Modern industrial laser marking and engraving systems have revolutionized the marking and engraving processes in many manufacturing industries. These systems are advanced and integrated to different fields to increase productivity, optimize traceability, and improve product standards. Laser marking systems are used for various applications such as marking barcodes or serial numbers and engraving logos for branding and product differentiation. This technology is known for its versatility which entails its ability to adapt to many materials and processes. This article discusses the benefits of laser marking and engraving, the various systems of lasers available, and new considerations for their acquisition and use. In addition, it will cover new trends in laser technology and provide information on maintenance, safety, and incorporation of laser marking machines into the workflow. This information is designed for anyone interested in improving efficiency and differentiating products and serves as a starting point on the benefits of industrial laser marking systems.

What are the benefits of using laser marking systems in industrial applications?

Laser marking systems are beneficial in many industries because of their speed and accuracy. The legibility of markings produced using laser systems is also exceptional, making it easy to trace items and follow industry guidelines. Additionally, laser marking systems have less downtime compared to traditional systems enabling increased productivity. Unlike conventional approaches, laser engraving does not require physical contact, drastically reducing the risk of material damage and the overall operational cost of the process. Lastly, laser marking is not limited to specific materials. It can be used on metals, ceramics, plastics, and more.

How does laser marking improve traceability in manufacturing?

Simply put, laser marking improves traceability in manufacturing through tracing and the use of components and product marking. It utilizes specific legible identifiers such as serial numbers, QR codes, or barcodes, allowing the user to identify things easily. This is especially beneficial for industries with strict regulations regarding the tracking of products as it ensures accurate control. The high level of precision in laser markings promotes the trust of quality control systems since misidentifications or counterfeits are unlikely. Also, laser markings are permanently etched onto a product withstand extreme temperatures and other tough conditions.

Why is laser marking preferred over traditional methods?

The advantages of using laser marking over more traditional marking techniques, such as mechanical engraving and ink-based printing, are noteworthy. Unlike mechanical engravings, laser marking is a non-contact approach. This drastically minimizes material deformation while also easing the need for consumables such as ink or etching chemicals. This means lower maintenance and operational costs over time. In addition, laser systems are very accurate. Their resolution is excellent, even achieving a spectacular 1-2 microns. This makes it possible to mark tiny or intricate components with laser systems and achieve consistency and detail.

Alongside all the previously mentioned benefits, laser marking proves to be highly durable. The markings are certainly not prone to fading because of abrasion, heat or chemical exposure. This ensures that laser marking will last long even in demanding environments. Moreover, these markings are simple to make on various materials, including metals, plastic, ceramics, and coated surfaces. This multi-material flexibility applies to numerous industries such as automotive, aerospace, medicine and electronics.

In what ways do laser marking systems improve product quality and enhance branding?

Laser marking systems improve product quality and branding by providing permanent, high-quality markings that endure for years. These systems enable labeling traceability and compliance with industry standards, minimizing risks linked to manual classification. Suitable engraved designs, such as complex barcodes, logos, and serial numbers, take brand association further while still enhancing the product aesthetic. Further, their ability to engrave across different materials without compromising structural integrity further ensures consistent quality across a wide range of products.

Which types of laser marking systems are best for different materials?

Due to their exceptional precision and power, fiber laser marking systems are best for metals like stainless steel, aluminum, and titanium. They are also helpful for some types of plastic and ceramics, especially when a noticeable difference in contrast is needed. Like CO2 laser marking systems do well with wooden materials, leather, glass, and fabrics because they are swift and effective. UV laser marking systems work better with low heat emission. Because of this, they are perfect for plastics, delicate materials, and sensitive electronics with minimum chances of deforming the material and a need for high contrast results. The choice of laser marking systems depends on the materials’ properties and the desired marking results.

What are the differences between fiber, CO2, and UV laser marking systems?

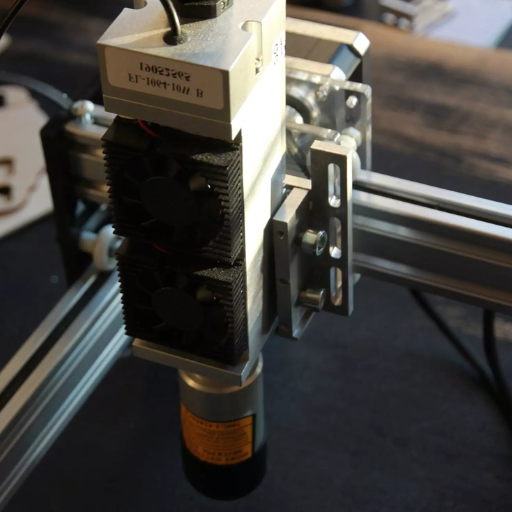

The distinguishing aspect of fiber, CO2, and UV laser marking systems is the difference in their laser wavelengths, power ratings and the materials they work on as these greatly determine their use and effectiveness. Fiber laser systems standardly work at a wavelength of 1064 nm. This explains why fiber laser systems are most suitable for marking metals such as stainless steel, aluminum, and titanium. They are precise and can deep high contrast engravings. They also mark some hard plastics with a high level of efficiency. The power of these systems is usually offered in options ranging from 10W to over 50W. Having these makes it easier to control marking speed and depth.

Systems that use CO2 lasers have a longer wavelength of around 10.6 µm, which allows them to excel in working with non-metal materials such as wood, glass, acrylic, paper, or leather. These laser systems also cut or engrave organic materials at speeds and power levels of 20 to 150 watts, which gives them clean edges.

UV lasers are different because they work at a short wavelength of 355 nm, allowing them to use a “cold” process when marking materials. With these lasers, there is a minimal damaged area so it is best to use it on sensitive materials like polymers, soft plastic, or electronic parts. UV laser systems usually have power levels of 3 to 10 watts, and are excellent while working on delicate surfaces that require high-resolution markings while keeping everything intact.

Selecting a laser marking system is typically dependent on the materials, and the quality of marking desired, but all systems have different advantages suited for various industries.

Choosing a Laser Marking System for Metals

When choosing the laser marking system, it is important to focus on the type of material, required marking detail, and production pace. Fiber laser systems are usually the best options because they can provide remarkable energy efficiency and beam quality while still being adaptable to materials such as stainless steel, aluminum, and titanium. These lasers require little upkeep while providing permanent, high-contrast markings that are ideal for industrial use. Also, determine the appropriate depth of the mark, its finish, and the environment in which it will be used to achieve the best performance and durability. For further, unmatched versatility in marking various metal substrates, performance parameters like power and speed must be adjustable.

What are the best plastic and non-metal materials for laser marking solutions?

When it comes to plastic and non-metal materials, CO2 lasers rank best due to their efficacy with various polymers and other non-metallic surfaces. These lasers function on a wavelength of 10.6 µm, which is great for marking, engraving, and cutting non-metals such as acrylic, wood, glass, and rubber. CO2 lasers maintain foresight while marking materials that are usually highly fragile and thus want both efficiency and precision.

Important features like laser power (usually 10W to 100W), marking speed, and laser focusation must be precise to avoid overheating and warping the material when working with plastics. Low power settings paired with high speed scanning are best for intricate items like barcodes and logos. For specialized results, certain plastics like polypropylene or ABS can incorporate additives or specific lasers such as UV lasers at a wavelength of 355 nm. Utilizing a laser system with adjustable power, pulse duration, and frequency gives additional power for manipulating various non-metal materials.

How can laser marking machines boost productivity in industrial settings?

The Laser marking machine is designed to achieve maximum productivity in industries by streamlining the speed and accuracy of marking processes as well as reducing the marking machine’s idle time. These machines consistently produce high-quality output, which minimizes the chances of rejected parts or reworked sections of the part components. Moreover, maintenance costs and time are significantly reduced since the non-contact method does not result in wear and tear typically associated with traditional marking tools. More so, these tools help in marking different materials with complex designs at no additional tool changes, further increasing efficiency. Streamlined workflows with advanced automation integration enhance productivity in high volume manufacturing environments.

What features should you look for in high-speed laser marking systems?

- Fast Scanning Speed

High-speed laser marking systems are designed to scan high volumes of content with precision and accuracy, increasing the speed at which large volumes are completed. This is made possible by a galvanometer scanner that can move the laser beam rapidly.

- High-Powered Laser Source

Achieving clear, deep, and distinctly contrasting marks on different materials requires scant attention. High-powered lasers provide a speedy solution by marking metals or ceramics efficiently and quickly. The robust source allows for quicker marking processes as opposed to lower-powered options.

- Adjustable Pulses and Waveforms

The system is able to mark a variety of material types due to the custom range of laser pulse durations and waveforms. This feature enables it to deal with both delicate and tough surfaces equally well.

- Enhanced Cooling Mechanisms

Advanced cooling systems, such as air or water cooling, enable sustained operations without overheating, which greatly enhances the machinery’s lifespan and ensures reliability during peak demand periods.

- Automation Integration

Integration with industrial automation systems enhances production line efficiency. Thanks to features like robotic arm interfaces and conveyor belt synchronization, the laser marking system can be easily incorporated into sophisticated manufacturing processes.

- User-Friendly Software

Different industries can easily operate the system because of the advanced control software’s user-friendly design. Additional features like template designs, database connectivity, and multi-language function further enhance usability.

- Compact and Durable Design

The system is compact and robustly constructed, allowing for use in industrial settings that have low space availability and are subject to deterioration from regular use.

- Material Versatility

The ability to mark so many different materials, ranging from metals and plastic to glass and even composites, means no more markers are needed for different industries and the scope of applicability is greatly increased.

- Micro Marking Accuracy

Ultra-precise beam functionalities, like small codes or intricate designs needed in medicine and electronics, are part of high-speed systems’ capabilities, which allows a high degree of accuracy on the micro-scale.

- Cost-effectiveness

The modern iteration of high-speed systems integrates the latest approaches to energy consumption, which improve operational costs, enhance performance, and decrease environmental impact simultaneously.

What is the procedure for the incorporation of automated laser marking in production lines?

Implementing automated laser marking into existing production lines is easily achieved through the use of dedicated hardware and software systems for modern factories. This means that they can plug to existing equipment via PLCs (programmable logic controllers) or industrial communications. These devices ensure that the marking is correctly coordinated with the assembly steps. They can also communicate with MES in real time for increased traceability and improved workflow automation. Furthermore, compact and modular designs make them easy to integrate with existing production systems due to minimal changes or alterations to the floor layouts. At the same time, advanced automation features allow the systems to work autonomously with little input from staff.

What are the efficiency gains of using laser marking for part identification?

Using lasers for marking parts can significantly increase operational productivity because of its accuracy, quickness, and toughness. It foregoes using materials such as ink or labels, which brings down further expenses alongside maintenance costs. Laser markers generate permanent codes that can withstand rough abrasion, heat, and chemicals; therefore, they ensure long-term traceability within unforgiving environments. In addition, automated systems improve the marking’s throughput while combining with modern data collection systems, which ensures that production aspects and their precision are increased in totality.

What are the latest advancements in industrial laser marking technology?

The modern industrial laser marking techniques used today has seen considerable advancement with the introduction of higher speed. These more precise fiber lasers allows for marking at a greater speed and with improved quality. Enhanced software tools now support real-time monitoring, remote operation, and creating complex patterns and codes on demand. Moreover, new developments in green and ultraviolet (UV) laser technologies allow greater precision in marking a wider range of materials, including delicate substrates like glass and plastics, where the clarity is exceptional and the heat impact is minimal. Last but not least, developments in sustainability have concentrated on energy efficiency and lowering the workload on the environment which complements the shifts in the industry aiming for greener production processes.

In what ways have fiber laser marking systems changed within the last few years?

The major advancements in fiber laser marking systems center on performance, efficiency, and versatility. Newer systems are increasingly quicker and more accurate due to innovations in laser beam quality and control over pulse duration. These advancements also feature marked improvement in energy efficiency, lowering operational costs and promoting sustainable business practices. Moreover, fiber laser systems now incorporate more advanced software components enabling greater customization, active monitoring, and more straightforward automation, making the devices applicable in fast-paced industrial settings. More advancements have been made so that the systems can mark more materials, including metals and sensitive plastics, with little thermal distortion.

Which innovations are improving aspects of laser UV marking?

Innovations in UV laser marking focus on precision, minimizing the heat-affected zones, and maximizing the marking speed. Newer methods of pulse duration shortening and beam quality improvement allow high-detail marking on glasses and plastics without thermal damage. Using finer optimizations also increased the ability to mark contrast on a wider spectrum of materials. Moreover, new designs are more efficient in power management, making them greener, cheaper, and operationally more cost-effective while still achieving high throughput for industrial-scale uses.

In what ways has software been improving laser marking?

Sophisticated software design has improved modern laser marking systems by increasing efficiency, precision, and automation. Integrated automatisms now allow complex pattern design, setting specific marking parameters, and image tracking of the marking operation. New algorithms allow high data processing speeds, increasing mark accuracy while reducing cycle times. In addition, dynamic focus and material tracking automation increase efficiency of operations by ensuring consistency in high volume production. Along with interface user-friendliness, these software changes help operators make more complicated designs faster with less training, improving productivity.

How do you implement laser marking for various industrial applications?

Implementing laser marking on an industrial level is challenging from the perspective of material compatibility and the operational needs of the system. Different materials have different marking requirements, for instance: lasers used in marking metals and plastics are different than those used to mark ceramics or glass which would need fiber, CO2, or UV lasers respectively. The marking process starts with choosing the right laser marking system considering the marking depth, speed, and accuracy required. Integration within the existing production lines ought to be achieved alongside using automated handling systems or robots to ensure maximum productivity. In addition, the laser power, focus, and frequency settings are adjusted to the specific application to ensure the laser mark is precise and permanent. Maintenance and system calibration is a continuous process needed to maintain the system in good condition while adhering to industry standards.

How can one optimally laser mark Barcodes and Serial Numbers?

When it comes to laser marking barcodes and serial numbers, an emphasis on precision and quality will guarantee the optimal results. To begin, select a laser system that can accommodate the material being used and the resolution required to be readable by all scanning devices. Adjusting the laser parameters, including power, speed, and beam focus—enables the marks to be made without damaging the material while ensuring they are clear and in high contrast. Proper alignment of the marking area is essential to prevent distortion and allow accurate information placement. Also, mark compliance and traceability requirements verification systems enable the fulfillment of industrial standards. General system servicing and software updating provides aid to the longevity of the system as well as ensures that the marked barcodes and serial numbers will be durable over time.

How is Laser Marking Used in Logo Engraving and Brand Marketing?

Laser marking has become one of the most efficient strategies used for logo engraving and branding because of the level of detail that laser markers provide while also being time and cost efficient. The lack of necessary consumables such as ink or stencils allows for highly detailed and permanent engraving designs on metals, plastics, and glass. Custom brand logos can also be made precise during engraving as it is highly adjustable. Laser marking also provides considerable resistance to wear and the effects of the environment, thereby making it easier for brands to remain visible over long durations of time.

What are the Restrictions for Direct Part Marking in Different Sectors or Industries?

Direct part marking (DPM) is a vital aspect to consider while engraving logos on products as it provides many branding opportunities. However, its major drawback is that its restrictions differ from industry to industry because of differing operational and regulatory factors. The marking method chosen (laser or dot-peen) will always need to ensure accuracy through material compatibility with metals, plastics, and ceramics. The AEROSPACE and automotive industries are additional vital parts because they require marks that can withstand tough conditions from extreme temperatures, corrosion, and abrasion. Compliance and traceability remains an equally important factor in industries such as healthcare and electronics, but this is more focused on having precise, readable markings to fulfill strict requirements. Also, the marking method needs to allow for high production throughput while ensuring reliability and quality simultaneously.

What maintenance and safety considerations are important for laser marking systems?

Following safety procedures may be the most important aspect when operating a laser marking system. Performance of the system and its optical components, lenses and mirrors for example, requires regular maintenance to prevent dust accumulation or the potential of being damaged. Cooling systems should also be checked to ensure the temperature remains stable to avoid overheating of the laser source. Moreover, cleaning the system and maintaining it residue-free will ensure that the output is of high quality and increase the lifespan of the laser marking system.

Operators, on the other hand, have to take extra precautions. They must always wear protective equipment like laser protective glasses when using the machine as they could be exposed to harmful lasers. Interlock mechanisms or enclosures should be present to avoid accidental laser contact. The standards for laser safety should always be adhered to, like proper training and signage, so the risks are minimal. Other methods of ensuring safe operation include regular equipment and software calibration. Businesses can achieve increased reliability and safety of the laser marking systems by applying such measures.

How should one maintain industrial laser markers effectively?

To maintain the industrial laser markers, I frequently clean crucial parts like lenses and mirrors to help prevent residue buildup that might obstruct proper functioning. Also, I ensure that the cooling system is operational to prevent overheating. I regularly check for any mechanical wear, alignment problems, and overheating indicators. I also follow the manufacturer’s suggestions for preventive maintenance like issuing periodic calibrations and software updates so that the machine operates in ideal conditions. Where appropriate, using high-quality replacement parts increases the longevity and efficiency of the system.

Which procedures must be observed during the use of laser marking machines to avoid hazards?

One protocol I ensure to enforce when operating laser marking machines is that all laser safety measures are followed. Laser marking machines are powerful tools; therefore, protective equipment such as laser protective goggles must always be worn. The machine’s area of operation should be free from unauthorized personnel and should be marked with sufficient danger signs. Untrained users are not authorized. All safety interlocks and emergency stops are tested on a regular basis to make sure they work correctly. I do not use reflective materials anywhere in the laser’s surrounding to minimize unwanted beam reflections.

Common Issues with Laser Marking Equipment and How to Solve Them

Start by checking the power supply and ensuring the device has adequate and stable voltage. After that, examine the lens for any dirt, dust, or scratches that may mar the marking quality and clean it if necessary. Check the alignment of the laser beam and the calibration of the focusing lens. If the marking quality is blobby, then examine the material to check whether it is suitable for the laser wavelength and power. Don’t forget to regularly update the control software and check system software settings to ensure they are within the operational requirements. Further, keep an eye on the cooling systems since overheating can severely affect performance. In case of persistent problems, refer to the equipment manual or contact the manufacturer’s technical support for comprehensive diagnostics.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are the main benefits of using industrial laser marking systems?

A: Industrial laser marking systems offer numerous benefits, including high-speed marking, permanent marking, and versatility across a wide range of materials. They provide precise and consistent results, are environmentally friendly, and can handle complex designs. The benefits of laser marking include increased productivity, reduced operational costs, and improved traceability in various industrial sectors.

Q: How do laser engraving machines differ from traditional engraving methods?

A: Laser engraving machines offer several advantages over traditional engraving methods. They provide faster processing times, higher precision, and the ability to work on a wider variety of materials. Laser engraving is non-contact, reducing wear on tools, and can create more intricate designs. Additionally, laser engraving machines are more versatile, allowing for easy switching between different marking applications without changing tools.

Q: What types of industrial laser marking systems are available?

A: There are several types of industrial laser marking systems available, including CO2 laser markers, fiber laser markers, and UV laser markers. Each type is suited for different materials and applications. CO2 lasers are ideal for organic materials, while fiber lasers excel at marking metals. UV laser markers are perfect for heat-sensitive materials. The choice depends on the specific marking applications and materials being processed.

Q: What is the difference between laser engraving, laser etching, and laser marking?

A: While these terms are often used interchangeably, they refer to slightly different processes. Laser engraving involves removing material to create deep marks. Laser etching melts the surface of the material to create raised marks. Laser marking, which includes processes like laser annealing and laser ablation, alters the surface properties or color of the material without significant depth. The choice between these methods depends on the desired outcome and the material being processed.

Q: What materials can be processed using a laser engraver?

A: Modern laser engraving machines can process a wide variety of materials. This includes metals, plastics, wood, glass, leather, and ceramics. The specific laser system used (CO2, fiber, or UV) will determine which materials can be effectively marked. For example, CO2 lasers are excellent for organic materials like wood and leather, while fiber lasers are ideal for metals and some plastics.

Q: What safety considerations should be taken into account when using industrial laser marking systems?

A: Safety is paramount when operating industrial laser marking systems. Many modern systems are Class-1 laser devices, which means they are enclosed and safe under normal operation. However, operators should still receive proper training, wear appropriate personal protective equipment, and follow all safety protocols. Proper ventilation is crucial to remove fumes and particles generated during the marking process. Regular maintenance and adherence to safety guidelines are essential for safe operation.

Q: How do laser marking applications contribute to product traceability?

A: Laser marking applications play a crucial role in product traceability across various industries. They can create permanent, high-contrast marks that include serial numbers, barcodes, QR codes, and other identifying information. This enables efficient tracking throughout the supply chain, helps in quality control, and assists in combating counterfeiting. The durability of laser marks ensures that the traceability information remains intact throughout the product’s lifecycle.

Q: What factors should be considered when choosing the best marking system for industrial applications?

A: When selecting the best marking system for industrial applications, several factors should be considered. These include the type of materials to be marked, the required marking speed, the complexity of the designs, the size of the marking field, and the production environment. Additionally, consider the long-term costs, including maintenance and consumables. The versatility of the system is also important, as it should be able to handle a variety of industrial laser marking tasks to maximize productivity.