In the food business sector, regardless of the size of the firms, custom meat grinders are one of the most indispensable equipment which enables efficiency, uniformity as well as large production output. This guide is crafted so as to give all the readers a good scope and appreciation of the different types of industrial meat grinders along with their various use as well as benefits in the meat processing operations. We will look at the things that one has to bear in mind when selecting a meat grinder, what it is used for in the industry, and what measures to take for an extended life and high efficiency of the appliance. A meat grinder is an appliance that packs a lot of advantages for whoever succeeds in its application either for the first time or is experienced in the food processing industry. This article, therefore, is aimed at enabling the readers to make appropriate and well-informed decisions about industrial meat grinders.

What is a Commercial Meat Grinder?

Understanding the Basics of a Meat Grinder

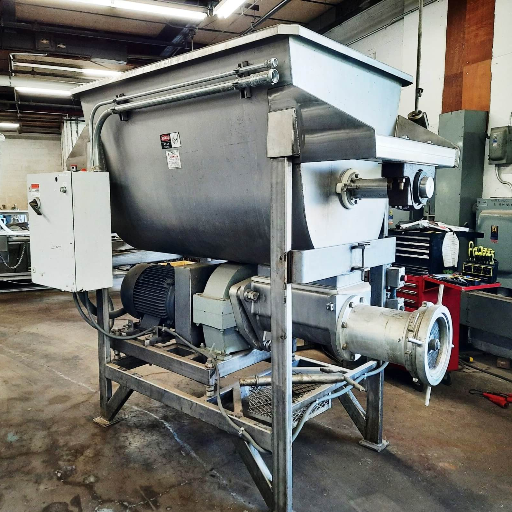

A commercial meat grinder represents a more complex setup as it is primarily used in large scale meat processing and other procedures in various food business sectors. It functions by having a heavy-duty motor which is connected to a blade assembly or a series of plates which grinds meat into smaller pieces or equipping the meat with more cuts for easier reshaping. Businesses that require pounded meat have commercial meat grinder appliances as they are reliable machines capable of large meat processing regardless of the amount required. Most of these grinders come with adjustments in them so that varying degrees of grinding can be achieved as per the requirement.

Key Parts of Commercial Meat Grinders

There are various critical parts which when used together help in the effective functioning of the commercial meat grinders. These are, continuous and efficient work of somatic motor, a feed pipe, and blades or plates to ground the meat. Moreover, certain settings of the grinders are also availed for adjusting the kind of grind which increases its ergonomics to form different food types. Other attachments can be used including funnels, sausage stuffers, and plates which can make the machine more efficient and thus can be considered an essential tool in a commercial kitchen.

How is Electric Meat Grinder Used? An Analysis of Its Operation Principles

The working principle of electric meat grinders involves using an electric motor that drives an auger that crops meat content through an incorporated cutting plate. Then the meat is presented to the blades at rotation that are embedded in the cutting plate to trim the meat as it moves down the auger’s length. Electric meat cutters are rather flexible instruments for various types of meat processing, as the speed and consistency of the cut can be adjusted either by using a different plate or by modifying the grinder controls.

How to Choose the Right Industrial Meat Grinder for Your Needs?

Choosing an Efficiency-Enhancing Commercial Meat Grinder

When buying a commercial meat grinder, think of the following factors:

- Volume – Identify the amount of meat which has to be minced frequently. An etiological model of a grinding machine with the required volume should be selected to ensure continuous capacity loading.

- Strength – Select a grinder which has enough electrical power to be able to operate without interruption and tackle the larger and tougher cuts of meat. The stronger the motor, the better the performance and the length of service period of the equipment.

- Construction – Buy a meat grinder made of materials that are suitable for rough commercial usage such as stainless steel which also allows for easy cleaning and maintenance.

- Size and Space: Determine how much space you have in your kitchen or processing room so that you will choose a grinder that will comfortably be placed without obstructing processes.

- Multifunctionality – Choose models that have various functions, additional equipment such as various grinding plates, sausage stuffing attachments as well as cutting blades to enhance your food preparation.

By taking the above factors into consideration, it is easy to understand how to pick an industrial meat grinder that best suits the intended processing activity.

Evaluating the benefits of stainless steels’ and aluminum’s grinders

While comparing stainless steel and aluminum grinders, the factors that stand out include durability, maintenance and cost. Well built stainless steel grinders are suitable for high turnover commercial operations because they combine strength, cleaning, and rust free surfaces. Of course, they are a bit more costly but on the long run, their life span is greater and they can withstand serious nicks without rusting. Aluminum grinders, on the other hand, are lighter and cheaper. They do not, however, seem to have the toughness and rust resistance of stainless steel which means they could be changed more often when used in harsh conditions. In the end, this choice comes down to the trade off between cost and the requirement for a robust and durable piece of equipment.

Identifying the Proper HP and Motor Capacity of the Grinder

Horsepower (HP) and motor capacity are key specifications when choosing any of the industrial meat grinders as they define the efficiency and effectiveness of the grinder. In other words, as the power of the horsepower of the motor increases, the grinder would be in a gleeful position of processing large volumes of thick and tough pieces of meat. It is also referred to as motor capacity, and can be given in volts or watts, determines the voltage requirement and the efficiency of the motor in operation. In general, a higher power tends to relate to better energy consumption and enhanced performance of the motor, making it possible for the grinder to run smoothly without strain. For this reason, heavy usage which is often associated with commercial premises is when a grinder with higher HP and capacity is ideal.

What Are the Benefits of Using a Meat Grinder?

Improved Effectivity in the Meat Processing Sector

The use of a meat grinder saves much of the preparation time and also helps in maintaining a uniform texture or quality throughout the process, which in turn increases efficiency in meat processing. It helps the user to quickly process large amounts of meat and guarantees a consistent size and texture of the grind which is a class requirement. Furthermore, a meat grinder gives more control over the quality and quantity of the ingredients used which enables the catering of particular culinary requirements and preferences.

Measures to Enhance the Uniformity and the Quality of Ground Meat

A meat grinder allows for uniformity in the end product since it is possible to control the actual grinding process. This makes it possible to opt for specific cuts and loads of meat and fat in order to modify the texture and taste of the finished product. Consequently, both amateur and professional chefs are able to provide superior quality of minced or ground meat catering to rigorous requirements and specific culinary needs which improves the overall quality of the meals.

Cost Advantages of Industrial Meat Grinders

Apart from their high production volume, industrial meat grinders provide savings on labor costs because of their ability to process large volumes of meat quickly and in an efficient manner. This leads to a quick turnover times during the manufacturing process and higher output which is beneficial for profitability. Moreover, because of the presence of in-house grinding of meat, businesses can cut down on losses, avoid the buying of minced meat in advance, and also enjoy bulk purchases in an attempt to cut down on costs.

How to Maintain Your Commercial Meat Grinder?

Cleaning and Maintenance of Stainless Steel Meat Grinders

To maintain a stainless steel meat grinder in working condition, it has to be cleansed after every use and taken care of regularly. After every use, the grinder should be taken apart and each part must be washed with warm, soapy water on its own. Make sure to scrub off all the protein remnants that, in contact with microbes, may cause spoilage. Each component must be cleaned and completely dried out to prevent oxidation. Every now and then, an application of grease to the moving components may be required. Moreover, keep your grinder in a dry place and perform regular inspections to identify damage to it, thus ensuring it is ready for work whenever it is needed.

Commercial Meat Equipment Maintenance and Care Tips

As professional meat grinder maintenance goes on, there are several maintenance modes and cycles your commercial meat grinders will need. To begin with, make sure that all parts are clean and dry in order to avoid rust and contamination. Moving parts should be regularly oiled and greased using food grade lubricants. Also, Inspect and replace if necessary all worn out or broken parts as they impact performance and safety. Furthermore, any routine inspection should look into the tightness of screws and bolts so that they do not cause functional failure. Maintenance records for replacements and service of tools and equipment can elongate their effective life.

Troubleshooting Common Meat Grinder Issues

It is common to fix the meat grinder feed tube or grinding mechanism whenever blockages and clogs are noticed which can cause malfunction. Also, check if the blades are sharp enough and sharpen handles properly, blades that are improperly fixed together can affect its use. Check power sources as well as scope all essential power utilities to determine where faults or disruptions occur in the power lines. Watch out for mechanical sounds which are not deliberately made, such sounds indicate that some minor mechanical faults exist and some things do require taking the equipment to a professional repair specialist. Whenever your equipment, such as screws or bolts, loosen during routine use, take time to regularly examine them to ensure that you do not have operational problems.

What Accessories and Attachments are Available for Meat Grinders?

Further studying stuffing tubes and other accessories

Out of all the accessories and attachments for meat grinders, stuffing tubes are quite common as well as greatly prized for their ability to assist the user in filling sausage casings in a more effective manner than without the tube. Further, meat grinders come with the attachments like plates of different sizes which can be used to produce granules of different sizes, vegetable cutter and shredders to make meat grinder a multi-functional machine. These attachments do improve the functionality of the grinder and allow it to carry out several kitchen functions easily.

Benefits of Using Grinding Plates and Knives

In the meat grinder industry, use of grinding plates and knives can greatly enhance its functioning and gain valuable results for gourmets. Grinding plates have holes of various diameters so that the end products of various coarseness can be obtained which is beneficial for lots of recipes and culinary appreciation. Sharp, high-quality knives make the cutting bite smooth and quick, so the machine will be operating effectively, and avoid being overloaded. In short, these items will make it easy to accomplish meat processing tasks and meet clients’ expectations.

The Ways in Which Meat Mixers Augment the Process of Grinding

A meat mixer allows for a better grinding process as it guarantees an even distribution of ingredients, be it meat or other elements or spices incorporated in the mixture. They save time and manual efforts as well, resulting in a uniform and concentrated taste and texture across the ground meat. Furthermore, the grinding process can be made more efficient by reducing the chances of lead clogging through the use of a meat mixer which helps mix components prior to entering the grinder.

Reference sources

-

Outdoor Life – “The Best Meat Grinders, Tested and Reviewed”

-

WebstaurantStore – “Best Commercial Meat Grinders of 2024: Reviews & Features”

-

ResearchGate – “Engineering Parameters Affecting the Performance of Meat Grinder”

Frequently Asked Questions (FAQs)

Q: What is an industrial meat grinder?

A: An industrial meat grinder can be described as a massive machine that serves a purpose in the Restaurant industry of grinding large amounts of meat. Such machines are sometimes used in butcher shops or meat processing plants.

Q: What feature makes a commercial meat grinder different from a home use meat grinder?

A: A commercial meat grinder has, as its name suggests, used in commercial establishments where there is high volume processing. Most meat grinders used in homes are usually smaller, and have less power than industrial meat grinders. Commercial grinders have a stainless steel build giving them the ability to process large chunks of meat in a minute.

Q: What materials are used in the construction of an industrial meat grinder?

A: Most industrial meat grinders are made from materials that would serve the strength purpose as well as protection against rust and most other factors that relate to corrosion such as stainless steel. Other if not all parts like plates and knives may be made out of stainless steel because these parts wear out first.

Q: What does the grinder plate accomplish in the meat grinder?

A: The grinder plate is also referred to as a hole plate which plays a significant cut in a meat grinder. It performs the function of limiting what size of meat chunks will be able to pass through it. There are different plates for different coarseness levels or fineness.

Q: What power of motor do I need for a commercial meat grinder?

A: The power of the motor in a commercial meat grinder depends on the expected use. Normally, a motor will range from 1 hp to 1.5 hp for most commercial applications which are more than enough for the purpose of grinding a huge amount of meat in one go.

Q: What advantage does the user get for using an electric meat grinder?

A: An electric meat grinder is capable of handling many kinds of meat such as beef, pork, chicken, and lamb. It can also be used to grind other food products such as vegetables or stuffing sausage with the required attachments.

Q: What are the different attachments that can be used with a meat grinder?

A: Sausage stuffing tubes, slicers, and meat mixers are some of the many attachments that meat grinders can have. This allows greater flexibility, such as being able to create sausages or mix in other ingredients with the meat.

Q: How do you care for a stainless steel meat grinder so that it lasts long?

A: Stainless steel meat grinders can be prevented from getting meat sediment by ensuring that each stainless steel meat grinder is cleaned properly after use. It is paramount on occasions where the disassemble and warm soapy water wash is used how crucial the use of harsh detergents must not be. The knife and grinding plates should be inspected and sharpened with paint so that sharpening can be accomplished.

Q: What should be done to ensure safety of the user during use of the commercial meat grinder?

A: Great precautions must be taken when preparing and affiliated with commercial meat grinders, and these include the procedure and instructions of usage undertaken to control vegetation to those that require reading. The jaw and the blades of the machine are still fastened to the body, therefore it is wise to keep one’s hands or loose clothing away.