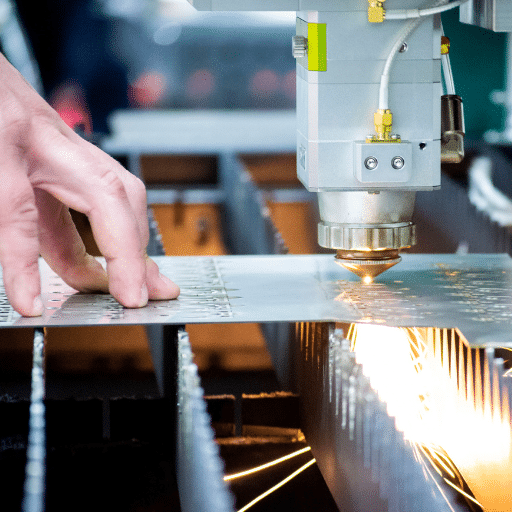

Implementing cutting and engraving works in the design and manufacturing sectors is no longer time-consuming and tedious, thanks to the introduction of laser cutting machines. These advanced machines work with a focused laser beam, providing unparalleled precision and making them ideal for intricate designs and complex shapes. The design and mechanical structure of laser cutting machines are quite advanced as they incorporate modern concepts of optics, material science, and computer technology to allow proper interaction between the laser and the material’s surface. This essay aims to discuss the most common methods of laser cutting, the types of lasers used, and the variety of industries that benefit from the technology. By the end of the essay, readers will appreciate this sophisticated technology, the mechanisms utilized, the edges it possesses, and the purposes it serves.

What is a laser cutter and how does it work?

A laser cutter is a tool that is used to cut, etch or engrave materials through a focused beam of light. It involves the use of high-energy lasers that melt, burn, or vaporize portions of material in its path. The shape or design to be achieved determines the rough outline of the area that needs to be worked on. Optics and CNC (Computer Numeric Control) control the movement and intensity of a laser. Depending on the type of material and the application, different types of lasers CO2, fiber or diode may be used. Laser cutting is fast and precise, making it suitable for metals, plastics, textiles, wood, and many other materials.

Understanding the basics of laser cutting technology

In laser cutting technology, the primary focus is on a laser beam and a workpiece that are both integrated into a system in which the laser beam interacts with the workpiece to modify its state for precise cutting or outlining intricate designs. Different technical parameters govern the efficiency of the cutting process:

- Laser Power: This is the energy output of the laser and is measured in watts (W). High power is needed to cut denser or thicker material, which in the case of industrial applications is usually between 500W and 10kW.

- Wavelength: Lasers are also categorised according to the wavelength they emit. For example, CO2 lasers have a wavelength of 10.6 um, which is best for non-metallic materials, while fiber lasers at 1.064 um are best used with metals due to their higher absorption rates.

- Spot Size: A micrometer-sized laser spot size produces cutting operations with finer detail and cleaner edges due to increased accuracy.

- Cutting Speed: Measured in mm/s, cutting speed is determined by the material properties, the thickness of the material, and the power of the laser. The faster the speed, the lower the quality, and vice versa; thus, a balance needs to be achieved.

- Assist Gas: Gaseous oxygen, nitrogen, or even compressed air cools the molten materials, oxidises the edge, or enhances the cutting by getting rid of the melted material during the operation.

- Material Properties: The properties of the material, such as thickness, density, or even reflectivity, make it unique to a specific requirement of laser parameters.

Each must be set accurately to a certain standard in order to measure precision, material destruction, and optimum results in different industries.

Cutting with Laser Beams: A Focused Beam’s Functionality

A focused laser beam cuts through an item by concentrating its energy on a single point. Once the energy is focused, it can vaporize, melt, or burn through the material. This technique requires very minimal energy due to the laser’s precision. The focus point of the beam should align with the material’s surface to maintain cutting quality and adjust to various thicknesses or materials. This will allow the beam to produce a consistent cutting quality.

The Basics of Laser Cutter Components

- Laser Resonator: This piece is responsible for creating the beam of a laser and it commonly does so through CO2 gas, fibers, or crystal systems. A resonator focuses a laser beam’s wavelength and determines the power for the laser. Thus, a resonator is pivotal for precise cutting.

- Beam Delivery System: Said system uses mirrors, lenses, and fiber optics which receive the beam from the resonator and transmit it to the cutting head. In addition, alignment and stability should be accurate to allow perfectly focused and efficient beams.

- Cutting Head: This assembly consists of focusing lenses and nozzles that cut the head. The lenses concentrate the laser beam to the necessary intensity and focal diameter, while the nozzle provides assisted gas flow to improve the cut quality and material ejection.

- Assist Gas Supply System: This system provides oxygen, nitrogen, or air to a cutting head. The gas used is specific to the material being processed. For example, nitrogen inhibits the oxidation process, while oxygen improves cutting speed.

- Motion Control System: The CNC system is the most precise type of movimiento system. It maps pattern instructions to motors, allowing people to control the position of the cutting head and the materials during the operation. It contains the hardware and software that allows the cutting head to move up and down, left and right, and rotate.

- Cooling System: Lasers produce a large amount of heat during operation, and a cooling system, which is usually water-based, is needed to maintain thermal stability for the resonator and optics.

- Frame and Worktable: The frame structure includes the worktable, which holds the material in a fixed position while the machine components mechanically shift. Heavy-duty frames are utilized to reduce vibration that could impair precision.

- Control Unit: The center processor communicates and interacts with the operative, enabling him or her to input cutting parameters, check performance, and exercise general supervision over the entire process. Recent units usually have an interface and combine with CAD/CAM systems.

What are the main types of laser cutters available?

Laser cutters can be grouped into broad categories based on their laser technology. The most common ones are CO2, fiber, and crystal lasers. CO2 lasers are widely used in cutting, engraving, and marking a range of non-metallic materials and some metals due to their relatively affordable price. Fiber lasers have high precision and speed making them suitable for processing metals and reflective materials, which is why they are common in industrial applications. Crystal lasers such as Nd:YAG and Nd:YVO lasers provide high power for cutting thicker materials. However, they are usually more expensive and have lower durability than the other types of lasers. Each type services different applications and material needs providing different performance features.

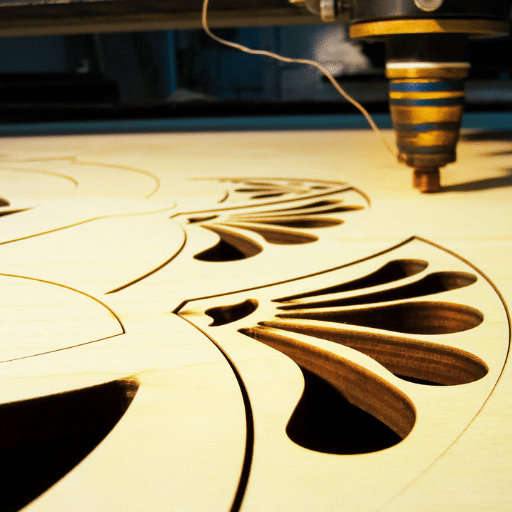

CO2 laser cutters: Applications and advantages

The versatility of CO2 laser cutters in cutting a wide range of non-metallic and some thin metals makes them ubiquitous in various industries. They are suitable for cutting, engraving, or marking wood, acrylic, paper, textiles, glass, and some plastics. C02 lasers have a wavelength of approximately 10.6 micrometers, which makes them ideal for organic material as they cut it cleanly and precisely. These cutters are sought because of their affordability and efficiency in meeting high production capacity while maintaining detail in their designs.

The power of a CO2 laser system often surpasses 400W, with the 30W to 400W range depending on industrial needs. Fine engravings on delicate materials can be achieved with low power settings, while good-quality cuts up to 20mm in thickness on certain non-metallic substrates begin at higher settings. In comparison to other forms of laser, CO2 beams have better beam quality and stability, making them better suited for detailed work. The low operational costs also increase their suitability for prototyping, signage, and artistic manufacturing applications.

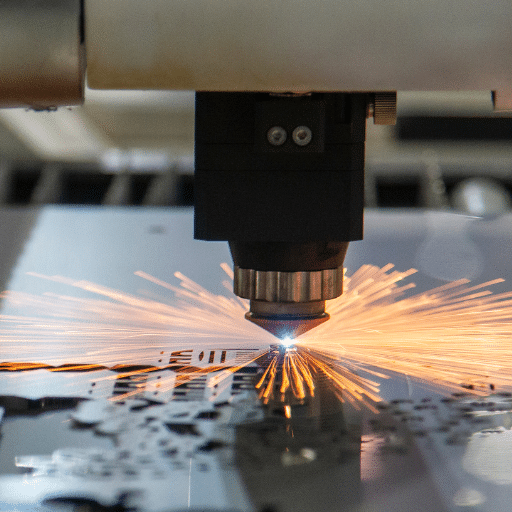

Fiber Laser Cutters Provide Precision in Metal Cutting

Designed with precision and efficiency in mind, fiber laser cutters excel in metal cutting. In comparison to CO2 lasers, fiber lasers have a shorter wavelength, which is generally 1.06 micrometers. As they are handier in absorbing metals, fiber lasers are more effective than CO2 lasers in cutting stainless steel, carbon steel, and aluminum. In addition, as fiber lasers have higher energy intensity and faster processing speed, they are more suited for industrial-grade production lines.

For fiber laser systems, technical parameters commonly range from 500W to 12kW based on the thickness and type of material being processed. A lower power level of around 500W to 2000W is preferable for cutting up to 6mm thin sheets. Laser systems 6KW and above are better suited for thicker metals as they can cut metals up to 40mm. Compared to CO2 systems, fiber lasers do consume less energy, further reducing operational costs while maintaining high performance. With minimal downtime and extended operational life, fiber laser diodes also enhance productivity. Because of these features, fiber laser systems preferred in the automotive, aerospace, and metal fabrication industries.

Crystal laser cutters: Precision and versatility

Crystal lasers are spots known for their strength as well as versatility. Systems employing crystal laser Nd handlebars, such as Nd:YAG and Nd:YVO4, receive rave reviews for their accuracy. These systems are very precise and are used for detailing tasks like engraving or fine-cutting of metals, ceramics, and plastics. The lasers can concentrate their beam to generate high-intensity spots. This results in finer edge quality with higher yields and lower material waste. Although crystal laser cutters are exact, they are usually not as energy efficient as fiber lasers nor do they tend to last long before requiring maintenance from wear and tear on the crystal rods. In any case, their versatility enables them to be used in detail-sensitive industries such as electronics, manufacturing of medical devices, and jewelry making.

How do different materials affect laser cutting processes?

The absorption rate, thermal conductivity, and melting point of each material influence the laser-cutting process. Steel and aluminum, as well as other metals by virtue, tend to require a higher laser power to achieve precise cuts when compared to nonmetals such as plastics or wood, which tend to warp or burn at higher levels of power. Highly reflective materials such as brass and copper pose their own challenges as they reflect laser beams, resulting in laser power loss. This makes it necessary to have specific machines or coatings equipped to handle such materials. Other materials also have their own unique challenges such as the thickness and type of the reflective material affecting the optimal laser power setting and other parameters.

Cutting metal: Techniques and considerations

In order to attain an accurate and effective cut on metal, one is required to account for the distinct properties of the material and adjust the techniques as well as tools appropriately. For instance, stainless steel cutting necessitates laser power of around 500 to 2000 watts for thin stainless steel sheets. On the other hand, thicker sheets might require between 6000 watts. The use of auxiliary gases like oxygen can potentially increase the cut’s speed due to oxidation although edge quality may suffer. On the contrary, nitrogen helps keep the edges clean by preventing oxidation during the cut.

Moreover, reflectivity of materials is quite important. Fiber lasers are better suited for dealing with reflective metals such as copper because their absorption efficiency is higher at shorter wavelengths (around 1 µm). Moreover, anti-reflective coatings and beam trapping methods protect the laser system from malfunction.

With every material, precise parameters such as beam focus, travel speed, and pulse frequency must be altered to achieve the minimum heat-affected zones and the best edge quality. For example, thicker materials should be cut with slower speeds to increase the chances of clean, burr-free cuts, while thinner sheets are cut with higher speeds to be more efficient.

Utilizing non-metallic materials such as wood, acrylic, and others.

Laser cutting offers precision and adaptability in nonmetallic components like acrylic and wood. While working with wood, one should ensure the settings are lower and slower so charring does not occur, especially in softer woods. The density and grain variation should also be kept in mind. Picking the correct type of acrylic will also eliminate the need for additional processing, resulting in polished edges. However, care must be taken for the correct power levels and speeds to avoid discoloration or clouding. While other non-metallic materials like foam and rubber are compatible with laser systems, special care must be catered towards the material’s combustibility and thickness in order to ensure safety. The cut materials must only be breached within a well-ventilated place as these materials can result in fumes that affect the environment.

Changing the laser’s settings for different materials

Changing the laser’s settings include adjusting the power and speed as well as the focal distance of the laser machine to suit the material type. Non-metallic materials such as wood and acrylic require lower power settings to prevent charring or damaging to the material. Furthermore, metals tend to require high-powered settings and slower speeds for more exact cuts or engravings. Also, surface thickness matters too; thicker materials typically need more energy or increased passes. For cleaner and sharper results, focus precision plays a major role. To get the best results, it is advisable to do test cuts to fine-tune them.

What are the key factors influencing laser cutting quality?

Multiple factors contribute to the effectiveness of laser cutting results. Material characteristics like thickness and composition dictate the precision and edge finish. This is because denser or reflective materials need different laser settings. Machining parameters such as laser power, speed, and focus must be set to achieve cuts free of burning and melting. Without system-placed maintenance, like lens cleaning and alignment, there will always be a lack of beam quality. Efficient ventilation and cooling are also significant in ensuring that overheating and debris are well managed. Lastly, a stable cutting environment assists in minimizing vibrations which guarantees accuracy as well as smooth edges.

Influence of laser power and cutting speed on cutting accuracy

The effects of laser power and speed on cutting accuracy are crucial about the quality of the cut as they set the limits of precision and efficiency. Increased power means that thicker or harder materials can easily be cut through, however, overheating will cause significant thermal damage which results in edges that are burnt or are rough. When it comes to carbon steel, the adequate level of power for thickness ranges from 500W to 2kW, and for optimal cutting of stainless steel or aluminum, it is required to cut from 1kW to 3kW.

Faster speeds improve the heat-affected zone but negatively affect edge quality, while lower speeds, like 1m/min for precise cuts in metals, achieve more aggressive penetration. The smoothness of the cut and the degree of material melt is primarily influenced by cutting speed. The edge quality can be reduced with faster speeds for materials that are not easily vaporized. There is a balance that must be achieved with both parameters in order to obtain accurate desired results for specific situations where material characteristics and results are prerequisites.

Importance of proper focus and beam alignment

Efficient and precise results in laser cutting relies on proper focus and beam alignment, meaning these are immensely important factors as well. The material surface should be placed correctly about the laser’s focal point, ensuring optimal energy density at the cutting line. If the focus point is placed in the wrong area, it results in low efficiency, excessive kerf width, and poor edge quality. Most of the time, the focal position of thinner materials is positioned above the material, whereas thicker materials are placed on the material’s surface.

A mechanical and optical fuse must be created within a laser system to align effectively. The alignment specs are loose in that a mechanical linkage system, or precisely a frame, can sustain a base tolerance spec of + or—0.01 mm. In the alignment of optical components like mirrors and lenses, there exist cases of fundamental reasons for precisely amiss alignment that need to be calibrated.

Cutouts with controlled HAZs minimize further deburring work

Cutouts with performed heat-affected zones need to maintain the appropriate focus, speed, and ample laser power without any contact, which assists gasses. HAZ is the area around which enduring structural alterations might occur while maintaining microstructural integrity. Too little coolant and the drill will burn, way too cool and the system can freeze. A balance between these two extremes must be struck if a cutout is to be impactful and retain accuracy.

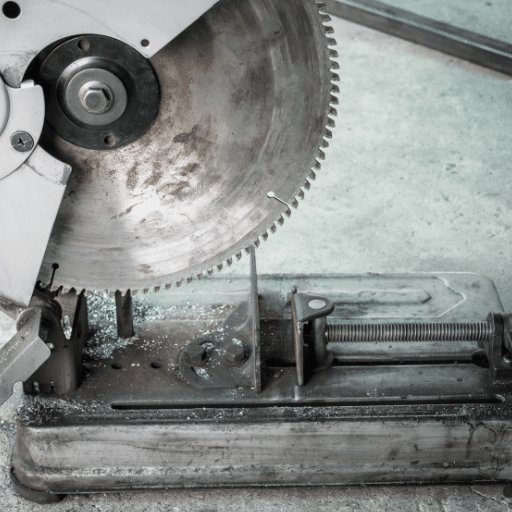

How do laser cutters compare to other cutting methods?

Laser cutters have great advantages about traditional cutting methods such as enhanced precision, lower material waste, and intricate motifs that experience minimal tool wear. In contrast to mechanical cutting processes, laser cutters perform contactless processing, which minimizes distortion and contamination of the material. As a result, they can be used for a variety of materials, including metals, plastics, and even organic materials such as wood. Furthermore, the rapid processing and high level of customization potential achieved through laser cutting makes it ideal for industries that require precise and intricate detail fabrication. On the other hand, some alternative techniques may have lesser costs and are more effective when working with highly reflective and thick materials which may be a limitation for this method.

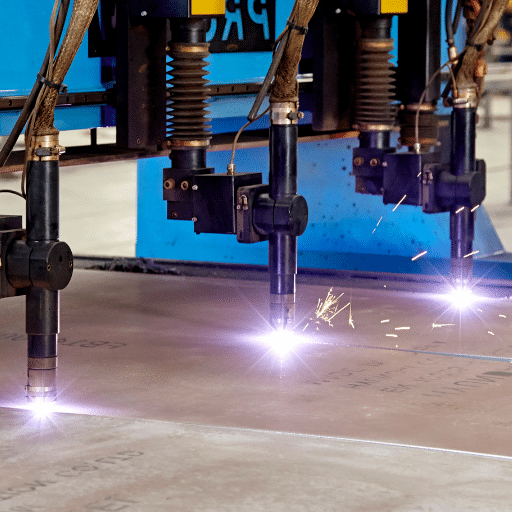

Laser cutting vs plasma cutting: Pro and Con Analysis

As with any process, there are positives and negatives when comparing laser and plasma cutting. When it comes to thin sheets of material, laser cutting is exceptional regarding precision and edge accuracy. It is also beneficial for overheating since it has minimal heat affected zones. On the other hand, with plasma cutting, there is more cost efficiency when dealing with thicker steel or aluminum sheets as the equipment is cheaper. Plasma cutting is usually quicker than laser cutting when dealing with thick sheets but is slower regarding more intricate features and designs. Even though laser systems are more precise than plasma ones, most laser systems have more advanced and expensive features. This is why laser systems come with a higher initial investment than plasma cutting equipment.

Benefits of laser cutting compared to traditional cutting methods

Due to the complexity of design in the modern world, there is a significant move from traditional methods to laser cutting techniques. This is owing to the flexibility and efficiency offered by these advanced techniques. One of its key benefits stems from the precision offered with reduced time and effort. The tolerances offered are within ±0.001 inches. The reason for this is the laser cutter’s focused beam, which results in superior edge quality and reduced kerf width.

Flexibility concerning materials is another major advantage, particularly in metals, plastics, and composites. Unlike mechanical processes, laser cutting does not exert direct force on the material, eliminating the possibility of deformation and reducing wear on cutting tools. It also makes it possible to operate at high speeds, varying cutting speeds based on material thickness. For example, specific steel alloys can be cut at 20 mm/s using high powered CO2 lasers. The automation possibilities of laser cutting systems, often used with CNC systems, further increase productivity, making them suitable for high-volume and complex geometries.

In addition, laser cutting is very economical regarding the raw materials used since very little is wasted, which is beneficial for many businesses whose main focus is controlling costs and sustainability. This technology also enables cutting without contact, which results in less contamination and a cleaner cutting process. Laser cutting also offers reduced thermal distortion and improved surface finish when compared with mechanical or oxyfuel cutting, making it a solid choice for advanced manufacturing processes.

What safety measures are essential when operating laser cutters?

Compliance with safety regulations is crucial while working with laser cutters. Operators are required to wear suitable personal protective equipment (PPE), such as safety goggles that safeguard against laser radiation from the machine’s specific wavelength. It is important to ensure the equipment is operated in a well-ventilated space to prevent contact with harmful fumes and matter that is destroyed during the cutting processes. Routine exercises like cleaning the laser optics and inspecting the computerized pantograph ensure ventilation and prevent the machine from cosmatic malfunctioning. Access to the laser cutter should be controlled and set to trained operators, and sufficient warning notifications should be placed. Additionally, ensuring emergency stops and interlocks are operational ensure that the system always turns off in the event of misuse or further more serious malfunctions. Also, all operators need to follow machine guidelines and policies routinely and to maintain safety.

PPE for operators of laser cutters

Operators of laser cutters should put on appropriate personal protective equipment (PPE) while operating the machine. PPE for laser cutting devices includes laser goggles to protect the operator’s eyes from the cutter’s radiation beams. Furthermore, operators should put on gloves that are resistant to fire to protect themselves from burns caused by hot materials. Masks and respirators are helpful in environments when cutting may generate harmful fumes or particulate matter. Adding garments that are non-flammable, long-sleeved, and cover the operator’s skin reduces chances of exposure to cuts and excessive heat. -It is also necessary to ensure that all PPE fulfills safety requirements to provide a safe working environment.

Factors to consider for ventilation and fume extraction

Meanwhile, while using laser cutters, efficient ventilation and fume extraction systems are necessary for eliminating vapors and smokes and removing particulate matter created during the cutting process. These systems help maintain air quality, filter hazardous materials, protect the operator from fumes, and minimize the chances of fire. Ensuring that the extraction units are correctly installed and maintained regularly is equally essential as boundaries put by safety regulations. Also, these units must be capable of handling the specific processed materials. Following these boundaries is essential for every person involved at the workplace.

Safety instructions and training protocols for lasers

Such techniques guarantee everything around the operating laser system is secure, and there are no chances of danger to the personnel. The comprehensive safety measures include classifying different laser types according to their possible hazards and using proper engineering controls such as enclosures and beam shutters. Furthermore, implementing administrative controls through laser safety zones and access restriction is essential. Allocated instruction focuses on personnel’s training on the biological classification of lasers and their possible effects on the skin, eyes, and PPE (Personal Protective Equipment) standards. Safety drills and ongoing training exercises ensure that all personnel and operators who handle laser equipment are appropriately trained and can effectively respond to emergencies.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are the main types of laser cutting?

A: The main types of laser cutting include fusion cutting, vaporization cutting, and reactive cutting. Fusion cutting melts the material, vaporization cutting turns the material into vapor, and reactive cutting uses a chemical reaction with the material. Each type is suited for different materials and applications.

Q: How do laser cutters work?

A: Laser cutters work by using a high power laser to cut materials with precision. The process begins with a laser generator and external optics that focus the intense laser beam onto the material. The laser head moves along a predetermined cutting path, melting, vaporizing, or chemically altering the material. The cutting rate and depth are controlled by adjusting the laser power and speed.

Q: What materials can be cut using laser cutting machines?

A: Laser cutting machines can be used to cut a variety of materials including sheet metal, plastics, wood, textiles, and ceramics. The specific laser type and power will determine which materials can be effectively cut. For instance, CO2 lasers are ideal for cutting non-metals, while fiber lasers excel at cutting and scribing metals.

Q: What is the cutting rate in laser cutting?

A: The cutting rate in laser cutting refers to the speed at which the laser can cut through the material. It depends on factors such as the laser power, material thickness, and type of material being cut. Higher power lasers generally allow for faster cutting rates, while thicker or denser materials typically require slower cutting speeds.

Q: What is laser microjet cutting?

A: Laser microjet cutting is an advanced laser cutting technique that uses a pulsed laser beam guided by a high-pressure water jet. This method combines the precision of laser cutting with the cooling properties of water, allowing for clean cuts with minimal heat-affected zones. It’s particularly useful for cutting heat-sensitive materials or achieving very fine cuts.

Q: How does the laser cutting process begin?

A: The laser cutting process begins with the generation of a high-powered laser beam. This beam is then focused through a series of mirrors and lenses onto the material to be cut. The intense heat of the laser melts, vaporizes, or chemically alters the material along the cutting path. In many systems, a computer-controlled motion system guides the laser head along the desired cutting pattern.

Q: What are the advantages of using a pulsed laser beam in cutting?

A: Using a pulsed laser beam in cutting offers several advantages. It allows for better control of heat input, reducing the heat-affected zone around the cut. Pulsed lasers can achieve higher peak powers, enabling the cutting of thicker materials. They also provide improved edge quality and can be more effective for cutting reflective materials. Additionally, pulsed lasers are often used for precision cutting and drilling applications.

Q: What is the application of laser cutting in industrial settings?

A: Laser cutting is widely used for industrial cutting applications. It’s employed in manufacturing for cutting sheet metal, creating precision parts, and prototyping. The technology is also used for cutting and scribing metals in the automotive and aerospace industries. In the textile industry, laser cutters are used for cutting fabrics with precision. The versatility, speed, and accuracy of laser cutting make it invaluable in many industrial processes.