Investing in an embroidery machine can be a significant decision, especially for businesses and hobbyists aiming to enhance their textile creations. Ricoma, a renowned brand known for its innovative and versatile machines, offers a range of options catering to different needs and expertise levels. This guide aims to provide readers with valuable insights into the cost factors associated with Ricoma embroidery machines, focusing on essential features like multi-needle capabilities and user-friendly interfaces. We will explore the various models available, their functionalities, and the pricing structures, helping you make an informed choice that aligns with your budget and embroidery goals. Whether you are a seasoned professional or a beginner, this article will equip you with the knowledge to select the right Ricoma machine for your crafting journey.

What are the different types of Ricoma embroidery machines available?

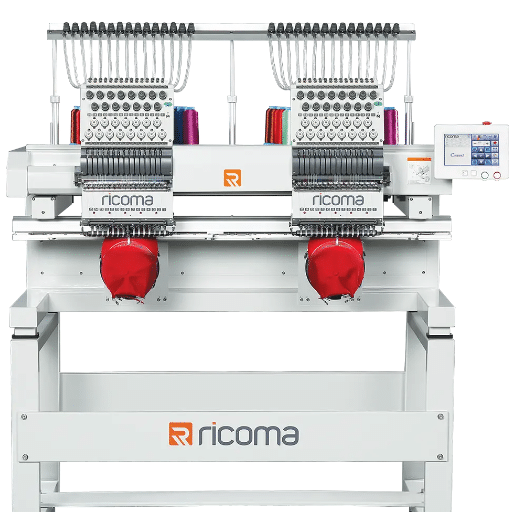

Ricoma has many embroidery machines that satisfy the needs of individual crafters and mass-production entities. To this end, in their catalog, Ricoma EM-1010 has a small and reasonably priced 10-needle machine ideal for small and increasing businesses or workforce embroiderer lovers. For more strenuous work, there are the multi-head machines of the Ricoma MT series with MT-1501, which is known for its efficiency and flexibility for high-volume designs, which is ideal for medium-sized embroidery businesses. The same goes for the Ricoma RCM series, single-head multi-needle machines with the power and speed needed while still having user-friendly high-end components. The overall layout of the machine is constructed in a way that supports various concepts and, at the same time, can suit different scales of production.

Exploring the EM-1010 and its features

The practicality and versatility of the machine have contributed to its popularity among embroiderers and businesses. For such a machine as the EM-1010, it is designed for up to ten needles; it enables rapid color changes, so it is possible to reduce the idle time between threads, which increases the overall efficiency. Its dimensions are moderate, which makes it very useful in a home studio or cramped quarters, and it does not damage the quality or performance of the machine. The software offered by Ricoma makes it easy to manage, as even the most complex designs can be made quickly. Advanced features include Wi-Fi connectivity, enabling efficient design uploads and updates. The machine also comes pre-loaded with numerous designs and fonts to express your creativity immediately. With the unwanted complexity of operations removed, EM-1010 caters to the needs of those who need simple but effective solutions for making embroidery more advanced.

Understanding multi-needle options

Different types of multi-need embroidery machines have different parameters, such as design and portfolio, which need to be evaluated according to the requirements and operational profile of the future machine. For example, the number of needles is critical because it will determine the number of colors that can be used without changing the thread. More complex designs consisting of layers of multiple colors are more effectively stitched and embroidered on machines with more needles, such as Ricoma MT-1501. Other important factors include the highest sewing speed of the machine, which is between 800 and 1200 stitches per minute, and the working area where the highest dimension of the design that can be worked on is set. Other parameters such as automatic threading, automatic or semi-automatic tensioning, and the type of hoops are also critical because they enable the machine’s smooth operation and use different kinds of fabrics for stitching. A thorough understanding of these parameters allows the operator to select a device suitable to the expected construction level and workload while enhancing smooth operation.

Comparing Ricoma with Tajima and other brands

When examining Ricoma in conjunction with reputed manufacturers such as Tajima, several considerations may assist you in agreeing on the one to purchase. Both brands feature some revolutionary technology, but the emphasis is on different particulars and customers. Machines of the Ricoma brand, such as the MT-1501 model, are more affordable as they tend to be of reasonable strength with features such as tension adjustment with generic interfaces. Essential parameters such as a maximum sewing speed of 1200 stitches per minute and a range of embroidery areas to suit larger designs make Ricoma win the hearts of small businesses, enthusiasts, and hobbyists alike.

On the other hand, Tajima has the best reputation in the market. It earns its prestige quality and reliable function concerned with massive scales of the commercial world. Tajima models assure great endurance of components as well as the availability of powerful/strong servo motors for movement control and satisfactory advanced integration of software. Their machines usually provide more than 1200 stitches per minute, plus a fair amount of volume for embroidery. Such high load and complex tasks can be satisfied.

The number of needles is significant for Ricoma and Tajima. The MT-1501 model by Ricoma and some types of Tajima have 15 needles; thus, many colors can be used without changing them by hand. Additionally, both brands help customers speed up the embroidery process with automatic threading and threading adjustments.

Ricoma is more appropriate for buyers looking for affordability and efficiency in their embroidery machine. At the same time, Tajima seems to be targeted due to its premium, top-quality offerings suitable for heavy-duty commercial use. Keeping these differences in mind will allow you to choose the suitable embroidery machine that balances your needs and expectations regarding production.

How do you choose the suitable Ricoma embroidery machine for your needs?

While looking for a Ricoma embroidery machine, factor in your project’s scope and budget. First, determine how elaborate your embroidery patterns will be and their size. If you anticipate handling more significant designs, find machines that have relatively larger embroidery areas, like the MT-1501. Consider whether speed is essential in your processes because Ricoma machines usually have an acceptable speed of 1200 stitches per minute, which is quite okay for most small businesses and avid hobbyists. Take note of the number of needles; the more needles you have, the more colors you can include without changing the threads manually, which boosts productivity. Furthermore, consider the following questions: how simple is the embroidery machine to operate, and what features, such as auto threading, may target audiences and assist in streamlining the workflow? Match these factors with your available finances to buy the model with the greatest return on your investment.

Considering the embroidery area and hoop sizes

It is necessary to clearly state the expectations, the area’s dimensions to be embroidered, and the hoop sizes for the Ricoma machine. Larger embroidery hoop sizes mean the possibility of more extensive and more detailed designs, which is preferred in commercial applications where logos are complex and bulk production is needed. Top resources online recommend combining the above with the standard sizes of the designs as if selecting a machine with rightly sized hoops, there is optimal usage of resources and material is not wasted. What also needs to be understood is that out of the many sizes available. Ricoma uses several different-sized hoops for small, medium, and big projects to make the machine versatile. Also, when conducting such a purchase, the manufacturing, with the capabilities of expanding the supplied sets of hoops, will come in handy when an increase must be dealt with. You can get the machine without compromising productivity and quality by paying attention to these facts and the functional requirements.

Evaluating embroidery designs and digitizing software

Regarding embroidery software, look for those capable of processing different file formats.DST,.PES,EXP, and other standard formats on the market when installing embroidery designs and digitizing software for Ricoma machines. It should be validated if the proceeded software delivers optimized resolution graphics and, in one way or another, allows advanced editing such as stylizing colors, modifying scale, and adjusting stitch density. Ideally, check if the software has design/ No Embroidery Template options, enabling the user to see how the final piece will appear before commencing with the embroidery work. For technical parameters, search for a device offering sewing, which delivers a minimum 0.4mm space between stitches, followed by other features such as satin, fill, and running stitches. Also, high-quality digitizing software can produce a more effective procedure that combines manual and automatic digitizing for fast transitions while providing the opportunity to make changes. Choosing the software that meets these parameters is also advantageous because it will integrate well with the embroidery machine during production.

Assessing startup requirements and financing options

You must understand the startup requirements when starting your embroidery business using the Ricoma machine. First, ensure you have an appropriate location for the machine and associated materials. Aspects to consider include adequate electrical supply for the machine’s operation and adequate temperature to ensure the threads and fabric materials are not compromised.

Concerning finance options, do not just rely on bank loans but also look for small business grants or equipment leasing to relieve yourself of initial costs. It is also advisable to look into any trade-in programs offered by Ricoma Company or whether the vendor may offer financing at a lower interest rate and better repayment terms. Considering these, however, should ensure effective financial management so that you only gamble large amounts on necessary resources and technology.

It is also critical for any start-up to factor in that the machine’s power supply source doesn’t exceed the recommended voltage requirements of 110V-240V; this should also be stable. General rule-of-thumb maintenance procedures, such as oiling the machine every 15 to 30 operational hours, can help increase the machine’s life span.

What are the benefits of using a Ricoma embroidery machine?

Many embroiderers, whether beginners or veterans have much to gain from using a Ricoma embroidery machine. First and foremost, they do not compromise on versatility or performance, meaning they can work with different materials and threads effortlessly. They offer a user-friendly interface to aid with designing and modifying, letting new users figure things out more quickly. Further, Ricoma machines come fitted with cutting-edge technologies that guarantee high levels of accuracy and repeatability of the embroidery, thus always promising a sound output. Thanks to the sturdy architecture and dependable functionality of Ricoma machines, downtime or maintenance troubles are significantly reduced, enabling a seamless workflow. Ricoma embroidery machines have that perfect mix of performance, affordability, and results that make them essential in any embroidery business.

The advantage of high-quality and reliable embroidery

The most significant advantage of good quality and reliable embroidery is that it benefits businesses and the end consumer. Aesthetic appeal is one of the benefits since embroideries are often used to decorate garments and other products. High-quality embroidery comprises tight, clear, colorful, and well-defined stitching, making the overall image more professional and refined, thus improving brand image and consumer satisfaction. Consistent embroidery practices ensure that product lines are the same, essential for any business to create a unique image in customers’ minds. Further, because of the quality of embroidery, the products have a longer life span, and they can withhold many uses and wearouts while still maintaining their attractiveness. Such durability reduces the possibility of mending or changing objects, thus saving expenses. The fact that aesthetic appeal, uniformity, and longevity are all attributes achieved through embroidery means it is definitely an asset in the textile. Such insights are further validated by authority opinions in the area.

How Ricoma machines expand your embroidery capabilities

Ricoma embroidery machines augment your embroidery capabilities with numerous technical improvements and enhanced features. First of all, these machines offer various sizes and configurations of the hoop, skillfully adapting to handle different project types suitable for the machine, be it small logos or large jacket back designs. Another amenity of a Ricoma machine is its high speed and efficiency because such machines can sew up to 1,200 stitches in one minute, which enhances time without compromising quality. Also, many Ricoma machine models have touch screens, making it easier for the user to change the design or the machine settings. Automatic trimmers and color changers are also advanced enough to minimize the number of operators’ interventions and mistakes while working. Also, on some models, updating the design and fixing problems can be done over the internet through Wi-Fi. These technical parameters generally allow thinking about customers’ ability to get embroiders with a wide range of applications effectively and efficiently. Ricoma company supports its clients with the right tools and ensures they are not limited in their designs.

Understanding the ease of use and touchscreen features

Virtually anyone can operate embroidery machines by Ricoma! Yes, even those with little or no experience in embroidery can handle the machines without any problem. Several models have an interactive touch screen, so the user can simply scroll and choose the required option without difficulty. Such screens are synonymous with clarity and high definition, so navigation has never been easy.

The screens are primarily between 7 and 10 inches, enough for good previews of the designs. These devices offer multilingual support, and most come with videos illustrating various machine operating methods that can assist newbie users. Other technological features like auto centering and size fitting make it easier for users to make fewer physical adjustments and instead be more imaginative or creative.

Another interesting technical aspect is the presence of a backlit LED or LCD, which is helpful for low-light situations, and capacitive touch, which responds well to input touch. These improvements make Ricoma’s machines effective and give embroidery specialists a high degree of flexibility for the market’s ever-changing demands.

How do I maintain and troubleshoot my Ricoma embroidery machine?

Regular activities must be completed for the precoma embroidery machine to work optimally and have a longer life span. First, clean the machine by removing dust and lint that might have accumulated in the bobbin area and needle plate with a brush or compressed air. To avoid the machine’s mechanical parts from overheating and seizing, oil them in specific locations mentioned in the user’s manual. Using only high-quality threads and needles is essential to avoid undue damage.

When dealing with everyday problems, the first task is to check the threading path and confirm that it is properly threaded and not connected in ways it is not supposed to be. Re-thread if necessary. In case of tension malfunction, gradually change tension settings while using the test foul to avoid attacking the settings. For software problems, usually, power off or update the software, and cash problems are easily fixed in this manner. Follow basic use instructions in the guide and contact Ricoma Machine’s service support for other complex issues. All types of rich precoma maintenance and its fragility during operation will allow users to enjoy working with this machine.

Essential maintenance tips for your embroidery machine

Some maintenance procedures require attention so that the embroidery machine will run smoothly. What is the importance of comprehensive cleaning on a routine basis? After all, block dust and yarn from the bobbin house and the needle plate with a small brush or compressed air. This avoids accumulation, which can result in mechanical breakdown. Another crucial maintenance activity is oiling the machine. Check the lubricating points in the user manual provided with the machine. It shows where and how much oil is to be applied for the smooth functioning of the machinery. Further on, there are numerous threads and needles that mushroom in the market, and using neat and up-to-mark ones reduces the wear and tear and performance of the machine.

In case of the need for machine troubleshooting, always check the machine threading first, as whatever incorrect ties and angles there are will probably create stitching and machine faults during its operation. In case of difficulty of tension, the tension settings should be changed in small increments. As far as this method is concerned, adjust the tension settings on scrap material until satisfactory tension has been reached. Begin with restarting the machine reinstall sequential updates if applicable; and such devices can be effective cures for software malfunctions. Remember that the machine manual should be read from cover to cover, and Chroma support services should also be sought in cases of deeper problems. However, following these recommendations will help you in some way to increase the service life and performance of the Ricoma embroidery machine.

Standard troubleshooting techniques for Ricoma models

When using a Ricoma model, the first troubleshooting measure is measuring thread tension in most situations outside of factory repairs. An ideal tension will vary depending on the fabric and the thread, but a ‘middle’ tension is best to use as this will avoid any tufts of thread protruding on either side of the fabric. It makes sense to begin with upper and bobbin tensions set to mid-range for the machine and adjust post-operation. If some stitched areas are left because the needle is out of ‘thickness’ deemed suitable for the thread-matrix fabric, consider reducing the current needle and using a stronger one for the current textile. In most cases, needles should be in the range of 75/11 to 90/14, with the crochet thread being the most common type for these needles.

When the machine fails to operate normally, or software issues are encountered, disconnecting the power supply and restarting the machine usually takes care of these minor problems. As much as possible, continually update the machine’s firmware to ensure up-to-date functionality and compatibility. In cases where needle breakage occurs often, make sure that the needle is set at the appropriate height where it is firmly secured, and reduce the speed of the machine to around 600 to 800 stitches per minute or to what is stated in the manual for thick or rigid materials. In case of thread breakages, check the thread path for debris or damage and employ quality embroidery threads to minimize these incidences. These recommendations deal with technical parameters that should be handled carefully to sustain an efficient operating condition in a Ricoma embroidery machine.

Where to find support and resources from Ricoma International Corp

If you want assistance or resources from Ricoma International Corp, their website is a good start since it contains valuable materials such as manuals, FAQs, and tutorial videos. They have a specific support page to entertain requests and offer technical support. Also, Ricoma is very active on social networks and YouTube, where they post compelling how-to videos and other helpful content. To save time when looking for assistance, it is better to contact them by email or phone, as their customer support can offer you precise help and advice concerning the technical parameters of your model and the problem you are solving. When requesting assistance for your equipment, always have the model number of your machine and its relevant specifications.

What accessories and tools are necessary for Ricoma embroidery machines?

To effectively operate Ricoma embroidery machines, several accessories and tools are essential. These include a variety of embroidery hoops for different fabric sizes and types, stabilizers to prevent fabric shifting, and embroidery threads in multiple colors for diverse designs. Additionally, a bobbin winder and pre-wound bobbins are practical for efficient thread management. Needles appropriate for different fabric weights are necessary, and using a lint brush or compressed air ensures the machine remains clean and functions smoothly. Lastly, having specialized software for design creation and editing can greatly enhance the possibilities for intricate embroidery work.

Exploring embroidery hoops and mighty hoop options

Embroidery hoops are crucial for success in embroidery tasks as they support maintaining the fabric in a firm position while sewing designs over the fabric. Among the options that can be sought, everyday wooden and plastic hoops can be found in several different sizes and shapes that can be used for other projects. All of them are alterable, thus enabling the user to clamp various fabrics securely for neat and clear results.

Mighty Hoops also incorporate magnetic locking mechanisms to ease the stress of hooping and unhooping the fabric. Fabric slippage is less likely to occur with these hoops, which helps maintain stability. The requirement of readjustments is greatly reduced. Mighty Hoops can be found in multiple sizes and are very effective, as they provide a good grip and can hold light and even heavy fabric materials.

If you choose between regular embroidery hoops and Mighty Hoops, remember to consider characteristics like the fabric type used in the project, its dimensions, and ease of use, which might be a factor in your preference. With the proper selection of the right hoop, the quality and productivity of the embroidery task, whether a hobbyist or a professional embroiderer, can be significantly improved.

Utilizing heat press and heat transfer tools

You can apply designs to different materials by pairing heat press and heat transfer tools with embroidery. A heat press machine uses heat and pressure to transfer images onto fabrics or other surfaces. When choosing a heat press, also evaluate the different technical specifications such as its temperature range, usually between 120 °C and 220 °C or 248 °F to 428 °F, and pressure settings that are generally adjustable for the different thicknesses of materials. The heat transfer process entails applying a printed design on the substrate, which is placed onto the substrate and pressed using controlled temperature and pressure for best bonding and image quality. Standard heat transfer techniques are vinyl, sublimation, and inkjet transfer, which have different compatibility and finish properties with other fabrics. Therefore, adhering to the open manufacturer’s instructions about the specific materials’ time, temperature, and pressure is essential. When heat presses and heat transfer tools are included, there is a promising outlook for finished embroidered projects, and this suits professional offices and small home hobbyists as well.

Understanding essential embroidery software and chroma

Reliable embroidery software is the best for making, editing, and digitizing designs since it’s critical in design and production. Other functionalities of the best embroidery software include the ability to edit designs, include texts, and simulate stitches, boosting the creativity of novice and expert tailors. Such software includes Wilcom, Hatch, and Brother PE-Design, and their distinction is that they possess different tools suitable for various levels and types of projects.

Color management becomes even more relevant when dealing with chroma in embroidery. Chroma is a measure of color purity and brightness, which is vital to the design’s overall look. Advanced embroidery software offers integrated color wheel features, Pantone color matching, and thread charts to achieve the desired color and smooth transitions between all colors. These tools help maintain uniformity and vibrance in the finished embroidery product.

The technical parameters of embroidery software include the file formats supported (DST, PES, EXP) and their compatibility with embroidery machines. Furthermore, the software should set stitch density and length with adjustable coefficients, usually within 0,2 mm and 1,5 mm, to suit different fabrics and design details. Embroidery Software’s advanced features also allow skilled workers to see a 3-dimensional image of the design and perform editing processes in real time. This enables them to check how their designs will appear in reality after the ideas are implemented. However, the target-specific areas in design are achieved through the user’s selection of the appropriate embroidery design software.

References

Frequently Asked Questions (FAQ)

Q: What are the main factors affecting the cost of a Ricoma embroidery machine?

A: The cost of a Ricoma embroidery machine is influenced by several factors, including the model type, number of needles, built-in features such as an LCD touchscreen, and whether it is designed for industrial embroidery or beginners. Additional tools and accessories can also impact the overall price.

Q: Is a multi-need embroidery machine suitable for beginners?

A: Yes, multi-needle embroidery machines, especially those from Ricoma, can be suitable for beginners. They often offer easy-to-use features and built-in designs that make learning smoother. However, beginners should be prepared for a learning curve when transitioning from single-needle to multi-needle machines.

Q: How does a Ricoma machine handle large embroidery projects?

A: Ricoma offers a range of machines capable of handling large embroidery projects. These machines often include features such as a large embroidery area and high stitches per minute, making them ideal for custom apparel and other large-scale projects.

Q: What makes the Ricoma MT-1501 model prevalent in the embroidery industry?

A: The Ricoma MT-1501 model is popular due to its 15-needle capability, speed, efficiency, and user-friendly LCD touchscreen. It is designed to handle a variety of materials and is a choice for businesses looking for reliable and versatile embroidery solutions.

Q: What should I consider when purchasing a machine for embroidery and sewing?

A: When purchasing a machine for embroidery and sewing, consider the upfront cost, the range of built-in designs, the ease of use, and the machine’s ability to handle different materials. Also, the support and resources from the manufacturer, such as training and customer service, must be assessed.

Q: Are Ricoma machines catering to embroidery and direct-to-garment (DTG) printing?

A: Ricoma does not typically combine embroidery machines with DTG printing; however, they offer various machines for each specific purpose. For those interested in both, it may be necessary to invest in separate equipment to meet all custom apparel needs.

Q: Does Ricoma provide a starter kit with their embroidery machines?

A: Ricoma machines often come with a starter kit with everything you need to begin embroidery. This may consist of essential tools and accessories like hoops, bobbins, and threads, which can help beginners get started quickly.

Q: How does the LCD touchscreen enhance the embroidery experience?

A: The LCD touchscreen on Ricoma machines enhances the embroidery experience by providing an intuitive interface for easy design selection, editing, and machine operation. This feature particularly benefits beginners and experts, as it simplifies the process and cuts your work time.

Q: What types of businesses benefit most from Ricoma’s range of machines?

A: Ricoma’s range of machines benefits custom apparel creators, embroidery service providers, and startups looking for reliable, high-quality industrial embroidery solutions. Ricoma machines are designed to offer speed and efficiency, making them ideal for businesses that need to handle a variety of materials and large orders.