Considered a craft practice for centuries now, engraving jewelry involves putting a person’s personal touch on a piece of wealth. Introducing modern technology like computer-controlled laser machines has changed the game for engravers as they are far more accurate and adaptable than traditional methods. This article will take a closer look at the effects of laser machines on jewelry engraving while articulating their essential features, other technological benefits, and their uses in contemporary jewelry. Sophisticated designs with incredible detail and flawless repeats are where laser engraving technology outshines, and jewelers are now free to explore new heights of creativity without sacrificing their time or accuracy. This article will explain the filtration of laser engraving machines into the jewelry design industry and the repercussions of eliminating the engraver’s trade, whether you are a professional jeweler, a hobbyist engraver, or just someone keen on the blend of art and science.

What is a jewelry engraving machine and how does it work?

Using advanced techniques, Jewelry engraving machines inscribe specific texts or patterns onto jewelry. Jewelry engraving machines are further categorized into two subgroups, namely laser and mechanical engravers. These machines work with great accuracy and proficiency. Laser engraving machines specifically do not come in direct contact with the jewelry. Instead, they operate with the help of specialized lasers. Detailed grades are inscribed onto jewelry through CAD soft wares, which allow gold, silver, platinum, and non-metal to be ornamented accurately. This form of technology is hugely sophisticated modern-day science.

Understanding laser engraving technology for jewelry

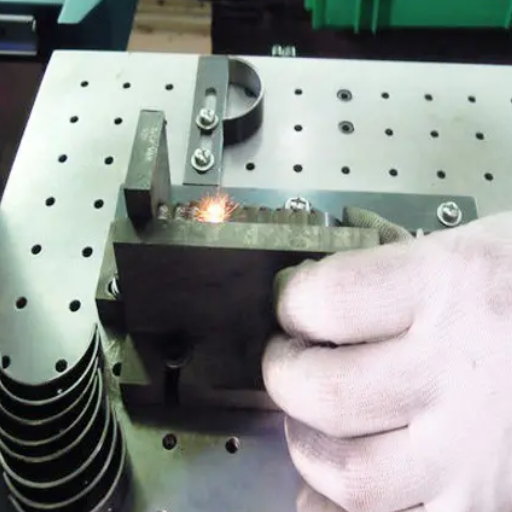

Jewelry engraving uses lasers to vaporize the specific material to mark intricate patterns, exposing the specific fitted area of the jewelry. As with engraved metal surfaces, CAD software is the crucial component that allows any intricate detail to be implemented on time. With no direct contact with the item’s surface, this method is also one of the fastest ways to mark surfaces, which aids in modernizing jewelry craft designs.

The engraving process: From design to finished piece

The laser engraving process starts with a designer using CAD software to create a model. This software is designed with flexibility, enabling the jeweler to precisely place details and adjust other design parameters to the desired dimensions and materials. Once the design is complete, it is uploaded to the laser engraving machine, which employs light focused on a fine beam to vaporize the material with unmatched precision. The machine is set to change the engraving’s intensity, speed, and depth to achieve the best results with gold, silver, non-metal, or whatever else is chosen. Since the entire process is contactless, the risk of damage to delicate pieces is minimal. After engraving, the jewelry is inspected for quality, and the final polish enhances magnificence, making the piece durable, intricate, and customized for use or adornment.

How to choose the right laser engraving machine for jewelry?

Precision, compatibility, and functionality are the most important factors when choosing a laser engraving machine for jewelry. The first stage is to verify that the machine offers fingers, wrists, and fez as much detail as possible since that is important for engraving jewelry. Equally important is the engraving of gold, silver, and other metals since the project may be diverse. Furthermore, try to find upper-side adjustable settings, which control the level of speed and depth for engraving, as that increases the scope of work. Depending on the type and place of work, the machine’s size and mobility could also be significant. Finally, looking for systems that offer software and customer support assistance is best because that facilitates effortless managing and troubleshooting when necessary.

Key features to look for in a jewelry laser engraver

Three primary issues about a jewelry laser engraver tend to capture my attention because of research. To begin with, laser engravers ought to be accurate. The precision of the gadget is essential in the engraving step since jewelry ranges from interweaving to jewelry. Versatility is also critical. Quality assurance means the machine should be able to engrave gold and silver jewelry, stainless steel, and even nonmetals, so the user does not have to be limited to one type of project. Lastly, I value reliability. Enhanced systems with unobtrusive command programs dramatically cut the time spent on the maintenance process. These supportive measures foster improvements in business productivity.

Comparing fiber laser vs. CO2 laser for metal engraving

When comparing fiber and CO2 lasers for metal engraving, the distinguishing features appear to differ in their principles of operation, most valuable applications, and efficiency. Fiber lasers are built into a solid-state structure that incorporates optical fibers containing rare earth elements, thus allowing for greater precision at faster engraving speeds. They effectively engrave metals such as stainless steel, aluminum, and gold. This is because the lasers’ shorter wavelength, approximately 1.06 microns, attains an energy density ideal for intricate designs and deep engravings.

On the other hand, CO2 lasers use a different mechanism, with the energy coming from electrically stimulated gas mixtures that primarily contain carbon dioxide. CO2 lasers have a longer wavelength of 10.6 microns and thus engrave non-metal materials such as wood, plastic, leather, and glass. While CO2 lasers can engrave coated or treated metals, they are notoriously known for lacking fiber lasers’ efficiency and precision, specifically for direct metal engraving.

In terms of cost, fiber lasers require a more significant initial investment. While fiber lasers require more investment, they require less maintenance and have longer useful lives, thus allowing for better long-term value in metal engraving. Ultimately, it all now hinges on application requirements—dedicated metalwork is better done using fiber lasers. At the same time, more general works across a wider variety of materials are best suited for CO2 lasers.

Best laser engravers for different types of jewelry

I would suggest three alternatives for the optimal laser engraver for specialized jewelry creations, keeping essential aspects in mind, such as workmanship, material use, and accuracy. For intricate metal jewelry, a fiber laser engraver like EPILOG Fusion Pro or OMTech 50W provides near-perfect results, as engravers offer a wider range of metal precision capabilities. For softer materials like wood or acrylic used in custom jewelry, the Glowforge Pro CO2 Laser Engraver is enormously versatile compared to non-metal May of wood and acrylic, making it an excellent engraving tool. Finally, the xTool D1 Pro is affordable and best suited for hobbyist jewelers. Each choice fulfills a particular purpose, so optimal results for your approaches are guaranteed.

What are the benefits of using a laser engraving machine for jewelry?

Combining laser engravers into the craftsmanship of jewelry brings many benefits around precision, efficiency, and flexibility. These machines operate with high accuracy, allowing complex designs, text, or patterns to be engraved with minimal error. They can also work with metals, wood, acrylic, and even leather, making them suitable for delicate and custom jewelry. Moreover, laser engraving is a contactless process that eliminates the possibility of damaging delicate materials. The speed and automation of laser engravers contribute to high stock production efficiency, allowing jewelers to work on multiple projects at once while ensuring a high level of quality on each piece. All in all, laser engraving contributes positively to creativity and productivity in jewelry making.

Precision and detail in engraving precious metals

Laser engraving is, without a doubt, the most effective method to achieve precision and detail when engraving gold, silver, platinum, or titanium. It permits the creation of complex designs, a high level of detail, and intricate designs with the numerous engraver machines available today. Using narrow laser beams, engravers can stipple and control the exact depth, texture as well as the clarity of the design. These feats, alongside various others, would be hard to achieve through conventional means. Lasers can engrave delicate stipples or patterns and bold, detailed lettering without harming the material, so they’re perfect for the job. Due to this high level of engraving precision, jewelry is effortless to personalize while still maintaining the conservative value and durability of the metal.

Time-saving advantages over traditional hand engraving

I find laser engraving far more convenient than traditional hand engraving. For a simple engraving that usually takes hours to craft, a laser engraver would take mere minutes without sacrificing quality. In addition, the automated nature of laser technology minimizes the chance of human error and the need to make corrections during the engraving process. A business can significantly benefit from this new technology due to its accuracy, which allows customer satisfaction to happen much faster and more efficiently.

Versatility in engraving various jewelry pieces and materials

The power of laser engraver technology shows incredible versatility for different jewelry objects and materials. Other pieces can be made from or have parts of gold, silver, platinum, stainless steel, titanium, wood, acrylic, or ceramics. This enables engravers and manufacturers to showcase their skill on rings, pendants, and bracelets, as well as on watches and other custom-made items. Moreover, it is the nature of laser technology itself that enables the engraving of fine text or elaborate patterns on a piece, regardless of how hard or soft the material is. The non-contact approach means that fragile, thin metals or delicate heirlooms are not damaged during engraving. Such universal compatibility of different materials and objects makes laser engraving an indispensable tool in today’s jewelry industry.

How to get started with laser engraving jewelry?

As a first step, before commencing with laser engraving any form of jewelry, one must identify the primary purpose of the jewelry in question. In simpler terms, ask yourself what is the fundamental reason the jewelry piece is being created. If it is meant to serve as a gift, determine if the recipient places any significance on the particular piece of jewelry, such as a ring or necklace. Some people may find novelty value in their jewelry, while others may appreciate it aesthetically. Even if the reason for creating a piece of jewelry is ‘for personal use,’ a click or a claim on one’s intricacies in outfit and fashion should be understood. However, setting your priorities right before outlining the process to achieve the best laser engraving jewelry piece is more important. Adhering to the prior conditions will also set parameters of maximum utility value.

Essential tools and accessories for jewelry laser engraving

Whether this is a wedding engraving or a birth date pendant piece, the personalization factor in the work needs deeper understanding in terms of its value. Some people often get obsessed with the engraving or the personalized laser cut features. It is fascinating that while some can grasp the idea immediately and appreciate its value, the same can not be said for all. Such jewelry pieces come packed with a value sculpted out over a significant amount of time. In conclusion, it is vital to appreciate it as a part of added cultures, civilizations, and views. Doing so would allow one to gain newer perspectives on its remarkable value.

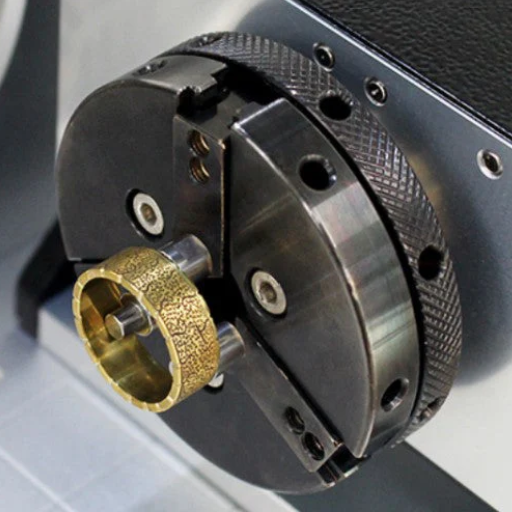

Supporting accessories include a rotary device that allows engraving rings or bracelets with engravings on their curves. Ventilation or fume exhaust systems are needed to remove harmful particles and fumes from the workspace and maintain a clean environment. Additional tools that should be available to ensure the system is efficient and precise include high-end designing software, calibration tools, and cleaning products for the jewelry pieces. Having these tools guarantees safe professional-standard results and operational safety.

Learning the software and design process

To master the software and the design procedure, one must know how to design software like Adobe Illustrator, CorelDRAW, or laser engraving software like LightBurn. I began learning by concentrating on tutorials rather than spending too long on trial-and-error, which allowed me to understand quickly. A working knowledge of vector graphics is necessary because precision engraving machines cut out paths and layers in the image sequentially, so their movement has to be designed in a certain way. I also enhanced my designs for engraving on other materials by testing different file types like SVG or DXF. The most important thing is always to practice and always use online forums when problems arise.

Safety precautions when using a laser engraver

Safety measures while using a laser engraver are essential to avoid injury or damage to the equipment. Firstly, ensure you have the proper personal protective equipment (PPE), such as specialized safety goggles, to protect your eyes from harmful radiation. Additionally, ensure that the engraving workspace is ventilated or has a fume extraction system because toxic fumes and particles can be emitted depending on the engraved material. Lastly, clear the workspace of flammable items, as the laser can start fires.

Inspect the machine regularly for any wear and tear or damage to its components, such as the laser tube, mirrors, or belts. The manufacturer has guidelines for cleaning and maintenance – make sure to follow these so the device is always functional. Stick with the approved materials for the engraver and never attempt engraving PVC or any other prohibited material, as they can emit dangerous chemicals. Be attentive to the machine while running; never leave it on without supervision. Always keep a fire extinguisher nearby. A laser engraver will be safe and effective if these precautions are followed.

What are the most popular techniques for laser engraving jewelry?

Laser engraving jewelry is one of the most common techniques that have gained popularity due to their ease of use and the accuracy achieved while performing them. One of the most common is deep engraving: this is where a laser is utilized to etch a design onto the surface of gold, silver, or stained steel. This ensures that the details added are highly durable and can be touched. Engraving, patterns, or logos that require a part of jewelry to be wearable quite several times need this technique, and this laser engraving is best suited for such tasks.

Surface or shallow engraving is another common technique. With this type of engraving, shallow depths are logged, and precise laser settings are utilized for softer materials or plated surfaces. Frequently, tensioning is done to plated surface structures to cover them with intricate patterns or personalized text on rings, pendants, or bracelets. This technique is best suited for producing finer details on plated surface structures without undergoing material weakening.

A last example is laser marking, which is dominantly used for marking high-contrast markings. Deep engraving of designs like names, dates, or barcode stamping works well on textures of various metals and alloys with annealing or engraving on the surface, removing material edges to preserve structural strength while enhancing structural aesthetics. When targets that are jewelers prefer to use such techniques, it enables providing high levels of customization catered to personal and professional needs.

Deep engraving vs. surface marking on metal jewelry

I notice specific benefits for deep engraving and surface marking on metal jewelry depending on how the piece will be used. For engraving, it is more convenient to mark emblems which need to be durable utilizing physically removing material, as it makes robust, lasting designs. Such designs are ideal for heritage heirloom quality pieces or those heavily used. Surface marking is more accurate and can create intricate designs because an emblem of high precision can be achieved. It can make high contrast marks without damaging the material and applies to lightweight or decorative emblems. The selection is finally based on the durability and the aesthetic value the piece of jewelry is to provide.

Creating intricate patterns and personalized designs

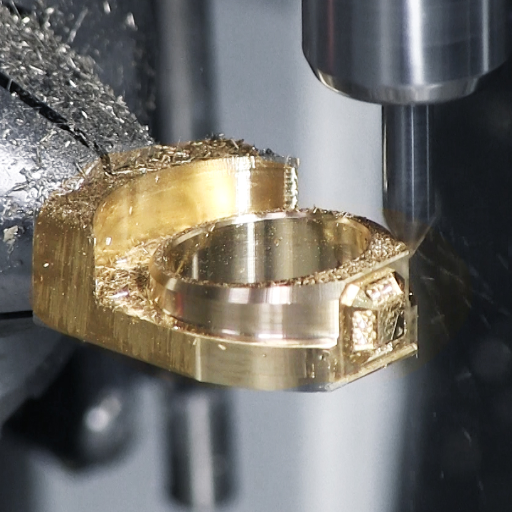

With the creation of unique patterns and personalized designs for metal jewelry, advanced methods such as laser engraving, CNC machining, chemical engravings, and etching are commonplace. Jewelers can engrave finer details down to a microscale because lasers can engrave with unmatched precision. CNC plugs machined with specific three-dimensional shapes can easily create complex patterns and multi-layered designs. Apart from that, in chemical etching, a pattern is applied through selective corroding, which enables the achievement of thin, delicate motifs. Every method permits the application of varying detail levels, depth, and contrast, aligning a design with the jeweler’s wants and functions. Using these techniques makes it possible to do simple engravings or complex artistic designs while ensuring that he or she meets various beauty and construction needs.

Combining laser engraving with other jewelry making methods

The synergy of laser engraving and other jewelry-making techniques allows us to improve design aesthetics and functionality significantly. For example, integrating the traditional handcrafting skill with laser engraving achieves precision and retains the end product’s artistry. Also, laser engraving can be used in casting to add delicate parts to a bold and sculptural design. Contrasts that magnify specific engraved patterns are achieved with polishing and finishing processes. This combination of different methods sets new limits of creativity while still preserving the standards of craft and technique.

How do you maintain and care for your jewelry engraving machine?

To maintain optimal performance for as long as possible, it is integral to ensure an engraving machine is regularly maintained. For example, when cleaning the machine, checked periodically components such as lenses, mirrors, and internal and external surfaces should be serviced as dust and debris can impair engraving accuracy. Using the manufacturer’s specified tools and solutions is best to avoid harm. Inspect the moving components, including guide rails and belts, for deterioration and lubricate them to prevent operational problems, as the user manual states. If there are any laser tubes, they should be inspected from time to time to ensure they are in line and power efficient while replacing them when needed to achieve desired outcomes.

Furthermore, the current software must be confirmed, and calibration tests must be performed to check accuracy. Keeping the machine in a dry and clean location will also prevent damage from corrosion. Following these guidelines ensures the optimum performance of the machine and increases longevity.

Regular cleaning and maintenance tips

To keep my jewelry engraving machine in proper operating condition, I regularly clean and maintain it. I use approved, non-abrasive cleaning products to clean the lens, mirrors, and all areas that are prone to collecting dust. Moving parts like the guide rails and belts are checked and lubricated to eliminate friction and wear. Additionally, I adjust or replace the laser tube when performance decreases and check the laser tube alignment. I guarantee accuracy by regularly updating the software and running calibration tests. I place the machine in a clean, controlled environment to keep it safe. These steps help an individual achieve high quality and precision for each engraving.

Troubleshooting common issues with laser engravers

My troubleshooting method with a laser engraver begins with identifying the issue. For instance, when the laser does not fire, I check the power supply, wiring, and the condition of the laser tube. I ensure the lens covers and mirrors are cleaned and placed adequately for irregular and poor engraving results. I’m accurate with the recalibrations, so I’m restoring accuracy. If no response comes from the machine, I check the control board, USB connection, and software drivers. Regarding the overheating, I check if the cooling system is operational and the water pump is functional. My approach resolves an issue while minimizing as much downtime as possible.

What are the latest trends in laser engraved jewelry?

As with most industries, consumer trends and technological advances aided in the growth of the laser engraved jewelry market. Personalized designs remain one of the prominent trends, with names, initials, and messages being some of the most popular choices. Moreover, creating intricate patterns and detailed artwork using the laser engraving is particularly appealing for wedding bands and pendants. Etchings are made on gemstones in clean outlines depicting objects reflecting minimalist styles, while leaves and flowers exhibit a sense of nature and stand out. Alongside this, the use of sustainable materials is increasing, and laser engraving is now done on eco-friendly metals and recycled materials to cope with the demand for sustainable products.

Innovative designs and techniques in the jewelry industry

Due to the never-ending pursuit of innovation in design and strategies used, the jewelry industry is ever-changing. Powered by sophisticated CAD software, parametric design facilitates the construction of highly detailed and customizable patterns that were never possible before. 3D printing is changing the landscape of jewelry design, making prototyping, complex design, and detailing much more manageable with minimal material loss and better accuracy. Laser engraving is also becoming more widely used because of the unmatched personalization and detail trimming it allows across various materials. Furthermore, eco-friendly metals, lab-grown diamonds, and recycled materials place sustainable practices at the forefront, which is gaining preference. With varying technology, jewelers are meeting the demands for creativity, personalization, and eco-conscious practices without limits.

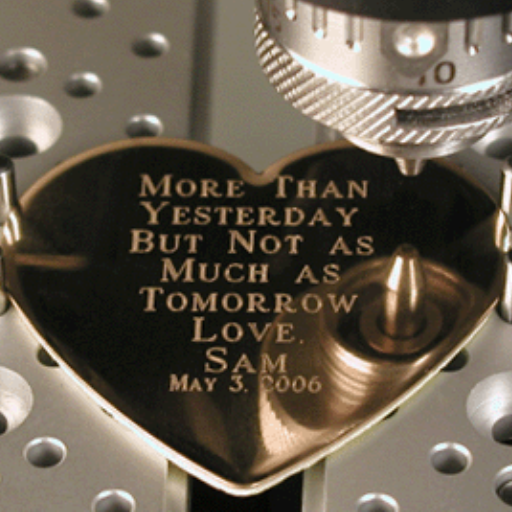

Customization options for clients using laser engraving

Through the use of laser engraving technology, clients can choose from a multitude of customization options. With utmost detail and strength, initials, names, important dates, and customized messages can be added to rings and bracelets. Clients are offered myriad fonts and symbols, while engraving patterns can also modify the designed pieces to reflect the client’s taste. Other jewelry pieces can have logos and detailed patterns engraved, making them highly personal. Beyond enhancing the look of the jewelry, this process helps in creating sentimental valuables that are one of a kind.

References

Frequently Asked Questions (FAQ)

Q: What is a jewelry laser engraving machine and how does it work?

A: A jewelry laser engraving machine is a specialized device that uses a focused laser beam to engrave or mark various types of jewelry. It works by directing a high-intensity laser onto the surface of the jewelry, vaporizing or altering the material to create intricate designs, text, or patterns. These machines can engrave metal, precious stones, and other materials commonly used in jewelry, offering precise and detailed engraving results.

Q: What are the different types of laser engraving machines suitable for jewelry?

A: Several laser engraving machines are suitable for jewelry, including: 1. Fiber laser engravers: Ideal for engraving metal jewelry and hard materials. 2. CO2 laser engravers: Suitable for softer materials and non-metallic components. 3. Diode laser engravers: Compact and versatile, suitable for small-scale jewelry engraving. 4. YAG laser engravers: Effective for both metal and non-metal materials. Each type has strengths and is suited for different engraving tasks and materials.

Q: What are the advantages of using a laser engraver for jewelry over traditional engraving methods?

A: Laser engravers for jewelry offer several advantages over traditional engraving techniques: 1. Precision and accuracy for detailed engraving 2. Consistency in quality across multiple pieces 3. Ability to engrave complex designs and small text 4. Faster engraving process, especially for bulk orders 5. Versatility in engraving various materials 6. Non-contact method, reducing the risk of damage to delicate jewelry 7. Easy customization for personalized jewelry

Q: What materials can be engraved using a jewelry laser engraving machine?

A: Jewelry laser engraving machines can engrave various materials, including 1. Precious metals (gold, silver, platinum) 2. Stainless steel and other metals 3. Precious and semi-precious stones 4. Glass and crystal 5. Wood and leather (for certain types of jewelry) 6. Plastic and acrylic components: The specific materials that can be engraved may vary depending on the type of laser engraver used.

Q: How do I choose the best laser engraver for jewelry?

A: To choose the best laser engraver for jewelry, consider the following factors: 1. Types of materials you’ll be engraving most frequently 2—required level of detail and precision 3. The volume of work and production speed needs 4. Available space in your workshop 5. Budget constraints 6. Ease of use and software compatibility 7. Power of the laser and its suitability for your specific jewelry items 8. After-sales support and warranty options

Q: What safety precautions should be taken when using a laser engraving machine for jewelry?

A: When using a laser engraving machine for jewelry, it’s crucial to follow these safety precautions: 1. Wear appropriate protective eyewear designed for the specific laser wavelength 2. Ensure proper ventilation to remove fumes and particles 3. Use a fume extraction system 4. Keep the work area clean and free of reflective surfaces 5. Never leave the machine unattended while in operation 6. Follow the manufacturer’s guidelines for machine operation and maintenance 7. Train all users on proper safety protocols and emergency procedures

Q: How can I control the engraving process to achieve the desired results on different types of jewelry?

A: To control the engraving process and achieve desired results: 1. Adjust laser power, speed, and frequency based on the material 2. Use appropriate focus settings for the jewelry’s surface 3—test settings on scrap material before engraving valuable pieces 4. Utilize software features for precise design placement 5. Consider multiple passes for deeper engraving when needed 6. Clean the jewelry surface before engraving to ensure quality results 7. Use specialized fixtures or jigs to hold jewelry pieces securely

Q: What are some popular laser engraving applications in the jewelry industry?

A: Laser engraving has numerous applications in the jewelry industry, including: 1. Creating custom jewelry with personalized messages or designs 2. Adding hallmarks or maker’s marks to pieces 3. Engraving serial numbers or identification codes for inventory management 4. Creating intricate patterns or textures on metal surfaces 5. Marking gemstones with certification numbers 6. Producing detailed miniature artworks on pendants or charms 7. Engraving QR codes or barcodes for product information or authentication