Understanding Zero Turn Mowers

Zero-turn mowers generally have a wider repair/maintenance reach over regular mowers, as they are well-suited for high-end operations. These mowers and most zero-turn mowing tools come with two levers in place of the standard steering wheel; as such, they give the operator more grip control in most mowing modes, and even when managing some flowering beds around the yard in tight circles. Consequently, it also allows for turning around obstacles easily, such as trees and hedges, as well as orange groves and other fruit-bearing plants. These higher mowing speeds could lead to savings in time, as well as more satisfactory results in terms of defect reduction, compared to the time spent mowing and other season-pass related parameters.

What is a Zero Turn Mower?

The zero-turn motor’s lawn mower is a highly powerful machine that incorporates two hydrostatic transmissions, operated by levers, to provide efficient movement and mowing on both complex and straightforward geometrical terrain, as well as widely planted areas.

How Zero Turn Mowers Differ from Traditional Lawn Mowers

| Feature | Zero Turn Mowers | Traditional Lawn Mowers |

|---|---|---|

| Maneuverability | Exceptional, turns on a dime | Limited, larger turning radius |

| Speed | Faster, up to 8-10 mph | Slower, around 3-5 mph |

| Cutting Precision | High, ideal for tight spaces | Moderate, may miss patches |

| Terrain Suitability | Best for flat, open areas | Better for uneven or hilly terrain |

| Towing Capacity | Limited or none | Can tow carts and attachments |

| Learning Curve | Steeper, uses lap bars | Easier, uses steering wheel |

| Comfort | High-back seats, ergonomic controls | Basic comfort, better for varied terrain |

| Price Range | Higher, $2,500 – $10,000+ | Lower, $1,500 – $4,000 |

| Maintenance | Fewer moving parts, less frequent upkeep | More parts, higher maintenance needs |

| Best Use Case | Large, flat lawns with obstacles | Mixed-use, hills, and multi-season tasks |

Benefits of Using a Zero Turn Mower

Increased Agility

Thanks to their construction, zero-turn mowers surpass other machines in terms of maneuverability. They permit their users to perform 180-degree pivots as they cut around flowers, shrubs, or contour vegetation from within these obstacles, thus saving on time and avoiding further ancillary cutting.

Reduced Mowing Times

The reason is the fact that for the traditional lawn mowers zero turn mowers will be relatively faster, up to half less the time that is usually taken. That’s because they tend to be used for larger areas of cutting that are too much for domestic purposes.

Accurate Cutting Performance

It is the double Hydrostatic transmission and its control structure that enables the machine operator to make clean and accurate cuts. These mowers provide uniform trimming of the boundaries of your grounds, thus making them appealing and giving a professional look.

Strength and Endurance

Zero-turn mowers tend to be reliable and robust since they are designed with strong materials and good mechanics for their longevity. Mowers are also typically made with reinforced decks and heavy frames to facilitate easy mowing even in the most demanding conditions.

Suitability for Various Landscapes

Zero-turn mowers work well on even more tricky grounds such as slopes and hills. They have a high center of gravity and have their decks adjusted to the heights needed. This is what makes them secure and capable of being used on different types of lawns.

Preparing to Drive a Zero Turn Mower

- Consult the Instruction Manual: Review the manual before using the rake to become familiar with the rider mower’s modes of operation and its safety features.

- Examine the Mower: Ensure the machine has fuel, recheck the tire pressure, and inspect all the parts that make it up. Ensure that any visible issues are resolved so that work can commence.

- Go through the Operation System: Mount the equipment, and then try the steering levers, throttle, brakes, and blade system.

- Empty that Section of Grass: Clear the yard of any objects, stones, or encumbrances which may have the potential to endanger safe and productive cutting.

- Increase Speed Gradually: Start driving at a very low speed for some time to get accustomed to steering and turning on the lawn mower.

This is the most reliable way to learn how to operate a zero-turn mower. Safety should be observed at all times; owners should heed the instructions.

Safety First: Essential Precautions

⚠️ Safety Guidelines

People who know how to turn a zero-turn mower must be aware of the risks involved and the steps towards safe operations. Accordingly, there are specific measures to protect and safeguard the operators from falling into this hazard:

Safety Wear – Protective Equipment

Try to wear supportive, well-constructed shoes with a rubber outsole that are not slick or overly baggy, as they may get tangled inside the rotating parts of the mower. Basic personal protection equipment (PPE) devices, such as goggles and earplugs, are recommended by OSHA, that is, the Occupational Safety and Health Administration, in order to aid safety.

Take a Look at the Mower before it is put to use

Check and ensure that your riding mower is in perfect condition before use. Ensure there are no loose nuts or bolts, inspect the belts and tire air pressure before work. Through research, about 30% of the chances of equipment failure can be eliminated through over-maintenance, hence enhancing the safety of the operator.

Watch Out for Hills

Mowers with a zero-turn radius tend to be more unstable on slopes. The ideal way to mow slopes is sideways rather than up or down to reduce the chances of a fall. The CPSC further recommends against operating on slopes greater than 15°.

Keep Bystanders Away

Ensure that children, animals, and other people are not present in the area being mowed. Approximately 85,000 cases of lawn mower injuries occur every year in the USA, and a number of them involve people who were not using the machine, according to the American Academy of Pediatrics.

Use Terrain With Caution

When the grass is wet, the mower tends to lose traction and get more complicated to operate. As well, the chances of tipping are higher on rough ground. According to a University of Kentucky study, many mowing accidents occur every year on either wet or uneven ground surfaces.

To minimize the risk of accidents while maximizing the efficiency of mowing operations, operators should stay updated on mower safety enhancements and adhere to the above safety precautions. Be sure to consult the safe operation manual provided by the manufacturer to understand how to operate a zero-turn mower safely.

Familiarizing Yourself with the Controls

Learning how to operate a zero-turn mower’s switches properly is essential and helps in performing activities safely and effectively. The modern lawnmower features several controls designed and installed for efficiency, convenience, and durability. Below are some of the main switches that one needs to know about:

- Throttle Control or Lever: The throttle control is used to control the speed of the engine; hence, how fast or slow one works is dependent on the ground conditions or the mowing conditions. When the grass is too thick or highly concentrated, higher throttle settings are used; however, for light work, lower throttle settings are more appropriate.

- Blade Engagement Lever/Switch: Activates Cutters – This lever engages the Cutters for cutting purposes only. It is never involved when the mower is starting or stopping.

- Brake: A braking component that keeps immobilizing the mower in one place. The parking brakes must be applied when stopping or leaving the mower.

- Height Adjustment Lever: This lever enables users to raise or lower the mower deck, determining how much of the grass should be cut. Maintaining correct grass heights is beneficial for growing purposes and minimizes the amount of grass clippings that are thrown out.

- Driving and Steering Controls: This includes either a steering wheel, hand controls, or push bars for navigation, depending on the type, make, and model of the mower. Harnessing these controls is the key to piloting and toggling the mower smoothly.

Ensure that you always read and clearly understand what each control does before using the mower, as this will increase safety levels during use and minimize any injuries arising from misuse or poor handling of the mower, resulting in the desired mowing effect.

Checking Your Mower Before Operation

Conducting a thorough examination of your mower is essential for operating it safely and maintaining its good condition. The following most basic issues are crucial to check:

Availability of Fuel and Oil

Check if the hot →wing the mower does not run without oil and the fuel is also within the range. The change in oil quality and the use of non-ethanol gas can help reduce the wear and tear on the engine. According to manufacturers’ findings, it is surprising but nearly 80% of mower failures are caused by a lack of understanding of the maintenance of two consumable spare parts: oil and fuel.

Air Cleaner

Cleaner with dirt can suffocate engine since it deprives the engine of air thus affecting horiwsment functioning of the engine. Inspect and clean the air cleaner, or replace it as necessary. The replacement of the blocked air filter provides up to 1a 5% performance boost to engines per business statistics.

Blade Related Problems

Examine the lawnmower’s blades for any damage or signs of wear. Sharp blades result in a precise cut, encourage the growth of healthy grass ,and do not cause extra strain on the mower. Research has proven that sharpening the blades increases cutting efficiency by 30% and also extends blade life. Do not opt to ‘make do’ with worn-out, low-cost blades rather than getting new ones or finding someone with the facility.

Tires and Wheel pressures

For wheeled mowers, ensure the tires are inflated to the correct pressure. Non-uniformity in tire pressure can cause the height of the cut to vary and also make it difficult to operate the mower. Maintaining the correct tire pressure is crucial to ensure uniform cutting and ease of operation, particularly when working on uneven surfaces.

Battery Testing (In Case of Electric Model)

For a battery electric mower, check for any damage or leaks in the battery, and ensure the battery is fully charged. Healthy batteries assist in delivering uninterrupted power when required as well as increasing the time that a machine. According to statistical data, most operational failures in electric mowers are attributed to battery concerns.

Belts & Control cable

All of the belts and cables must also be checked for any signs of damage, frayed edges, or misalignment installed on the machine. The equipment may cease to function correctly if the damaged or loose parts are not checked. According to recent maintenance statistics, regular belt checks have the potential to significantly reduce the risk of failure by up to 40% in terms of depreciation.

Cleaning the Deck

Grass clippings, dusty debris, and build-up on the mower’s deck are quite common. This cleaning exercise enhances ventilation and inhibits rust from advancing. Research investigates the prevention of deck corrosion via cleaning by fifty percent, thus increasing the shelf life of lawn mowers.

Safety Features

Ensure that the operational safety devices, such as protective guards and main switch-off elements, are in good working order. Safety features that do not work expose the operator to dangers; never use the lawnmower before ensuring that these are correctly set.

Avoiding each of these safety stops helps ensure that the mower is running as it should, and also reduces the likelihood of breakdowns or accidents. It is imperative to take this caution every time, as the best garden equipment companies and lawn care businesses will always encourage users to perform regular inspections.

Step-by-Step Instructions to Drive a Zero Turn Mower

| Step | Instruction |

|---|---|

| Safety Check | Wear protective gear, check surroundings. |

| Prepare Mower | Check fuel, oil, and tire pressure. |

| Start Engine | Engage the parking brake, turn the key to start. |

| Adjust Throttle | Set the throttle to mid or high after starting. |

| Engage Controls | Move steering levers inward to operate. |

| Move Forward | Push both levers forward slowly. |

| Reverse | Pull both levers backward. |

| Turn Left | Push the right lever forward, the left lever back. |

| Turn Right | Push the left lever forward, the right lever back. |

| Stop Safely | Return levers to neutral, engage parking brake. |

Starting the Zero Turn Mower

Before I start the engine of a zero-turn mower, I ensure it is in parking mode and in a neutral condition with regard to the control handles. A basic check ensures the blades are off before twisting the key to start the engine. If there is no problem with the engine starting even after running for a while, I cancel the parking mode and begin operating the mower by sliding the control handles forward.

Using the Levers for Steering

The application of leverage enables the control of a vehicle with such a design, and thus, levers become the primary steering and navigational controls of the machine. Thanks to the levers, it provides precision and smoothness by utilizing them effectively. The details below outline the essential information and functions of the levers as used, five of them.

Moving Forward

To advance the mower in a straight line, advancements are made on both levers with equal force. Pushing all the way makes the machine go faster.

Going Back

It outweighs everyone and allows the operator to pull together two levers, enabling the machine to move backward. While doing so, take care of the surroundings.

Left Turn

Push the right lever forward and leave the left lever in neutral or draw it slightly backward. Thus, the mower will be involved on the left.

Take A Right Turn

Forward move the left lever while the right lever is left in neutral or even slightly pulled back. Such a movement ensures turning to the right.

There is A Stopping Plummet

To completely stop the mower from operating, return both levers to their neutral positions. Control handles should always be returned to the center before getting off the unit to make any changes.

Excelling at the five functions makes riding a zero-turn mower effortless; it assists in operating the mower, including how to turn a zero-turn mower in confined areas, and cutting grass to the desired perfection.

Executing Turns and Maneuvers

Learning how to operate a zero-turn mower effectively is crucial for enhancing efficiency and achieving a high-quality cut. This is because these mowers are built in such a way that each of their wheels is controlled independently; therefore, they are more maneuverable than traditional types of mowers.

Turning within a given radius

A turning technique, referred to as a pivot turn, occurs when one of the wheels stops moving and only the opposite wheel continues to move, controlled to allow the mower to turn tightly around a fixed point. To achieve this, one of the levers should be raised to the neutral position, whereas the other should be pushed back. The motions should be carried out in a smooth manner, or else the grass will be damaged.

Turning totally to the Zero

To execute a 360-degree turn, one of the levers is pushed forward while the same distance pulls back the other. This simple action turns the mower around its vertical axis, but it is convenient when mowing around obstacles or changing directions. To keep the grass healthy, however, the procedure should be executed with the fewest possible turns to avoid scuffing and damaging the turf.

Figures about Usage with Bikes

According to field studies, the time spent on mowing with a zero-turn mower can be reduced by 30% and in some cases by 50% if compared with transportation-type mowers with more manipulations, especially when cutting areas with many segments. The introduction of these saves a significant amount of fuel, improving the mower’s ability to turn on the spot without requiring multiple rotations and passes, which enhances overall productivity. There is an improvement range of up to 20% in organisational productivity if one learns the basic techniques of working more efficiently in less time.

💡 Workout Tips for Getting the Desired Outcome

- Move at a constant pace: Administering sharp lever movements should be avoided because they tend to cause lawn unevenness.

- Analyze the terrain: making a turn in wet or muddy ground is more problematic due to the slippage of the wheels. Try to provide enough grip to control the vehicle.

- Begin in a less complicated area: Before entering detailed spaces, perfecting the turns by sitting idle in a horizontal area should be practiced and imitated.

With the perfection of the mentioned techniques and in addition to the modern turning movements of the mower, where the operator operates the machine, they may enjoy greater results without unnecessary overworking of the machinery and sodding.

Tips for Effective Operation

- Perform requisite upkeep: Keep the mower in top-notch performing shape by frequently inspecting various parts such as the blades, belts, tires, and more. For instance, properly sharpened blades can increase cutting performance by as much as 30% and inflation of tires within the prescribed range saves on fuel and improves agility when mowing.

- Lower when necessary: Adjust the cutting height for each trip according to the grass kind andthe period of the year. During cool periods, it is advisable to allow grass to grow higher, as this helps increase the root system. Though the majority of species do satisfactorily at 2.5-3 inches in height.

- Check the fuel gauge and fill fuel with caution: Major consequences of low fuel levels include running out of the engine or worse still, causing damage to the engine. When refilling the mower, use the valve in a ventilated area and refrain from filling too much to avoid petrol spillage.

- Organize the grass cutting process: Use correct mowing techniques, e.g., overlap to mow the lawn evenly, avoiding the possibility of any missed patches. This helps to vary the mowing pattern from week to week and also relieves the grass from excess pressure, avoiding compaction of the ground.

- Never stack the dishes on top of each other unless they are dry, or they may crack: This is kitchen equipment; it is unlike any other type of body transport equipment, and it is therefore essential to observe these safety instructions. Most comprise a spectrum of instructions on how to clean specific parts and how to care for the user. There might also be instructions on how to maneuver particular types of mowers, including instructions on how to turn a zero-turn mower.

- Keep an eye out for any obstacles: Clear any debris, rocks, and other objects away from the grass cutting area to avoid achieving damage to the mower, while also ensuring the user’s safety. Mower blades can suffer from wear or cause project evry dangerous objects even when there are tiny objects present on the way.

Best Practices for Mowing

Keep in mind the optimal height for the grass.

Cutting grass too low can cause damage to the turf; this act is called ‘scalping’. An expert’s piece of advice is to keep the height of the majority of lawns at 2.5 to 3 inches, as this provides the possibility for the supply of more beneficial growth of roots as well as the grass. Several studies suggest this because the higher height of the lawn keeps the soil temperature cooler as it physically shades it, and this reduces the presence of evaporative moisture by 30%.

Sticking to a mower schedule

The rate at which grass grows changes over different seasons and weather conditions. In order to keep the condition of one’s lawn perfect, mowing is not based on a specific calendar date but instead based on the level of growth. As a rule, during the growing seasons, especially late spring and early summer, the mower will be engaged once every seven days. Data shows that performing a regular cut prevents the lawn from growing excessively long and being overrun with thatch and misshapen.

Maintain sharp mower blades.

When blades become dull, they are unable to cut the grass. Instead, they make it appear torn. This can lead to unwanted brownish saw-shaped leaf tips and make the grass more susceptible to diseases. Consequently, it is advised that mower blades be sharpened approximately every 20 to 25 hours of mowing or at least in a season’s worth of use. And who wouldn’t want their lawn to enjoy all the benefits of a clean cut, along with enhanced aesthetic appeal?

Do not Remove Grass Clippings. Use them as Mulch.

It is also important not to remove the grass clippings, as such mowings can be left on the grounds to decompose. Some researches show that clippings can restore nearly 25 % of the nutrients picked up from the grass back to the ground, thus reducing the need for such fertilizer. With a bonus, they are environmentally friendly and can be applied as soil conditioners and moisture-saving derivatives.

Improve the efficiency of lawn maintenance by integrating the different approaches to watering and mowing.

According to the USDA, the lawn should be deep-watered, but not so often. This will result in approximately one to one-and-a-half inches of water (including rain) in a week. Mowing should be done when the grass is dry to reduce the risk of clumping and achieve a more uniform cut. Such a combination of techniques creates an ideal environment for optimal grass growth.

Using these time-tested methods in consideration of recent research, one can have better conditions of the lawn with the lowest possible investment of effort and resources.

Maintaining Speed and Control

Adequate management of pace and steering is crucial for achieving uniform and effective lawn care outcomes. The following are five specific ways and tools for guaranteeing accuracy and success.

Mowing Speed

For the optimal mowing process, different speed settings must be used depending on the type and the height of the grass. Current studies suggest that most individuals who use push mowers require a gentle walking speed of approximately 3 miles per hour to achieve both precision and control.

Address Mower Blade Sharpness

In the instance of cutting tools, it is essential to remember that blunt edges do not cut grass but rather rip it. As a result, the turf does not grow uniformly, and there is extensive damage to the grass. For optimal blade performance, the taken-up blades should be sharpened roughly every 20 to 25 hours of utilization.

Make Sure You Have the Right Tire Pressure

There is usually a correct pressure that mower tires must maintain for any make or model, as otherwise, the mower will not cut evenly due to improper contact with the ground. Furthermore, using adequate pressure promotes control. Now, onto how to turn a zero-turn mower.

Observe the One-third Protocol Responsive mowing.

Prevent more than a third of the overall height of grass being mowed at any one time. This will relieve the grass of undue stress and enhance its ability to regrow. As an illustration, do not cut more than a third in case of 3 inches high grass; only a maximum of 1inch should be cut.

Find an appropriate Mowing pattern according to the Area

To preserve the grip and reduce incidents of rolling over, mow areas with hills or uneven ground diagonally or horizontally. Results from studies indicate that this practice reduces the risk of slipping and provides a smoother surface.

By employing these practical techniques, you will be able to cut the grass at a terrace area properly, without speeding dangerously when operating a zero-turn mower, with added beauty to your lawn.

Avoiding Common Mistakes

Every person striving to maintain a lawn understands that any negative impact of even simple errors will affect the quality and appearance of his/her lawn. Below are some of these problems, researched and empirically specific and how they should be dealt with.

Lawn cutting too short; more commonly referred to as “lawn scalping”

The lawn damage that results from scalping or cutting the lawn too short leaves the lawn vulnerable to diseases, weeds, and pest attack. Purdue University reports that cutting the lawn more than a third of its original height does so much harm to the grass. It should be generally checked when cutting ,as most grass should be cut in levels of 2.5 to 3.5 inches.

When cutting grass, use devices with sharp cutting blades.

It is very frustrating to do straight cuts when the blades of the lawnmower are blunt as opposed to cutting grass neatly with a sharp blade. University of Florida’s Speclalislss are of a view that mower blades need to be whetted and sharpened every 20 to 25 hours of usage to cut grass effectively as well as maintain good turf grass.

Using a Lawn Mower on Wet Surfaces

Wet grass binds itself to the blades of your mower, resulting in a blade that cuts often unequally and also clogs the mower. This also exposes your freshly cut grass to fungal infections. A report by Google in 2023 reports that it is better to wait for it to dry out before conducting such activity, which would lessen the chances of the mentioned problems and, at the same time, accomplish the task of mowing cleanly and evenly.

Failure to Manage Clippings

Contrary to people’s beliefs, they think grass clippings should not be left on the lawn after mowing (replicating), which is wrong. Researchers indicate that most of the clippings break down relatively quickly, restoring nutrients such as nitrogen to the ground. It helps to cut down the consumption of chemical fertilizers by twenty-five percent.

Repeatedly Mowing in the Same Fashion

Repetition of the same pattern while mowing in the end compresses the soil and results in some surfaces growing faster than others. Change the direction of mowing each time – mow vertically, horizontally, and diagonally in order to promote growth imbued vertically and avoid soil compression.

The above-stated mistakes should be avoided since the techniques that are mentioned first are well-supported by science, hence, homesteaders will always have their lawns going green. Advice on how to cut grass changes every yea,r and that helps to make sure lawn care methods are up to date and helpful.

Post-Operation Care for Your Zero Turn Mower

| Step | Instruction |

|---|---|

| 1. Clean Mower Deck | Remove grass, dirt, and debris after use. |

| 2. Check Air Filter | Inspect and replace if dirty or damaged. |

| 3. Sharpen Blades | Ensure blades are sharp for clean cuts. |

| 4. Inspect Belts | Check for cracks or wear, replace if needed. |

| 5. Change Engine Oil | Follow manual for oil change intervals. |

| 6. Grease Components | Lubricate spindles and moving parts. |

| 7. Check Tire Pressure | Ensure even pressure for balanced mowing. |

| 8. Add Fuel Stabilizer | Prevent fuel degradation during storage. |

| 9. Store Properly | Keep in a dry, covered area. |

| 10. Inspect for Damage | Look for wear or loose parts after use. |

Cleaning and Maintenance Tips

🔧 Essential Maintenance Tasks

Clean the Bottom Part of the Mower Deck

The compressor deck must be kept clean, and most importantly, clean every time it is mowed – it is a consequence of grass and soil that can get lodged under the deck. Such conditions always result in dull mowing blades. For this purpose, use water hoses or pressure washers after mowing.

Checking the Air Filter and Replacing if Needed

If the air filter is too dirty or even blocked, it will prevent the engine from running at its full potential. Perform a regular inspection of the air filter cavity after 25 working hours, and if it is filthy, replace the air filter to maintain the engine’s good condition.

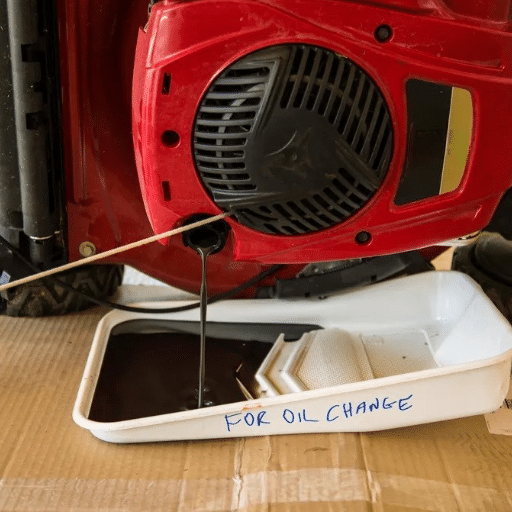

Draining and Changing the Oil as well as the Oil Filter

An engine long life would not be possible without constant oil control. First, change the oil after 5 hours of mowing and subsequently after each 50 hours of operation if properly directed by the manufacturer. Also, make sure the filter is changed as well, and in some cases, keep the oil filter installed like this to provide further contamination protection for the engine.

Blade Inspection and Detailing

Each time the mower is used, the blades are to be inspected, and if they seem blunt, they should be sharpened. Where nicks and chips occur, these can be removed using a file, while bent blades or blades with worn-out cutting edges should be changed for smooth and even cutting.

Examine Tire Pressures

Variations in tire pressure or incorrect tire pressure can lead to inconsistent grass cutting and tire wear. Utilizing a tire gauge, check all four tires to determine that they are at the correct PSI desired by the manufacturers in order to maintain proper balance and even cutting.

Storing Your Mower Properly

Proper storage of your lawn mower has positive effects on the durability, efficiency, and savings from expenditure on replacements and repairs. Below are the most essential tips on how to turn a zero-turn mower into a storage box without damaging it:

Wash the Machine

Ensure that before any packing of the mower, the blade areas are cleaned well since small amounts of grass dust or dirt remain and cause it to rust or easily attract insects. You can use a garden hose, power washer, or take the mower to a car wash for a complete cleaning. However, ensure that it is scorched after this step to prevent any formation that could cause rust.

Empty the Gas or Fill it with Stabilized Fuel.

Any remaining gas should be drained from the mower since it has the tendency to turn stale with time and may clog the machine if you intend to keep your mower beyond the thirty-day mark, either empty the gas tank or pour in some stabilizer so that the fuel does not change its character during storage. In this regard, it is opined in some quarters that fuel deterioration typically starts within thirty days or so, and the engine can no longer perform.

Replacing Engine Oil

One aspect of the old oil is that unfresh oil tends to develop particles that will damage the engine parts over time. Perform an oil change before storing the mower, to protect the engine against residual substances that can accumulate during idle periods.

Take Out or Disconnect the Battery

Okay, in case you have a battery-powered mower, unplug the battery to avoid any discharge from occurring. The battery should be stored in a cool, dry place. The charge status of the battery should be checked within some time frame if the usage of the mower has been compromised for months.

Guard the Blades including any metallic parts.

Running-in oil or rust-preventing oil can be sprayed over the blades and other metals so that they are not exposed during storage. This measure is taken to avoid any air moisture and rust from affecting the blades and metals.

Decide where to Store Each part of the Mower

It’s always best to leave the machine in a dry, sheltered area, such as a garage or shed, rather than leaving it outdoors. Do not expose the machine to the elements, meaning machines should not be left outdoors or in moist surroundings where rain, frost, or high humidity will cause the components to rust and may even lose vital components; machines should always be covered. Temperatures between 40°F and 85°F are regarded as the optimal storage ranges.

Store the Mower

Covering the equipment with an agency-appropriate breathable mote cover to protect it from dust, dirt and moisture high will help allow proper air circulation within the units. Do not use any plastic cover, as this will lead to condensation, promoting corrosion.

Following these steps of packing, rather than just waiting for the upcoming season and using your mower, helps it last longer. If there is some effort at the beginning, it makes it unnecessary to incur wasteful expenses on repairs or purchases afterwards.

Regular Maintenance Checks to Ensure Optimal Performance

Proper maintenance is crucial not only for the longevity of your mower but also for its enhanced performance and adequate functioning. To ensure your machine remains in good condition and functions properly for an extended period, perform the following simple checks periodically. Here you can find a few basic maintenance steps that should be done:

Examine and Change the Air Filter

Air filters prevent dust and other objects from reaching the engine. Check the air filter regularly, especially when mowing season is in full swing. A dirty air filter very often decreases the engine’s power and results in an increase in fuel consumption. If it is messy, that means it should be replaced or after about 25 running hours it is advisable to replace it.

Oil and Oil Filter

New oil keeps the engine lubricated and prevents the degeneration of the wear and tear characteristics of moving parts. For most mowers, regular oil changes are recommended in the user’s manual and should be performed every 50 hours of use or at the end of each season. The type of oil applicable to your mower should be adhered to.

Blades and it’s sharpening.

Unsharpened mower cutters break the turf as opposed to slicing it sharply and cleanly, which causes improper growth and elevates the probability of various diseases. Examine the blades frequently and if needed, sharpen them every 20-25 hours or in case one notices that it is leaving uneven ‘cuts’. Replace blades that are severely damaged for safety purposes and to prevent inefficiencies.

Check the Spark Plug

This, however, can be due to the malfunctioning of the spark plug, hence making it hard for the mower to start and also its performance. Be sure to check the spark plug at the beginning and end of mowing season and change it if it is corroded or shows signs of wear and tear. As a general rule, it is recommended to change a spark plug at least once a year.

Clean the Undercarriage

The under deck of the mower can trap any grass cuttings, soil, or other materials, which compromises air flow, which affects its clipping capacity. After each mowing operation, clean the mower’s undercarriage using a garden hose or a scraper to allow proper airflow and prevent rusting.

Carrying out the above-mentioned maintenance checks regularly will ensure proper functioning of the equipment, as well as increase the longevity of the mower, saving time and cost in the future. Introduce these activities as part of your standard operating procedure, and it will not be a problem if there is a need to use the lawnmower’s services because it will always be ready for any action!

References

- Columbia University – Zero Turn Attachments: Revolutionize Your Lawn with Zero Turn Attachments – This guide covers various types, benefits, installation, and maintenance tips for zero-turn mower attachments.

- Tufts University – Zero Turn Electric Mower Conversion: Re: (ET) Zero Turn Electric Mower Conversion – Discusses early zero-turn mower designs and their mechanical systems.

- Clemson University – Hydraulic Circuits for Zero Turn Mowers: Remote Hydraulic Circuits for Zero Turning Radius Mowers – Explores the development of hydraulic circuits for accessory implements on zero-turn mowers.