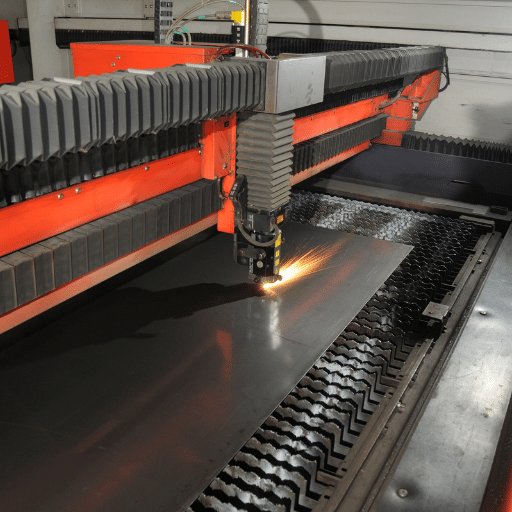

Modern manufacturing has become increasingly reliant on industrial laser cutters due to their precision, speed, and versatility. High-power lasers can precisely focus light beams to cut, engrave, or shape various materials, including metals, plastics, and even composites. Active laser cutters can operate within industry standards by achieving complex designs with the least possible waste and significantly reduced manufacturing times. As a result, the automobile, aviation, construction, and electronics industries depend highly on laser cutters. This article will analyze the impact of modern laser cutters on current production processes along with their specific functions, developed technologies, and areas of application to demonstrate the provided solution’s effectiveness and innovation.

What are industrial laser cutters and how do they work?

High industrial laser cutters are high-precision tools that cut and engrave with a laser beam. These tools have a high-intensity laser that focuses on the surface of a material. This produces heat that is capable of melting, burning, or vaporizing the material. They are often accompanied by shields made from nitrogens and oxygens, which improve cutting efficiency while keeping the edge sharp. These laser cutters are managed through computer-operated controls, which enable detailed designs and complex patterns that need high accuracy and low material waste to be crafted. With their unique form and structure, a wide range of materials, such as metals, plastics, wood, and composites, can be processed.

Understanding laser cutting technology and its components

- Laser Resonator

The resonator is the heart of the laser cutter and the high-speed laser beam generator. To achieve cutting, a laser beam must be generated. Laser resonators can employ gas-based systems like CO2 lasers or solid-state options like fiber and crystal lasers. Each type of laser system is best suited for certain applications depending on the type of material, its thickness, and the required speed.

- Beam Delivery System

The laser beam is first generated and then guided to the cutting head with mirrors or fiber-optic cables. This methodology preserves the beam’s robustness and direction over longer distances, allowing effective cutting even on large-scale instruments.

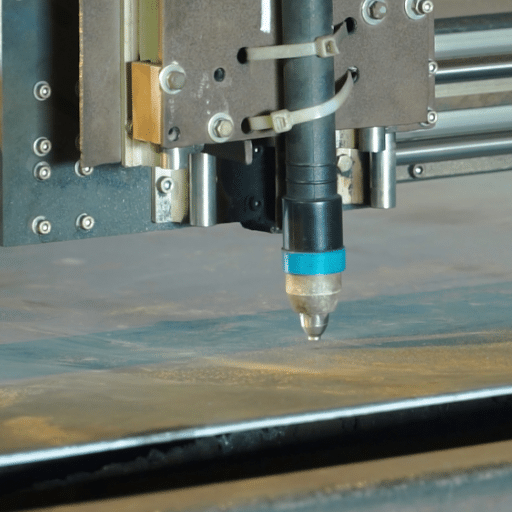

- Cutting Head

The cutting head encapsulates some of the most essential parts: the focusing lens, the nozzle, and the assist gas supply. It concentrates the laser beam into a specific point on the surface of the material for proper cutting. The assist gas removes the molten material from the cutting area to prevent excessive thermal exposure of the region underneath the cut and to ensure smooth edges around the cut.

- CNC Control System

The CNC (Computer Numerical Control) system is the one responsible for cutting and physically changing the material with minimal human supervision. It allows for precisely reproducing figures designed on a computer with a laser cutter by laser engraving. Such systems allow for encompassing patterns of intricate designs and high repeatability rates without human involvement.

- Material Support Table

A material support table is a specialized table or bed meant to hold the material in place while it’s being cut. It is further engineered to hinder reflection and secure the material throughout the cutting process. Most systems have slatted surfaces to aid air flow and waste collection.

- Cooling System

A sophisticated cooling system maintains the temperature of the laser resonator and other heat-sensitive components. This system guarantees reliable functioning, and avoids overheating, which can potentially impact precision as well as the equipment itself.

- Exhaust and Filtration System

While laser cutting takes place, fumes, particulates, and other debris are produced. The exhaust and filtration system removes and cleanses these byproducts, safeguarding the working environment and the machine or material from contamination.

All these units function in perfect synergy to enhance laser cutting technology’s effectiveness, accuracy, and adaptability to many different fields.

Types of industrial lasers: CO2, fiber, and gas lasers

- CO2 Lasers

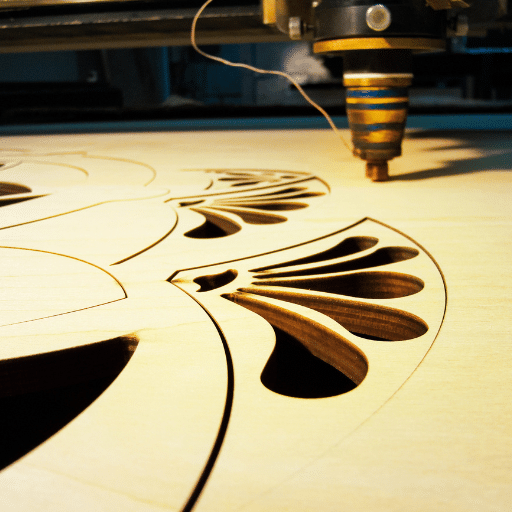

CO2 lasers utilize the method of exciting a mixture of carbon dioxide gas, which helps produce a powerful and efficient laser beam. These lasers are well known for their capacity to cut non-metal materials such as wood, plastics, paper, and fabrics with astonishing accuracy. Due to their 10.6 micrometer wavelength, they also perform extremely well in engraving and marking applications. CO2 lasers are popular among industries requiring high-speed processing and meticulous detail.

- Fiber Lasers

Fiber lasers operate on the principle of optical pumping using solid-state construction, with the active gain medium being a rare earth-doped optical fiber. Fiber lasers have high energy efficiency and long lifespans. They are handy for the cutting and engraving of metals such as stainless steel, aluminum, and even bronze. Fiber lasers are also more advanced than CO2 lasers due to their cutting efficacy. The wavelength of fiber lasers is around 1 micrometer, so their focal diameter is comparatively smaller, achieving higher cutting speeds and precision.

- Gas Lasers

Gas lasers encompass remote categories of lasers, which include CO2 lasers, helium-neon lasers, and nitrogen lasers. The beam of gas lasers is created through the excitation of a gas medium, thus making them extensible for use in scientific research and even industrial etching. Moreover, certain gas lasers like excimer lasers are beneficial in medical microfabrication applications because of their UV wavelength and the ability to ablate thin layers of material without inflicting thermal harm.

The laser cutting process: From beam generation to material removal

In the world of cutting materials with lasers, the first step is the bringing forth of a focused laser beam. This is done by using a gain medium such as gas or an optical fiber. The beam of light is then amplified and aided by mirrors or fiber optic cables to direct it towards the material to be cut. After the beam reaches its destination, it is focused using a lens to achieve the highest energy possible to be at the focal point. The energy at the focal point then ends up heating, melting, or vaporizing the material. While this is happening, an assist gas like oxygen, nitrogen, or compressed air is used to aid in the removal of the molten material from the area. The combination of thermal energy and assist gases guarantees that the cut is clean and with minimal distortion. This can now be done on complex shaped objects or polished materials. Sophisticated motion control systems make it even more accurate and faster by guiding the laser head along the designed path.

What materials can industrial laser cutters handle?

The proficiency and speed of industrial laser cutters cover various materials like metal, wood, acrylic and even plastic. Apart from steel, stainless steel, aluminum and titanium are also common in engineering. In addition to packaging, signage, and consumer goods production, laser cutters can be used to engrave and cut glass, plastics, and ceramics. Because of this, laser cutters are applicable in various industries, including automotive, aerospace, electronics, and custom fabrication.

Technology Overview: CO2 Vs Fiber Lasers

Adjusting frequencies, power, and cutting speeds can increase the precision of laser cutting non-metals like wood and metals such as steel, stainless steel, and aluminum. Metals with thicknesses from 0.5 mm to over 25 mm are made easy to cut with fiber or CO2 lasers. Depending on the type of laser and its wattage, different energies are effective for cutting plastics and non-metals. For example, using a fiber laser with a power of 1,000 watts permits effective cutting of stainless steel with a thickness of 3mm and above. Higher power levels also can cut larger pieces.

Acrylics and wood are non-metals that need adjustments in focus and wavelength. The CO2 lasers are preferred in this area because they can work with more sensitive and delicate heat materials. 14, Amodel 10, or 28 from the polyimide family when making cuts, the power intensity is decreased, and the speed is set to a precision point. That gets the cutoff edges smooth. Some settings like the 10 mm acrylic have over 150 watts of laser power and 20 mm per second of speed. That setting gets the piece polished without fearing warping or overheating a piece. In addition, other techniques like pulse modulation are used with ceramics and composites in order to get the structural integrity of the material while keeping the thermal stresses flexed. The way modern laser cutting systems work proves the versatility in handling the material and further serves as a testimony to how much technical advancement has been achieved.

Laser cutting stainless steel, mild steel, and carbon steel

Cutting of carbon steel, mild steel, and stainless steel laser cutting involves meticulous power, speed, and assist gas adjustments to achieve desired results. Cuts in stainless steel can be cleanly performed with the assistance of nitrogen or oxygen, whereas nitrogen provides an oxide free edge. Being slightly higher on the oxidation resistance scale, mild steel can efficiently be cut using oxygen as an assist gas which increases the cutting rate due to exothermic actions. In steel, oxygen remains advantageous for thicker sections, while nitrogen is suitable for thinner profiles. It is beneficial in preventing surface discoloration. Important variables like, laser power, beam quality, and even nozzle positioning should be set to optimum values to ensure reasonably fast speeds while the edges still have decent quality. Greater accuracy, reduced thermal distortions, and effective material processing is achieved by enhanced control in these varibles.

Abilities for cutting thin materials and thick ones

While working cutting thin or thick materials, I make sure that I factor in the characteristics of the materials. For high precision edges on thinner materials, I use high-speed cutting at a reduced laser power setting while simultaneously using assist gases like nitrogen. For thicker materials, optimized laser power settings, slower cutting speeds, and oxygen use enhance the material through combustion. I specialize on parameters fine focusing position, beam quality, and gas pressure. This method ensures effectiveness and high standard quality on varying applications.

How do CO2 laser cutters differ from fiber laser cutting machines?

The disparity between CO2 laser cutters and fiber laser cutting machines stems from their laser generation methods and their application uses. A gas mixture in CO2 lasers produces infrared light. CO2 lasers, alongside metal processing, are great for cutting non-metal materials such as wood, acrylic, and plastic. Solid state technology is used for fiber lasers, therefore they generate focused beams that are more efficient. Due to this, fiber lasers are most suited for cutting metals, especially reflective materials like aluminum or brass. Moreover, fiber lasers need less maintenance, operate at faster cutting speeds, and offer higher overall productivity. Each technology’s strengths depend on the material type and specific application requirements.

Comparing CO2 and fiber laser technology

The performance characteristics for CO2 and fiber laser technologies differ, resulting in different use cases. CO2 lasers have a wavelength of 10.6 micrometers and operate on non-metal materials such as wood, acrylic, leather, and glass due to their ability to engrave, mark, and cut these materials. CO2 lasers can also cut metals, although they do lose efficiency when cutting highly reflective materials such as aluminum or copper. Typical power ranges for CO2 lasers vary from 30W for engraving applications to several kilowatts for industrial cutting.

Fiber lasers, on the other hand, operate at a shorter wavelength, around 1.06 micrometers. This results in metal materials having a higher absorption rate. It enables precise cutting of highly reflective substances like aluminum, brass, and stainless steel much faster. Fiber lasers also have higher energy efficiency, typically converting over 25% of electrical energy into the laser versus CO2 lasers that only convert around 10-20%. Fiber systems are less maintenance intensive because of their solid state structure. They also generally last longer because the diode lifetime usually exceeds 100 000 hours.

Pros and cons of each laser type

Depending on the particular tasks at hand, CO2 lasers and fiber lasers may differ significantly in their advantages and limitations. CO2 lasers have a considerably longer wavelength of 10.6 micrometers, which makes them very effective for cutting, engraving, and marking non-metallic substances like wood, plastic, and glass, however, it diminishes in efficiency for highly reflective metals like copper and aluminum. Like CO2 systems, CO2 lasers also have operational downsides, requiring regular maintenance like gas refills and mirror realignments. The operational costs increase with the level of maintenance required. Power CO2 lasers can reach for lighter engraving processes at around 30W, while industrial-grade cutting requires several kilowatts.

Fiber lasers outperform all others while working with metals such as stainless steel, brass, and aluminum because of their enhanced energy absorption resulting from their shorter wavelength measuring 1.06 micrometers. Fiber lasers have the highest cutting efficiency while retaining energy. Roughly 25-30% of electrical energy is transformed into laser energy. In addition, they consume less electricity throughout the process, making them energy efficient and offering high cutting speed and precision with both thin and medium-thick materials. The solid state design also improves the lifetime of the machines and increases performance efficiency since Diodes can last more than 100,000 hours. However, fiber lasers fall short when working with non-metal materials and materials that require deep engraving or processing over large areas.

It is also critical to ensure optimal performance when working with lasers by taking into account the material that is intended to be processed, operational costs, and energy efficiency. Industrial settings and commercial businesses can utilize both technologies because both have features that enable them to operate effectively.

Selecting the right laser for particular operations within an industry

In selecting the appropriate laser for a particular industrial setting, there are many things I look into for detail such as results. For example, in metal, processing tasks where deep engraving or cutting of bigger pieces is needed, fiber lasers would be an excellent choice because they are precise, energy efficient, and can work with many different types of metals. If the work involves non-metal substances, CO2 lasers are often more appropriate as they are much better for these kinds of tasks. The balance between operational costs, accuracy levels, maintenance demands, and the accuracy significantly needed aids in choosing the right laser type. It is easier to make my final decision once I know what my technical constraints and budget limits are.

How versatile are industrial laser cutting systems?

Industrial laser cutting systems work proficiently as they can program custom cuts on various types of materials, including metal, plastic, wood, and even composite materials. They achieve this by setting parameters like power, speed, and focus that are highly adjustable to meet certain application requirements. They are widely used in almost every industry for prototyping, intricate parts manufacturing, and creative engraving. More so, greater efficiency, reduced waste, and increased scalability means these systems are extremely valuable in contemporary manufacturing.

Productivity enhanced through cutting and laser engraving systems

Productivity and overall efficiency is achieved by integrating two processes, cutting and engraving, in one system. Modern machines can automatically switch from cutting to engraving, which helps undertake elaborate projects. This means that delicate designs can be made and placed with great accuracy while the material can swiftly be removed without the chance of damage, for many tools are expensive, and drilling takes time. Such machines are suitable for industries with high demand of precision customized work, which also reduces cost and time needed for production.

Large format laser cutters for unending manufacturing needs

Large format laser cutters are built to meet diverse and specific manufacturing needs, ensuring accuracy and high quality for multiple applications. These machines can handle larger sheets of materials, making them more efficient by minimizing the need to reposition the workpiece or join pieces together. As they accept substrates like metals, plastics, textiles and wood, they are critical machines in industries such as automotive, construction, and sign making. These machines also offer customization in power settings and automated material handling, guaranteeing that even the most complex structures are crafted precisely. Large format laser cutters are created to revolutionize production workflows for any industrial and artistic works by providing enhanced speed, flexibility, and accuracy.

Flexibility to Different Industrial Uses and Materials

Large-format laser cutters with exceptional accuracy can be used for almost any material and application. They can process metals, like stainless steel or aluminum, used for automotive parts and can cut and engrave plastic, textile, and composite materials used in the aerospace and fashion industries. These cutters possess advanced control features that guarantee quality of products regardless of the material density or thickness. This flexibility helps the industry consolidate several processes into one, cut down on waste, and make complex designs in many different manufacturing environments.

What should you consider when buying a laser cutting machine?

Investment in laser cutting machines requires serious consideration of your specific needs. First, determine the materials and thicknesses you will be using, as not all machines work with the same materials. Also, estimate the power and precision of the laser, as these will impact the speed and accuracy of cutting. In addition, consider the machine’s maintenance and operational expenses, including energy, and changing parts. Don’t forget to check if the software is user-friendly as intuitive controls boost productivity and minimize training. Last but not least, check the warranty, build quality of the machine, and manufacturer support for long-term reliability and performance.

Assessing the Specifications of the Laser Cutter Machine

Having the correct type of laser along with the appropriate cutting power and capacity is crucial to effectively functioning laser cutting machines. Using CO2 lasers is very effective for cutting wood, plastic, acrylics, and other non-metal materials, while fiber lasers are ideal for stainless steel, aluminum, and even brass as they cut quickly and accurately. The thickness of the material is a consideration when assigning laser power; approximately 500W to 1500W is adequate for metals that are 6mm thick or less, but anything over 6mm will require a more powerful laser of 2000W or above. The design of the machine as well as its focal length alter the cutting capacity, as depth and quality of the cuts are reliant upon it. The accuracy is enhanced through equipment with automatic focusing features, increasing the cutting efficiency for different materials. Verifying these parameters against the intended application will help ensure functionality and cost-effectiveness.

Evaluating machinery scale as well as working area constraints

To establish the ideal size of the machinery and the corresponding workload area, one has to consider the measurements of the intended materials and how much space is available for operations. For instance, small-scale applications require small-footprint desktop laser cutters that only need a workspace that is 2 feet by 2 feet. However, high volume or large format jobs are more efficiently handled by industrial-grade machines with larger beds like 1500mm x 1000mm or 1300mm x 900mm. Furthermore, the machine’s working area must be larger than the material’s largest dimension to increase operational efficiency without repositioning the machine or multi-step processes.

Further to that, it is important to have ventilation systems and exhausts built into the workspace for health and safety considerations. Machines that have external exhaust ports will need additional spacing for the ducting. Enclosures may also need to have specific dimensions for Fiber lasers so that the users can be protected from hazardous scattered light. All these considerations must be made to ensure that operational efficiency does not come at the cost of safety standards.

Calculating the Cost of Maintenance, Support, and Long Term Solutions

I set my sights on dependable warranties and reliable technical support regarding long-term maintenance, support, and costs. There should be detailed instructions for Maintenance, including how often servicing support is needed and the replacement parts cost since these factors will greatly impact operating costs over time. Furthermore, I check the energy usage and the potential software license payment to confirm that my budget will stretch enough for my needs. I aim to choose reliable equipment backed by great customer service to solve any issues that may arise without incurring extra costs and wasting time ensuring maximum efficiency in operations in the future.

How are industrial laser cutters revolutionizing modern manufacturing?

Modern manufacturers are being transformed by the use of industrial laser cutters as they offer precision, speed, and versatility that is unmatched in material processing. With the help of these cutters, intricate designs and cuts can be achieved on metals, plastics, composites, and a variety of other materials with very little waste produced. The efficiency achieved with these cutters reduces the production time without sacrificing quality, which makes them an ideal choice for industries that need precision and accuracy on small-batch or customized orders. Furthermore, the integration of CAD software into laser technology reduces manual intervention, which increases workplace safety and reduces labor costs. Integrating the CAD software into the systems allows for improved accuracy because one flaw in the design can ruin the entire process adding to costs.

Improving Precision and Production Efficiency

Using non-contact techniques such as laser beam cutting allows less effort and resources to be put into tool and material maintenance. The output received is high-quality and the method used reduces wear to the tools put through the laser beam cutting. This non-contact technology paired with the use of CAD software allows for greater speed in operations to be achieved without wasting materials or resulting in costly repairs because precision cuts can be made. Integrating CAD software with laser technology minimizes resource exploits while enabling comprehensive modifications to heighten workflow and curtail manufacturing errors.

Enabling Complex Designs and Rapid Prototyping

Industrial laser cutters can create rapid and intricate designs for ease of prototyping. Their range of materials broadens the scope of complex structures that can be produced, which is otherwise tricky using regular methods. This is especially positive for product development because it allows numerous rounds and tests of prototypes without extensive retooling. The adaptability of these machines assures scalability, making them suitable for small-scale innovation and large-scale production with consistent accuracy.

Sustainability and waste reduction in manufacturing

Waste reduction and improved sustanabilty, especially in the construction of prototype models, can be achieved by combining resource efficient approaches and advanced technologies. While doing a lean manufacturing approach, AI and automation increases resource allocation and minimizes mistakes. By embracing a circular economy, materials can be reused or recycled while also designing products in a way to conserve and change as little resources as possible. Additionally, there is further waste minimization, energy, and environmentally friendly material consumption by choosing energy-efficient equipment.

Reference sources

Frequently Asked Questions (FAQs)

Q: What is a laser machine and how does it work?

A: A laser machine, also known as a laser cutter or laser engraver, is a cutting tool that uses a focused laser beam to cut or engrave materials. It works by directing laser energy at the material, which then melts, burns, or vaporizes it, creating precise cuts or engravings. Industrial laser cutters can cut a variety of materials, including sheet metal, plastics, and wood, with high cutting quality and accuracy.

Q: What are the different types of laser used in industrial cutting?

A: The main types of laser used in industrial cutting are CO2 lasers, fiber lasers, and solid-state lasers. CO2 laser cutting machines are versatile and can cut non-metallic materials effectively. Fiber laser cutters are more efficient for metal cutting, especially for thick metal. Solid-state lasers, like Nd:YAG lasers, are used for specialized applications. The choice of laser type depends on the materials being cut and the desired cutting quality.

Q: What is the maximum cutting thickness a laser cutter can handle?

A: The cutting thickness a laser cutter can handle depends on the type of laser and its power. For example, a 1500W fiber laser can cut through mild steel up to 16mm thick, while a high-power CO2 laser might cut up to 25mm thick acrylic. Cutting thick materials requires more laser energy and may affect the cut edge quality. It’s important to match the laser’s cutting capabilities with the material and thickness requirements of your project.

Q: How does a laser engraver differ from a laser cutter?

A: While both use a laser beam to process materials, a laser engraver is primarily designed to create markings or shallow designs on the surface of materials, whereas a laser cutter is meant to cut through materials entirely. Many industrial laser cutting machines can perform both cutting and engraving functions, making them versatile tools for manufacturing. Laser engraving machines typically operate at lower power levels and can create intricate designs on various surfaces.

Q: What advantages does a fiber laser machine offer over other types?

A: Fiber laser machines offer several advantages in industrial applications. They are more energy-efficient, have lower maintenance requirements due to the absence of a laser tube, and can cut with a laser beam that’s more easily absorbed by metals. A fiber laser can cut faster than CO2 lasers when working with thin to medium-thickness metals, making them ideal for high-volume production. They also provide excellent cutting quality and precision, especially for sheet metal fabrication.

Q: Can industrial laser cutting machines cut 3D objects?

A: Yes, some advanced industrial laser cutting machines can perform 3D laser cutting. These systems use CNC (Computer Numerical Control) technology to move the laser beam or the workpiece in multiple axes, allowing for cutting and engraving on three-dimensional objects. This capability is particularly useful in industries like automotive manufacturing, where complex parts with varied geometries need to be processed.

Q: How do CO2 laser cutting machines compare to fiber lasers for industrial use?

A: CO2 laser cutting machines and fiber lasers each have their strengths in industrial applications. CO2 lasers excel at cutting non-metallic materials like wood, acrylic, and textiles, and can also cut thicker materials effectively. They’re often preferred for laser tube cutting of large-diameter pipes. Fiber lasers, on the other hand, are superior for cutting reflective metals like copper and brass, and they offer faster cutting speeds for thin to medium-thickness sheet metal. The choice between CO2 and fiber lasers depends on the specific materials and cutting requirements of the manufacturing process.