with tools to assist in regular maintenance to preserve the machine’s health. Lastly, one of the first and most essential components is high-quality cutters, whether it is CO2, fiber, or diode laser systems.

Products laser cut for business purposes

Custom-made laser cut products have a profitable range of new opportunities. There is an apparent demand for items such as wooden coasters, engraved signs, and wall art. Jewelry such as earrings, necklaces, and bracelets made from metal or acrylic are also very popular as they can be easily customized. Corporate gifts is another economically beneficial category, where many businesses look for customized branded items such as plaques, award engravings, or even promotional goods. Due to the precision and beauty that laser cut provides these products greatly appeal to a wide audience.

Promotion tips for your laser engraving venture

To better market your laser engraving venture, first focus on increasing your online visibility. Building a professional website to showcase the portfolio in the form of pictures and well-crafted descriptions will allow potential clients to see your laser engraving prowess. Make sure to include appropriate words and meta descriptions for better SEO (Search Engine Optimization) results, and ensure the site is designed in a mobile-friendly manner. These tips help your website get more attention through organic searches.

Social media marketing is yet another essential strategy. Instagram and Pinterest, for example, are great for showcasing visually appealing items, like laser-cut works. To build visibility, regularly post engaging videos that show current work, client testimonials, and instances of products in use. You can improve visibility even more through influencer marketing or giveaways to draw in new clientele.

Finally, consider having promotional items produced for local businesses or offering competitive priced custom work. Attend trade shows, craft fairs, and community events to promote your custom offerings and build relationships with potential customers. Also, consider launching PPC advertising campaigns to generate targeted leads looking for niche corporate gifts or branded items.

What are some creative laser cutter project ideas for beginners?

Personalized keychains, coasters, and necklaces are great beginner projects ideal for quenching one’s thirst for creativity. The fact that they can be custom made makes these projects highly engaging. Coasters can be achieved through inscribing an art or pattern on wood or acrylic, while necklaces such as pendants or keychain-shaped jewelry can easily involve one’s initials or simple designs. It also allows one to hone their engraving skills on various materials. Finally, engraved signs or plaques designed as nameplates put an individual’s creativity to the test and are a great way to practice text-based designs. Every one of these projects is a fantastic way to understand the different ways in which one can harness laser cutting technology.

Basic engravings of laser cut designs for home decor.

Basic engravings of laser cut designs for home decor can range from wall ART items to space utilization items and other space creative pieces. Some of the laser cut and engraved products include wall ART in the form of laser cut panels with geometric art designs to adjust with the spaces interior. More accommodating space is in photo frames with intricate designs and engravings where the person’s picture is meant to be inserted. Coasters, clocks, and key holders showcase the synergy of utility and beauty in laser cutting. Another creative idea is to use lampshades on a desk or table to create ambient lighting. All these projects have carved beauty to placed items while serving their purpose.

Memorable gifts created using laser engraving.

Engraving technology enables me to design authentically personalized gifts which can not only be unique but incredibly memorable. Be it wooden cutting boards, stainless steel tumblers, leather journals, or even customized jewelry, this technology allows for bespoke designs and text to be incorporated into almost any material. Each offer can be adjusted for the individual whether that is adding meaningful sayings like initials and bespoke patterns, the potential is limitless. Encompassing great functionality alongside deep engravings makes laser engraving perfect for any item on any occasion.

Projects involving laser cut jewelry for novices

The jewelry projects that use laser cutting for newbies serve as a practical introduction into the world of laser cutting as it requires planning and creativity. Small shapes such as geometric earrings, minimalist pendants, and tiny charms are effective introductory designs. Novices may use inexpensive and easy-to-cut materials like acrylic, wood, or leather. There are a wide range of ready templates with personalization options available for these projects. The most basic steps involve finding the correct material thickness, setting the machine for clear cuts, and other simple designs. These designs are ideal to improve one’s proficiency in the craft while producing attractive wearable artifacts.

How can I improve my laser engraving skills and techniques?

Improving laser engraving skills is done by practicing, researching, and optimizing the tools. Start with learning the features, settings, and maintenance of the machine as well as how to operate it. Test different materials at various power and speed levels to determine their reaction and adjust the output to suit them. Set the machine for the necessary precision setting and test on scrap materials first. Leveraging software also works, so make sure you can use a vector design program proficiently. Besides, other engravers operate online communities and forums, which can be helpful. To summarize, keep at it; you will improve at laser engraving with every new lesson.

Mastering vector designs for laser cutting

A certain level of proficiency is required for mastering vector designs for laser cutting especially in developing designs that would fit into the CNC laser cutter’s LaserWorks software. The first step is to make sure that your designs are accurately represented in vector format, since this is essential for the machine to interpret the cutting paths correctly. Adobe Illustrator, CorelDRAW, and even free programs like Inkscape are popular for these types of designs. When designing, use lines with a width of 0.01 mm and less to capture all details ensuring you mark cuts and engraves using different line colors. Also, make sure that your drawings’ DPI and resolution settings correspond to those of your laser cutter, typically between 250 and 1200 DPI depending on the material and level of detail required.

Avoid intricate designs that could needlessly dawdle or complicate the machine’s production timeframe. Rather, focus on precision and simplicity during the design phase. Set accurate kerf compensation settings to accommodate the laser beam width as it depends on the material’s characteristics and laser specifications, ranging from 0.1mm to 0.2mm. Optimization of your laser cutting projects, including efficiency and laser cutting precision, can be achieved by including these parameters and repetitively designing and iteratively testing them.

Tips for achieving precise engravings on various materials

Consider the material’s properties being engraved and how it reacts to the laser in use in terms of adjustment. Wood requires moderate power settings and increased speed to achieve clean engravings without excessively burning. Birch plywood works well with a power setting of 30 to 50% and speed settings of 300 to 500 mm/s depending on laser wattage. When carving acrylic, people recommend using higher power levels alongside lower speeds as they produce smoother polished engravings. More often than not, 60% power with 200 mm/s for smooth, clear acrylic works perfectly.

Accurate engraving is achieved through the application of high speed and low power to cover materials such as anodized aluminum. This is accomplished at speeds of 800-1000 mm/s and powers of 10-20% to ensure coating ablation without damaging the underlying substrate. For glass, which easily breaks under excessive temperature, a lower power level of 20-30% and slower speed ranging from 100-200 mm/s are a must. Masking tape or dampened paper towels can be applied to prevent chipping or cracking.

Always remember to perform small test scans for nonconventional materials to determine the optimum settings. Make sure the laser’s primary focus is set correctly for the material’s surface since that would greatly affect engraving quality. Also, ensure that the lens and mirrors are clean so that the intensity of the laser beam remains constant to avoid compromising the depth and uniformity of the engraving.

Complex and subjective designs with details: New laser cutting technologies

Low and high quality intricate designs differ in detail, which is needed to ensure precision while making adjustments. Consider using a focus lens that is fine in nature, since spot sizes are critical in producing necessary details. To improve the quality of the cuts, reduce laser power and simultaneously increase the rate at which the laser is moved over the workpiece. The choice of the laser’s material is also crucial. Low-quality materials can burn or distort, unlike high-quality thin materials. Designs that consist of intricate small corners and compact patterns can be executed simply by using a smaller kerf setting, which increases the machine calibration settings. To eliminate or reduce the cuts that are not necessary, use vector path optimization software. A proactive approach to maintenance is required. Clean the lenses and ensure that all machine parts are perfectly aligned to improve precision as soon as possible.

What are the laser cutter projects to try?

With the help of laser cutters, one can design and implement many complex and simple projects, as they are very versatile. You can cut and engrave wooden, acrylic, and metal parts for earrings, necklaces, and bracelets, which can be individually designed. Customized wall art, coasters, and even engraved cutting boards make popular choices for home decoration as well. Furthermore, other projects demonstrate the application of laser cutting, such as assembling furniture and prototype models to hone the precision of the cutting technology or even advanced custom organizers. These projects’ style and functional requirements vary depending on the material used.

Creative Ways To Arrange Your House With Laser Cut Accessories

Space-saving storage and decor pieces that are custom made for home organization issues can be crafted ideally using laser cutting. Modular desk organizers and drawer dividers provide a unique, stylish and accurate way to ensure precise space allocation. Wall-mounted organizers for keys or mail made of acrylic or wood can be used to save space in a room while keeping it stylish. Apart from that, small laser-cut accessories can be designed to help organize cluttered spaces. With the help of laser cutting, one is able to enhance the order of a space while saving it.

Distinctive, laser engraved art, and wall decor projects

With the use of a laser, it is possible to create highly specialized art and wall decor. Laser carving is fundamental for custom engravings and other elaborate wood, glass, and even metal designs. Rustic cabins can use engraved wooden panels as wall decorations which will blend with the interior. On the other hand, acrylics can be used as furniture to introduce a sleek and modern look. Other than nameplates, family names, vital sayings, and even abstract art can be engraved to give the decor and the room a personal touch. Artworks created through laser engraving transform basic materials into captivating long-lasting decor elements, combining precision with artistic expression.

Innovative laser cut-based creations for day-to-day activities

- Coasters

Coasters cut using a laser serve as good decor pieces while protecting furniture from stains. They can be personalized and crafted using cork, wood, or acrylic. With the addition of intricate designs, monograms, or thematic patterns, the laser-cut coasters serve their primary purpose as decor while making a personal statement.

- Organizer Trays

Trays cut through a laser are very useful as they store items while being within arm’s reach. Their precise craftsmanship ensures a snug fit when using the organizer trays to store electronics, stationery, or any other personal accessories that can be placed in the compartments.

- Key Holders

A key holder can be designed from either wood or metal as a designer item with both aesthetic value. Alongside decorative elements such as engraved patterns, geometric motifs, and names, laser-cut key holders often feature hooks or slots for keys.

- Bookmarks

Bookmarks cut using a laser cater style and function. As they can be fashioned out of thin acrylic or wood, bookmarks can posses detailed engravings, cutouts, decorative edges, and even captivating patterns that transform them into delightful gifts or cherished collectibles.

- Phone Stands

Phone holders provide a stable embrace for devices while maintaining an optimal watching angle. Phone stands are often designed using acrylic or plywood, which keeps them lightweight and portable. For increased customization, stands can be adjusted to suit varying sizes and designs.

- Jewelry Holders

Necklaces, rings, and earrings can be elegantly organized with intricate silhouettes and frames that possess detailed cutouts. Laser-cut jewelry holders are built for aesthetic appeal and serve as decor-enhancing functionality.

- Desk Accessories

The application of laser cutting makes it easy to produce desk accessories such as pen holders, cable organizers, and monitor stands. Sleek design meets high efficiency and sturdy construction, resulting in a polished workspace that emanates finesse.

- Personal Kitchen Aggregrates

Items for everyday use in the kitchen such as trivets, cutting boards, and utensil racks are laser cut to precision. The intricate engravings and patterns transform these tools into functional pieces of art.

How do I choose the right laser cutter for my projects?

Selecting a laser cutter for your projects requires determining your needs and checking if the machine can accomplish them. First, consider the types and thicknesses of materials you intend to work with, keeping in mind not all laser cutters are made for every material. Also, consider the machine’s wattage; greater power means thicker materials can be cut and processed faster. In addition, evaluate the work area size to ensure it can fit the largest project you may need to work on. Look for a machine with good user software, precision, and other tools because these affect workflow greatly. Additionally, consider what amount of maintenance is needed, what sort of safety certifications are required, and what the overall cost will be, including upgrades or accessories that may be needed.

Evaluating Laser Cutters for Desktop Use by Small Enterprises

While evaluating laser cutters for desktop use by small enterprises, one has to look closely to aspects such as quality, the user’s experience, and cost. An all-in-one unit powerful enough to both engrave and cut wood, acrylic, or leather is best for multitasking needs. Furthermore, having user-friendly software and low-maintenance CAD molding makes everyday tasks easier. Cost effectiveness is essential, yet the product must also withstand the test of time, thus, yielding value. From an overall perspective, having innovative safety measures, upgradeable technology, and other non-adaptive peripherals increases the worth and reliability of the machines, transforming them into powerful instruments for any professional.

Advantages of Features with Good Laser Engraver

- Wattage and Power Supply Laser

The capacity of a laser engraver to cut or etch various materials is determined by the amount of power it uses. Higher-wattage lasers can cut and engrave thicker and harder materials, while lower-wattage systems work best for light-duty engraving on softer materials.

- Engraving Precision and Resolution

Engraving accuracy relies on the machine’s precision and resolution. The advanced engraving appendage is suitable for intricate details and professional-grade designs, which is why it resolves at a higher DPI than most of the finer, more elaborate models.

- Compatibility with Materials

A particular laser engraver should be able to etch a range of materials like wood, acrylic, fabric, glass, metal, and even leather. This ensures wide applications and uses in creative or commercial pursuits.

- Integration with Other Software

Non-tech-savvy individuals should have easier software to operate, as product design increases their workload. The engraver should also be able to work with files of various formats, unlock advanced functions, and integrate with other software for efficient workflow.

- Additional Protective Features

Safety is an ever-present concern when it comes to engraving. Look for closed designs that can limit laser exposure, automatic shutoff systems in case of malfunction, and comprehensive warning systems that meet safety standards.

- Size of Work Area

The maximum dimensions of the projects being handled can be defined within the specified range of working area sizes. It is best to check that the engraver has a bed of adequate size to accommodate a selected variety of materials and project scales.

- Maintenance Made Easier

A machine with components placed and designed modularly is easy to service. This means that cleaning, replacing parts, and general servicing are effortless. Less downtime and good performance throughout the machine’s lifespan result.

Low cost choices for novices in laser cutting

At the outset, beginners venturing into laser cutting should look for low cost equipment that has small working areas and is inexpensive yet powerful enough for basic engraving and cutting. Supporting popular materials like wood, acrylic, and leather, these machines should also come with easy-to-use user interfaces. In addition, built-in safety features like enclosed designs and emergency power off functions should be prioritized for safe use at home or in a workshop environment. Besides ergonomics, these machines should easy to maintain and operate and have parts that can be easily replaced to increase the device’s lifespan.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are some popular laser cutter and engraver projects by material?

A: Popular laser cutter and engraver projects vary by material. For wood, consider creating custom wooden signs, intricate jewelry boxes, or personalized cutting boards. With acrylic, you can make LED-lit signs, decorative coasters, or unique jewelry pieces. For leather, try engraving custom wallets or bookmarks. Metal projects include personalized dog tags or business card holders. Each material offers unique possibilities for creative and marketable items.

Q: What are the laser cutter and engraver projects for beginners?

A: Some top laser cutter and engraver projects for beginners include: personalized phone cases, custom keychains, engraved picture frames, wooden coasters, acrylic signage, leather bookmarks, engraved cutting boards, wooden jigsaw puzzles, customized notebooks, decorative wall clocks, laser cut greeting cards, personalized pet tags, wooden ornaments, engraved wine glasses, custom laptop skins, wooden map art, acrylic jewelry, personalized pencil holders, and laser cut business cards. These projects allow you to explore various materials and techniques while creating practical and marketable items.

Q: What materials are suitable for laser cutters and engravers?

A: Laser cutters and engravers work well with a variety of materials. The most common include wood (such as plywood, MDF, and hardwoods), acrylic, leather, paper, cardboard, fabric, and certain plastics. Some machines can also engrave on glass, stone, and certain metals. However, it’s important to note that not all materials are safe for laser cutting, and some may require specific types of laser technology. Always check your machine’s specifications and safety guidelines before attempting to cut or engrave a new material.

Q: How can I find and use project files for my laser cutter and engraver?

A: To find project files for your laser cutter and engraver, you can explore online marketplaces like Etsy, creative communities such as Thingiverse, or dedicated laser cutting websites. Many of these platforms offer both free and paid files in formats compatible with laser cutting software. You can also create your own designs using vector graphics software like Adobe Illustrator or CorelDRAW. When using project files, ensure they’re compatible with your machine and software, and always respect copyright and licensing agreements.

Q: What are some amazing laser cutter projects that can make a statement?

A: Some amazing laser cutter projects that make a statement include: large-scale 3D assembled sculptures, intricate architectural models, custom-designed room dividers, detailed topographical maps, personalized multi-layered wall art, illuminated shadow boxes, engraved mirrors with complex patterns, and custom-designed furniture pieces. These projects showcase the precision of laser technology and allow you to create unique, eye-catching items that can serve as conversation starters or statement pieces in any space.

Q: How can I use a laser cutter and engraver to create great items to sell?

A: To create great items to sell with your laser cutter and engraver, focus on products that combine functionality with personalization. Popular options include custom-engraved cutting boards, personalized jewelry, unique home decor items, custom signage for businesses, engraved leather goods, and personalized gift items. The key is to identify a niche market, create high-quality products, and offer customization options. Utilize the precision of laser engraving to add intricate designs, logos, or personalized text to make your products stand out in the market.

Q: What are some tips for successful laser cut and engraved logo designs?

A: For successful laser cut and engraved logo designs, keep these tips in mind: Use vector graphics for crisp, scalable results; opt for simple, clean designs that translate well to different materials; consider the material you’ll be engraving on and adjust your design accordingly; test different power and speed settings to achieve the desired depth and contrast; for wood engraving, use a darker wood or stain for better contrast; for acrylic, consider using a two-tone material for a striking effect. Remember, a well-executed laser cut logo design can be a highly effective branding tool for businesses and products.

Q: How can I improve my skills in laser cutting and engraving?

A: To improve your laser cutting and engraving skills, practice regularly with different materials and project types. Experiment with various power and speed settings to understand how they affect different materials. Learn to use design software proficiently to create and modify project files. Join online communities or local makerspaces to share ideas and learn from others. Stay updated on new techniques and technologies in the field. Consider taking online courses or workshops specifically focused on laser cutting and engraving. Remember, mastery comes with experience, so don’t be afraid to try new and challenging projects.