The introduction of embroidery machines improved the situation for professionals and amateurs due to the combination of precision and efficiency. Such tasks as sewing large area projects usually require attention as they demand appliances that provide professional outcomes. In this blog, we will try to explain how proper machines for intensive sewing work should be viewed so that when you have an opportunity to engage in creative activities, it won’t matter what comes your way since you will be able to accomplish any tasks. We will look at some of the outstanding models developed with a combination of expansive embroidery fields and technology, which will meet the needs of anyone wanting to push their creative borders. We will try to present this category of customers with the necessary purchasing information so that even with minimal experience and enormous ambitions, it will not be challenging to select a machine that suits them best. Start your path into the world of embroidery confident that with our accessories, you won’t need anything else.

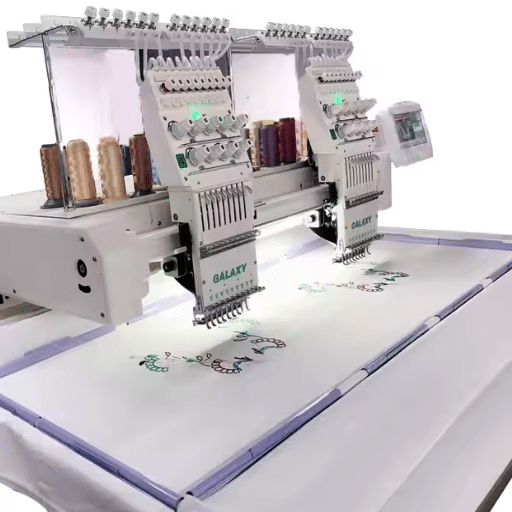

What is a Large Embroidery Machine?

A large embroidery machine is made for big and complex designs as it offers a large area of embroidery compared to most other machines. These machines are also technologically enhanced and have more stitches, which means sophisticated work can be done in more significant areas. This makes them ideal for makers who often create bulk clothing, large home furnishings, oversized bedspreads, and other large items. In addition to these improved capabilities, many of these machines have multiple designs and can upload custom designs for business or personal crafting projects.

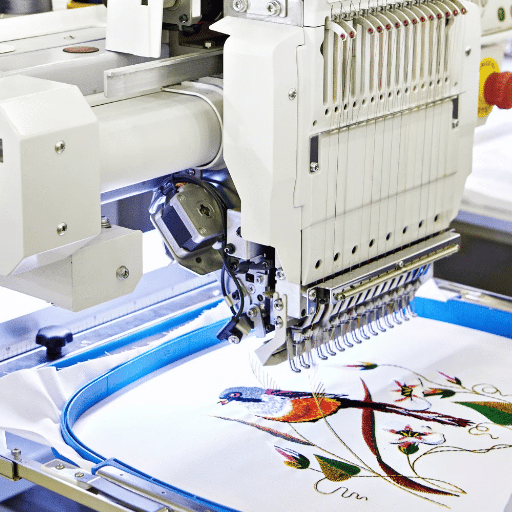

Understanding the Embroidery Area

The size of the design that a sewing machine can reach is referred to as the embroidery area or embroidery field, while the size of the design that the machine can stitch is known as compilation. Determining this when shopping for a machine is vital, particularly in what area of creativity you can achieve. It is customary for this measurement to be in inches or millimeters; the more significant the polyester embroidery area, the more and more extensive the designs can be created with less likelihood of re-hooping and realignment, techniques that are both delicate and take up hands. Over the past decade or so, high-tech embroidery machines have customarily been supplied with all sizes of hoops. Sizes can range from a small magpie patch to a quilting logomania. In addition, types of technology include cross-hair retracting and auto hoopers, which have scalp effects and fashion concepts. To this end, besides the models, an assessment of ease of use in its interface and compatibility with core software will widen the design ranges you can work with by simplifying the work of uploading or changing designs.

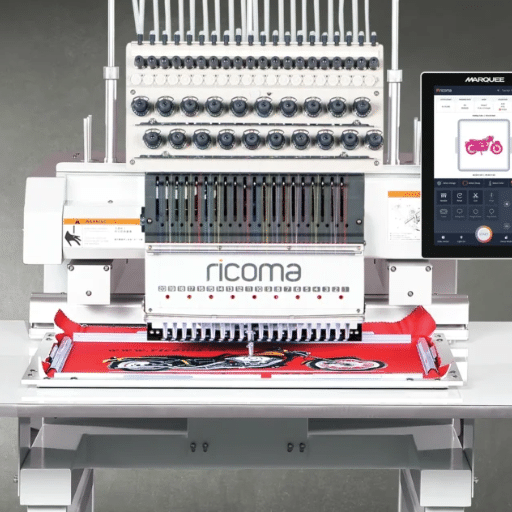

Features of Commercial Embroidery Machines

When looking at the features of commercial embroidery machines, I have seen that they usually have high speed and multi-needles, which help ease the work at an industry level. These overtime type embroidery machines also have different types of stitching to accommodate intricate designs and vital mechanical components to assist precise and complex stitching as needed. In addition، as I saw, many of the best-rated models extensively built customer control panels and programs, which are crucial to design and control the designs. Other options, such as USB or wi-fi, are also great, allowing me to send detailed patterns from my PC to the machine. Collectively, these factors make commercial embroidery machines a must-have for one who is serious about shooting up their productivity while providing delicate craftwork.

The Role of Hoop Size in Large Embroidery

In big embroidery works, the size of the hoop determines if the work is able or challenging to be done. The bigger the hoops, the larger the area to be embroidered on, which can be done without moving the material around, saving time and effort when dealing with such a project. Selecting the hoop size corresponding to the design and fabric is also necessary. For the specification, one has to be mindful of the machine’s maximum embroidery size, which is between 200mm x 300mm and 400mm x 600mm for most of the larger models, to ensure that hoop size remains within that limit. Furthermore, adjustable hoop tension is necessary, which assists in holding the fabric in place while stitching to avoid puckering or distortion of the embroidery pattern. Adherence to these technical parameters in selecting the hooper’s size ensures smooth running of the machines and super quality works in completed large embroidery projects.

How to Choose the Right Hoop Embroidery Machine

Several factors must be carefully considered when selecting a hoop embroidery machine for your projects. First, determine the machine’s maximum embroidering area and check that it coincides with the average size of the hoops that will be used. This is important so that the dimensions of your designs are able to fit into the embroidery area without the need to move the fabric around often. Then, check the machine’s adjustable hoop tension settings. This will affect the stability of the fabric during the embroidery process and the quality of the end product. Last, check the communication aspects of the machine and how it works to avoid selecting a machine that impedes your working methods. This makes it easy to transfer designs and operate the machine. Thus, considering all such factors, one can select an effective hoop embroidery machine that meets your production needs.

Evaluating Built-in Embroidery Designs

When assessing built-in embroidery designs, it is wise to seek machines with a fair number of designs suitable for multiple projects. According to statistics from top websites, sewing machines with extensive libraries consisting of hundreds and even thousands of designs are more effective. Moreover, it is a significant advantage if the machine enables easy alterations such as changing the scale, turning it, or adding those shifts to other designs as necessary for the project. Furthermore, the built-in designs should be well-defined and have multiple colors to make the outcome look neat and impressive. Finally, consider whether the machine is upgradable and allows you to load the new designs by USB connection or Wi-Fi; this way, you won’t get limited in your future work. All these considerations allow one to quickly choose a machine with built-in designs appropriate for future work.

Benefits of a Computerized Embroidery Machine

I don’t know what I would have done without choosing a computerized embroidery machine, as it has made the activity much more creative and easier. For instance, the machine does the hard work of doing the intricate detailing and precise levels of each pattern, which would be time-consuming if done manually. Furthermore, they come with rich libraries and modification options, allowing me to undertake different projects and expanding possibilities for creativity. In addition, the machines have simple interfaces and many connectivity ports, enabling the transfer of new and updated designs with ease. Overall, I have been able to increase the amount of time I spend on projects and the quality of my embroidery.

Understanding Embroidery Speed and Needle Options

There is always a trade-off between speed and precision, so one must consider embroidery speed, stitches per minute (SPM), and how many needles suit the design. The average speed of a machine tumbles within the range of 400 SPM to 1000 SPM. So, for example, if a shape is complex, one should turn down the speed for maybe a scroll for higher levels of detail to be visible, whereas a more straightforward shape wouldn’t need that much refinement and can be done with higher speeds for higher levels of efficiency.

There are different kinds of needles for various tasks and fabrics. First of all, an embroidery needle is between the range of 75/11 and 90/14, with the needle size changing due to the requirements that help determine the fine thread’s thickness; the more significant the needle, the thicker the thread for thicker and heavier fabrics, the eye of the needle should be big enough not to let it break. The tip should suit the fabric used and be a ballpoint for knits. In contrast, a sharp point for woven fabrics is that the quality of your work directly correlates with the appropriate needle that works when combined with the required design speed, which overall provides a professional aesthetic.

What Are the Advantages of a Brother Embroidery Machine?

Brother embroidery machines are well known for their flexibility and simplicity. One of the main advantages of technology is the computerized systems that enable practitioners to carry out precision and simple operations relating to intricate designs. They often come equipped with pre-designed patterns and the option to upload designs through a USB flash drive, encouraging imagination. Also, Brother machines are highly dependable and sturdy, making them worthwhile investments whether you are a casual or a professional embroiderer. In addition, they manufacture models designed for different levels of experience and various price ranges so that anyone looking to make embroidery items can afford them. Moreover, Brother machines have an easy operational structure and efficient customer services, which make the interface more enjoyable and offer a great learning experience and problem-solving.

Exploring Brother Embroidery Features

The Brother embroidery machines have various features which increase the capability and usability of their users. First of all, there is a whole range of models that have significant and clear LCD touch screens, which edits designs pretty easy since one can zoom, rotate, and mirror designs easily. Another noteworthy feature is the automatic needle threading system, which also helps reduce setup time and increase productivity. In addition, these machines support several design formats, including the commonly used PES format, which provides compatibility with many design application tools. Wifi connectivity in some of the models enables the user to send designs from their smart devices directly to the machine, hence assisting the user in the creative process. Also, the broad spectrum of stitches, such as utility, decorative, alphabet, and many others, widens development opportunities. Brother machines typically have a wide variety of sewing speeds and sewing feet, making them suitable for a wide range of projects. Finally, since the embroidery area size varies between the models, the user can choose the models based on the sizes of the projects he/she would like to work on.

Comparing Single-Needle vs. Multi-Needle Options

The availability of both single and multi-need embroidery machines allows users to exercise the use of whichever is most convenient for them. This is according to research gathered from various embroidery experts. A single embroidery needle machine is simple to use and ideal for beginners since it is easy to operate; this is true given that they are designed to operate like standard sewing machines. However, based on the information I have come across regarding multi-needle machines, they tend to be more efficient because they can perform more operations concurrently, as they usually come with several threads. While these machines may be costly, they are best suited for professionally managed centers or businesses. Another added advantage of multi-needle machines is their broader work area, allowing users to expand their creativity. The decision on whether to purchase a single-needle or a multi-needle machine rests on their needs and the resources available at their disposal.

Integration with Embroidery Software

When embroidery machinery works in conjunction with software, a new realm of features opens up for the user, enhancing both the design process and the level of accuracy achieved. In this regard, it is recommended that the embroidery machine be capable of opening signature files.PES.DST or.EXP is meant to alleviate potential concerns about compatibility software. This capability enables users to obtain and modify a design without too much effort. Numerous solutions in embroidery software have been designed to include digitizing images into embroiderable designs and so much more. It is now easy for users to adjust design parameters using software tools that allow them to set specifications, stitch density, thread color variations, and visual angles of the patterns. In addition, some advanced applications include built-in tutorials and design libraries to assist novices in learning the intricacies of embroidery design processes. As a final note, verify that the sewing machine has sufficient memory space that meets the requirements of the software embroidered on it and that the connectivity options are suitable for the machine’s intended applications.

How to Master Sewing and Embroidery with a Large Embroidery Area?

Acquiring knowledge about the unique features of the embroidery machines is of utmost importance before learning how to sew or embroider, and that’s because you can make appropriate use of these features. Be sure to practice how to position and secure your fabric in the hoop because failing to do this might cause a shift, leading to the alteration of the designed patterns upon stitching out. Once you are comfortable with the embroidery machine, start opening and working with the embroidering software to create and alter designs suitable for larger areas. Enhance your learning by utilizing various software tutorials and resources, allowing you to produce desired and unique output. Concentrate on the appropriate materials and stabilizers, which help hold the fabric in place while embroidering. Always check and conduct a service on your embroidery machine so that it can function with great precision. Lastly, consistent practice is all it takes; over time, you will gain the skills that make working on more intricate designs much easier.

Combining Sewing Machine and Embroidery Machine Capabilities

It is possible to broaden the scope of your creativity by integrating a sewing machine and an embroidery machine. The sewing and embroidery machine makes it easy to switch from one task to another, such as switching from sewing moderate complexity patterns to sewing complicated ones. Your machine can have excellent characteristics, including interchangeable presser feet for various stitches and a big embroidery area to create comprehensive designs. Muscle memory, trained on the motor structure of machine embroidery, suffices; it is essential to learn how to thread and set tension for both sewing and embroidery. You can digitize the machine to lie dormant or use some internal embroidery design packages present in the marketing area, which will help you develop a unique model, but remember to save designs in your files so your machine can recognize them as PES or DST copies. Regular cleaning and lubrication are just in maintenance to avoid trouble in sewing and embroidery. With this machine, you can choose different stitches and hoop sizes, try something new, and practice will boost your skills and the machine’s capabilities, bringing you satisfying end products.

Utilizing Touch Screen Technology for Design Precision

Screen touch features embedded in modern sewing and embroidery machines make the design easy and accurate. I can instruct the machine to bring up the options I want with a tap or a swipe because the interface is user-friendly and easy to navigate. One of the most outstanding features is viewing my designs on the screen before stitching, as this makes work easy and cuts on errors. In most cases, however, viewing the screen also allows features such as re-everting, repositioning, and stitching to make the whole process more straightforward. Hence, I can design elaborate and upscale personalized designs with more ease and trust with these features.

Exploring Automatic Needle Features

Automatic needle features and built-in sewing and embroidery machines save time and reduce manual changes, improving user experience. Such features often include automatic threading of the needle, which allows setting up with only the need to thread the needle, and automatic positioning of the needle’s beginning and end locations, in which the machine can freely adjust the starting and stopping locations of the needle. Automatic needle features equipped machines may have a cutting tool, which cuts threads after the sequence ends. Technical parameters related to these features often include speed adjustment, programmable NPM (Needles Per Minute, usually 600 – 1000), and stitch width and length (width – 0 to 7mm, length – 0.5 to 4mm). In sewing and embroidery, automatic needle features contribute to achieving the desired precision and getting the job done much faster.

What are the Common Challenges with Machine Embroidery?

Machine embroidery can be intrusive even though it has many advantages. Thread breakage is one of the most severe problems. This is a consequence of excessive or insufficient tension and inferior thread. Another concern is puckering, which results when the fabric pulls or wrinkles due to substandard backing or hooping problems. Moreover, some machines are also afflicted with design alignment problems, especially with more complex designs where placement has to be accurate. Another hindrance for novice embroiderers is the plethora of learning needed for complicated embroidery machines with so many features to comprehend. Lastly, effective machine operation and durability require time and effort because, as with any other technology, one must perform maintenance and seek solutions to the problems. If people know those challenges, they can deal with them effectively.

Dealing with Embroidery Thread Issues

To adequately address embroidery thread problems, it is vital to consider the common causes and solutions pointed out by experts. For example, about thread breakage, some might suggest that one of the ways to overcome this problem is to ensure that the tension setting is adequately adjusted relative to the kind and weight of the thread being used. Moreover, the thread being used must be of high quality; otherwise, one would experience constant snags and breaks on their machine. Most puckering problems in the fabric can arise due to inappropriate or inadequate stabilization, so it is necessary to use the correct type and weight of stabilizer to keep the fabric from getting distorted. Concerned resources have also said that proper lubrication, frequent changing of the needle, and using the appropriate needle reduce the fraying of threads, enabling smooth embroidery processes. One should conduct proper maintenance on the machine, such as cleaning the bobbin area and removing lint, since doing that will avoid problems. When these strategies are made concerning expert recommendations, it is possible to reduce threading issues immensely and elevate the effectiveness of one’s embroidery projects.

Maintaining Your Computerized Sewing and Embroidery Machine

I possess a computerized sewing and embroidery machine, which, like all machines, would require several malpractices to make it function effectively and also to make it last longer. First of all, I tend to the problem of malfunctions by ensuring that the machine is cleaned regularly – in most cases, the bobbin area accumulates dust and lint, which might eventually lead to the sewing and embroidery machine malfunctions. Furthermore, per the guidelines given by a concerned authority, I also oil the specific parts of the machine. Consequently, I make it a point to periodically use the update function and connect the system to the internet so that up-to-date software features that fix problems are readily available. Another crucial element I would consider is the use of specific threads and needles, which are regarded as high quality for the particular model of my machine, as the threads and needles minimize damage. Finally, I tend to have regular professional servicing, allowing the machine to be tweaked to its most optimum settings. By doing the listed points, I could keep the quality and performance of my machine constant.

Troubleshooting Large Design Complications

The first thing I do while diagnosing complex design problems is to ensure that the software on my machine is updated, as it resolves many issues associated with newer design formats. I also ascertain whether the hoop size corresponds to the design since a hoop that is too small may cause some mistakes. Modifying the stabilization technique and restating that all materials employed are consistent with my design is essential. The kind of needle and thread is evaluated as suitable for the fabric according to specialists’ prescriptions. Finally, I carefully review the design file to detect mistakes and check online forums or literature for some design problems I foresee. Following such steps, I can troubleshoot and fix even more complex design problems.

References

Frequently Asked Questions (FAQ)

Q: What should I consider when choosing an embroidery machine for large-area creations?

A: When selecting an embroidery machine for large-area creations, consider the size of the embroidery hoop, its capability to handle extra-large designs, and whether it is a computerized machine model. These features help ensure precision and efficiency in your embroidery projects.

Q: How does a single-needle embroidery machine differ from a multi-needle one?

A: A single-needle embroidery machine typically features one embroidery foot and is suitable for individual projects, making it ideal for home use. In contrast, multi-needle machines can handle multiple threads simultaneously, which is beneficial for complex designs and industrial embroidery tasks.

Q: Are there embroidery machines designed explicitly for hat embroidery?

A: Yes, hat embroidery machines are available and specifically designed to accommodate hats’ curved surfaces. These machines often have specialized hoops and attachments to ensure precise hat stitching.

Q: What advantages do machine computerized embroidery models offer?

A: Machine-computerized embroidery models provide greater precision and efficiency, allowing for intricate designs with minimal manual input. They often come with built-in embroidery patterns and can be updated with new designs, making them highly versatile for various projects.

Q: Can I use a sewing and quilting machine for embroidery purposes?

A: Yes, many sewing and quilting machines are also equipped for embroidery. These machines offer the flexibility to switch between sewing, quilting, and embroidery, making them versatile tools for creative projects.

Q: What are the benefits of using the giant hoop embroidery machines?

A: The largest hoop embroidery machines allow larger designs to be completed in a single hoop, reducing the need for re-hooping and ensuring continuous design patterns. This is especially beneficial for large-area creations and complex designs.

Q: How important is an automatic needle threader in an embroidery machine?

A: An automatic needle threader is a significant convenience feature in an embroidery machine. It simplifies the threading process and reduces strain on the eyes, allowing for a smoother start to your embroidery journey.

Q: What makes a high-end embroidery machine suitable for professional use?

A: High-end embroidery machines have features such as extensive built-in design libraries, the capability to handle large and complex designs and robust construction. These features make them suitable for professional use and high-volume production.

Q: Are there embroidery machines that come with specific features for beginners?

A: Yes, some embroidery machines are designed with beginners in mind. They offer user-friendly interfaces, step-by-step guides, and automatic functions like the needle threader, which help new users start their embroidery journey with ease.

Q: What is the benefit of using a single-head embroidery machine?

A: A single-head embroidery machine is ideal for producing one design at a time, making it suitable for smaller businesses or hobbyists who focus on custom, personalized items. It offers precise control over the embroidery process.